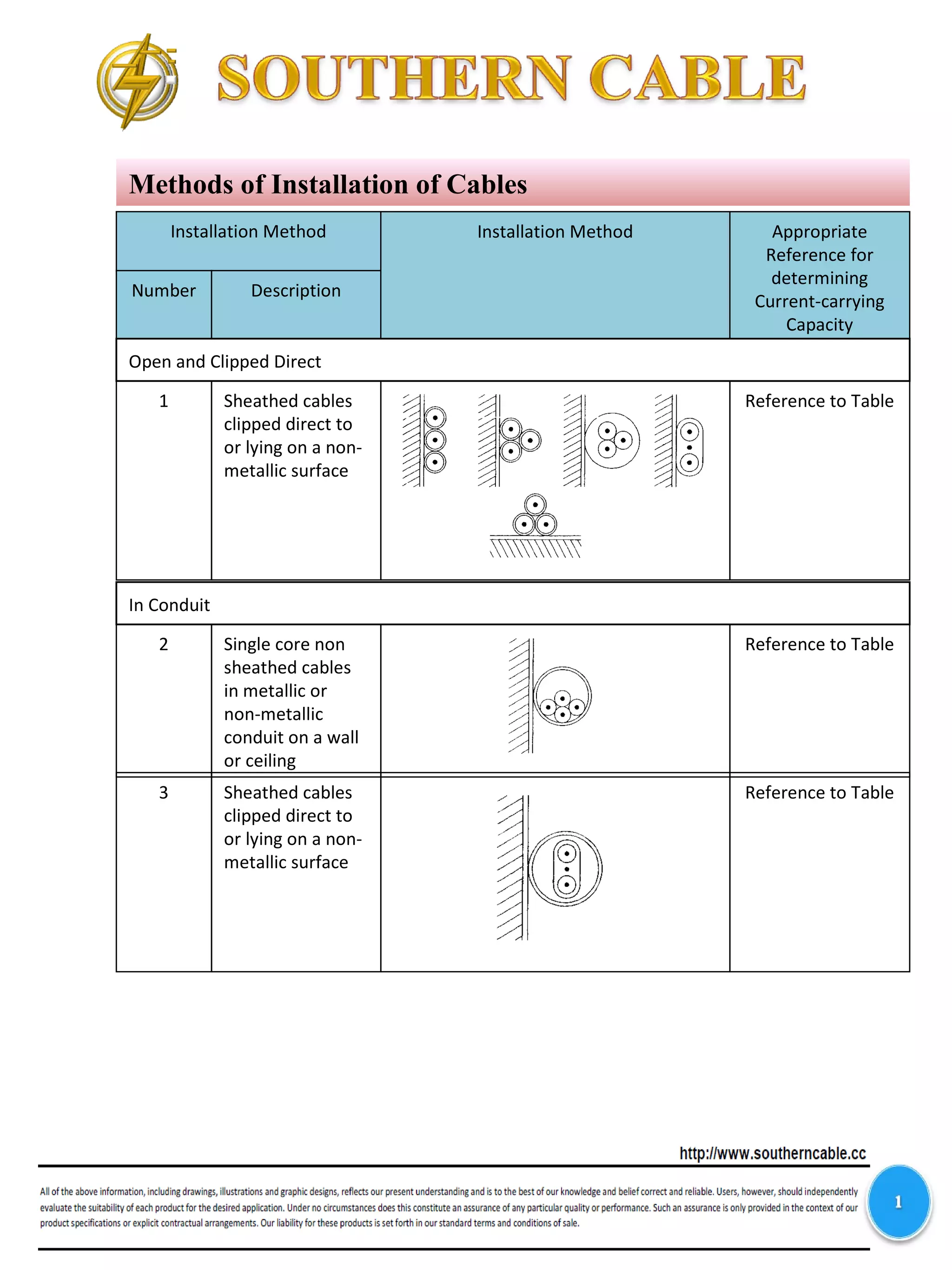

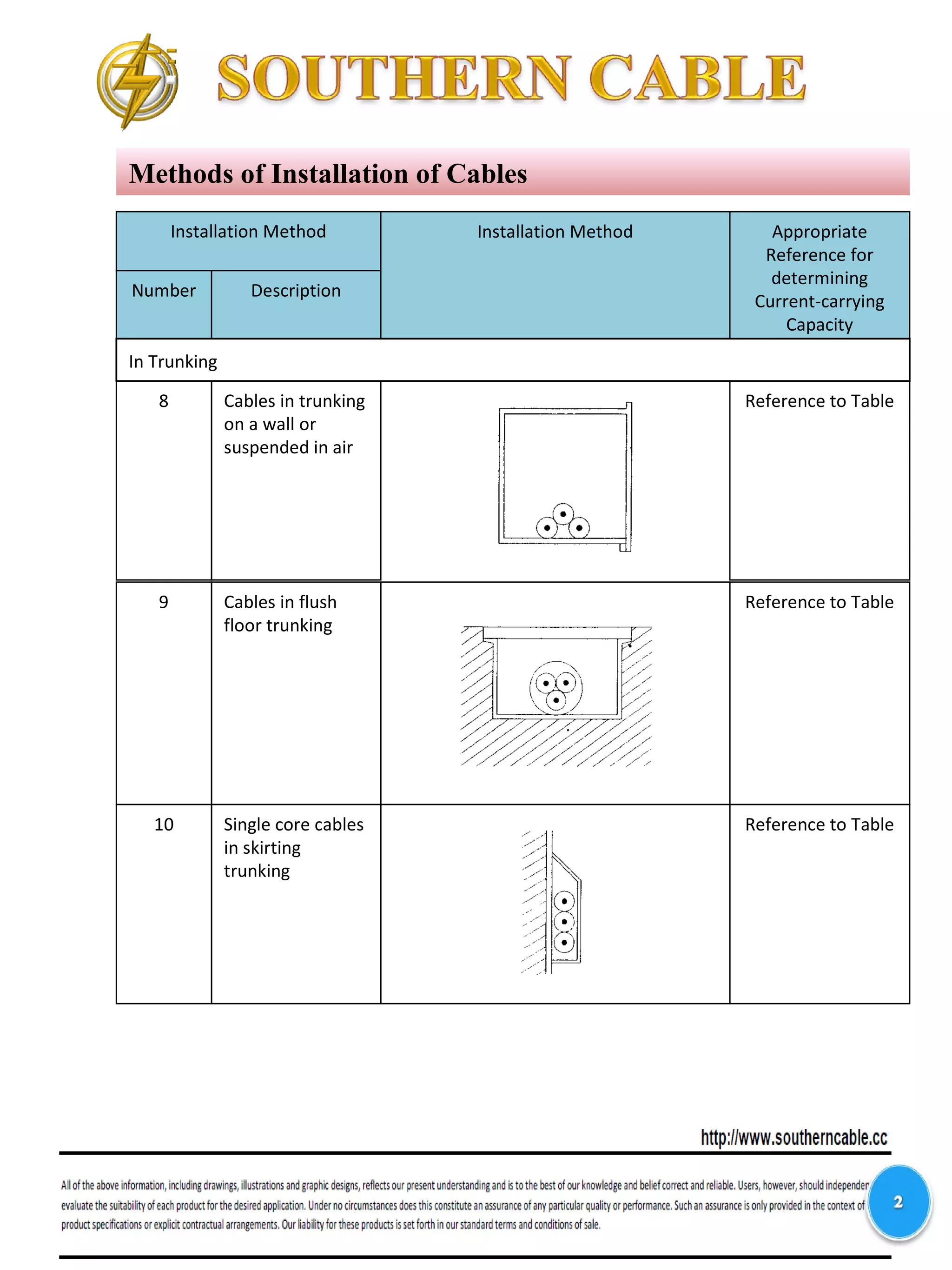

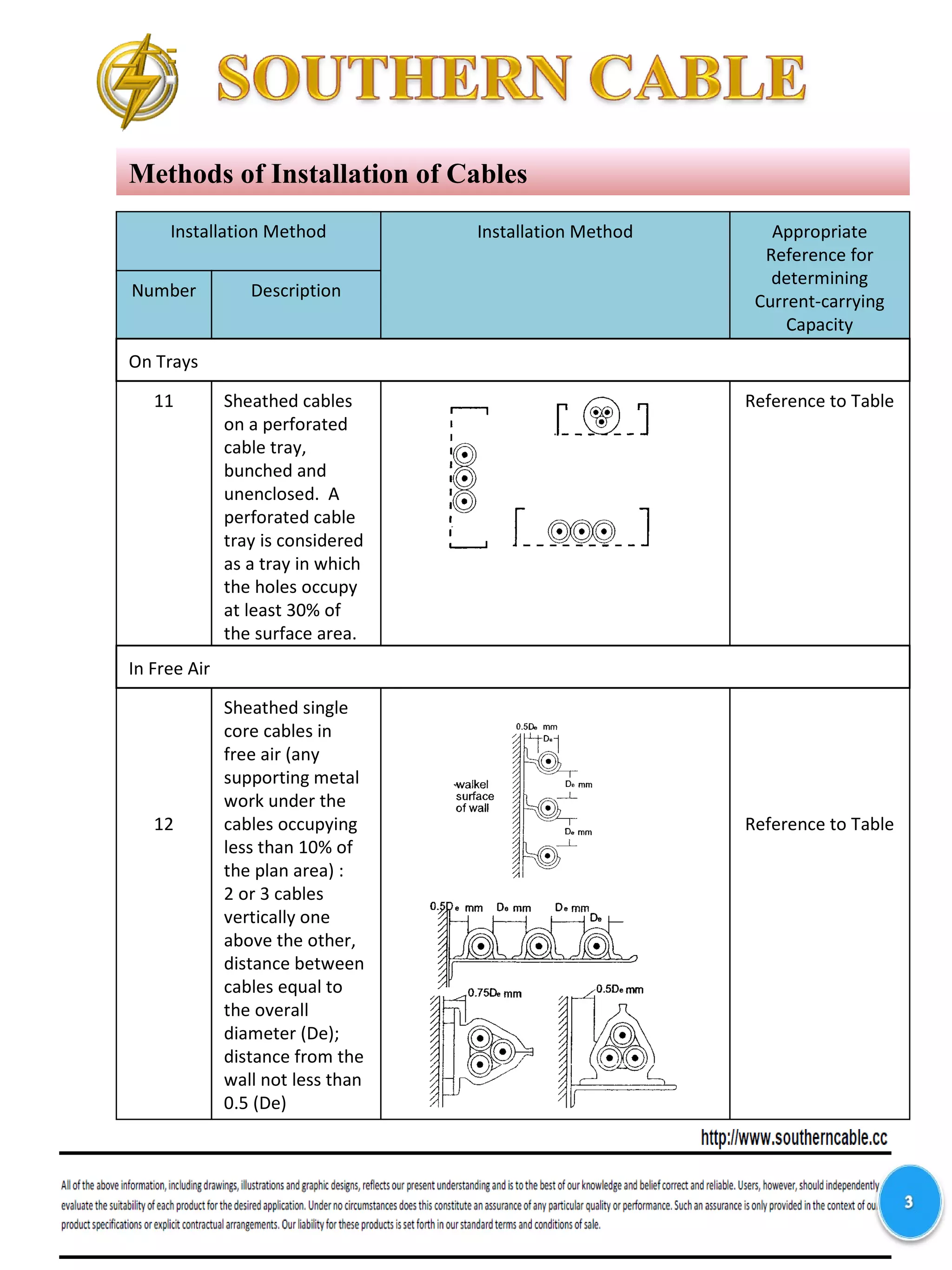

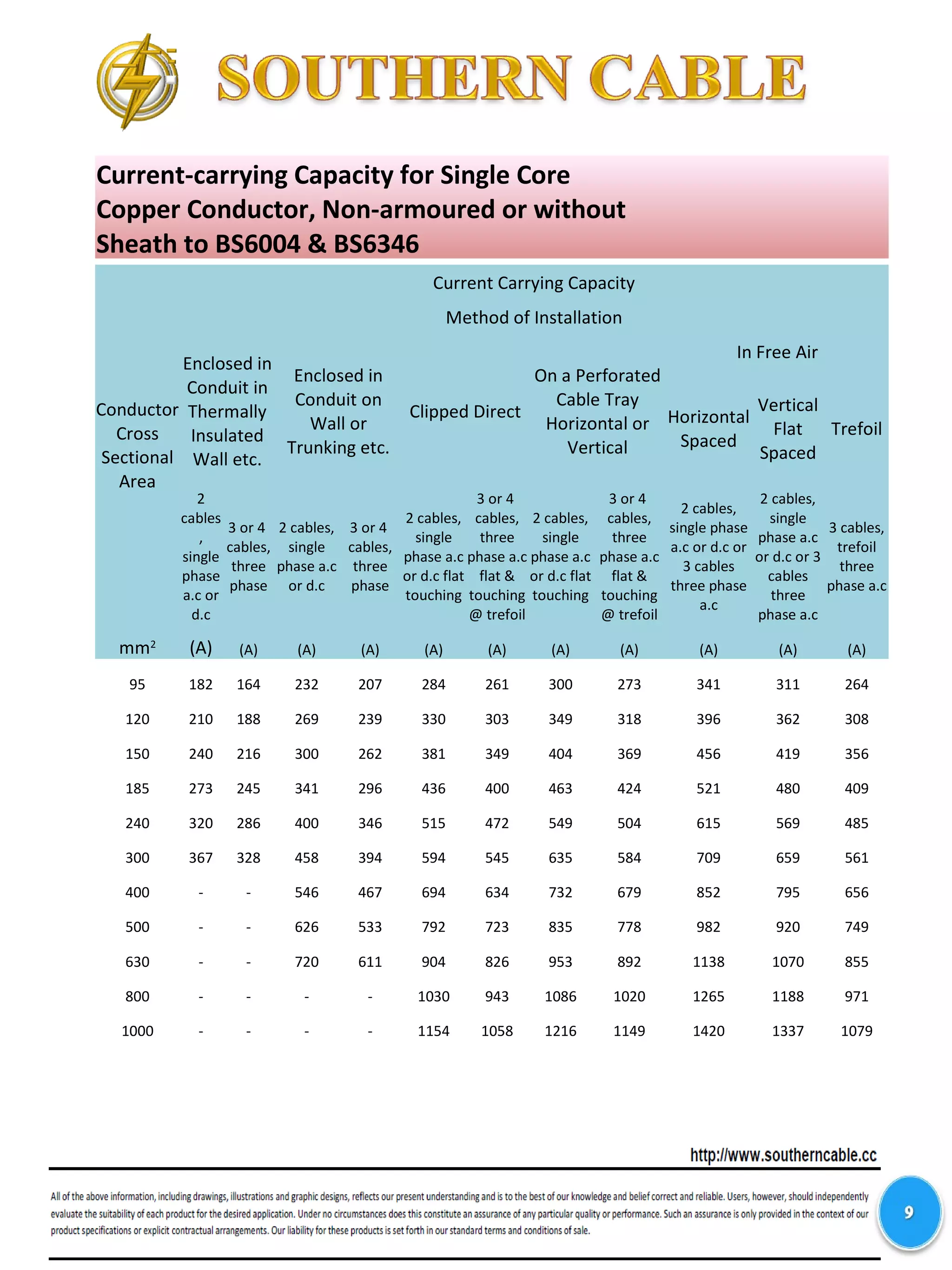

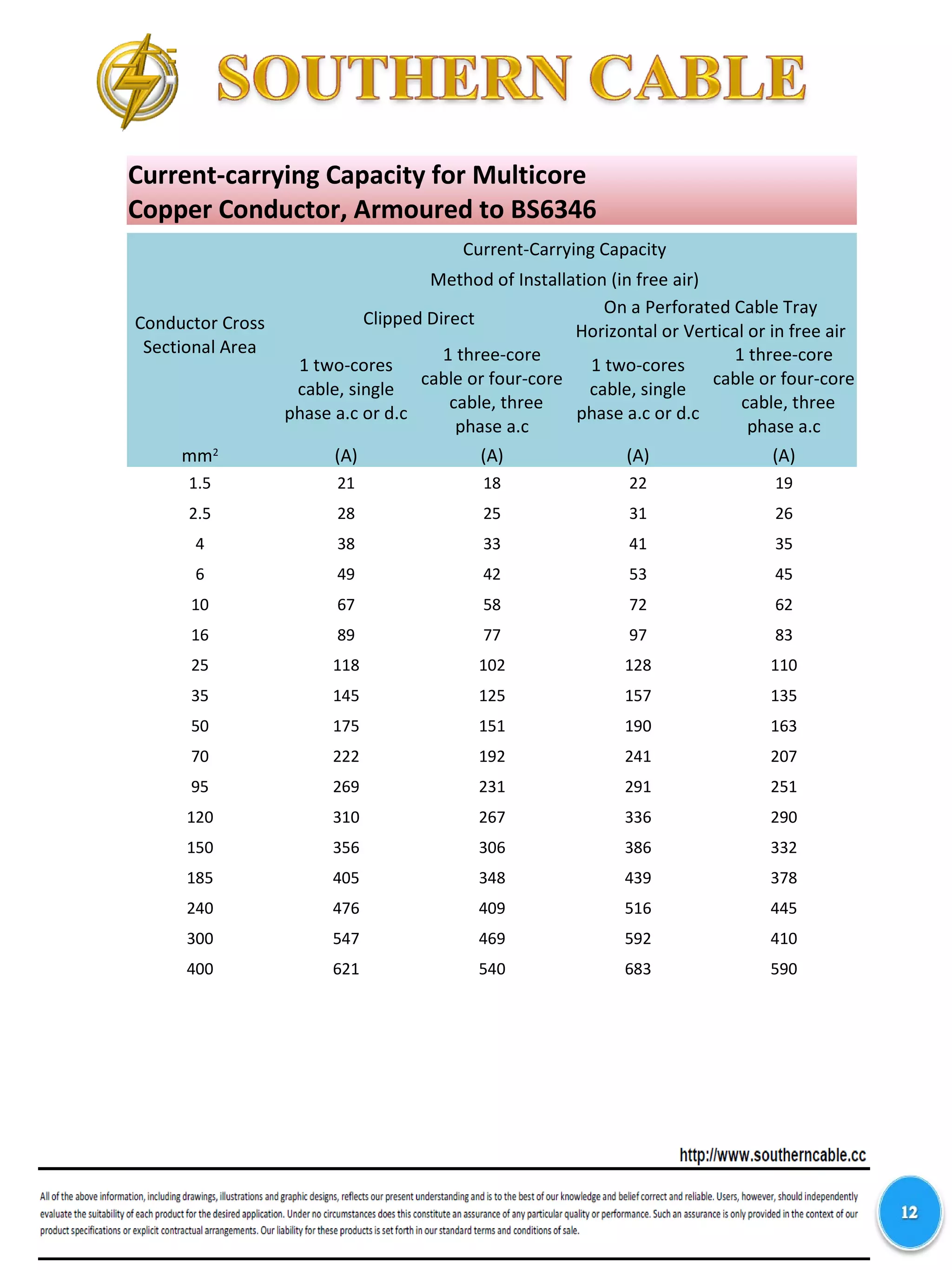

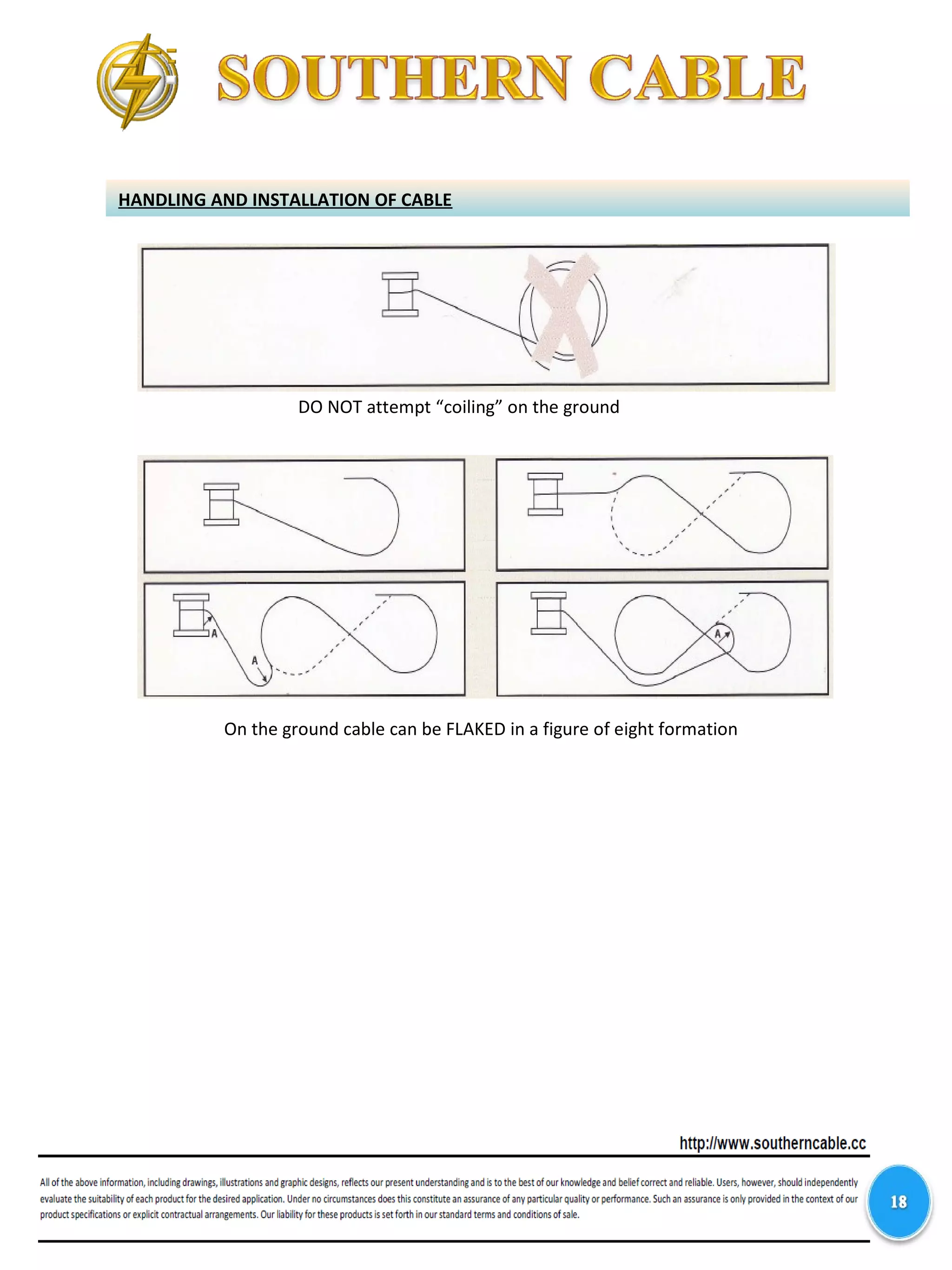

This document contains contact information for Southern Cable's KL and head offices, including addresses, phone numbers, fax, website and email addresses. It also includes information that Southern Cable is ISO9001:2000 certified with registration number AR1757. The rest of the document provides tables with specifications on cable types, sizes, current ratings and installation methods.