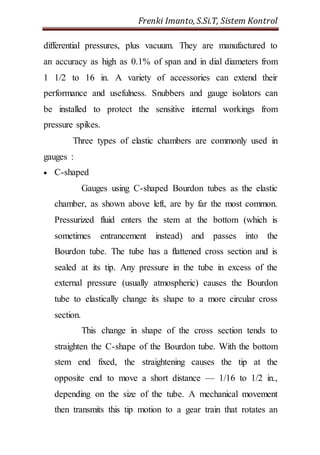

The Bourdon tube is the most common type of pressure gauge, where a metal tube senses pressure and converts it to displacement. As pressure increases, the tube tries to straighten out, causing its tip to move. This movement is amplified mechanically and indicated by a pointer to indirectly show pressure level. Bourdon tubes come in different shapes like C-shaped, helical, and spiral, with the material and size depending on the desired pressure range and gauge type. C-shaped tubes are most common, where pressure inside tries to straighten the tube and moves the tip to indicate pressure.