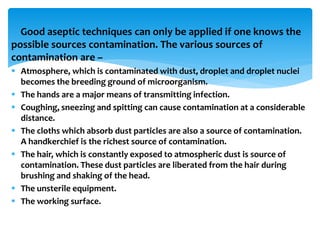

Aseptic techniques are methods used to prevent microorganisms from contaminating parenteral products during preparation and testing. They are important to reduce post-procedure infections and protect healthcare workers. Good aseptic technique requires understanding potential contamination sources like the atmosphere, hands, coughing, hair, and unsterile equipment. GMP requirements for manufacturing sterile products include clean area classifications, building specifications, sterilizing equipment, filtration, and following guidelines for environmental factors and water systems. Strict adherence to aseptic techniques and GMPs is necessary to avoid contamination and ensure high quality sterile pharmaceutical products.