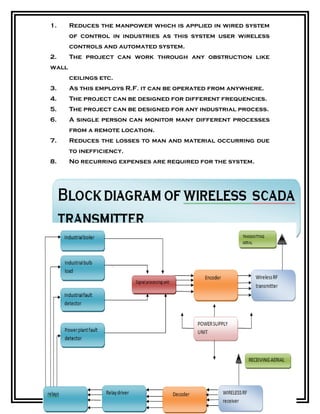

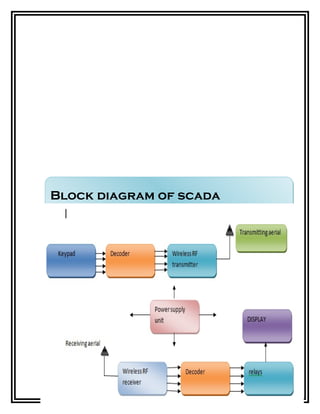

SCADA (Supervisory Control and Data Acquisition) is an industrial control system that monitors and controls a variety of processes including industrial, infrastructure, and facilities-based operations. It encompasses components such as Human-Machine Interfaces (HMIs), supervisory control systems, remote terminal units (RTUs), and communication infrastructure, enabling centralized oversight of operations across vast areas. The adoption of distributed control systems (DCS) within SCADA is evolving, facilitated by advancements in communication technologies that blur the lines between SCADA and DCS functionalities.

![This has also come under threat with some customers

wanting SCADA data to travel over their pre-established

corporate networks or to share the network with other

applications. The legacy of the early low-bandwidth

protocols remains, though. SCADA protocols are designed

to be very compact and many are designed to send

information to the master station only when the master

station polls the RTU. Typical legacy SCADA protocols

include Modbus RTU, RP-570, Profibus and Conitel. These

communication protocols are all SCADA-vendor specific but

are widely adopted and used. Standard protocols are IEC

60870-5-101 or 104, IEC 61850 and DNP3. These

communication protocols are standardized and recognized

by all major SCADA vendors. Many of these protocols now

contain extensions to operate over TCP/IP. It is good

security engineering practice to avoid connecting SCADA

systems to the Internet so the attack surface is reduced.

RTUs and other automatic controller devices were being

developed before the advent of industry wide standards for

interoperability. The result is that developers and their

management created a multitude of control protocols.

Among the larger vendors, there was also the incentive to

create their own protocol to "lock in" their customer base.

A list of automation protocols is being compiled here.

Recently, OLE for Process Control (OPC) has become a

widely accepted solution for intercommunicating different

hardware and software, allowing communication even

between devices originally not intended to be part of an

industrial network.

DESIGN MODULES

1] adC interfaCe

Analog to digital converters sense a voltage and

convert it into its corresponding digital

representation, based on the percentage of the full

range of the input. For an 8-bit A/D, there are 256

discrete representations of the input voltage. In other

words, it takes the input voltage range and divides it

into 256 equal parts. If, for instance, your input range

was 0 to 2.56 volts, the smallest increment the A/D can

measure is 2.56/256 or 10 mV. Since most micro

controllers operate with 8 bits, using an 8 bit A/D

works out well.

2] rfreCeiver](https://image.slidesharecdn.com/03scada-150305121205-conversion-gate01/85/03-scada-synopsis-7-320.jpg)

![The RF RECEIVER modulates the digital data an

RECEVER FROM TX.

3] rftransmitter

The RF transmitter modulates the digital data and

send to the PC. It’s transmission frequency

315MHZ.

Technical specification

915 MHz (70 cms pan-Euro pean ISM allocation)

75E antenna connection

RF output power programmable in 10 steps between

l.mWand 10 mW

Range 250 m line of sight (LOS) or 30 m in buildings

Data speed on host link: 2.4 to 38.4 kbits/s, adjustable

in

five steps

Fixed 19.2 kbits/s data speed on RF link

Two hardware handshaking signals

RSSI (received signal strength) analogue output

Supply voltage 3.3 V to 5.5 V

a dot-matrix liquid crystal display are internally

provided on one chip, a minimal system can be interfaced

with this controller/driver. A single HD44780U can

display up to one 8-character line or two 8-character

lines.

Analog inputs

Voltage range - 0 - 5V

Resolution - 8 / 10 bits

Conversion time - 100uS

Total access time - 21uS + 10 I/O clock periods

Input resistance - typically >100M

Advantages](https://image.slidesharecdn.com/03scada-150305121205-conversion-gate01/85/03-scada-synopsis-8-320.jpg)