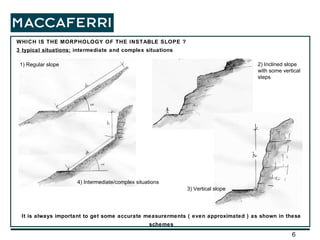

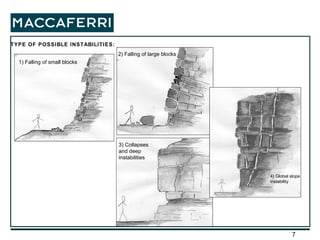

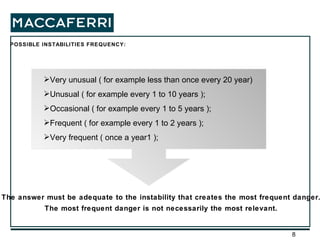

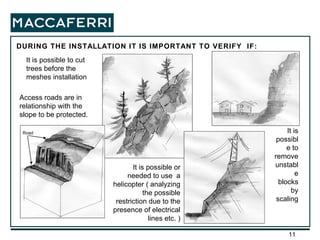

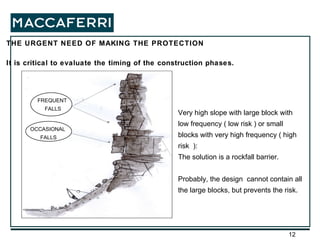

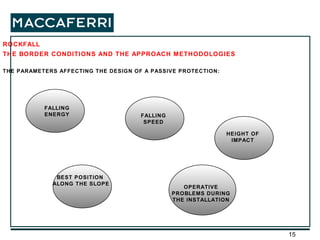

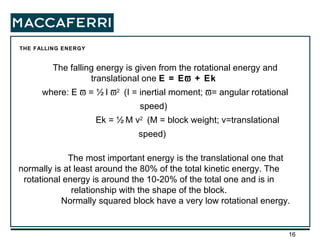

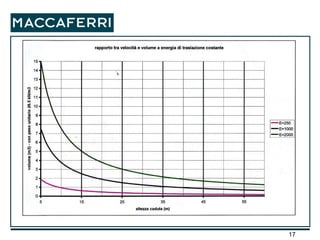

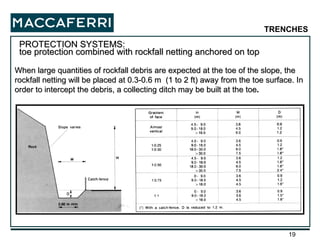

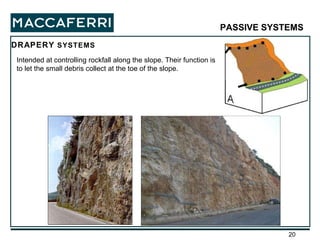

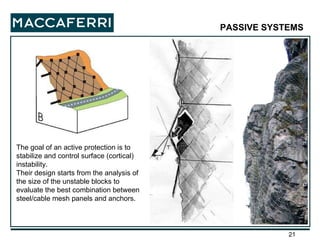

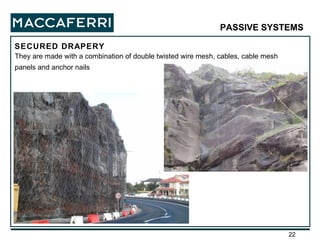

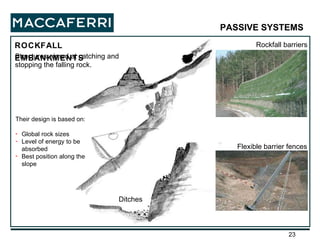

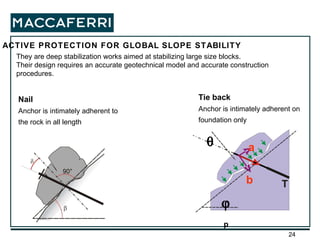

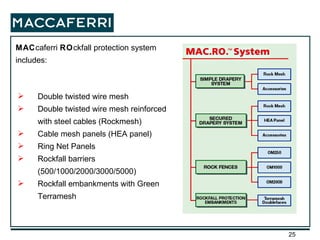

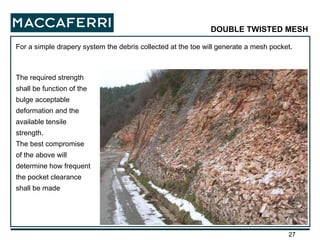

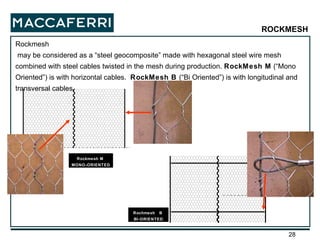

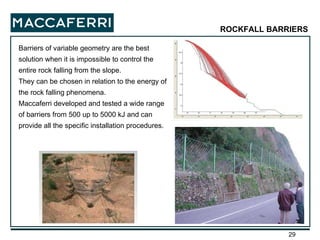

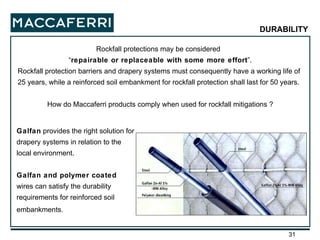

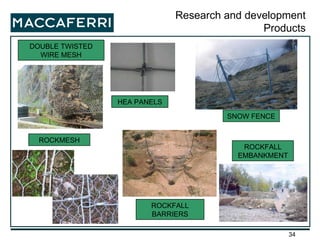

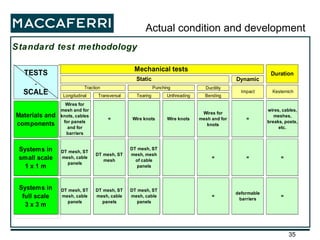

The document discusses rockfall mitigation solutions and the MACRO System. It outlines the complexities of rockfall projects and importance of risk analysis. A variety of active and passive protection systems are described, including secured drapery, rockfall embankments, barriers, and drapery systems. Key considerations for choosing solutions include the slope morphology, instability type and frequency, and environmental factors. Research and testing with various institutes has been conducted to develop the MACRO System solutions.