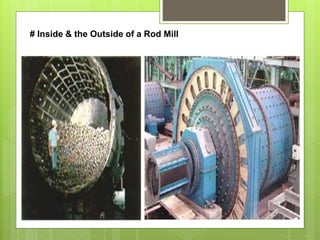

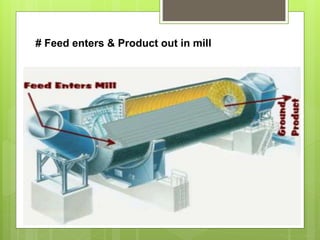

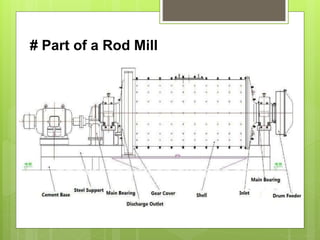

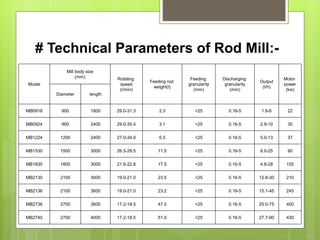

A rod mill is a tumbling mill that uses steel rods as the grinding medium. It is commonly used as the first stage of grinding in a milling process. Rod mills operate by tumbling the ore along with steel rods inside a rotating drum, which helps reduce the ore particles to sizes between 0.1-2 mm. Feed enters from one end and product discharges from the other or center of the mill. Rod mills are suitable for grinding hard minerals and are often used for initial size reduction in a milling circuit due to their lower cost compared to other mills.