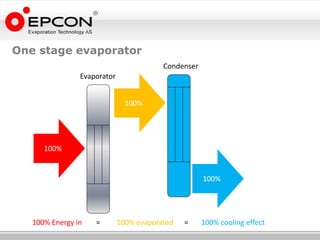

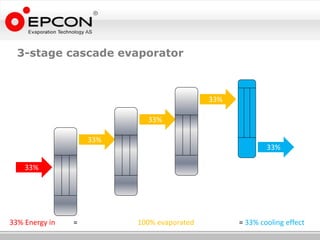

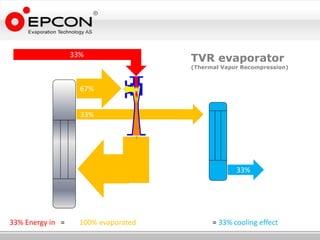

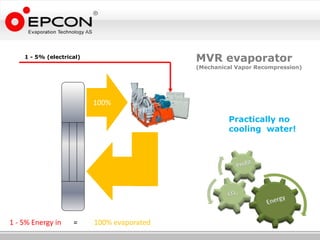

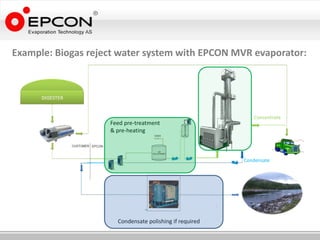

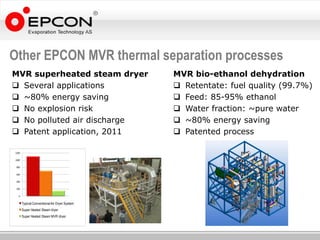

Significant energy saving can be achieved by utilizing MVR industrial heat pumps in thermal separation processes. MVR evaporators can reduce energy consumption by 90-99% compared to conventional systems by mechanically compressing vapor for reuse. They require practically no cooling water and are a reliable, proven technology. MVR is particularly efficient for applications like biogas reject water treatment where it can concentrate waste streams while using only 15-20 kWh of energy per ton of water evaporated.