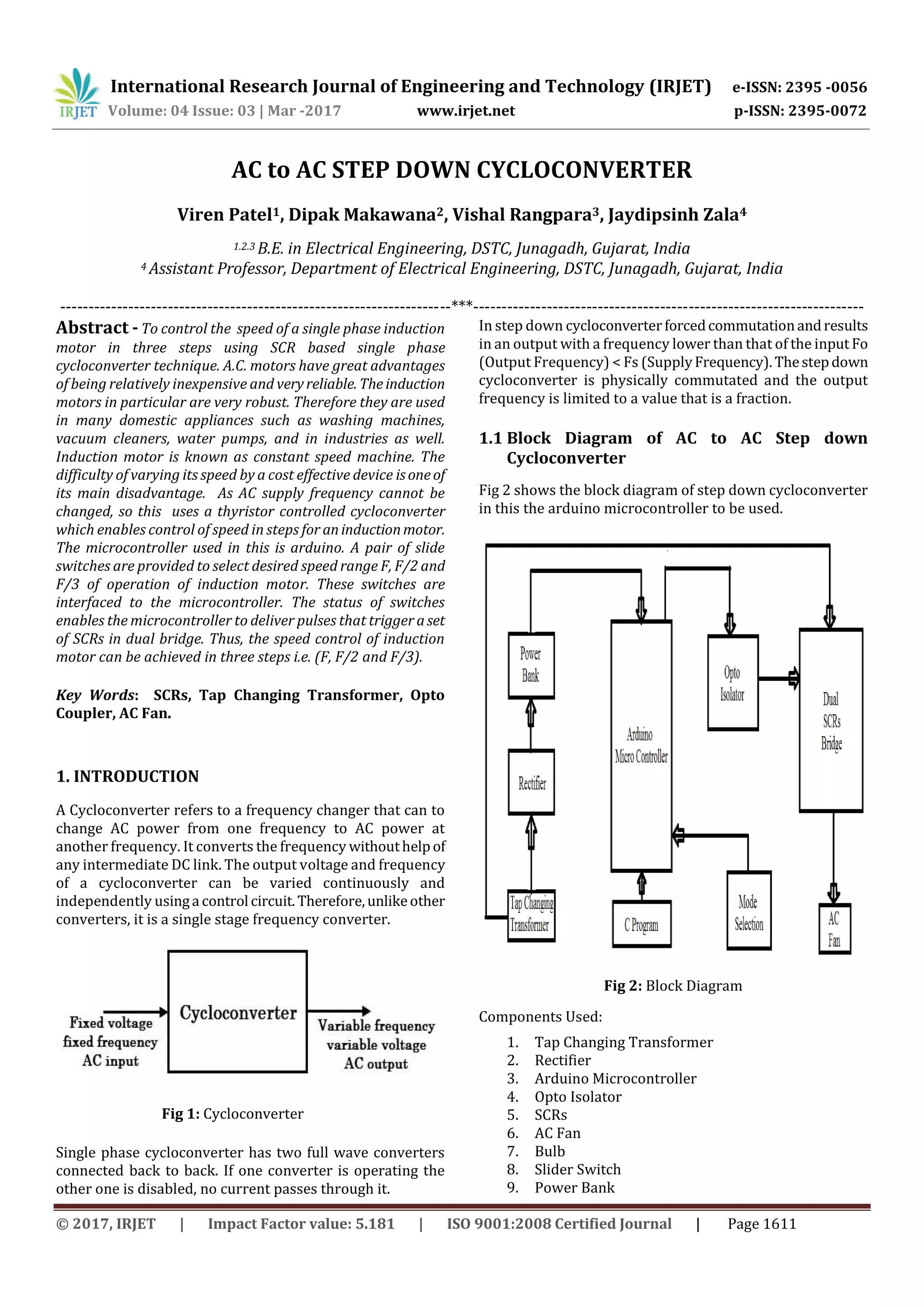

This document describes an AC to AC step down cycloconverter that uses SCRs and an Arduino microcontroller to control the speed of an induction motor in three steps (full speed, half speed, and one-third speed). A cycloconverter can change the frequency of AC power without an intermediate DC link. This single-stage cycloconverter has two full-wave thyristor bridges connected back-to-back to produce an output frequency lower than the input frequency. The Arduino receives signals from slide switches to select the motor speed and triggers the appropriate SCRs to achieve speed control in three steps. MATLAB simulations show the output waveforms at different speeds. Pseudocode is provided for the Arduino program.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 04 Issue: 03 | Mar -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 1615

digitalWrite(moc5,HIGH);

digitalWrite(moc6,HIGH);

digitalWrite(moc7,HIGH);

digitalWrite(moc8,HIGH);

delay(0.5);

digitalWrite(moc5,LOW);

digitalWrite(moc6,LOW);

digitalWrite(moc7,LOW);

digitalWrite(moc8,LOW);

delay(29.5);

}

else

{

digitalWrite(moc1,LOW);

digitalWrite(moc2,LOW);

digitalWrite(moc3,LOW);

digitalWrite(moc4,LOW);

digitalWrite(moc5,LOW);

digitalWrite(moc6,LOW);

digitalWrite(moc7,LOW);

digitalWrite(moc8,LOW);

}

}

}

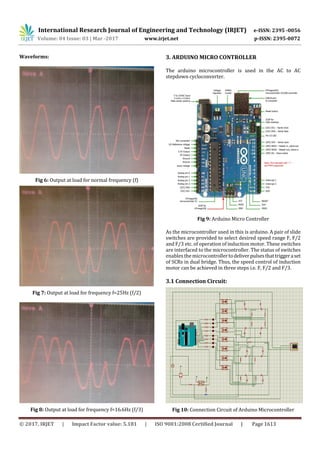

3.3 Technical Specifications of Arduino Micro -

Controller

Table of Technical Specifications:

Microcontroller ATmega328P

Operating Voltage 5V

Input Voltage (recommended) 7-12 V

Input Voltage (limit) 6-20 V

Digital I/O Pins 14

Clock Speed 16MHz

PWM Digital I/O Pins 6

Analog Input Pins 6

DC Current per I/O Pins 20mA

DC Current for 3.3V Pin 50mA

SRAM 2KB

EPROM 1KB

Flash Memory 32KB

LED BUILTIN 13

4. CONCLUSIONS

From this work it is observed that speed of an induction

motor can be efficiently controlled by using Cycloconverter.

The role of Cycloconverter is in speed control of induction

motor is to vary the supply frequency which inturn, changes

the speed of motor. The speed control of induction motor

can be achieved in three steps i.e. (F, F/2 and F/3).

REFERENCES

[1] Vinamra Kumar Govil, Yogesh Chaurasia “Modeling &

Simulation of PWM Controlled Cycloconverter FED Split

Phase Induction Motor” International Journal of Advanced

Research in Electrical, Electronics and Instrumentation

Engineering, Vol. 1, Issue 3, September 2012.

[2] E A Lewis “Cycloconverter Drive Systems” Power

Electronics and Variable Speed Drives, Conference

Publication No. 429, IEEE, 1996.

[3] C. Lander, Power Electronics, Second Edition, McGraw

Hill, England, 1987

[4] BurakOzpineci, Leon M. Tolbert, “Cycloconverters”,

University of Tennessee-Knoxville, Knoxville, USA.

[5] J. Zhang, “Single phase input cycloconverters driving an

induction motor” Ph.D. thesis, University of Technology,

Sydney.](https://image.slidesharecdn.com/irjet-v4i3362-171227083758/85/AC-to-AC-Step-Down-Cycloconverter-5-320.jpg)