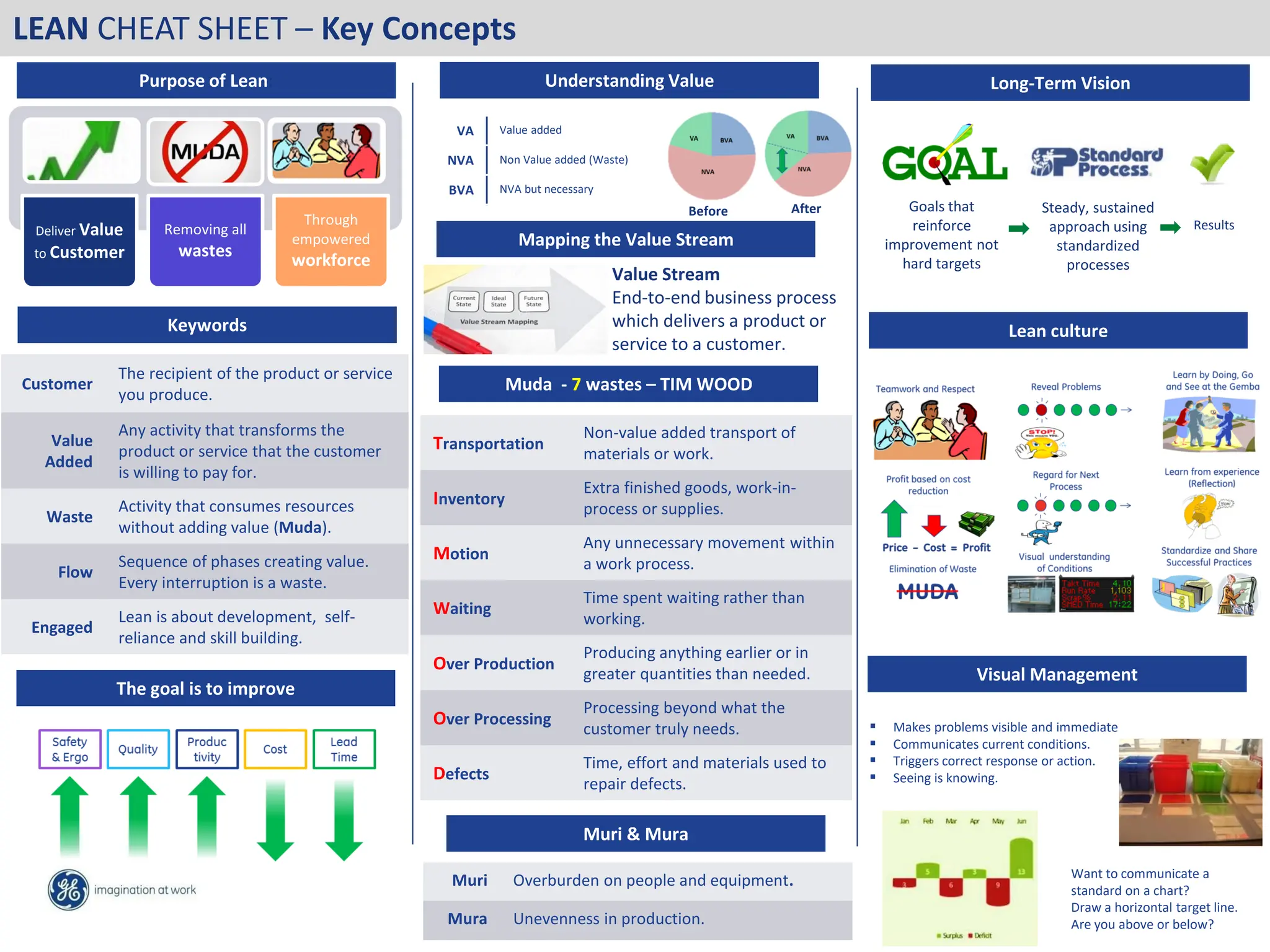

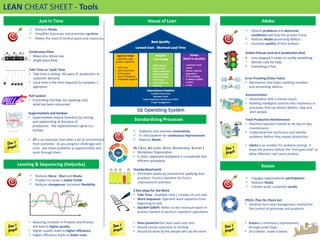

The document provides a lean cheat sheet that defines key lean concepts and tools. It defines lean as focusing on delivering value to customers by removing waste through an empowered workforce. Key concepts explained include value, waste, flow, and visual management. Tools summarized are leveling and sequencing, standardizing processes, just-in-time, jidoka, andon, error proofing, total productive maintenance, takt time vs. cycle time, 5S, standardized work, kaizen, and PDCA. The goal of lean is to improve understanding of value and mapping the value stream to create continuous flow and pull systems that engage workers.