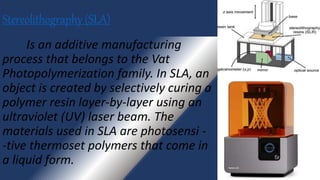

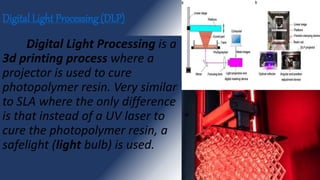

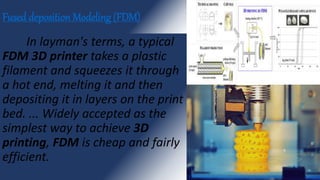

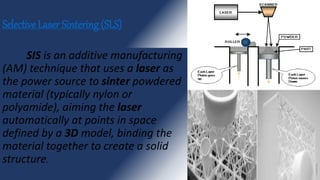

3D printing is a process that creates physical objects from digital models, first pioneered by Hideo Kodama in 1981. Various types of 3D printing technologies exist, including Stereolithography (SLA) and Fused Deposition Modeling (FDM), each with unique methods and materials. While 3D printing offers benefits like faster production and creative design freedom, it also faces drawbacks such as high energy consumption and reliance on plastics.