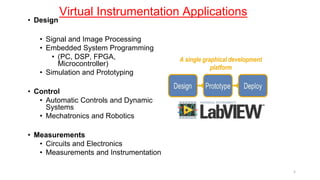

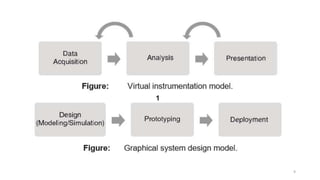

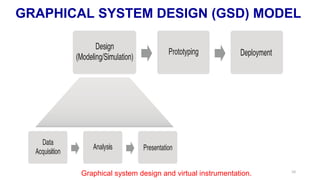

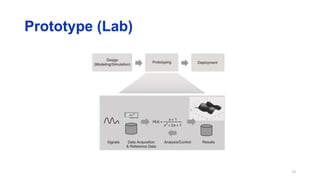

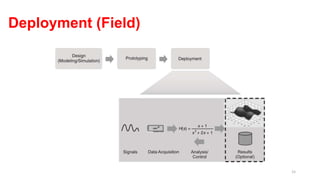

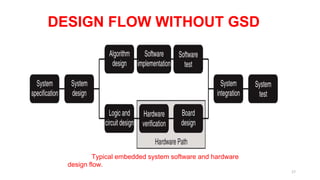

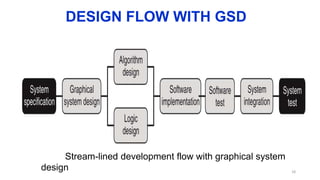

LabVIEW is a graphical programming language used for data acquisition, instrument control, and signal processing. It uses a flowchart-like interface where programs are created using function icons or "virtual instruments" (VIs) that are wired together to pass data. This allows for a graphical system design (GSD) approach to modeling, prototyping, and deploying systems. GSD streamlines development by allowing the same code to move from design to prototype to deployment without rewriting. LabVIEW is commonly used for measurement and automation applications in fields like engineering, science, and research.