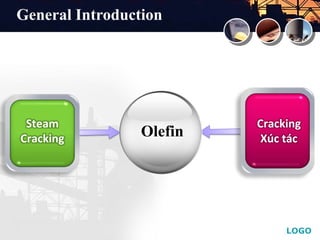

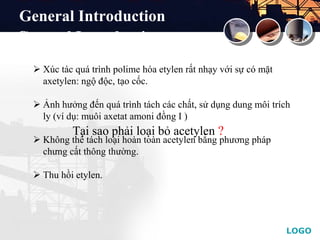

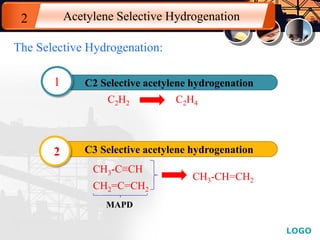

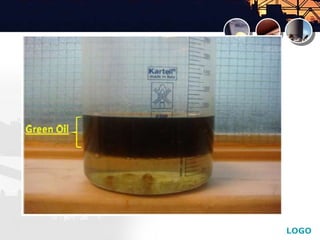

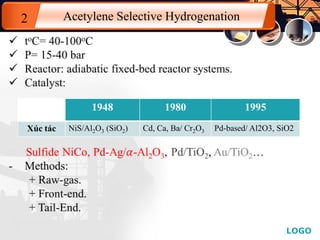

This document provides an overview of acetylene selective hydrogenation processes. It discusses how acetylene is extracted from hydrocarbon streams using solvent absorption or selective hydrogenation. The two main types of selective hydrogenation are front-end, which treats lighter feedstocks before fractionation, and tail-end, which treats C2 fractions after removal of lighter components. Tail-end hydrogenation is more common and uses palladium-based catalysts with high selectivity for acetylene. The document also reviews catalyst regeneration methods used to remove coke and restore activity.

![LOGO

Feedstock %Conv Acetylen

(%wt)

Ethane 65% 0.4 - 0.50

LPG 90% 0.65 - 1.35

Naphta - 0.10 - 1.0

[2]

General Introduction](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-5-320.jpg)

![LOGO

Specs Etylen Raw Propylen Clean Propylen

Axetylen, max

(ppm)

2 * 10 5

* <1ppm [3]

General Introduction](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-7-320.jpg)

![LOGO

General Introduction

[4]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-8-320.jpg)

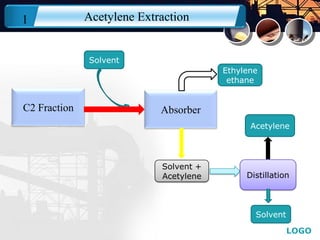

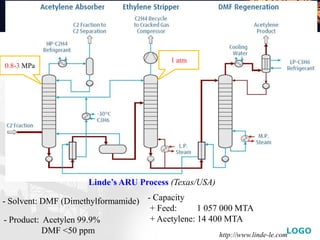

![LOGO

Acetylene Extraction1

Acetylene Selective Hydrogenation2

[2]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-9-320.jpg)

![LOGO

Acetylene Selective Hydrogenation2

[4]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-16-320.jpg)

![LOGO

Add YourText in here

Raw-gas Acetylene Hydrogenation

Drawing of Sud-Chemie [3]

C2,C3+

H2,CO, H2S

- HC feed: C3+ <<

- Catalysts: Ni-

based (Ni-Co-Cr)

[4]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-19-320.jpg)

![LOGO

Add YourText in here

Front-end Acetylene Hydrogenation

C2H2, C2H4, C2H6

H2, CO

Remove

CO2,H2S Drawing of Sud-Chemie [3]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-20-320.jpg)

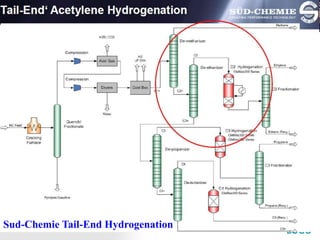

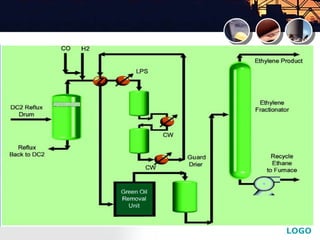

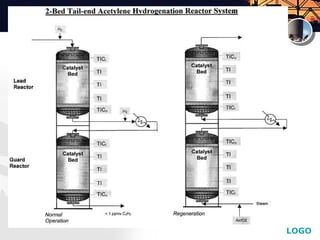

![LOGO

Add YourText in here

Tail-end Acetylene Hydrogenation

C2H2, C2H4,

C2H6

Removal

CO2,H2S

Drawing of Sud-Chemie [3]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-21-320.jpg)

![LOGO

Hydro hóa chọn lọc AcetylenAcetylene Selective Hydrogenation2

Front-end Tail-end

Feed C2 cut and lighter material.

-Excess hydrogenbecause all

the hydrogen produced in the

cracking furnaces is in the

reactor feed.

C2 cut only

-Hydrogen in the Craked gas

(CG) have been removed

- H2 (99.9%) and CO are

injected in stoichiometric

amountsinto feed

Position Before light end removal After light end removal

H2/C2H2 ratio Uncontrollable

Process Control

Parameters[5]

Temperature Temperature

Hydrogen & CO injection

The selectivity of

hydrogenation reaction

Lower Higher](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-22-320.jpg)

![LOGO

Frond-ent Tail-end

Ethylene

loss

Higher Minimize

Catalysts

- Chervon Phillips: E-Series (Pd-

Ag/Al2O3).

-Sud-Chemie:G-83C (Pd-Ag/Al2O3)

- BASF: HO-21 (Pd-Ag/ SiO2)

-Sud- Chemie:G-58C, G-58D,

G-58H (Pd-Ag)

- AXENS: LT-279

Cycle

length

Long

Typically no regeneration [5]

Exsitu regeneration

Short

Requires frequent regeneration

(1-4 times/years)

Insitu regeneration [3]

Catalyst

deactivation

Coke, COS Coke, Green Oil, COS

Acetylene Selective Hydrogenation2](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-23-320.jpg)

![LOGO

s Acetylene Selective Hydrogenation2

Frond-ent Tail-end

Design

parameters

[3]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-24-320.jpg)

![LOGO

Method Number of plants % of Plant

Tail-end 174 64

Front-end (Pd) 69 26

Front-end (Ni) 9 3

Extraction 19 7

Total 269 100%

Acetylene Selective Hydrogenation2

[4]

Tail-end

Front-end (Pd)

Front-end (Ni)

Extraction](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-25-320.jpg)

![LOGO

Tail –end Hydrogentation Catalyst

[5]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-27-320.jpg)

![LOGO

Advantages of OleMax 207 new catalyst

Increased:

Ethylene (>10% OleMax 201)

Catalyts Stability

Cycle lengths (>24 months)

Operation without CO injection

Low Polymer Formation

[5]

OleMax 207 catalyst:

+ Pd-Ag promoter/Al2O3

+ 2-4mm spheres](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-28-320.jpg)

![LOGO

[5]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-29-320.jpg)

![LOGO[5]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-30-320.jpg)

![LOGO

[3]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-31-320.jpg)

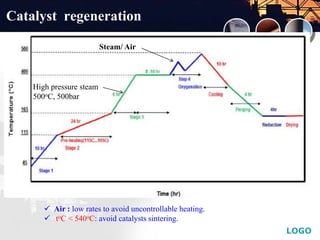

![LOGO

Catalyst regeneration

[4]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-33-320.jpg)

![LOGO

Catalyst regeneration

[4]

Start with warm up by nitrogen injection

to purge residual gases in reactor and

vaporize volatile compounds

Nitrogen and HP](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-35-320.jpg)

![LOGO

Add YourText in here

Catalyst regeneration

Cooling stage begins when [CO2] in oulets < 1%V

Cooling to 250oC

by air/steam

N2

H2

N2](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-37-320.jpg)

![LOGO[6]](https://image.slidesharecdn.com/acetylenehydrogenation-130902223655-phpapp02/85/Acetylene-hydrogenation-38-320.jpg)