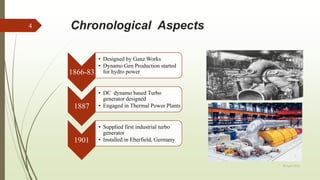

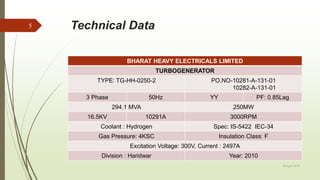

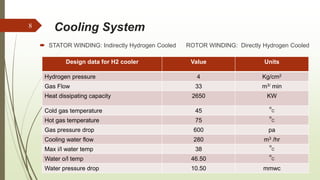

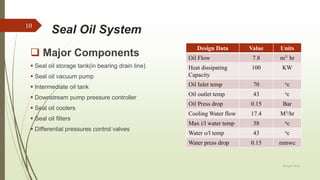

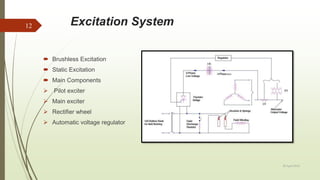

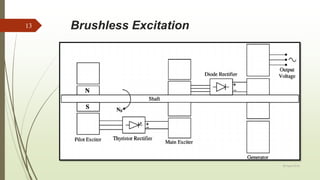

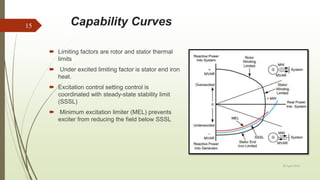

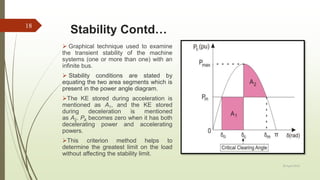

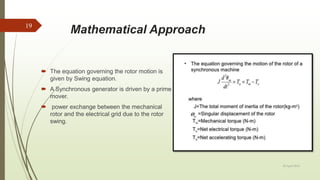

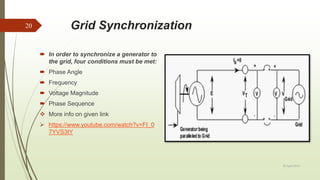

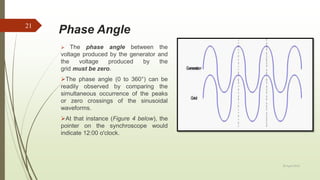

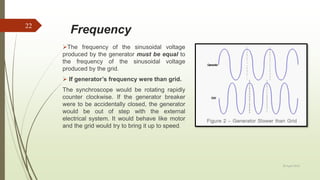

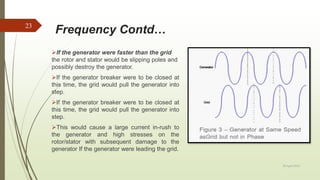

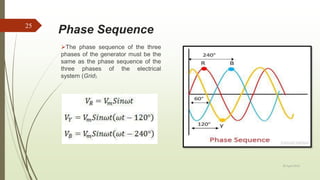

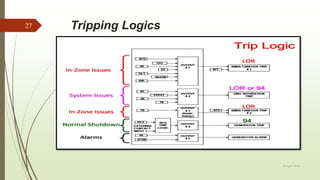

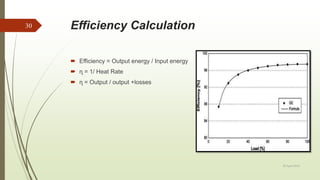

The document provides a comprehensive overview of a synchronous generator with a capacity of 250 MW, detailing its historical milestones, technical specifications, cooling and sealing systems, excitation methods, grid synchronization procedures, protection schemes, and testing methods. It emphasizes the importance of stability, efficiency calculations, and ongoing research and development in optimizing generator performance. The presentation concludes with references for further reading on turbo generators and related topics.