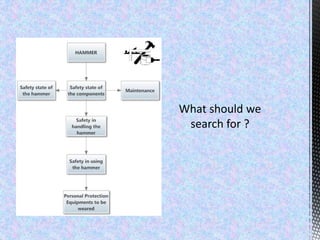

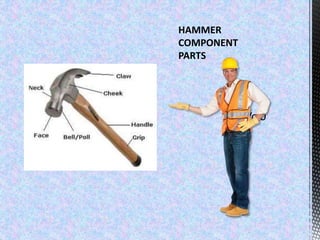

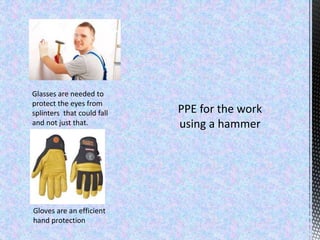

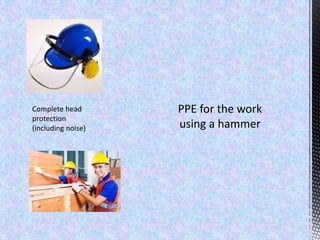

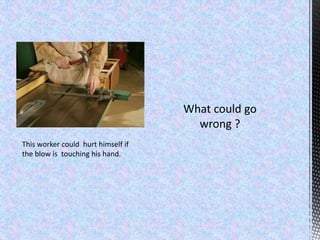

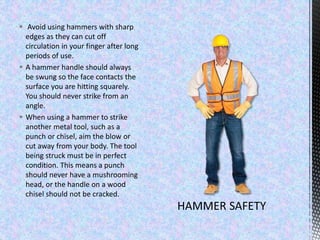

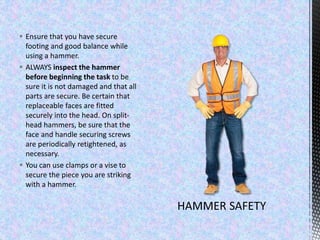

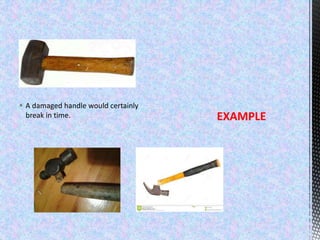

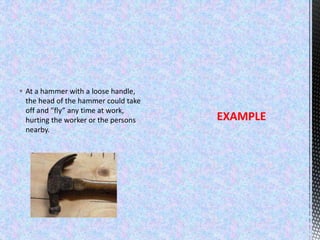

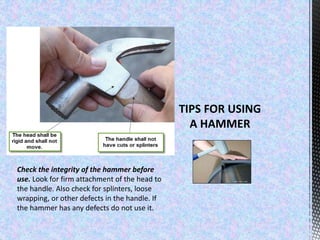

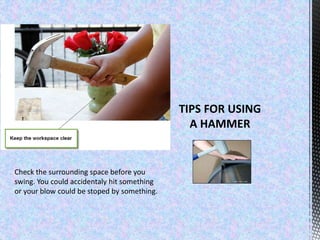

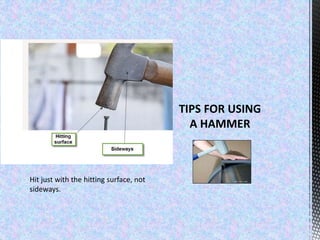

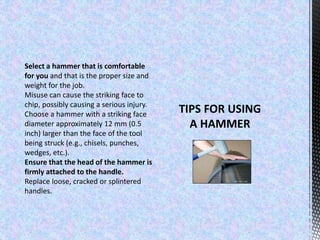

This document provides guidance on hammer safety. It discusses proper handling techniques, risks associated with hammer use, and recommendations to prevent injury. Key points include inspecting hammers for defects before use, choosing the right hammer for the job, striking surfaces squarely, maintaining secure footing, and ensuring clearance from other workers when swinging a hammer. Examples are given of safety issues that could arise from misuse, like accidentally hitting other objects or people nearby. Overall the document stresses using hammers as intended and replacing damaged tools to avoid injury to oneself or others.