1. 5S refers to a system for organizing and standardizing the workplace using five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke.

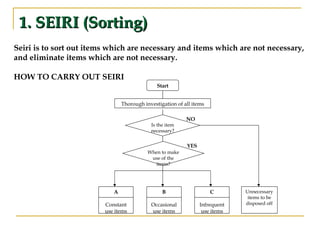

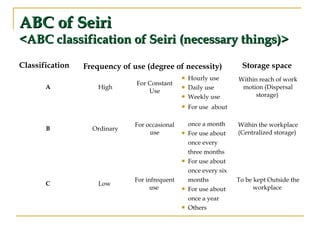

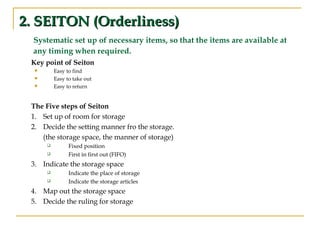

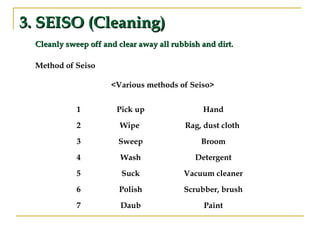

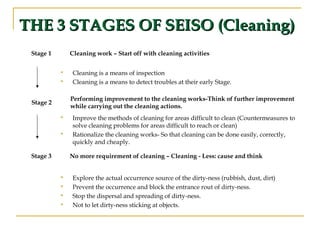

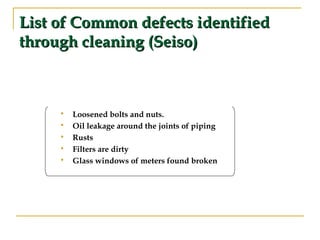

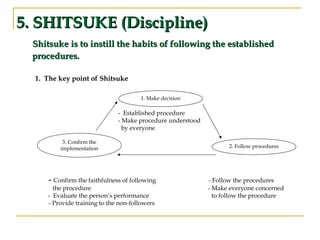

2. Seiri involves sorting through items in the workplace and removing any unneeded items. Seiton focuses on systematic storage and arrangement of necessary items. Seiso is cleaning the workplace to remove dirt and debris. Seiketsu maintains the clean and organized state achieved. Shitsuke aims to sustain these practices through habit and discipline.

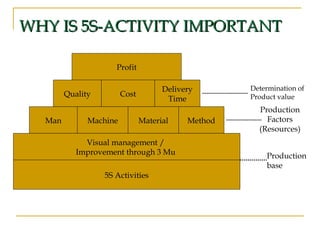

3. Implementing 5S brings benefits like improved productivity, quality, and safety by promoting a well-organized visual workplace where needed items are easily accessible and potential issues can be identified