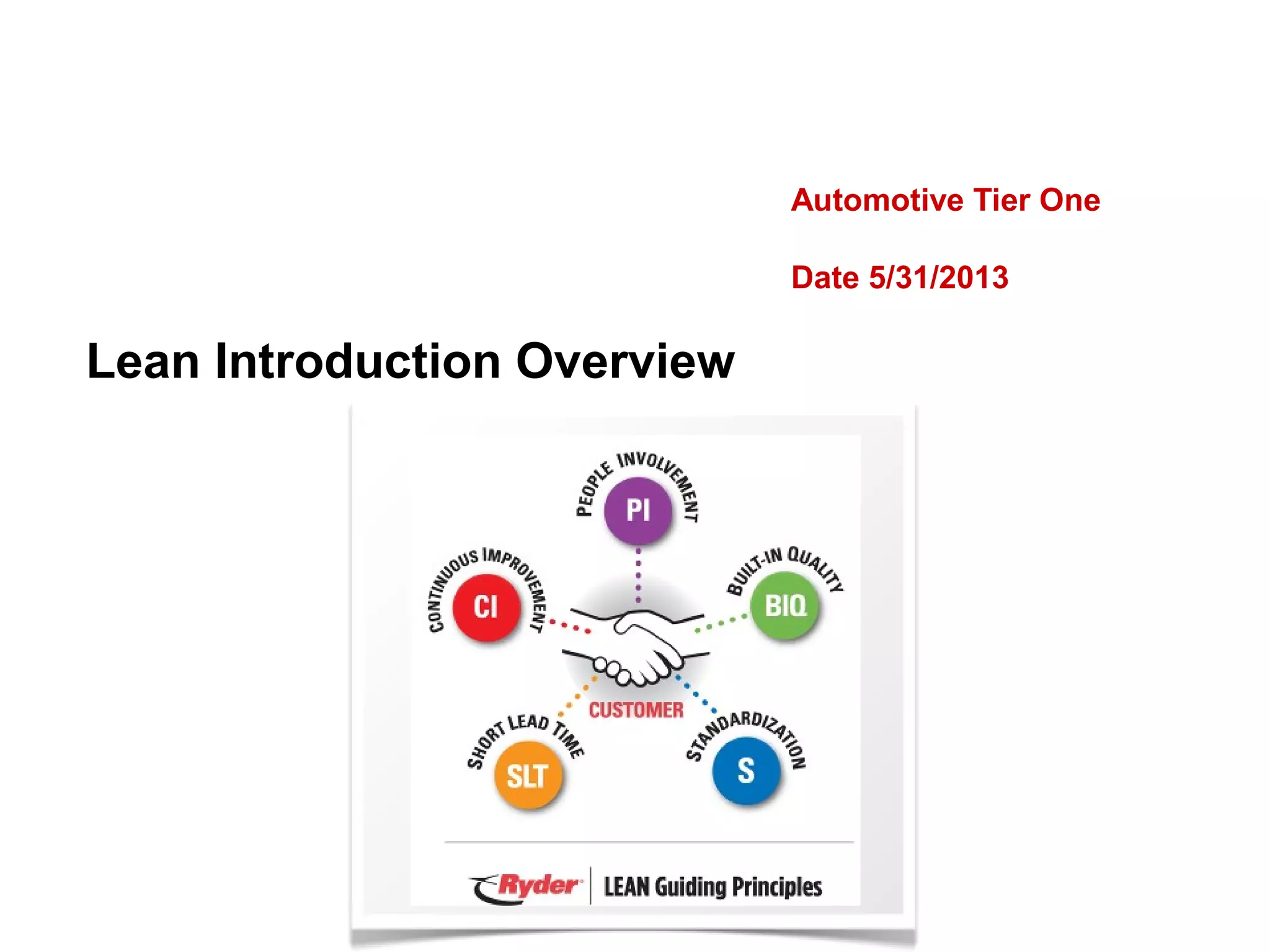

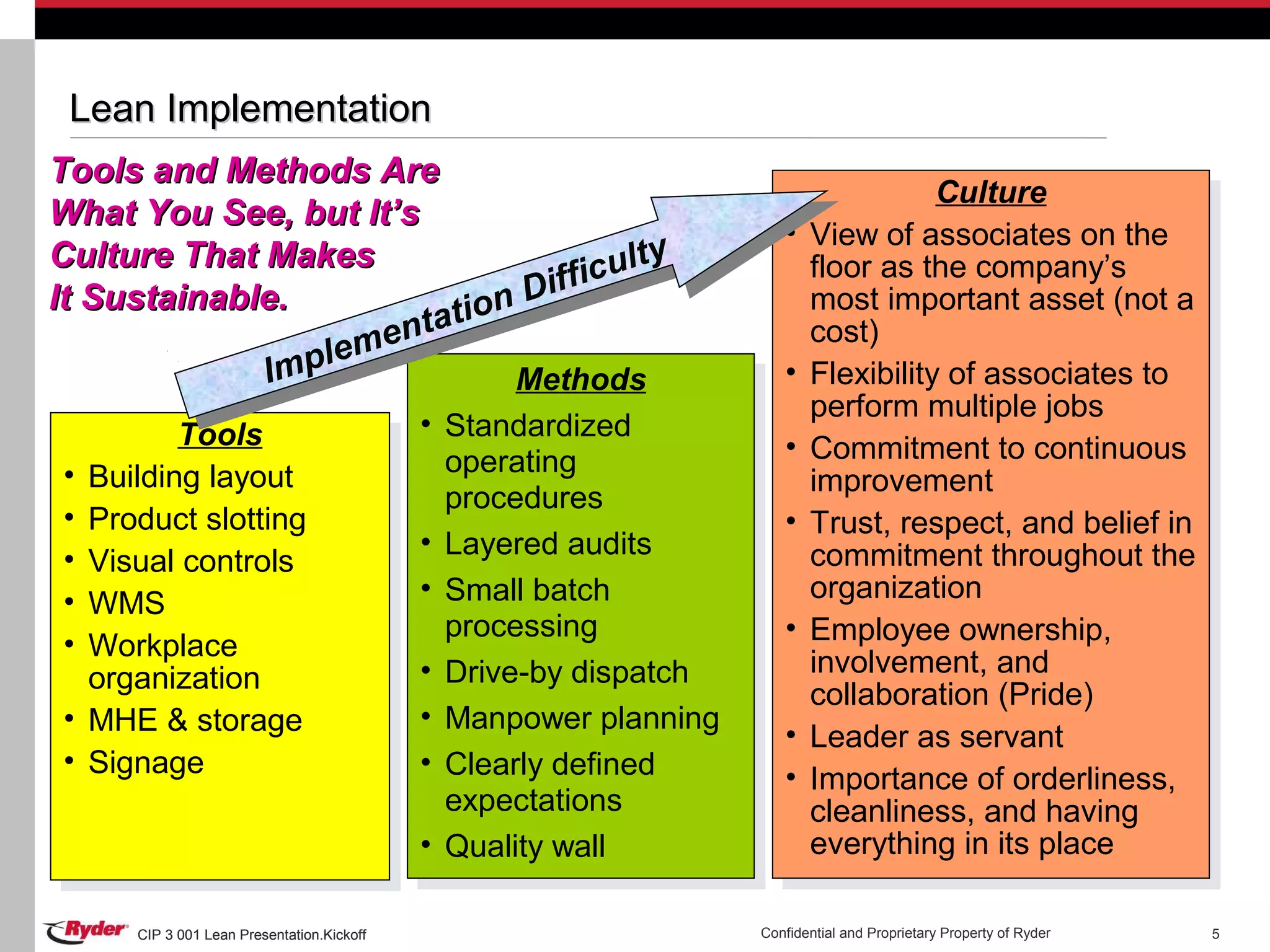

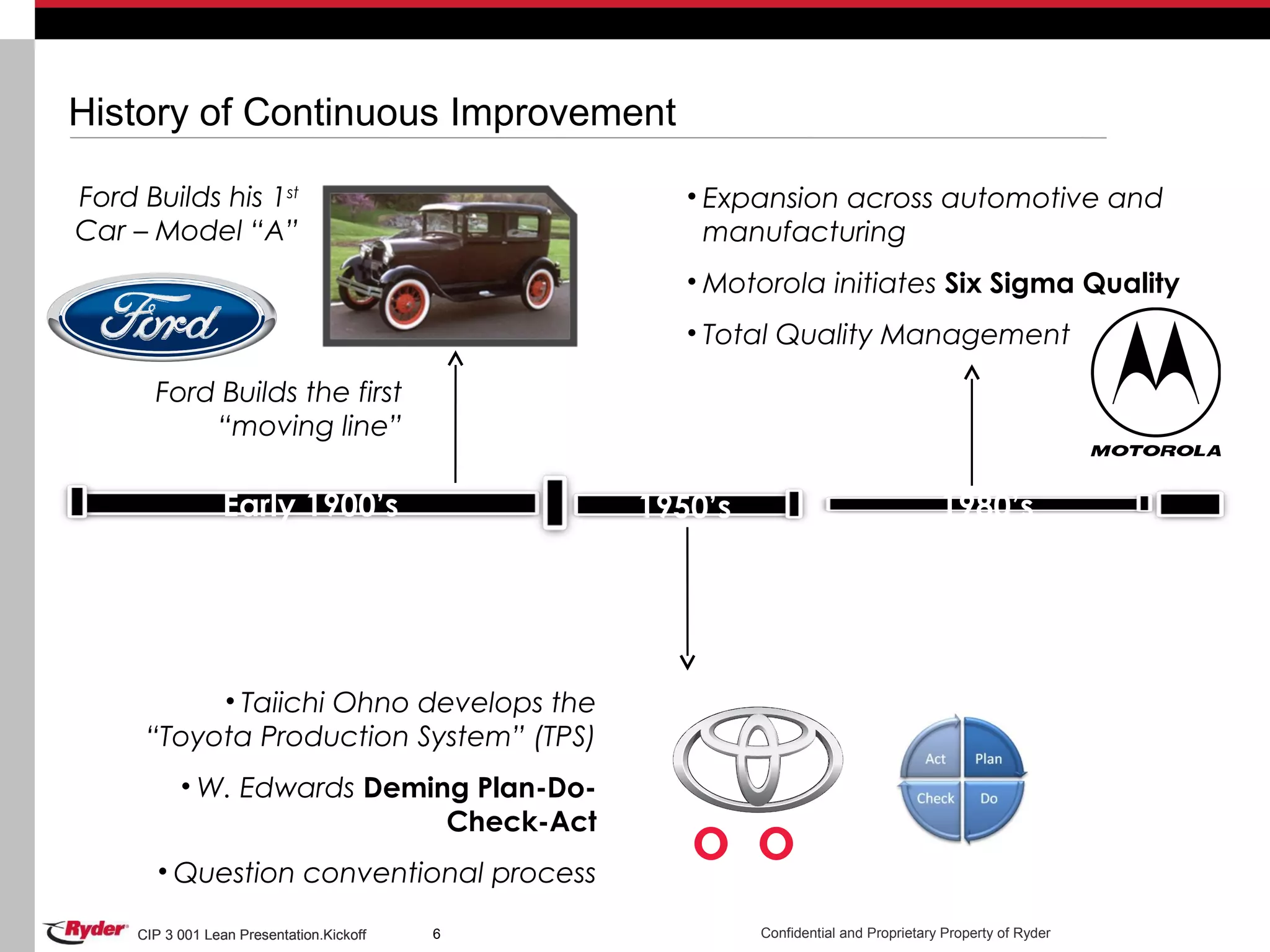

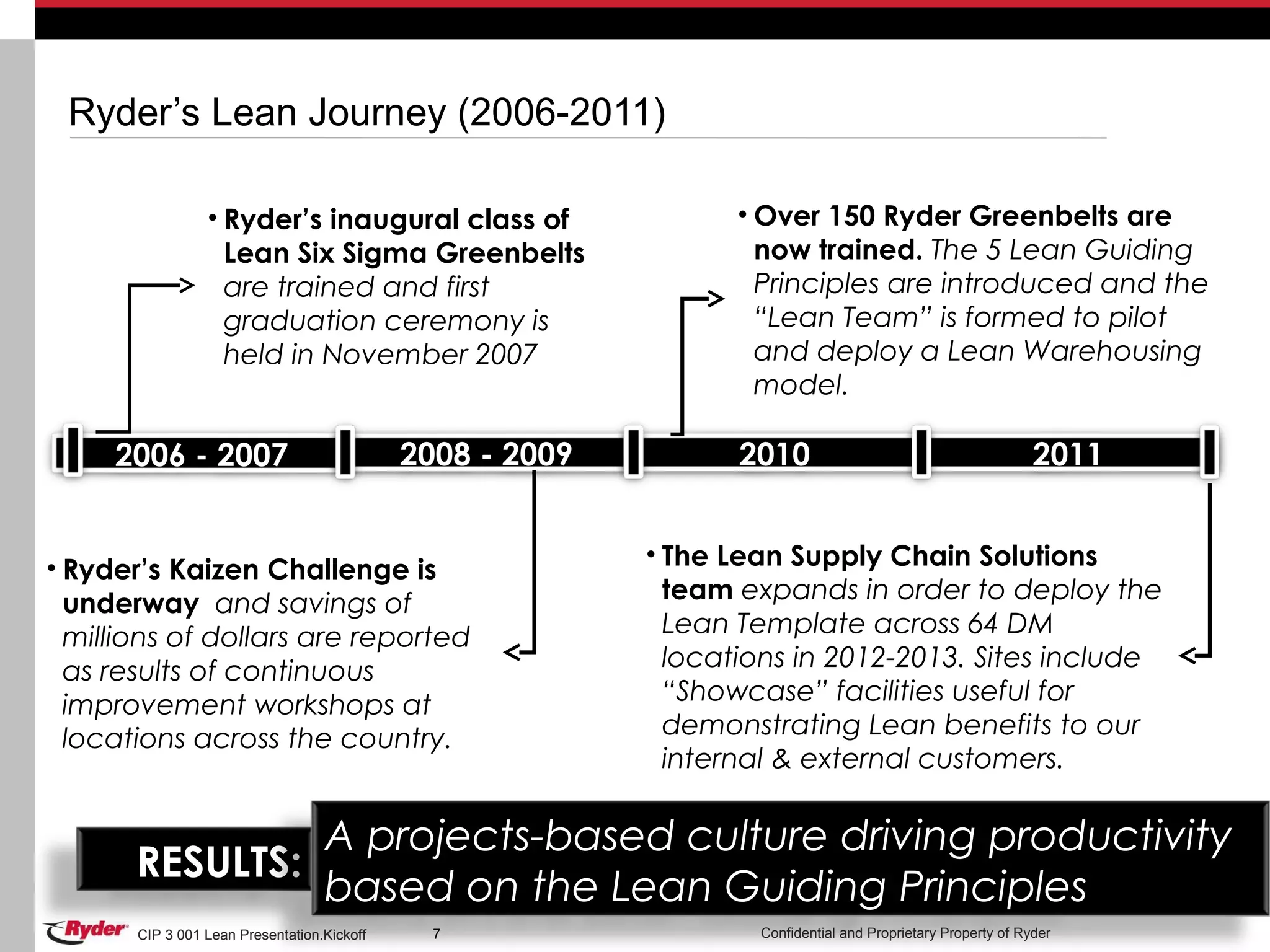

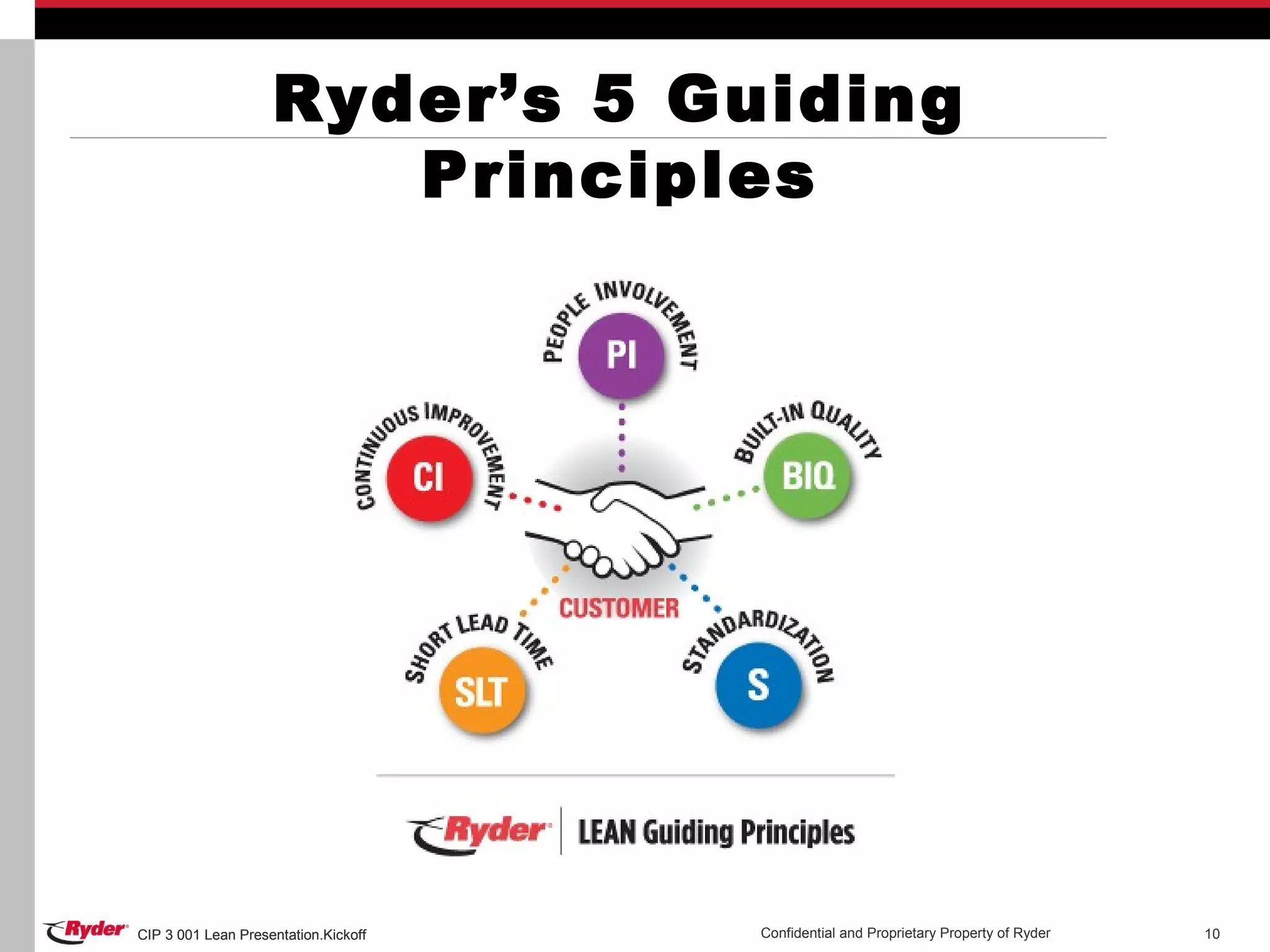

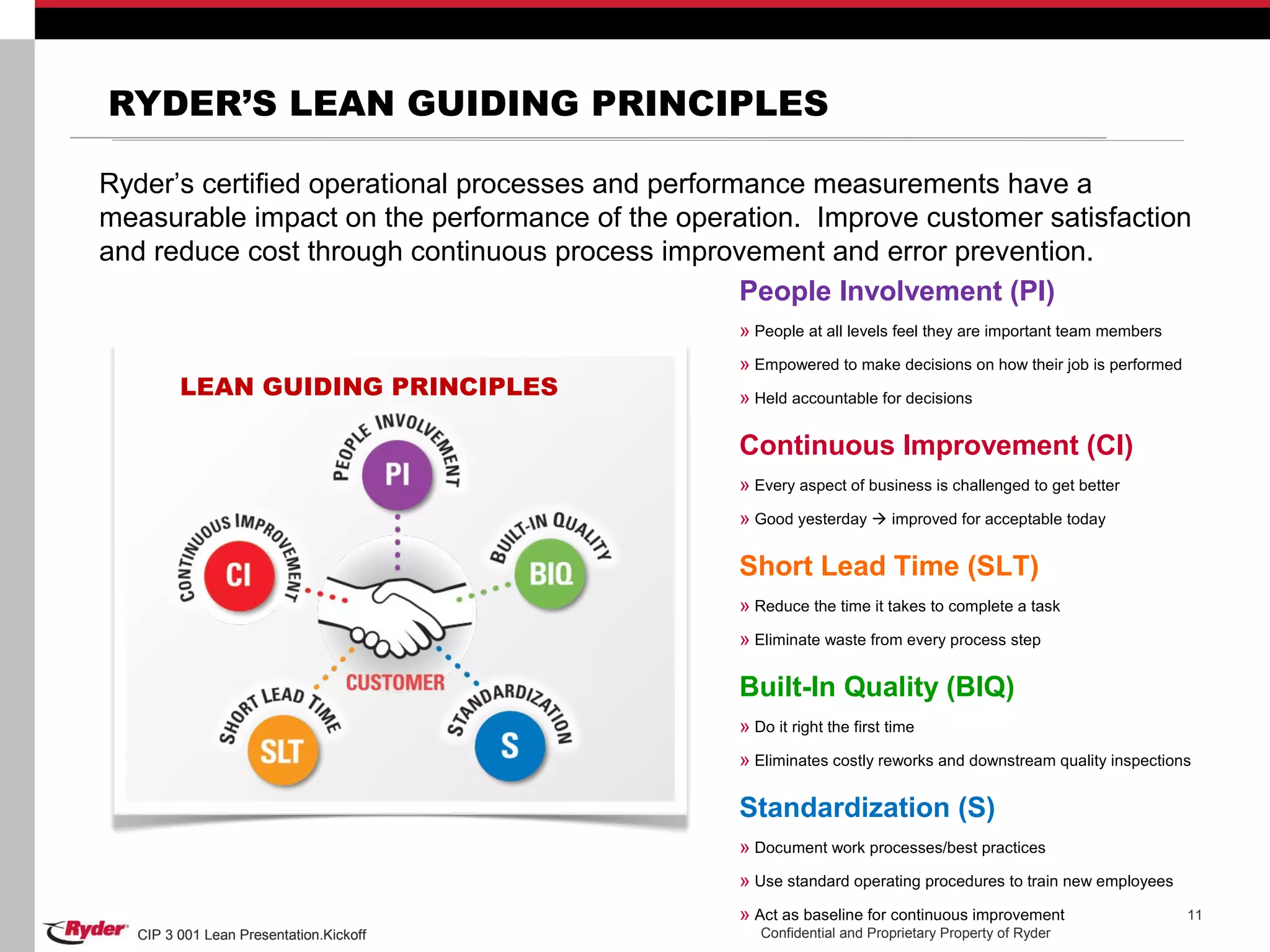

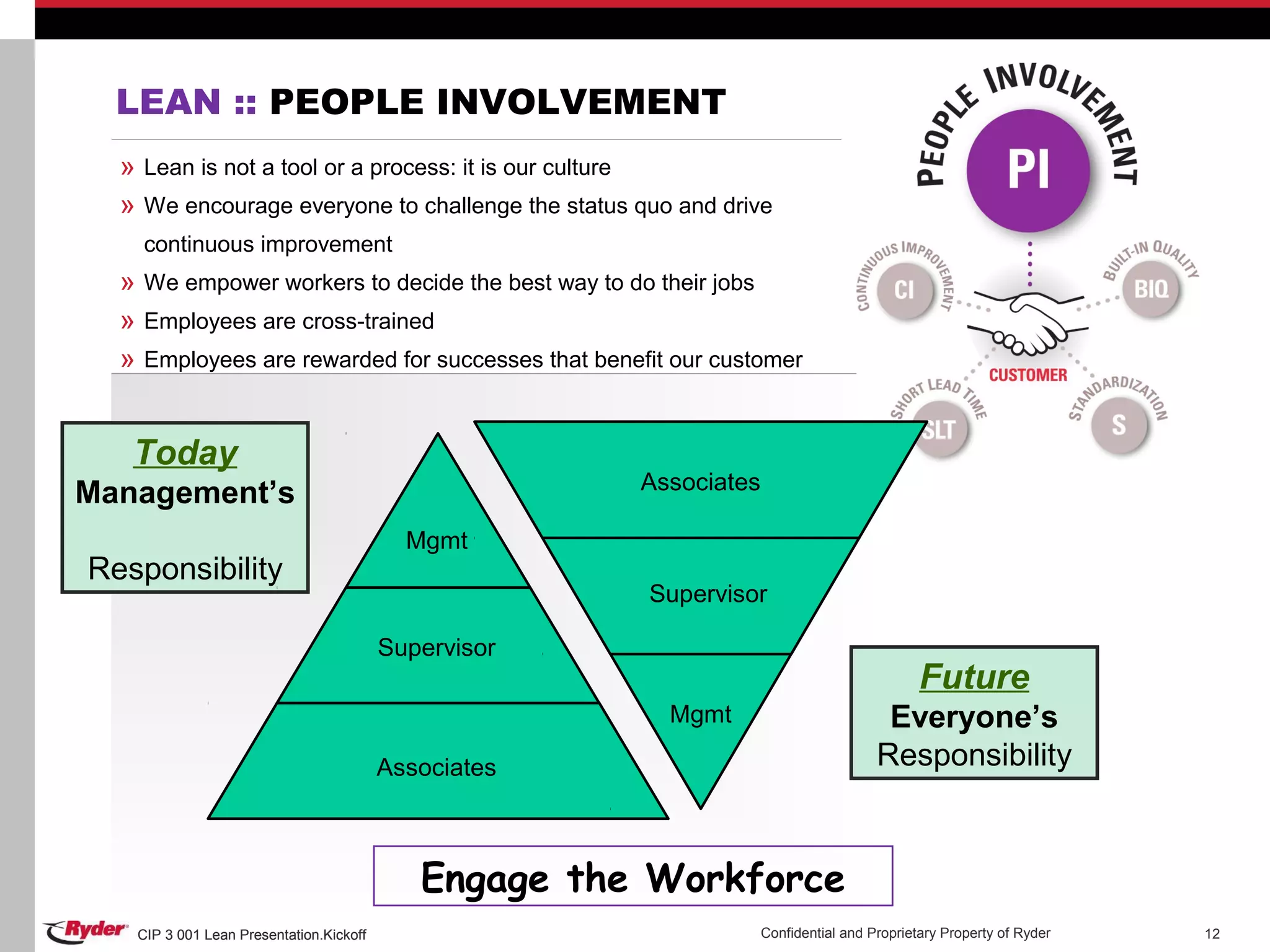

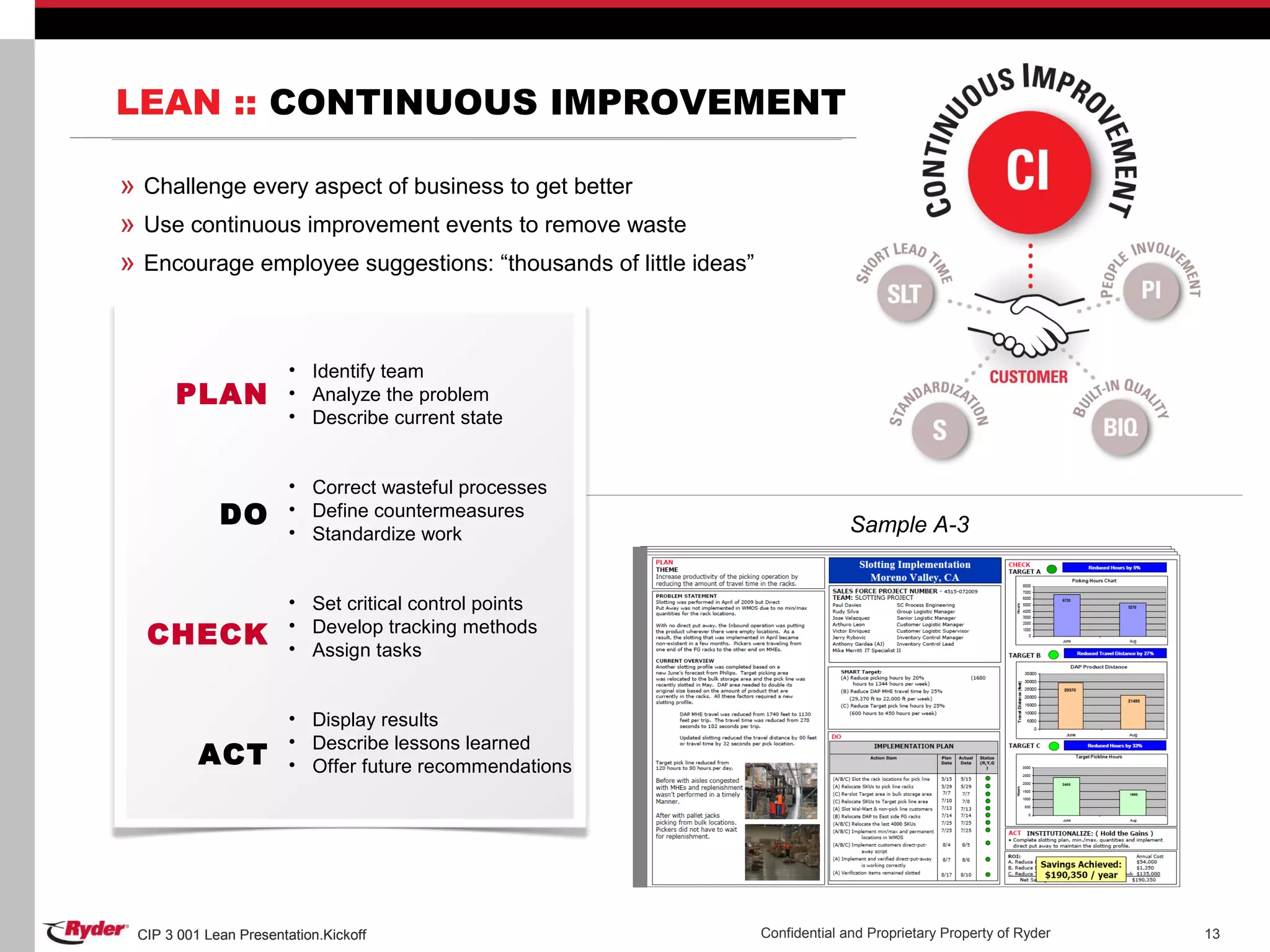

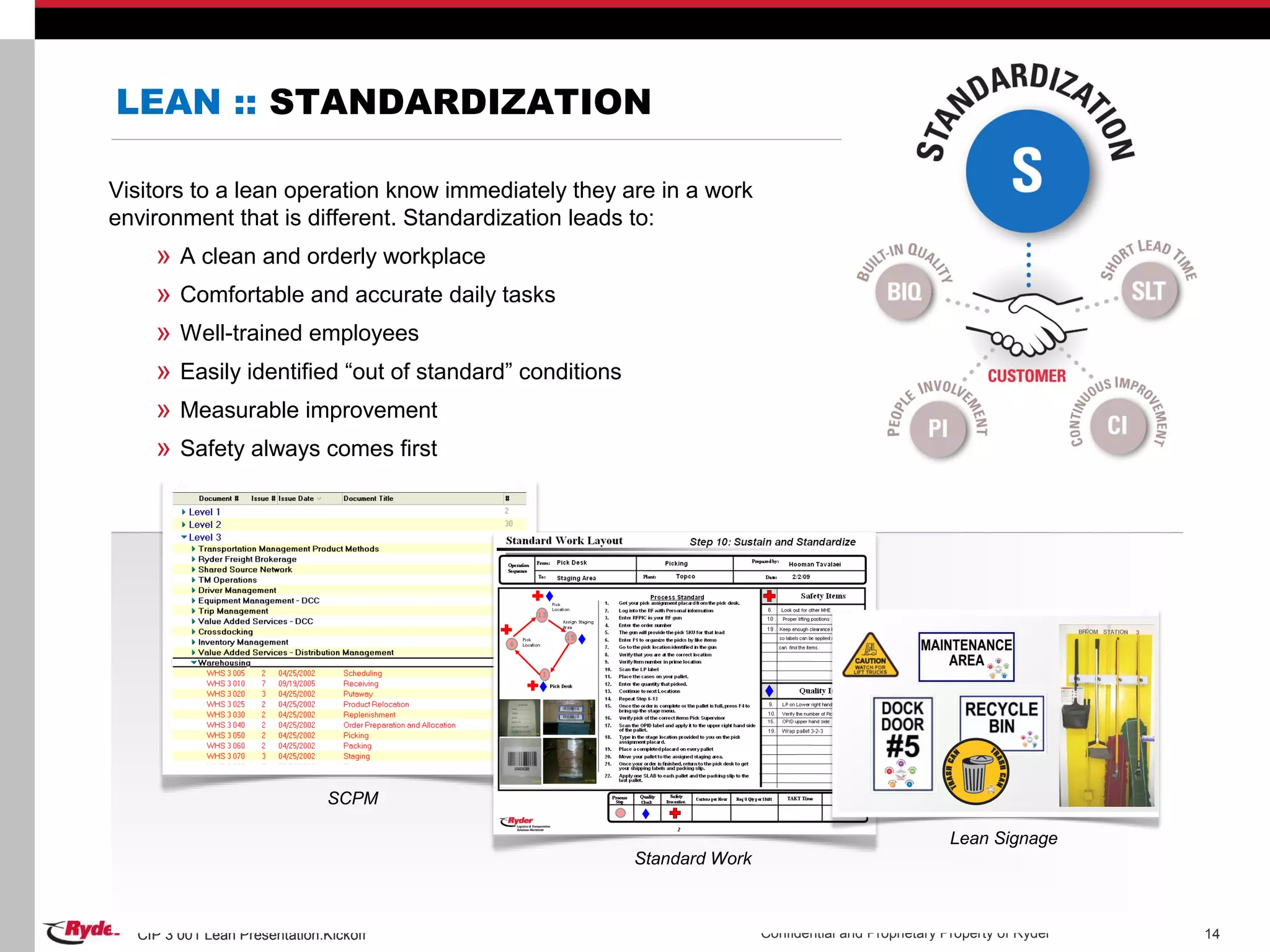

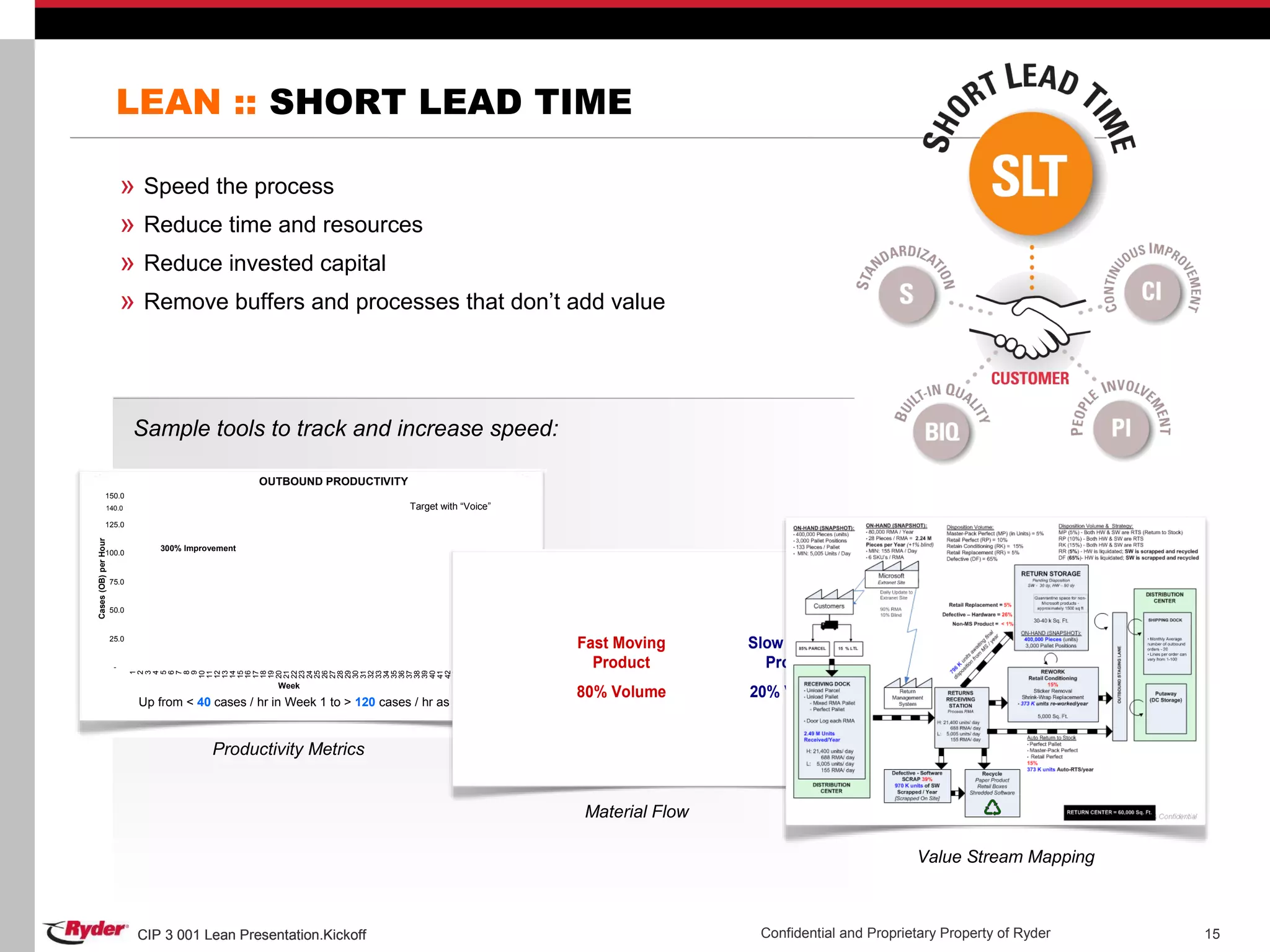

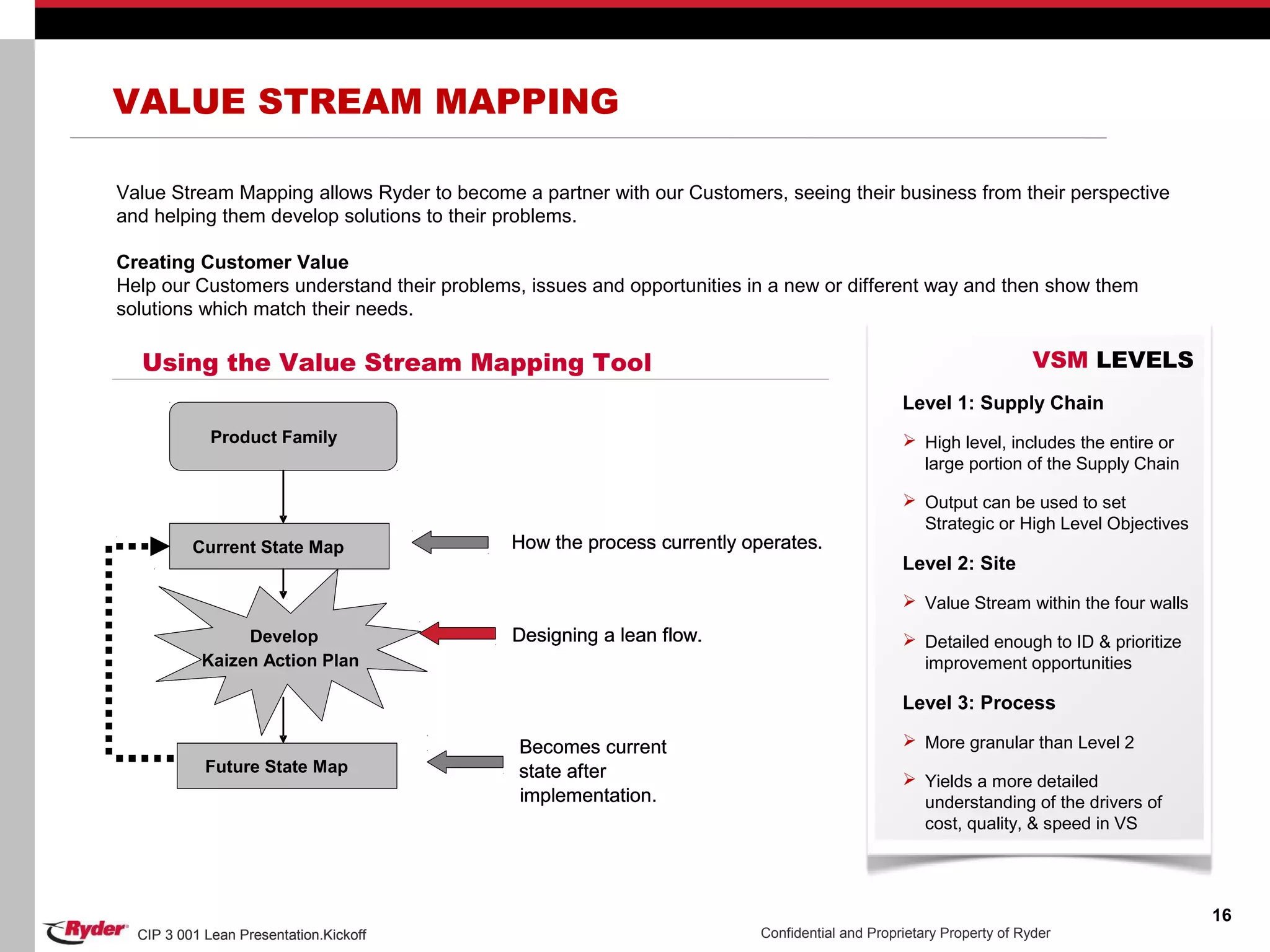

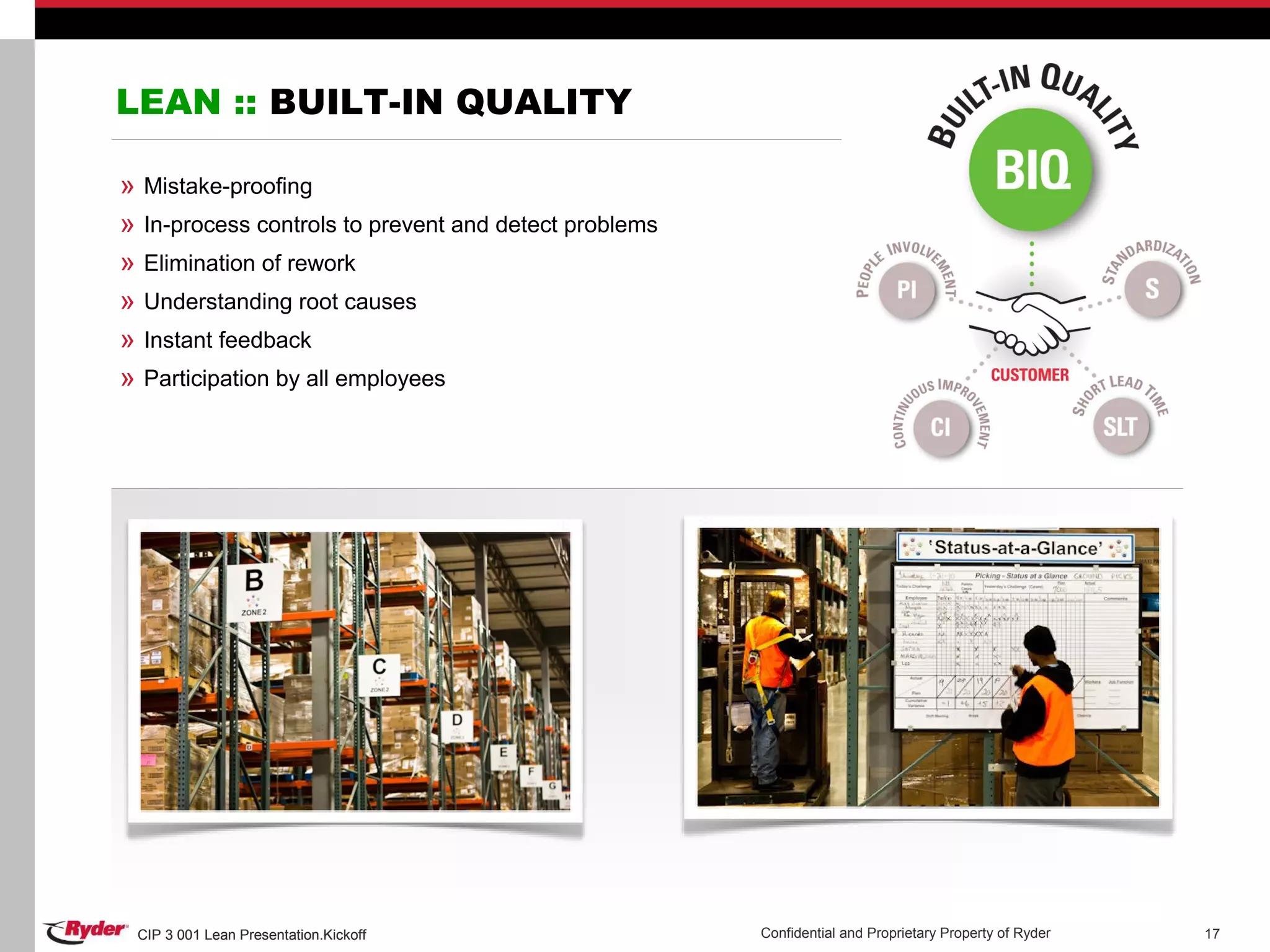

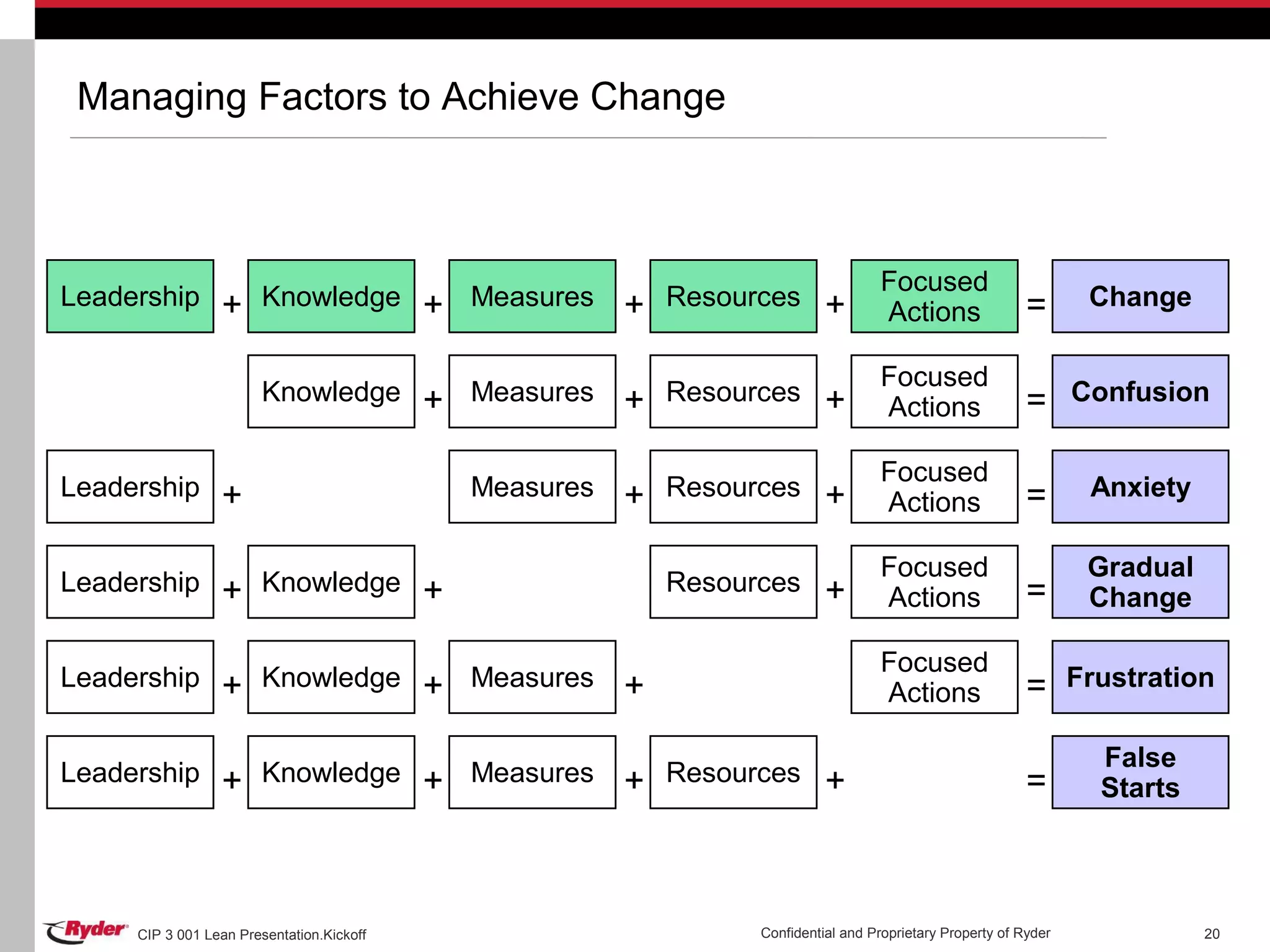

Lean is a philosophy aimed at reducing waste and increasing value for customers. The document provides an overview of lean for an automotive supplier, including definitions of lean and what it is not. It discusses Ryder's lean journey since 2006 and their five guiding principles of people involvement, continuous improvement, short lead time, built-in quality, and standardization. Tools and methods for implementing lean are presented, along with the goals of highest quality, lowest cost, and shortest lead time. Sustaining a lean culture long-term is emphasized as the real benefit.