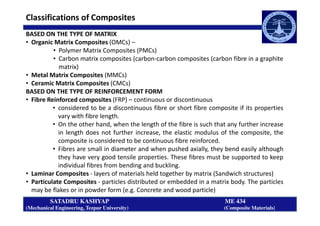

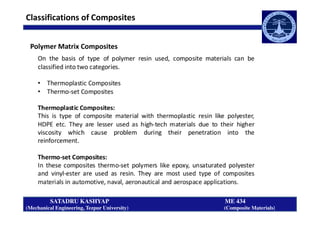

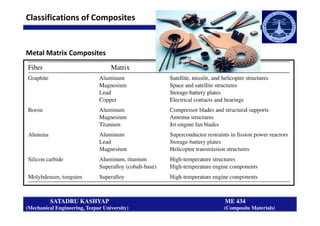

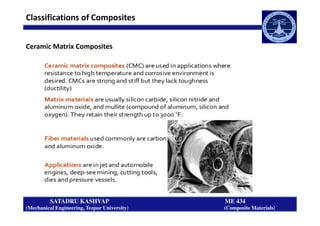

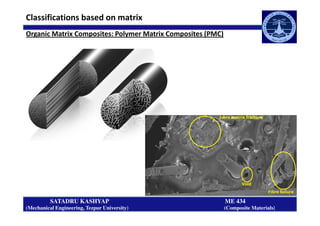

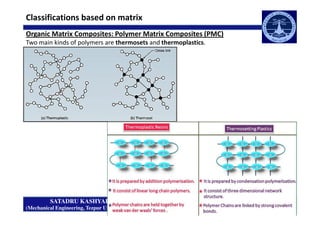

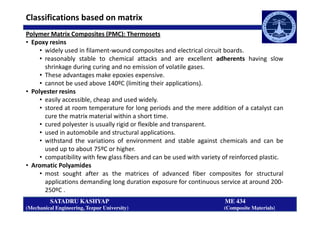

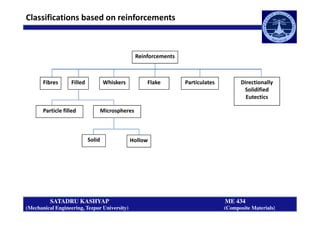

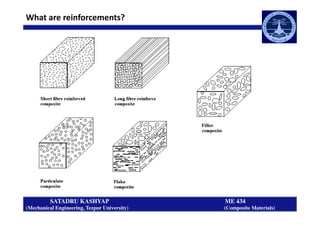

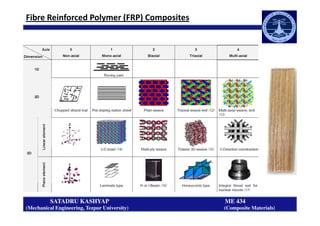

This document discusses the classification of composite materials. Composites can be classified based on the type of matrix, such as polymer matrix composites, metal matrix composites, and ceramic matrix composites. They can also be classified based on the type of reinforcement, such as fibre reinforced composites, particulate composites, and laminates. The document provides details on different types of matrices, reinforcements, and examples of various composite materials.