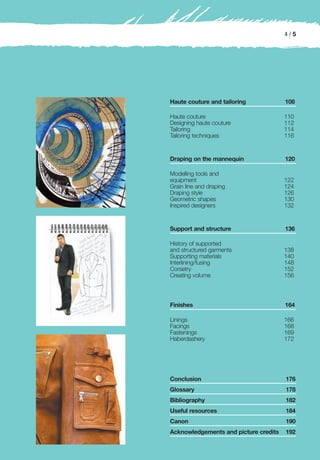

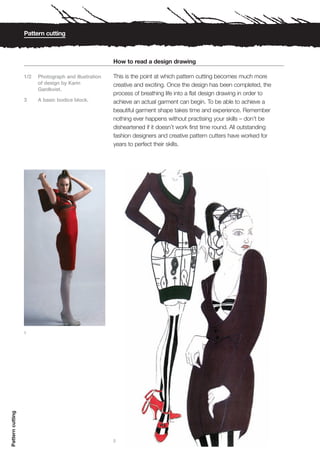

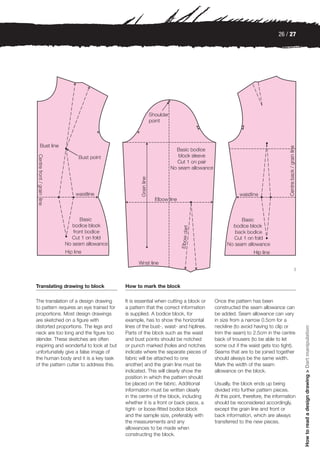

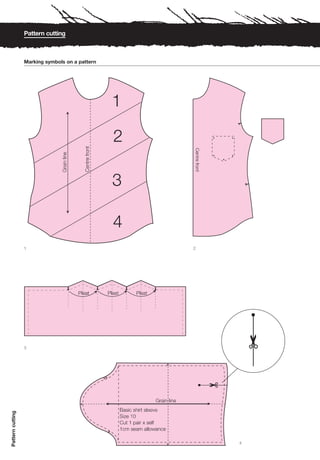

The document provides an introduction to the tools, equipment, and processes used for pattern cutting in fashion design. It discusses the importance of understanding how a garment is constructed in three dimensions from a two-dimensional pattern. The chapter covers silhouettes, sizing, basic blocks and patterns, and introduces the key equipment needed for pattern cutting.

![Pongees Ltd The Button Queen William Gee

(Silks) (Buttons, buckles, fastenings) (Haberdashery, trimmings)

28 Hoxton Square, 19 Marylebone Lane, London 520 Kingsland Road,

London EC1 Tel: 020 7935 1505 London E8 4AJ

Tel: 020 7739 9130

The Cloth House 2000 Tailoring Ltd

Riri Swiss (Fabrics) (Buttonholes, zips in any length,

(Zips and runners) 98 Berwick Street, canvas, tailoring tools [call first])

E.L. Watson 48 Elm Grove London W1 51 Lexington Street,

Orpington Kent BR6 0AD Tel: 020 7287 1555 London W1R 3LG

Tel: 01689 836471 Tel: 020 7439 1633

The Dover Book Shop

R.D. Franks Ltd (Fashion books)

(Fashion books and magazines) 18 Erlham Street,

5 Winsley Street London WC2H 9LN

London W1W 8HG Tel: 020 7836 2111

Tel: 020 7636 1244

V.M. Mason

Soho Silks (Zips, eyelets, studs, fastenings,

(Fabrics) jeans buttons)

24 Berwick Street, 49 Lawrence Road,

London W1 Tottenham N15 4EJ

Tel: 020 7434 3305 Tel: 020 8802 4227

Textile Kings Whaleys Ltd

(Fabrics) (Fabrics, samples available)

Useful resources

81 Berwick Street, Harris Court Gt Horton,

London W1 Bradford West Yorks BD7 4EQ

Tel: 020 7437 7372 Tel: 01274 576718](https://image.slidesharecdn.com/basicsfashiondesignconstruction2009bbs-120911054239-phpapp01/85/Basics-fashion-design-construction-2009-bbs-190-320.jpg)