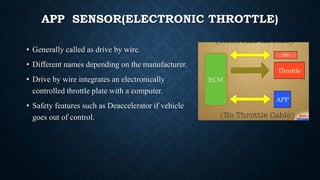

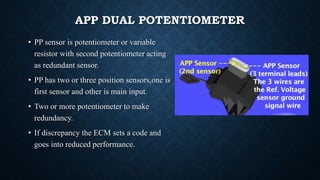

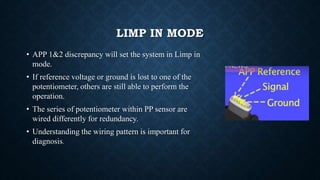

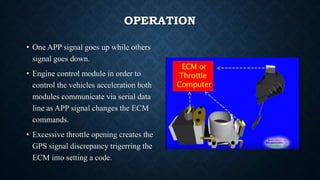

The accelerator pedal position (APP) sensor converts movement of the accelerator pedal into a voltage signal that is sent to the throttle actuator control module and powertrain control module. It is made up of two individual sensors for redundancy. As the pedal is pressed, the APP sensor signals the engine control module about the pedal position and rate of change, controlling acceleration. If the APP sensor fails, the vehicle may idle roughly, not respond to the pedal, or go into limp mode, with the engine light illuminating.