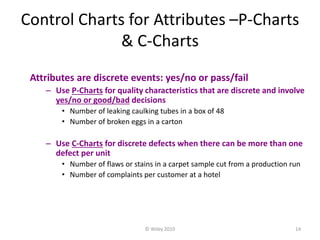

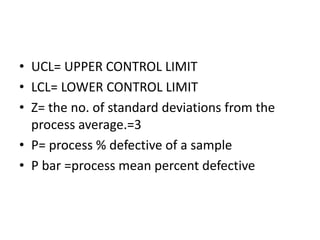

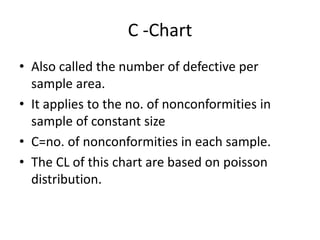

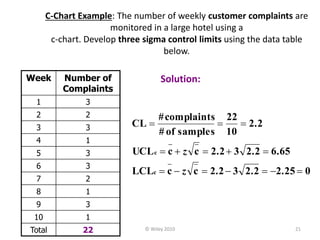

This document discusses P-charts and C-charts for statistical process control. P-charts and C-charts are types of control charts used for attributes data. P-charts monitor the proportion of defective items in samples, while C-charts monitor the number of defects in samples of constant size. The document provides examples of how to calculate control limits for P-charts and C-charts and discusses their applications in monitoring quality measures like defects in manufacturing processes.