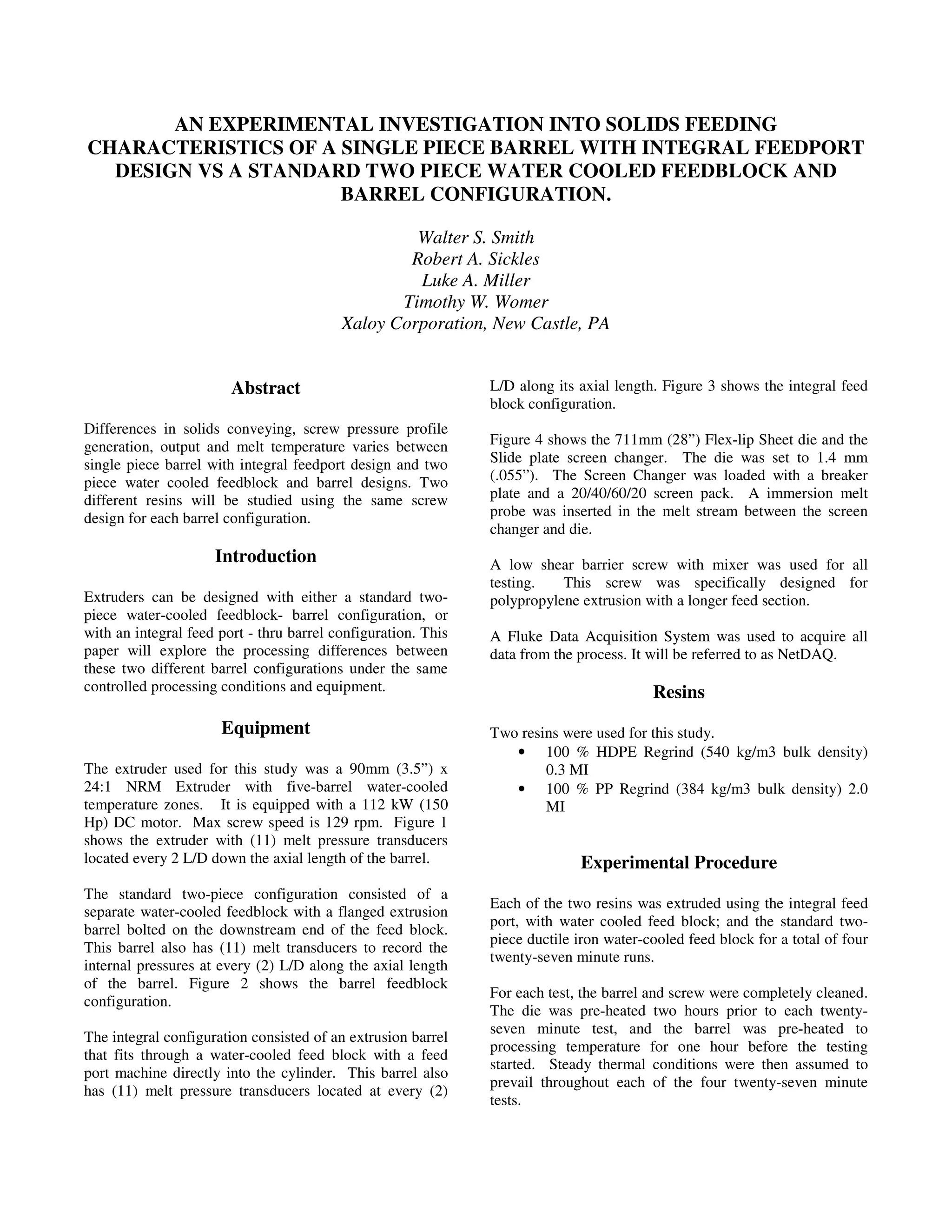

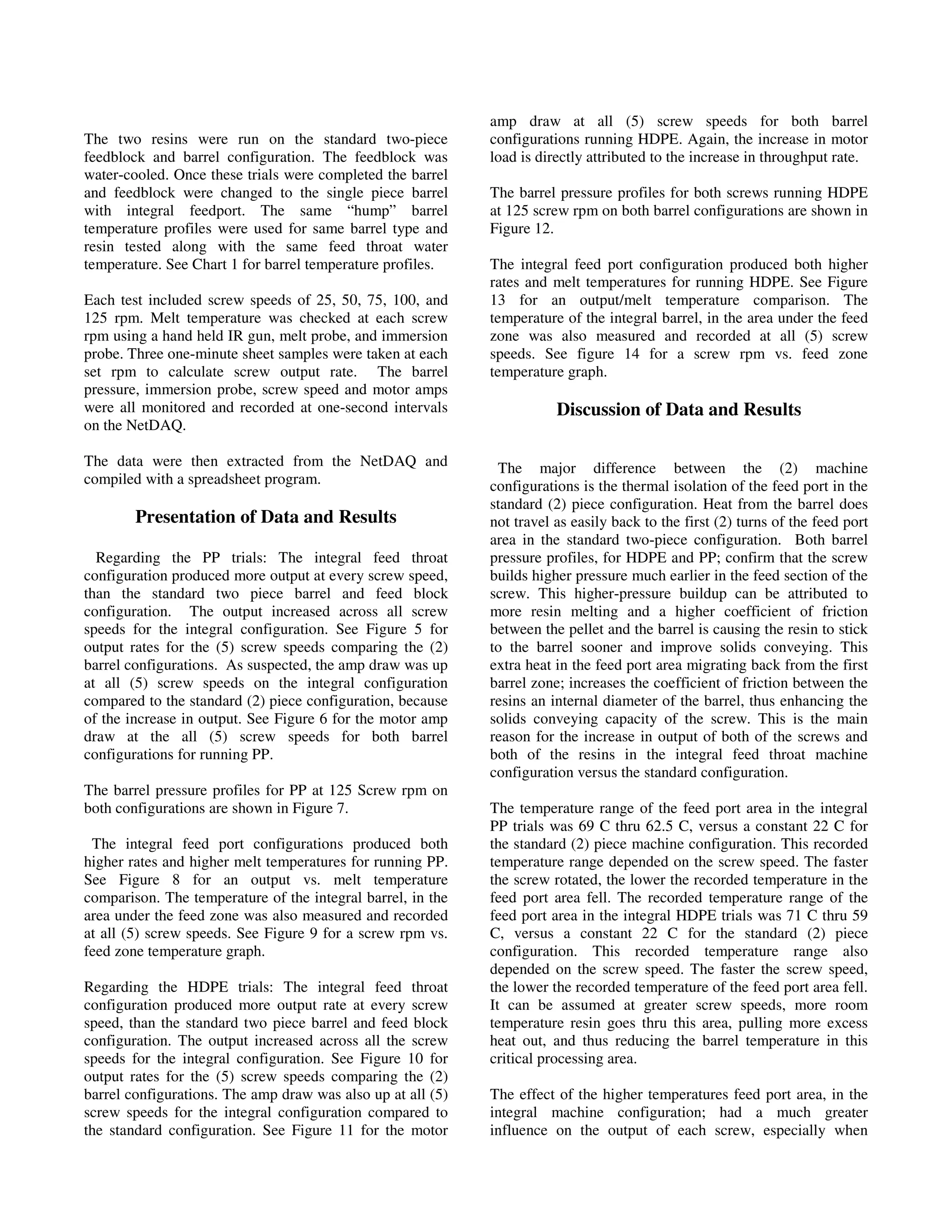

1. An experimental study compared the performance of an extruder with a single-piece barrel and integral feedport design to a standard two-piece barrel configuration.

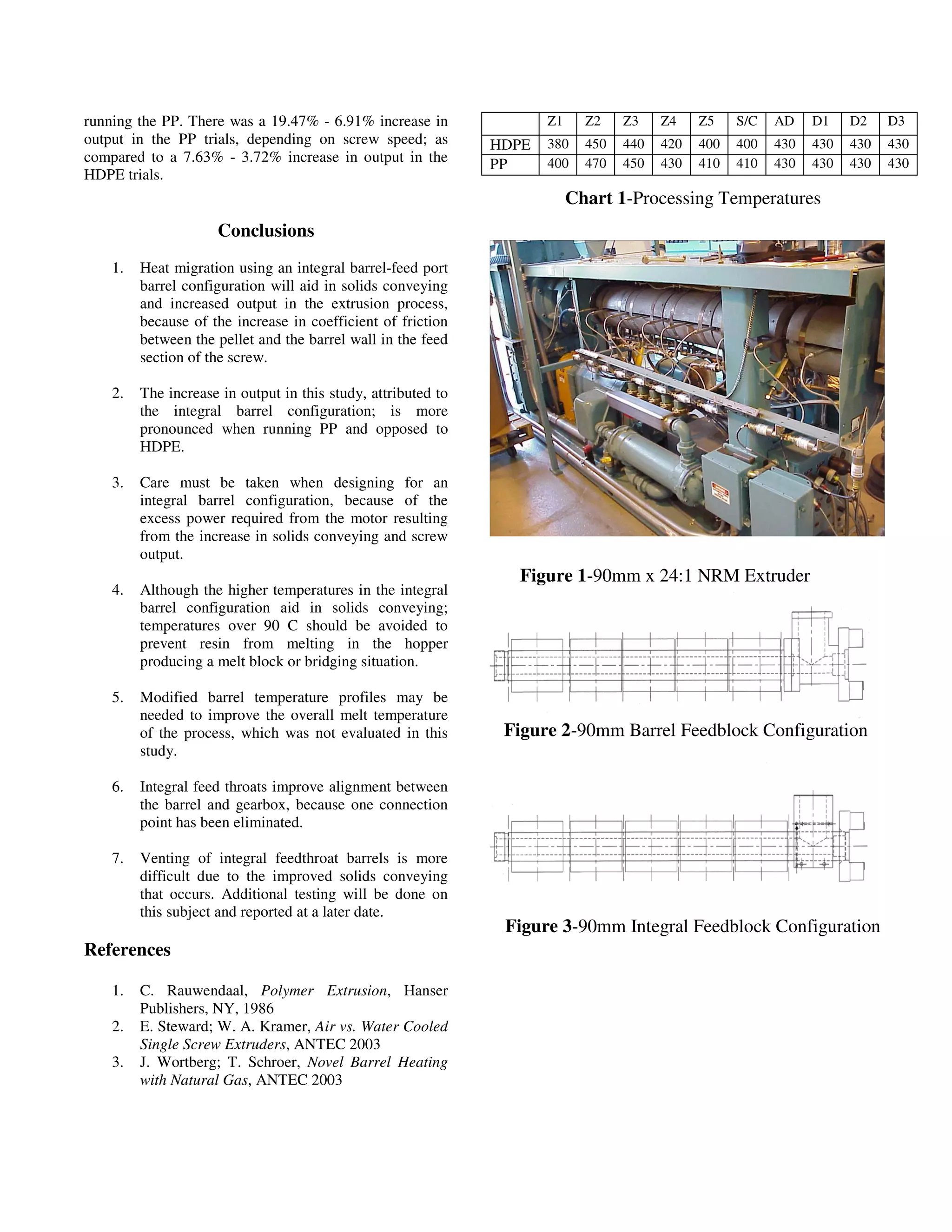

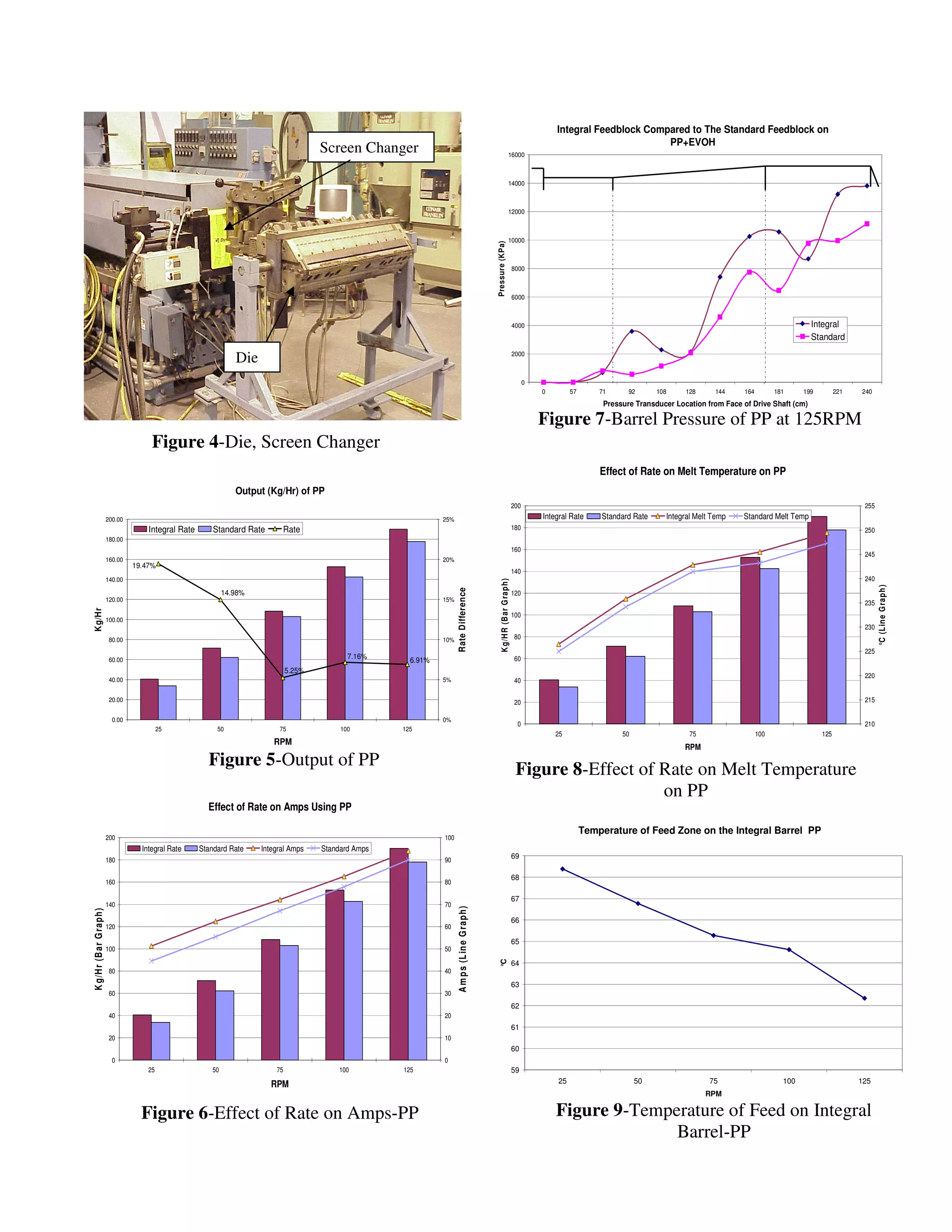

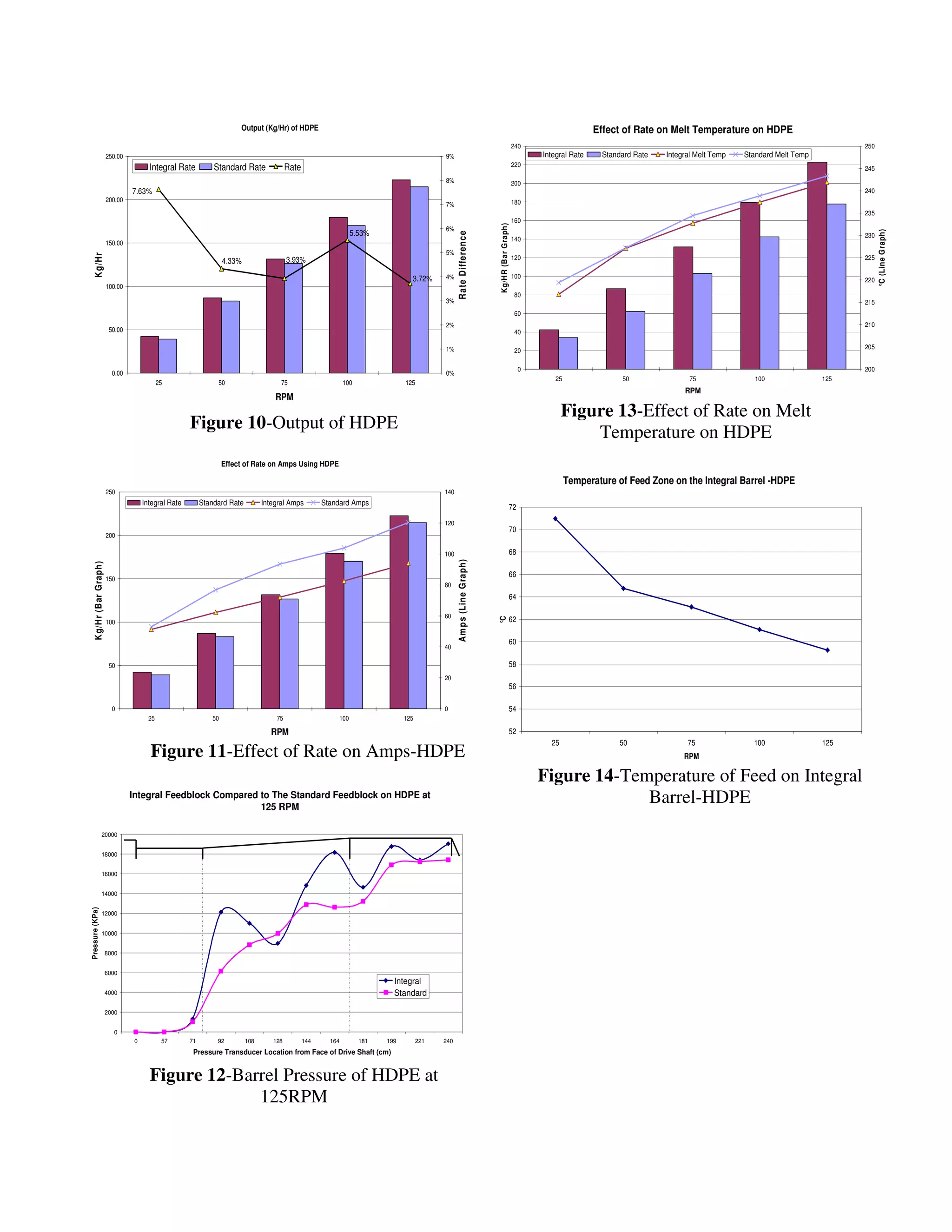

2. Testing was conducted using two resins (HDPE and PP) across a range of screw speeds.

3. Results showed the integral design produced higher output rates and melt temperatures for both resins compared to the standard configuration, with a more significant increase seen for PP.

4. The integral design improved solids conveying by increasing heat transfer to the feed zone, raising temperatures and the coefficient of friction between pellets and barrel wall.