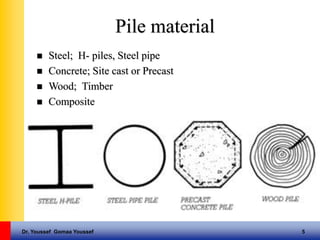

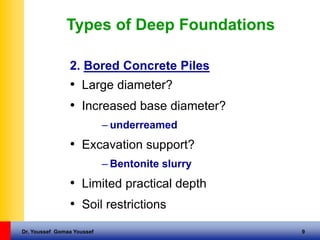

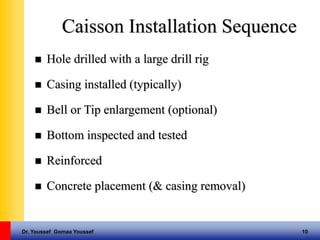

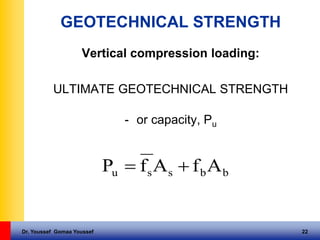

This document discusses deep foundations and pile design. It begins by explaining why deep foundations are needed when near surface soils are inadequate or there are concerns about settlement. It then describes the main types of deep foundations - driven piles, bored concrete piles, and other alternatives like driven cast in situ piles. Specific pile materials and installation methods are outlined for different pile types. The document also covers site investigation considerations, design aspects like geotechnical strength calculations, and factors of safety.

![Dr. Youssef Gomaa Youssef 3

Why go deep?

[A] Near surface soils inadequate

• weak relative to applied loads

• erodible

− watercourses, scour of soil

[B] Load orientation

• lateral loading – raked piles

• uplift loading - anchors

[C] Settlement concerns](https://image.slidesharecdn.com/7-deepfoundations1-161025165026/85/7-deep-foundations-1-3-320.jpg)