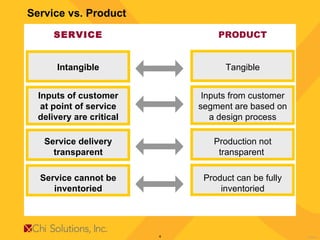

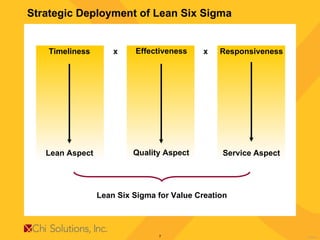

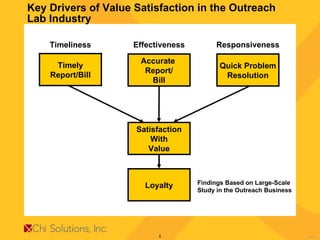

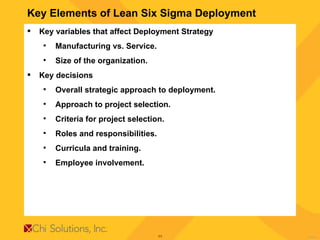

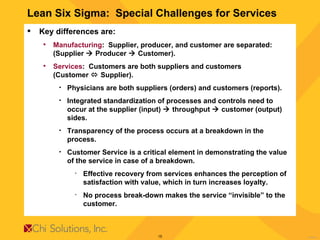

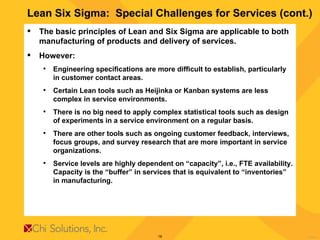

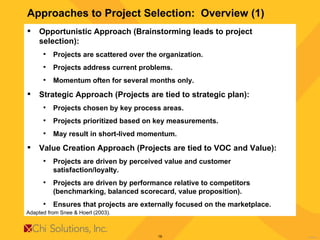

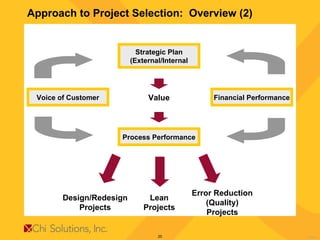

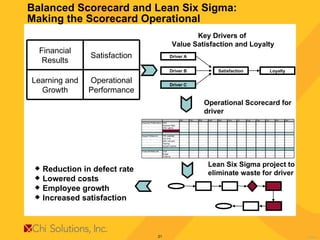

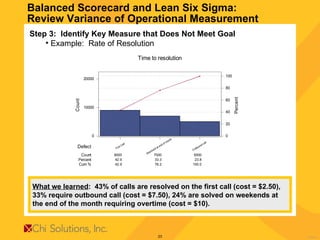

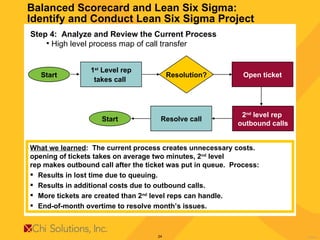

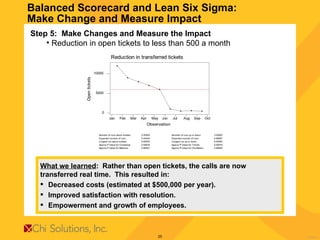

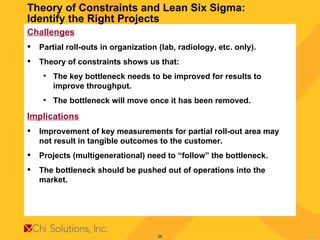

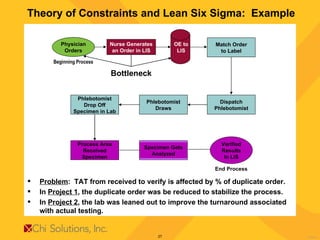

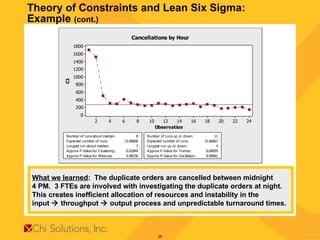

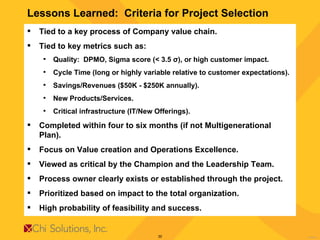

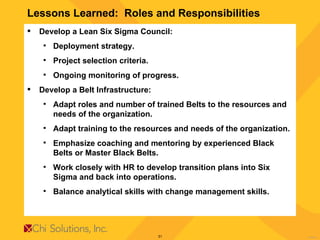

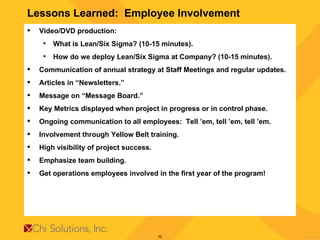

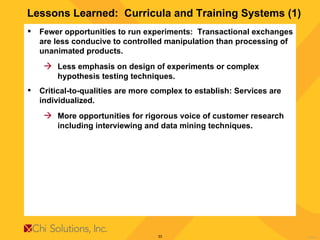

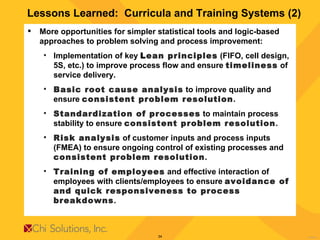

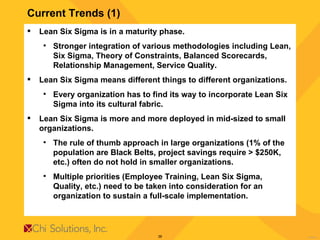

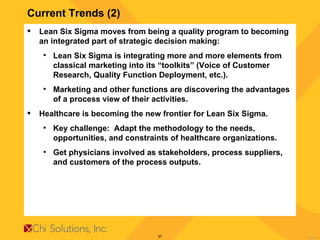

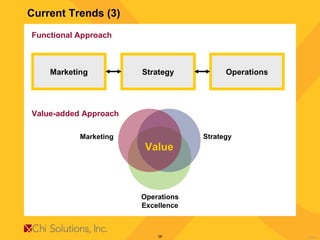

This document discusses lessons learned from deploying Lean Six Sigma in services organizations. It provides an overview of key differences between manufacturing and services and discusses challenges in applying Lean Six Sigma tools. The document also discusses approaches to strategic project selection using Balanced Scorecard and Theory of Constraints and outlines lessons learned around deployment criteria, roles, training, and measurement. Current trends indicate Lean Six Sigma is moving towards a more integrated approach and being applied in smaller organizations and healthcare.

![Follow-up Any questions or comments regarding this presentation can be forwarded to: Hans Froehling, DBA/CMBB Senior Consultant [email_address]](https://image.slidesharecdn.com/2008NovLessonsLearnedLeanSixSigmaBalancedScorecard-122802035459-phpapp02/85/2008-Nov-Lessons-Learned-Lean-Six-Sigma-Balanced-Scorecard-39-320.jpg)