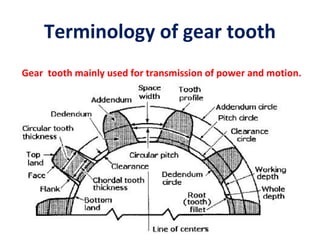

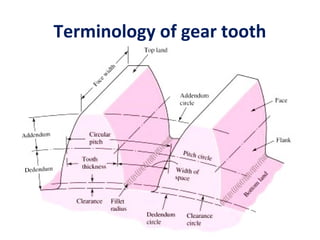

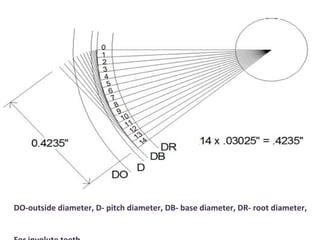

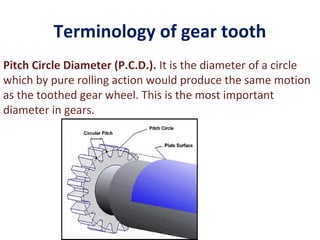

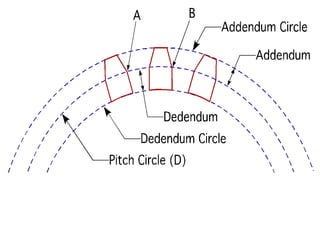

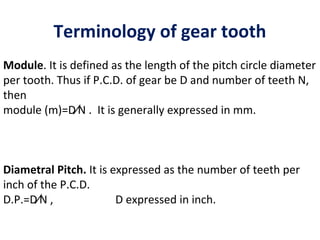

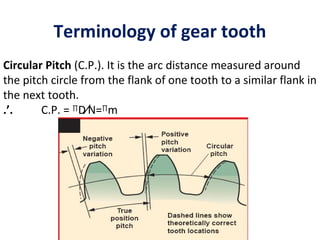

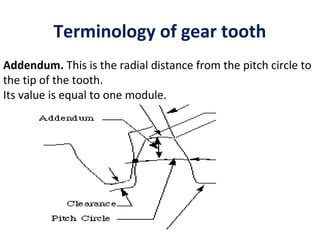

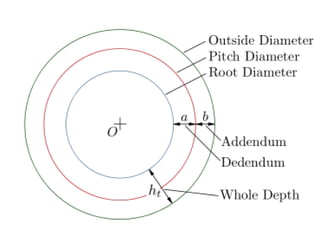

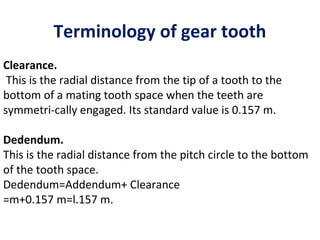

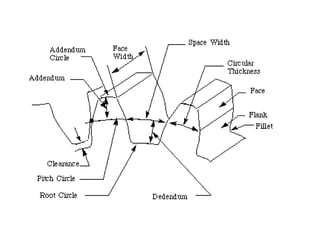

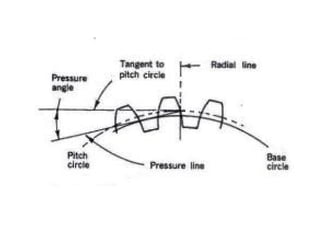

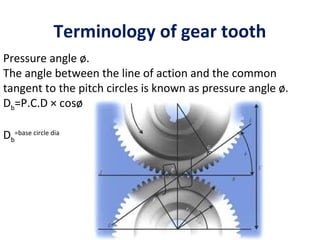

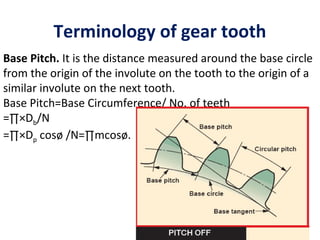

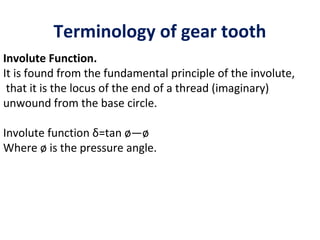

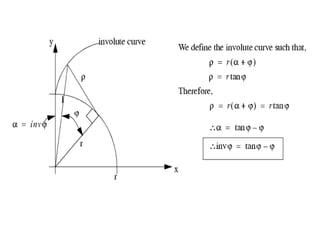

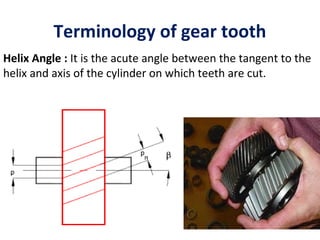

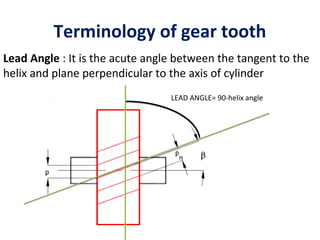

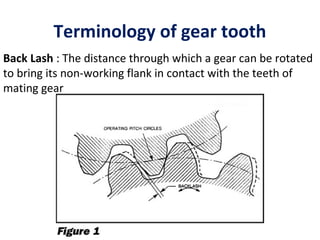

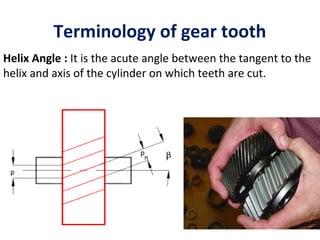

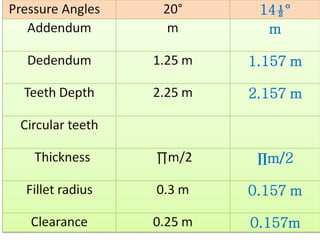

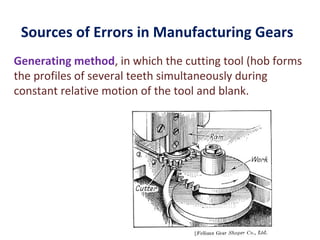

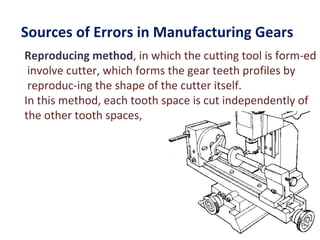

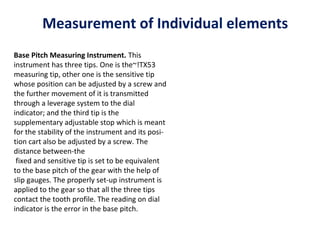

The document discusses various terms and measurements related to gear teeth. It defines terms like pitch circle, diametral pitch, module, addendum, dedendum, clearance, pressure angle, and helix angle. It also describes common methods for measuring individual elements of gear teeth, such as tooth thickness, pitch, and errors, using instruments like gear tooth calipers, constant chord method, and base tangent method. Sources of errors in gear manufacturing by generating and reproducing methods are also outlined.

![Measurement of Individual elements

Measurement of tooth thickness

The permissible error or the tolerance on

thickness of tooth is the variation of actual

thickness of tooth from its theoretical value.

The tooth thickness is generally measured at

pitch circle and is therefore, the pitch line

thickness of tooth.

There are various methods of measuring the

gear tooth thickness.

(i) Measurement of tooth thickness by gear

tooth vernier calliper.

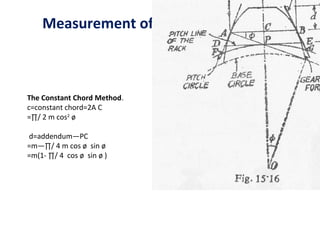

(ii) Constant chord method.

(iii) Base tangent method.

(iv) Measurement by dimension over pins.

Gear Tooth Caliper.

w=Nm. sin( 90∕N)

d= = Nm ∕2[1+2∕N− cos(90∕ N)]](https://image.slidesharecdn.com/gearthread-120918023938-phpapp01/85/Gear-thread-44-320.jpg)

![Measurement of Individual elements

The Base Tangent Method. (‘David Brown’

tangent comparator). In this method, the span

of a convenient number of teeth is measured

with the help of the tangent comparator. This

uses a single vernier calliper

BD=Nm cos ø [tanø –ø −∏ ∕ 2N +∏ S ∕ N ]](https://image.slidesharecdn.com/gearthread-120918023938-phpapp01/85/Gear-thread-47-320.jpg)