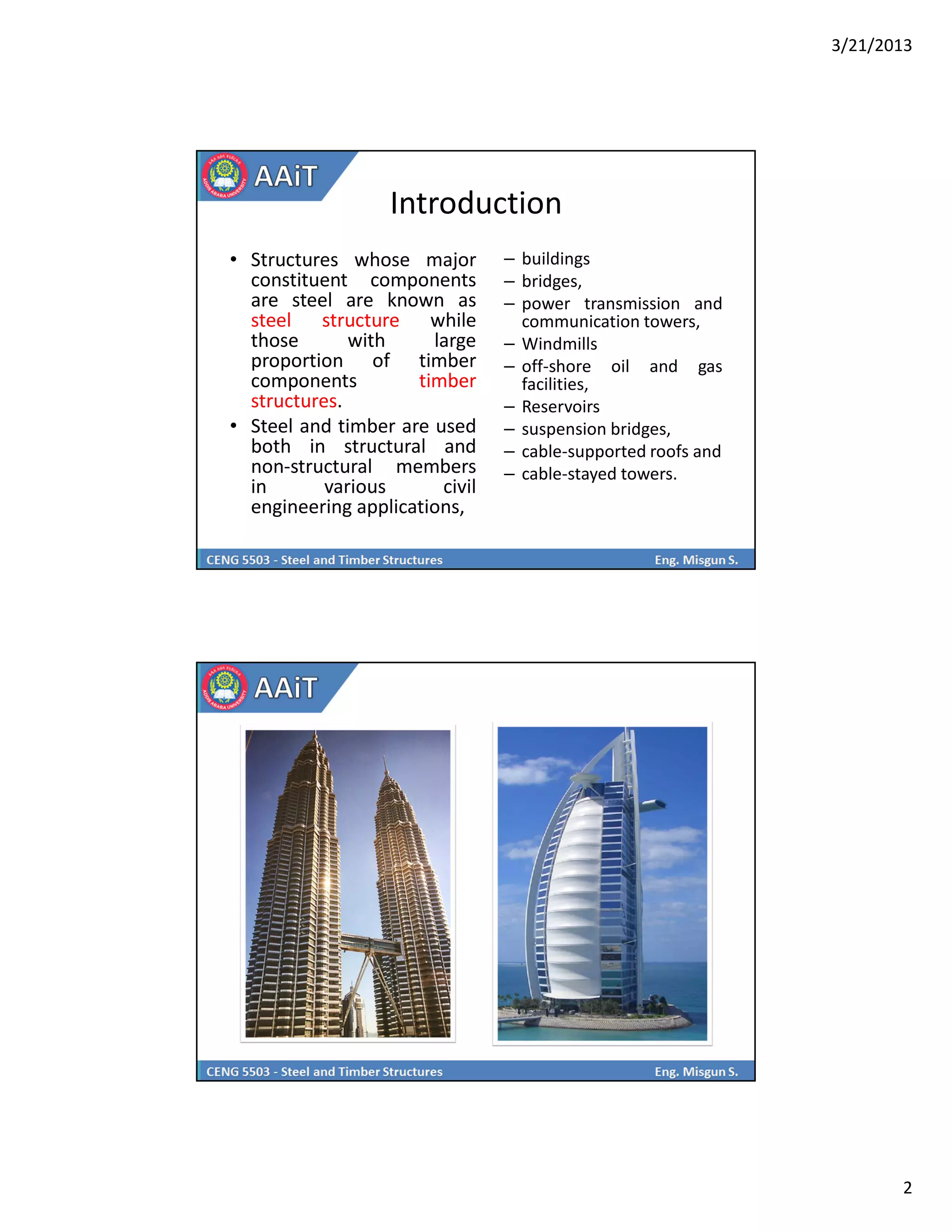

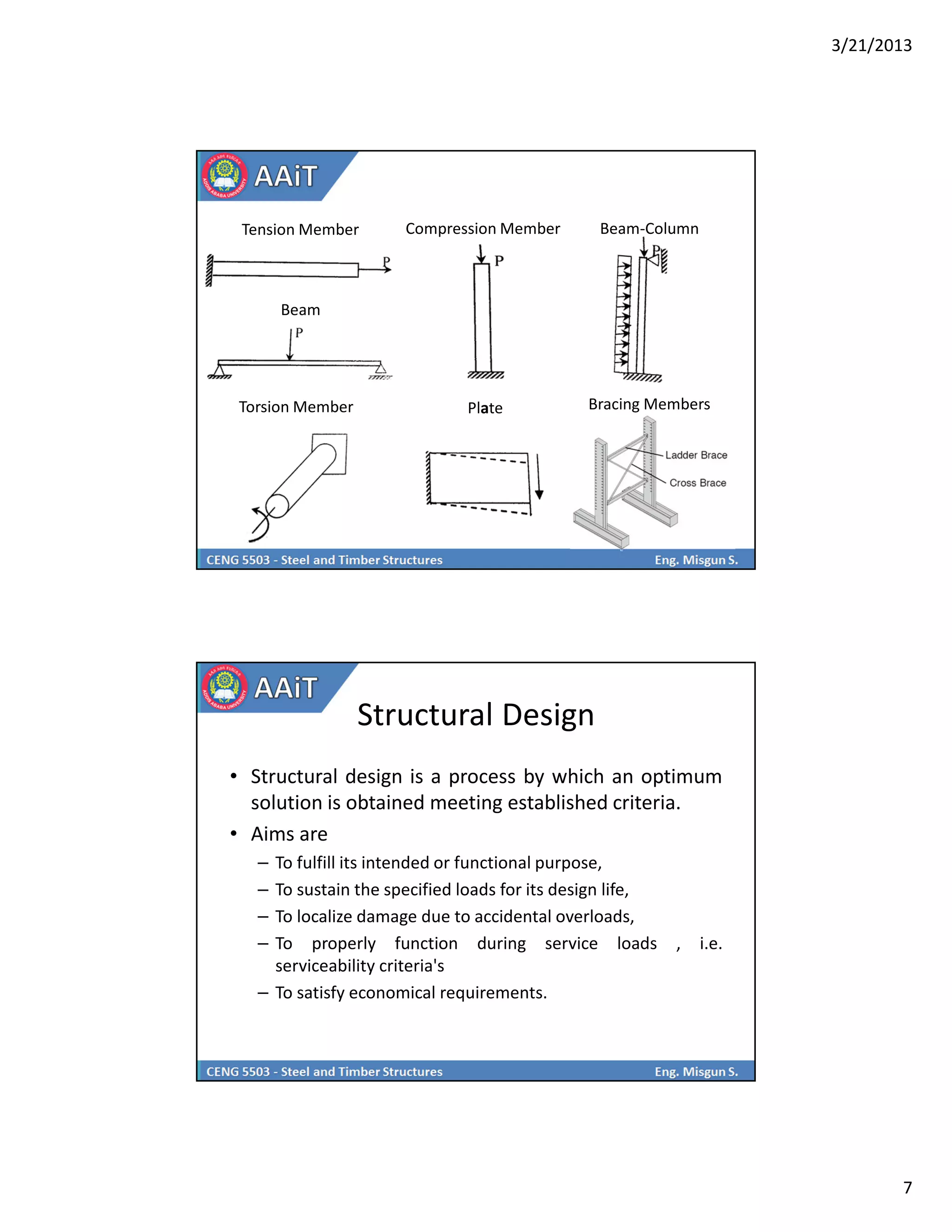

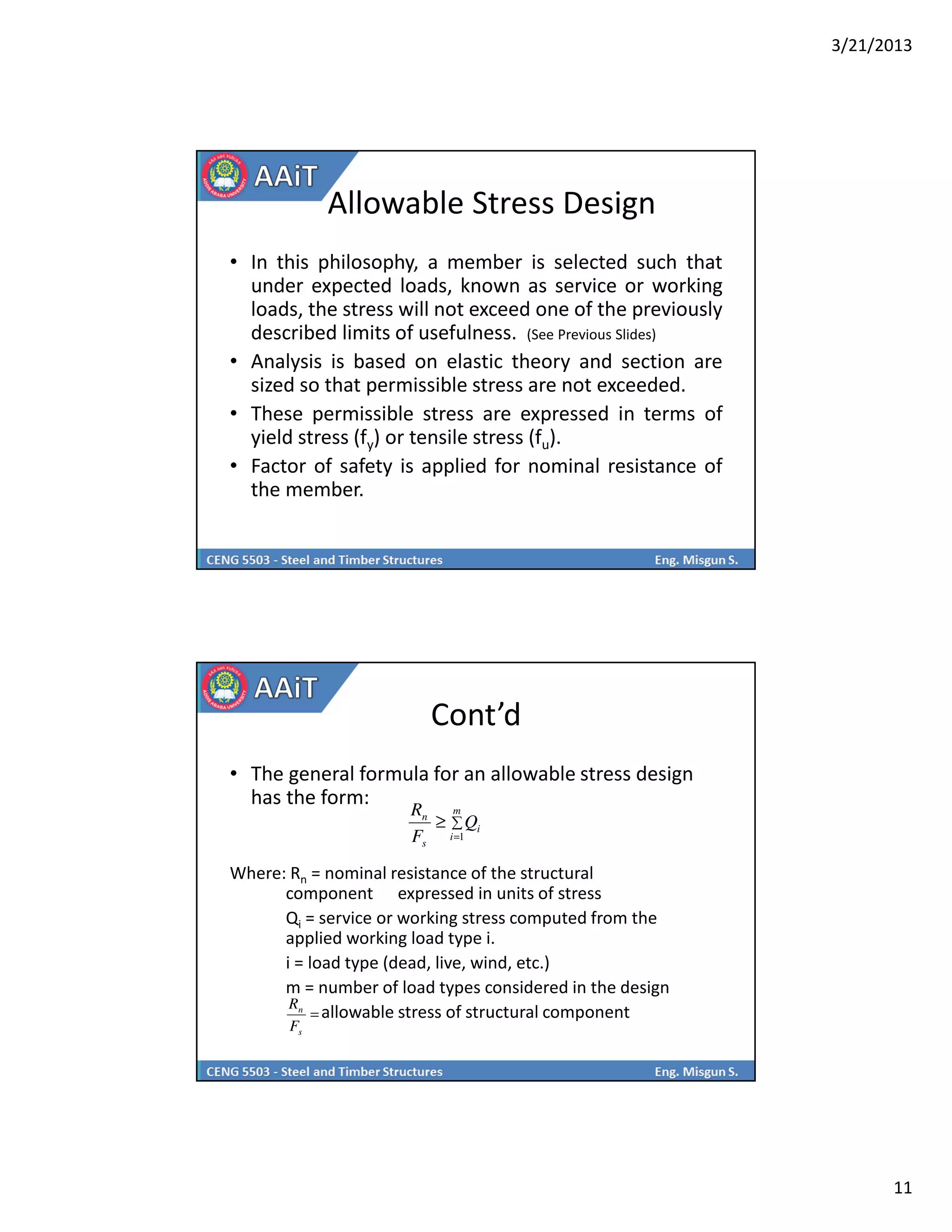

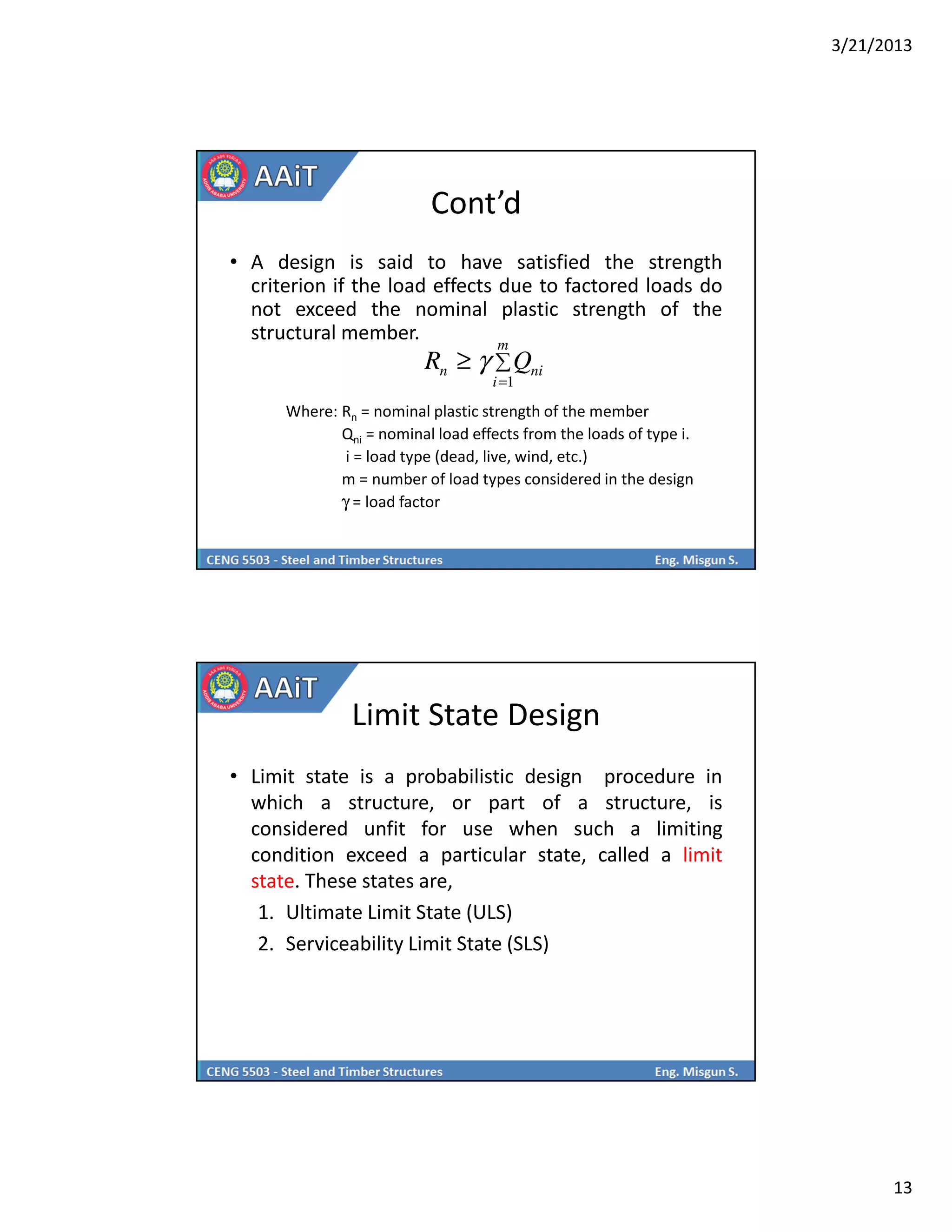

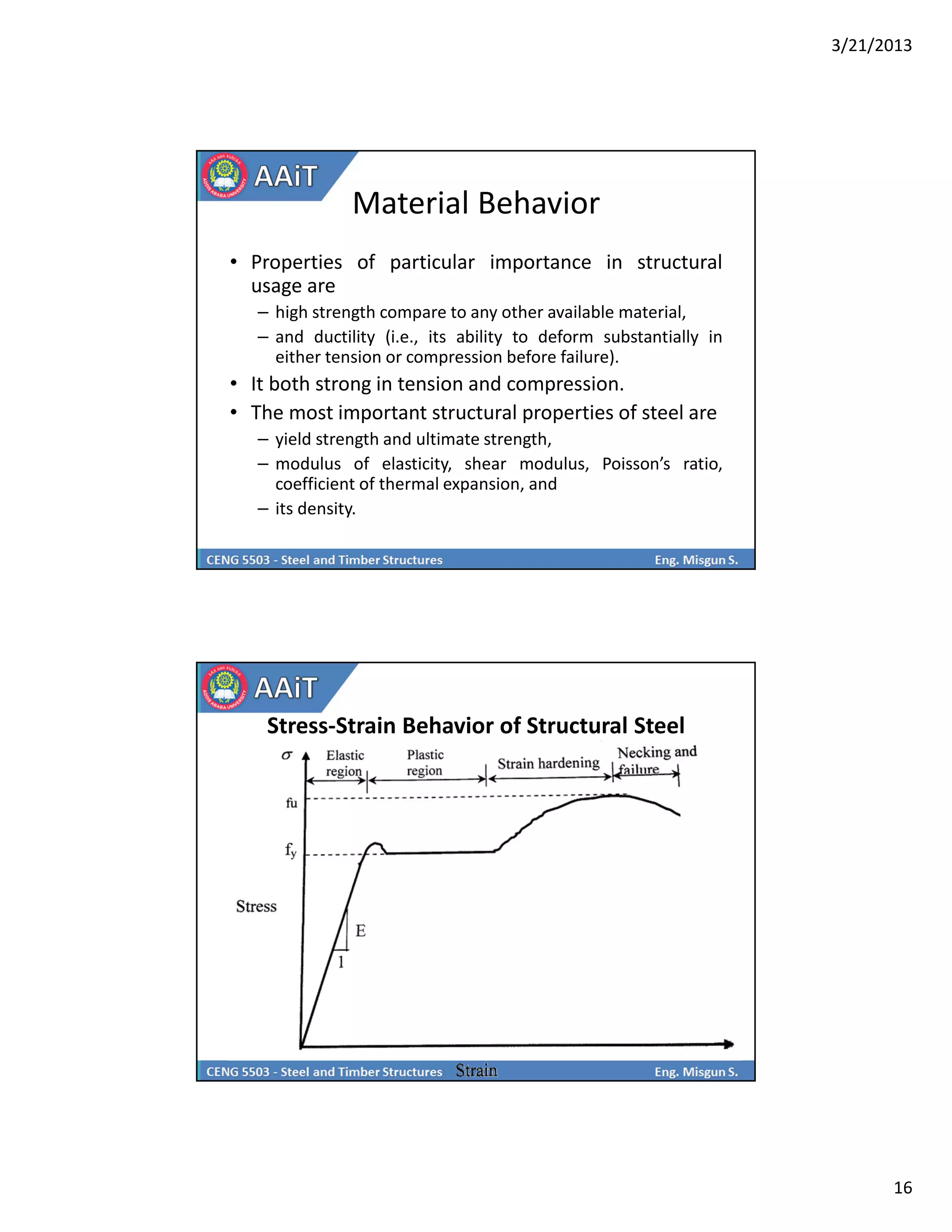

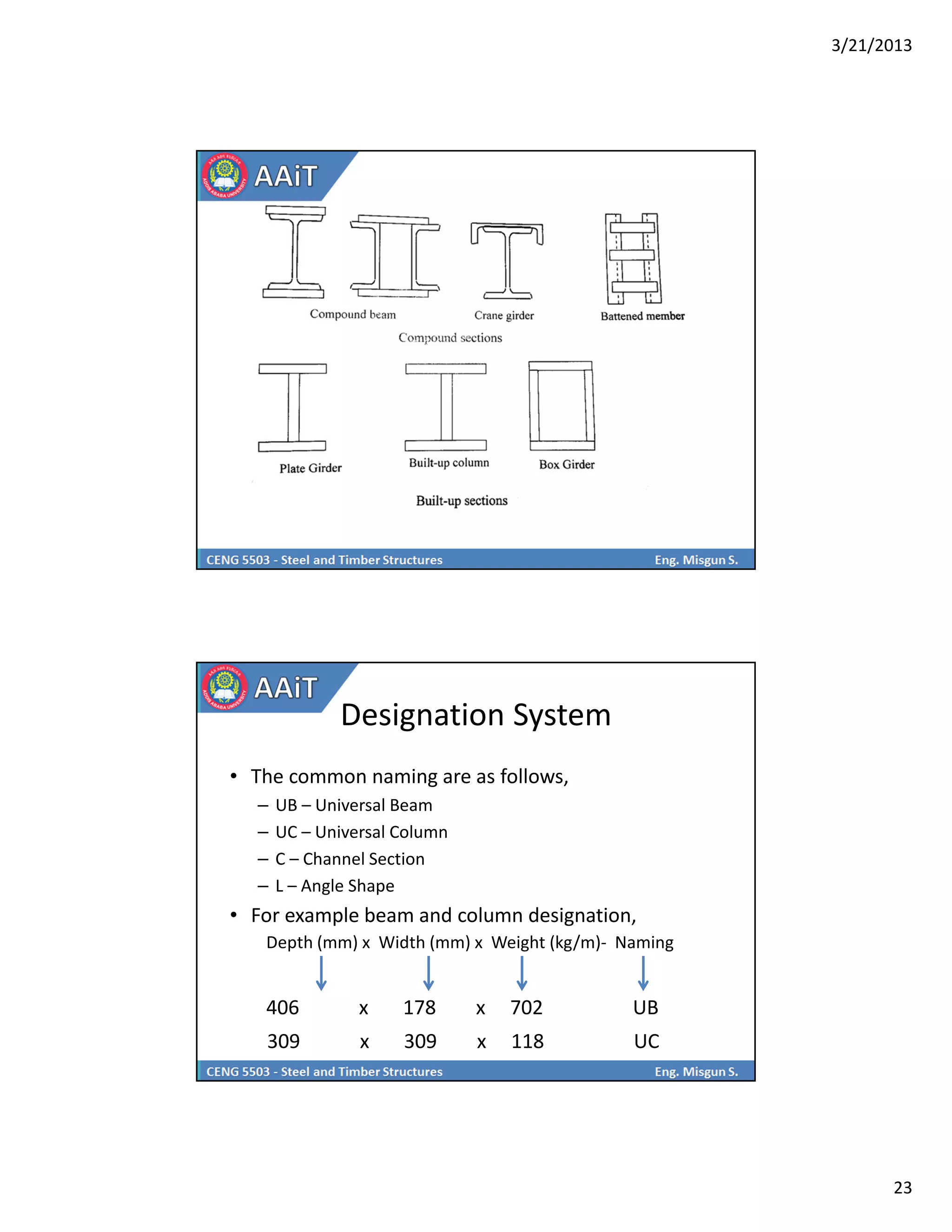

This document provides an introduction to steel and timber structures. It discusses the objectives of the chapter, which are to introduce structural steel, describe common structural members and shapes, explain structural design concepts and material properties of steel. It outlines different types of steel structures, why steel is used, various structural members, and design methods like allowable stress design, plastic design and limit state design. Key material properties of structural steel like its stress-strain behavior and grades are also summarized.