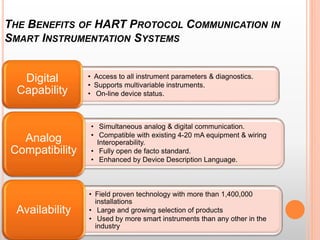

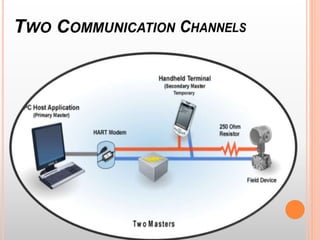

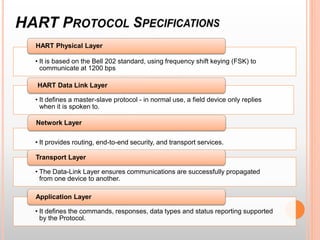

The document discusses the HART communication protocol, which defines a standard for sending and receiving digital information across analog wires between smart field devices and host systems. It describes how HART works by superimposing digital signals on top of the standard 4-20mA analog signal, allowing bidirectional communication at 1200 bits per second without interrupting the analog signal. Benefits of HART include access to device parameters and diagnostics, compatibility with existing equipment, and open interoperable standards.

![ “HART” is an acronym for Highway Addressable Remote Transducer. The

HART Protocol makes use of the Bell 202 Frequency Shift Keying (FSK)

standard to superimpose digital communication signals at a low level on top

of the 4-20mA.

The HART protocol communicates at 1200 bits per second without

interrupting the 4-20 mA signal and allows a host application to get two

or more physical updates per second from a smart field device.

This is the diagram of frequency shift keying[FSK].](https://image.slidesharecdn.com/236029677-hart-communication-pptx-230207042714-0fa5e22b/85/236029677-Hart-Communication-Pptx-pptx-5-320.jpg)