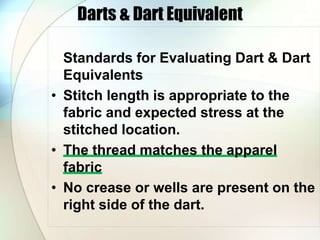

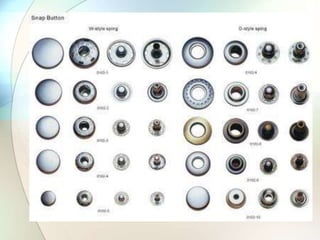

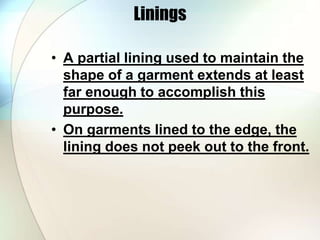

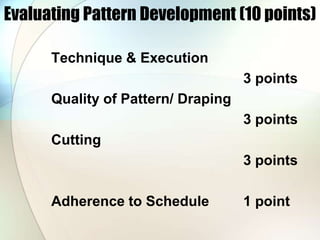

This document provides standards for evaluating the quality of various garment construction components. It discusses how to properly evaluate darts, seams, seam finishes, collars, hems, facings, closures, underlinings, interfacings, interlinings and linings. Key factors include stitching being even and appropriate for the fabric, seams lying flat without puckers, finishes preventing raveling, collars and hems being even and smooth, and interfacings/linings providing support and shape without adding excess bulk. The document emphasizes that all construction elements must be suitable for the garment design, fabric and intended care.