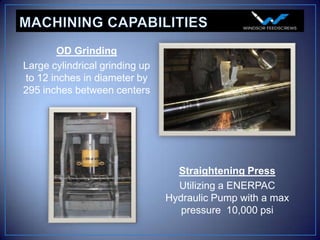

Windsor Feedscrews Inc. specializes in manufacturing and rebuilding a wide range of screws and barrels for various industries, including plastics and rubber, with over 22 years of experience. The company offers advanced machining services, including CNC milling, turning, and hardfacing, ensuring precision while handling complex designs. Windsor Feedscrews is dedicated to customer service and efficiency, providing repair options and modifications to enhance injection components, alongside a commitment to delivering projects on budget and on time.