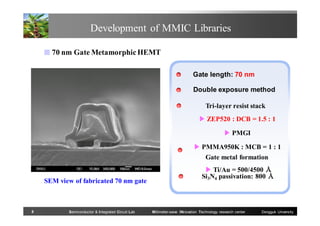

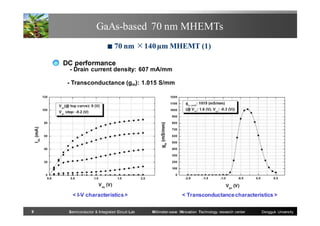

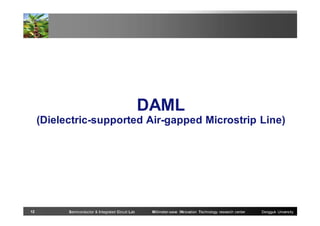

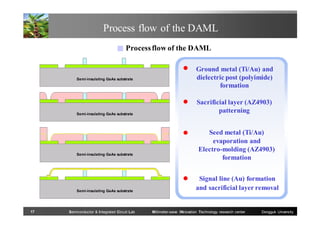

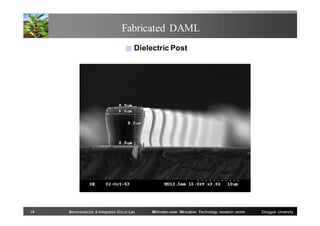

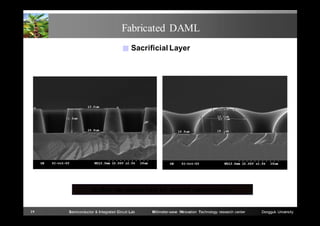

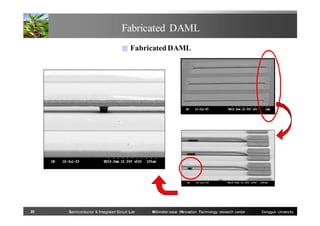

This document describes research in millimeter-wave integrated circuits conducted by Taejong Baek at Dongguk University. The research focuses on developing monolithic integrated circuits for millimeter-wave applications using semiconductor technologies like metamorphic HEMTs with 70nm gate lengths. Key accomplishments include fabricating 70nm gate length MHEMTs with an fT of 330GHz and fmax of 425GHz, as well as developing dielectric-supported air-gap microstrip lines (DAML) to reduce transmission line losses in millimeter-wave integrated circuits. The DAML fabrication process uses only photolithography and low-temperature processes for compatibility with standard MMIC fabrication.

![GaAs-based 70 nm MHEMTs

■ fT

comparison of HEMTs

[1] Y. Yamashita et al., IEEE Electron Device Letters,

vol. 23, no. 10, pp. 573-575, 2002.

[2] K. Shinohara et al., IEEE Electron Device Letters,

vol. 25, no. 5, pp. 241-243, 2004.

[3] T. Suemitsu et al., IEEE Trans. on Electron Devices,

[1]

vol. 49, no. 10, pp. 1694-1700, 2002.

[2]

[4] K. Shinohara et al., IEEE Electron Device Letters,

vol. 22, no. 11, pp. 507-509, 2001.

This

work

[4]

[5] K. Shinohara et al., IEEE MTT-S Digest,

vol. 3, pp. 2159-2162, 2001.

[6] S. Bollaert et al., IEE Electronics Letters,

vol. 38, no. 8, pp. 389-391, 2002.

[3]

[5]

[8]

[6]

[7] T. Parenty et al., Indium Phosphide and

[9]

[7]

[10]

Related Materials, pp. 626-629, 2001.

[8] A. Leuther et al., Indium Phosphide and

Related Materials, pp. 215-218, 2003.

[9] H. Wang et al., IEEE IEDM Digest,

pp. 239-242, 1993.

[10] Y. C. Lien et al., IEEE Electron Device Letters,

vol. 25, no. 6, pp. 348-350, 2004.

This work: Sung Chan Kim et al.,

IEEE Electron Device Letters,

vol. 27, no. 1, pp. 28-30, 2006.

11

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-12-320.jpg)

![DAML Characteristic

■ Comparison of transmission lines

[1] K. Nishikawa et al., IEEE MTT-S Digest, vol. 3,

2001, pp. 1881-1884.

[2] G.E. Ponchak et al., IEEE Trans. Components,

Packaging, and Manufacturing Technology-B,

vol. 21, no. 2, pp. 171-176, 1998.

[3] Suidong Yang et al., IEEE Trans. Microwave

Theory and Techniques,

vol. 46, no. 5, pp. 623-631, 1998.

[4] Y.C. Shih et al., Microwave Journal,

pp. 95-105, 1991.

[5] Youngwoo Kwon et al., IEEE Microwave

and Wireless Components Letters,

vol. 11, no. 2, pp. 59-61, 2001.

[6] S.V. Robertson et al., IEEE Trans. Microwave

Theory and Techniques,

vol. 46, no. 11, 1998, pp. 1845-1849, 1998.

This work: H. S. Lee et al.,

IEE Electronics Letters,

vol. 39, no. 25, pp. 1827-1828, 2003.

This work: Sung-Chan Kim et al., IEEE Microwave

and Wireless Components Letters,

vol. 15, no. 10, pp. 652-654, 2005.

21

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-22-320.jpg)

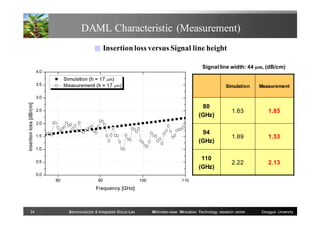

![SDAML Characteristic

■ Comparison of original DAML

4.0

DAML (h = 10 m)

DAML (h = 17 m )

SDAML (h = 17 m)

60

(GHz)

94

(GHz)

120

(GHz)

DAML

(10 µm)

1.87

2.56

3.1

DAML

(17 µm)

1.27

1.89

2.42

SDAML

(17 µm)

3.5

1.07

1.41

1.67

Insertion loss [dB/cm]

3.0

2.5

2.0

1.5

1.0

0.5

0.0

0

20

40

60

80

100

120

140

Frequency [GHz]

25

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-26-320.jpg)

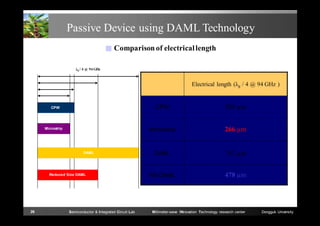

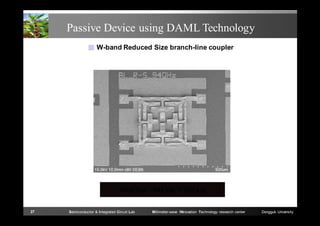

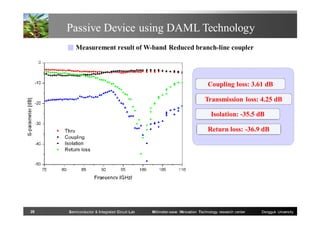

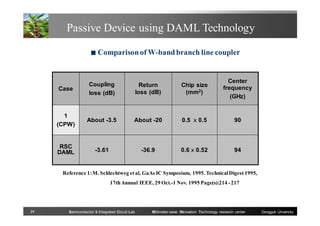

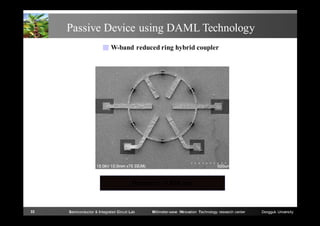

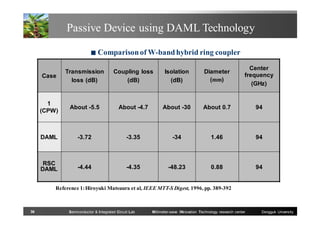

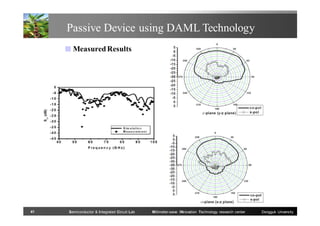

![Passive Device using DAML Technology

■ Measurement result of W-band reduced ring hybrid coupler

0

0

-10

S-parameter [dB]

S-parameter [dB]

-20

-30

-40

-50

S21Thru

S31coupling

S23Isolation

-60

75

80

85

-10

-20

-30

S11

S22

S33

-40

90

95

100

105

Frequency [GHz]

Insertion loss

110

70

75

80

85

90

95

100

105

115

Frequency [GHz]

Return loss

Coupling loss: 4.35 dB

Isolation: -48.23 dB

Transmission loss: 4.44 dB

35

110

Return loss: below -25 dB (all port)

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-36-320.jpg)

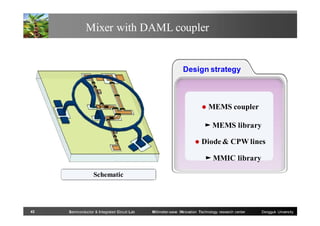

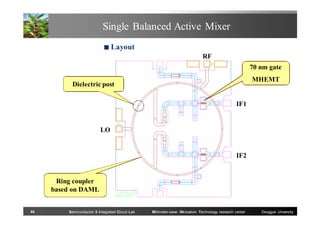

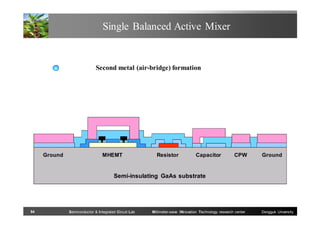

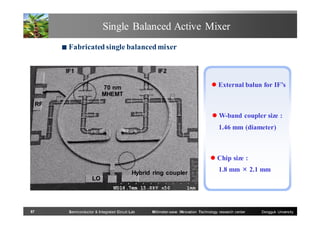

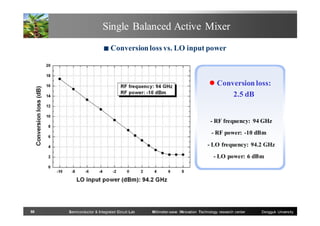

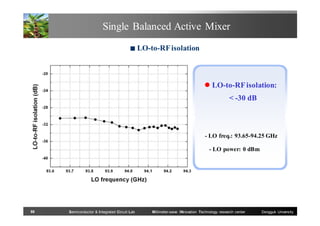

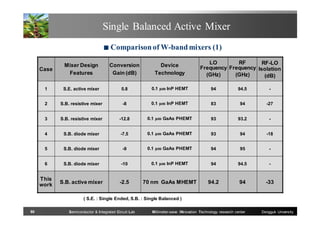

![Single Balanced Active Mixer

■

Comparison of W-band mixers (2)

Single balanced active mixer:

Low conversion loss: high-performance 70 nm MHEMTs

High isolation: hybrid ring coupler based on DAML

- References

[1] Robinder S. Virk et al., IEEE MTT-S Digest, 1997, pp. 435-438.

[2] A. R. Barnes et al., IEEE MTT-S Digest, 2002, pp. 1867-1870.

[3] K. W. Chang et al., IEEE Microwave and Guided Wave Letters, vol. 4, no. 9, pp. 301-302, 1994.

[4] K. W. Chang et al., IEEE Transactions on Microwave Theory and Techniques, vol. 39, no. 12, pp. 1972-1979, 1991.

[5] K. W. Chang et al., Proc. IEEE Microwave and Millimeter-wave Monolithic Circuits Symposium, 1993, pp. 41-44.

[6] Robinder S. Virk et al., IEEE MTT-S Digest, 1997, pp. 435-438.

This work: Sung Chan Kim et al., IEEE Electron Device Letters, vol. 27, no. 1, pp. 28-30, 2006.

61

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-62-320.jpg)

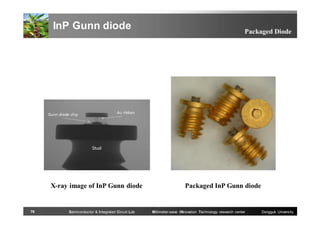

![InP Gunn diode

RF characteristic

Measurement results of packaged InP Gunn diode

Chip number

Voltage [V]

Current [mA]

Oscillation frequency [GHz]

Output Power [dBm]

1

12.4

299

94

17.8

2

11.7

260

93.98

16

3

9.7

299

94.25

15.6

4

10.9

349

93.9

16.6

5

9.3

349

93.8

16.4

Oscillation characteristics of fabricated InP Gunn diode

80

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-81-320.jpg)

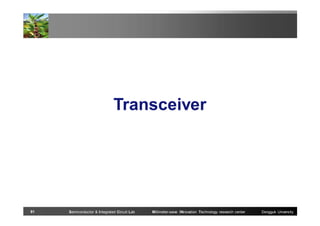

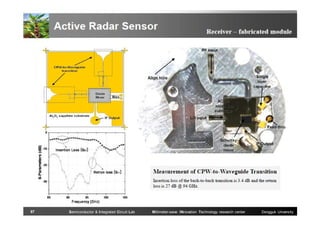

![Active Radar Sensor

RF Characteristic

0

S-parameter [dB]

-5

-10

-15

-20

-25

-30

Insertion loss

Return loss

-35

75

80

85

90

95

100

105

110

115

Frequency [dB]

Reference

Bump material

Bonding condition

Loss/frequency

[1]

Au

350℃, 20 g/pillar

0.2 dB/77 GHz

[2]

Au

275℃, 230 N/mm2

0.2 dB/NA

This work

Au / Ag epoxy

110℃, 30g/bump

0.205 dB/94 GHz

[1] Aoki, S.; Someta, H.; Yokokawa, S.; Ono, K.; Hirose, T.; Ohashi, Y.;, “A flip chip bonding technology using gold pillars for

millimeter-wave applications,” in Proc. IEEE MTT-S Int. Microw. Symp. Dig. 1997, vol. 2, pp. 731-734, 1997.

[2] Heinrich, W.; Jentzsch, A.; Richter, H.;, “Flip-chip interconnects for frequencies up to W band,” Electron. Lett., vol. 37, issue 3, pp.

180-181, 2001.

90

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-91-320.jpg)

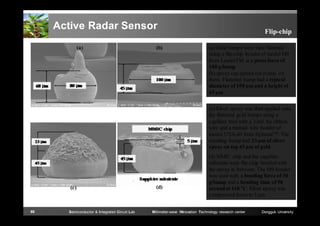

![Active Radar Sensor

Shear test

The shear tests were performed using a model 4000 series shear test machine from DageTM , widely used

to measure the interconnection strength between the MMIC chip and the sapphire substrate. The speed of

the shear blade was 300 μm/s, with the tip located at 40 μm above the surface of the sapphire substrate.

The flip-chip bonded die, which used proposed low-temperature flip-chip bonding method and 20 bumps

of 100 μm diameter, was separated at a force of 900 g.

Bonding temperature

Die shear strength [mg/ ㎛2]

100℃

1.55

150℃

2.19

200℃

4.38

ACP

220℃

1.05

ACF

220℃

1.07

[3]

CuSn

260℃

2.17

This work

Au/Ag epoxy

110℃

5.73

Reference

[1]

Bump material

Indium

[2]

[1] Kun-Mo Chu, Jung-Sub Lee, Han Seo Cho, Hyo-Hoon Park, Duk Young Jeon, “A fluxless flip-chip bonding for VCSEL arrays using

silver-coated indium solder bumps,” IEEE Trans. Electronics Packag. Manuf., vol. 27, no. 4, pp. 246-253, 2004.

[2] Tan Ai Min, Sharon Pei-Siang Lim and Charles Lee, “Development of solder replacement flip chip using anisotropic conductive

adhesives,” in Proc. 5 th Electron. Packag. Tech. Conf. 2003, pp. 390-396, 2003.

[3] Katsuyuki Sakuma, Jun Mizuno, Noriyasu Nagai, Naoko Unami, and Shuichi Shoji, “Effects of Vacuum Ultraviolet Surface

Treatment on the Bonding Interconnections for Flip Chip and 3-D Integration.” IEEE Trans. Electronics Packag. Manuf., vol. 33, no. 3,

pp. 212-220, 2010.

92

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-93-320.jpg)

![LNA

LNA module – 4-stage

80

60

S11

S-Parameter [dB]

40

S21

S12

20

S22

0

-20

-40

-60

-80

80

85

90

95

Frequency [GHz]

100

105

110

4-stage LNA module measured characteristics

Average linear gain: 65.8 dB @ 81 ~ 102 GHz

68.2 dB @ 94 GHz

112

Semiconductor & Integrated Circuit Lab

Millimeter-wave INnovation Technology research center

Dongguk University](https://image.slidesharecdn.com/20130723researchaccomplishmentud-131121200044-phpapp01/85/20130723-research-accomplishment_ud-113-320.jpg)