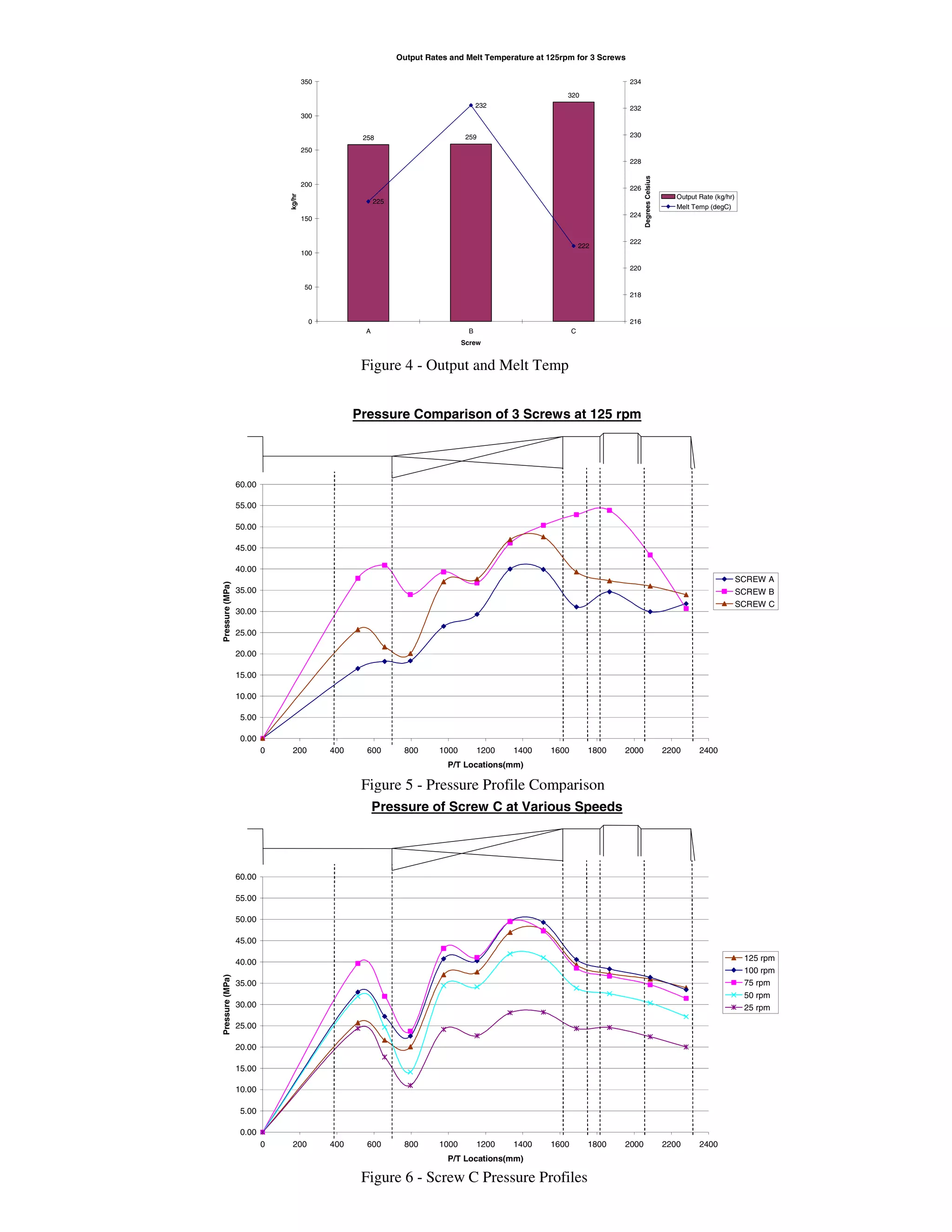

The document evaluates different groove feed screw geometries to enhance plasticization rates in extrusion processes, specifically for processing fractional melt HDPE. Three distinct screw designs were tested, with findings indicating that screw 'c' exhibited the highest throughput rate and lowest melt temperature, thereby demonstrating superior performance. The study highlights the significant impact of screw geometry on internal pressure, output, and melt temperature in groove feed extrusion technology.