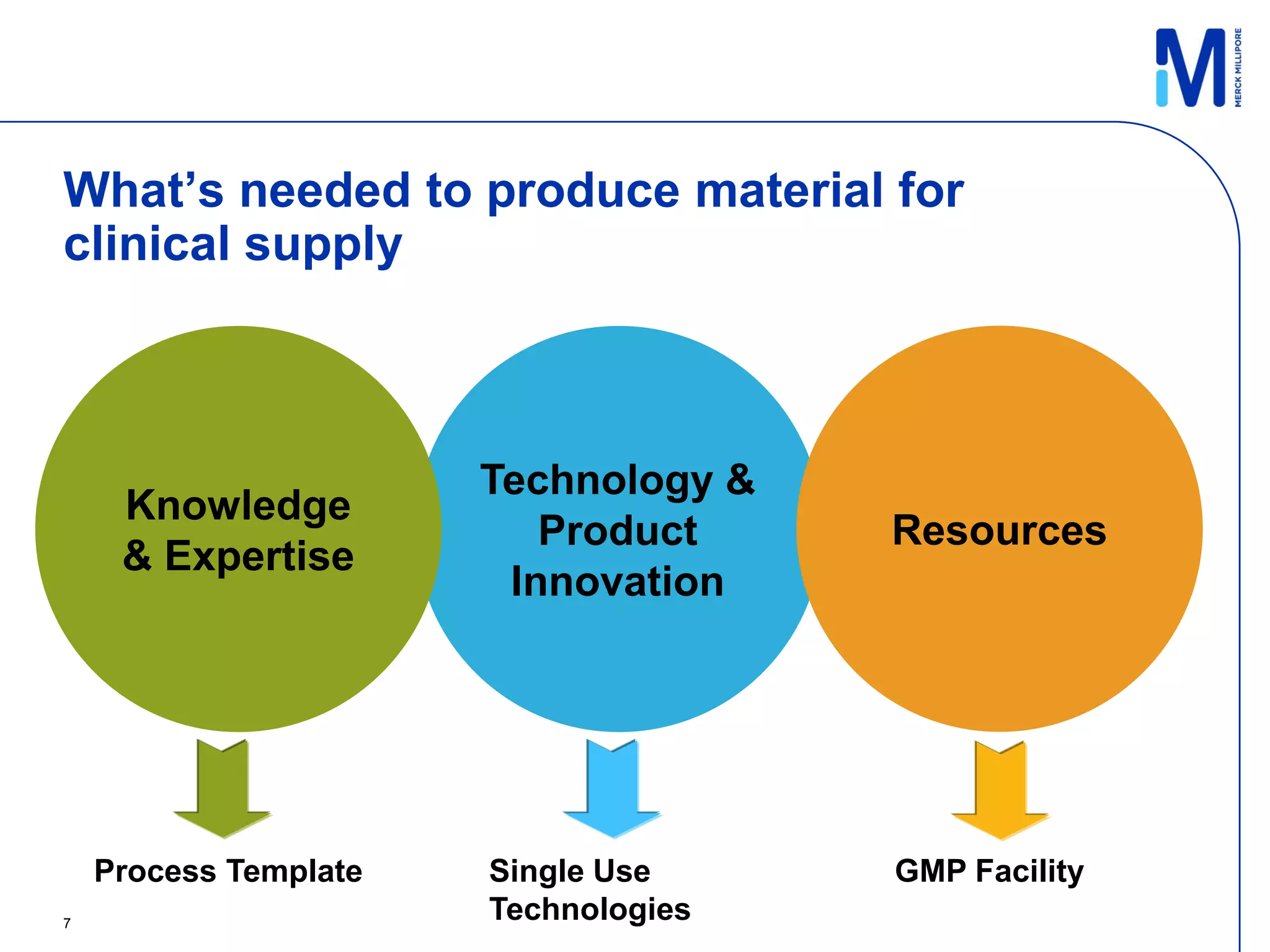

This document discusses implementing single-use technologies for a clinical drug supply pilot run. It summarizes:

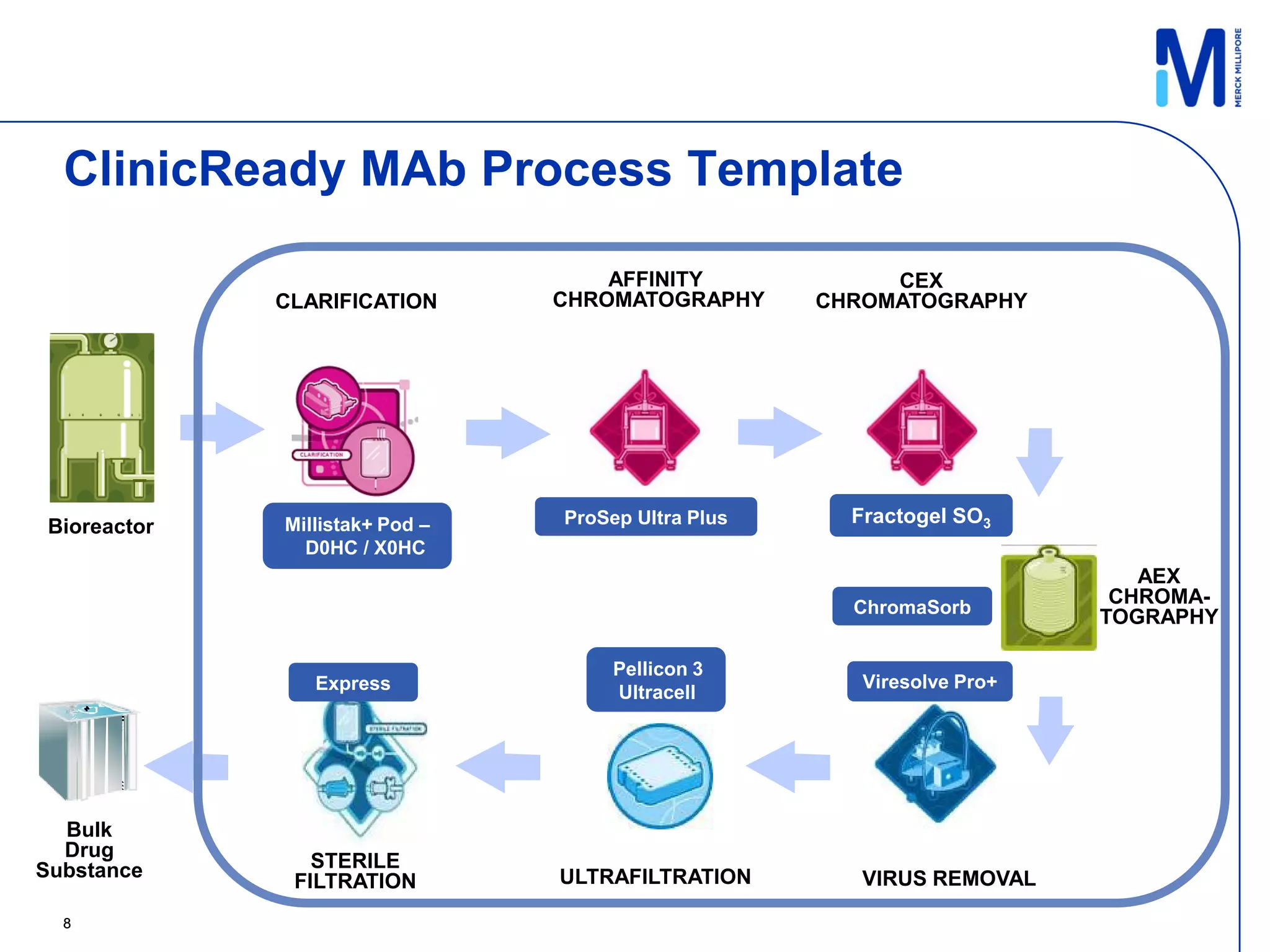

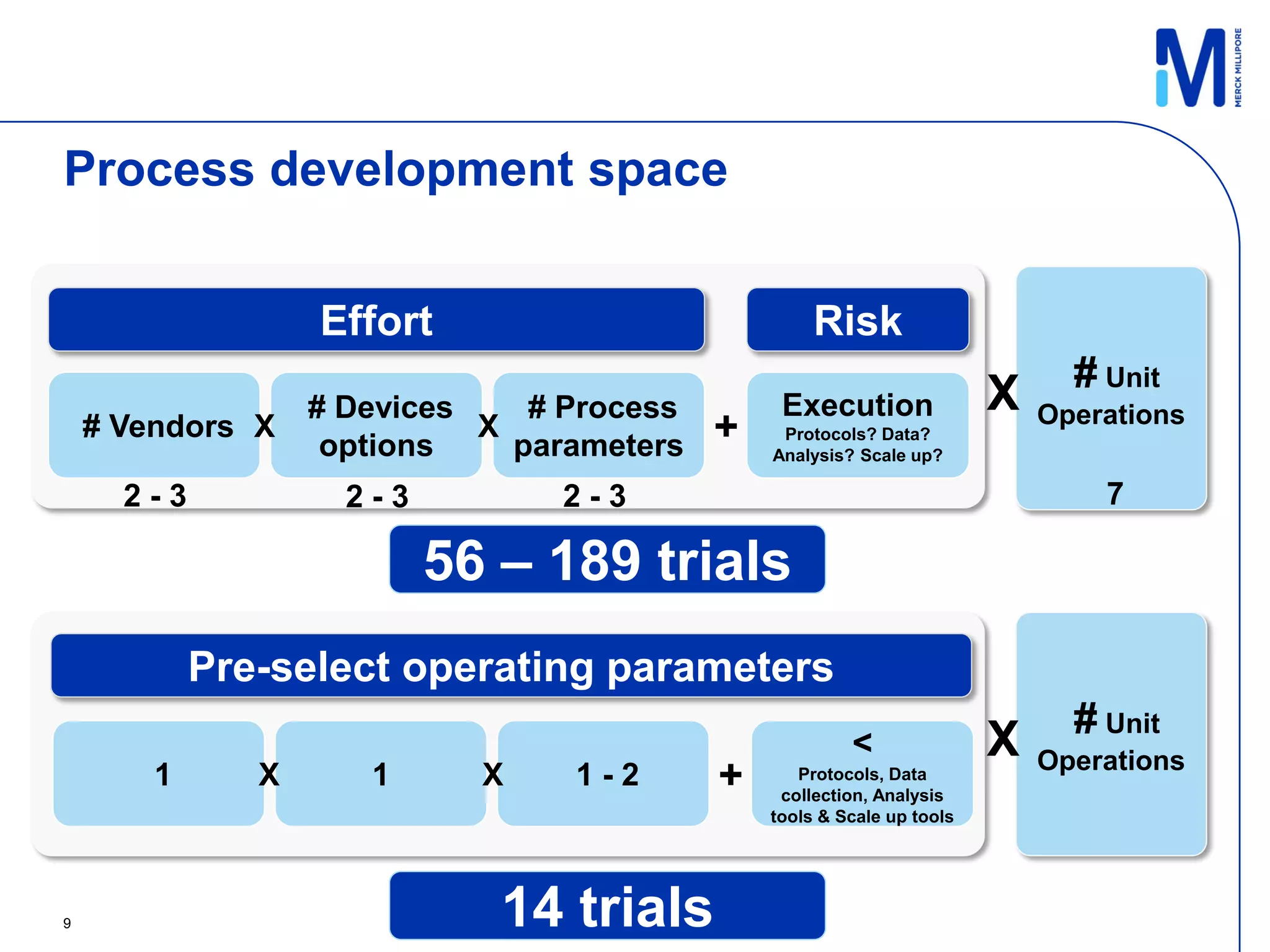

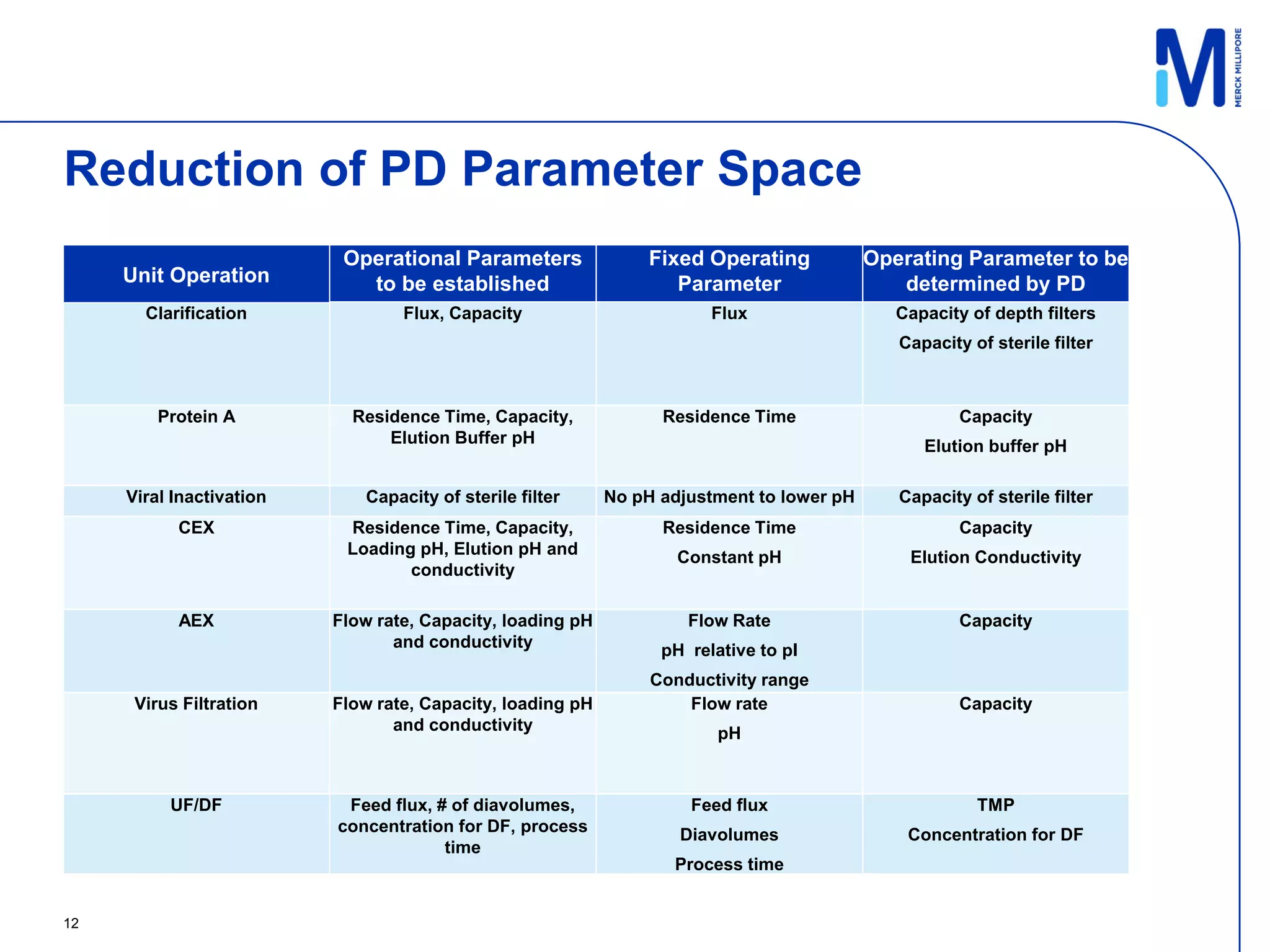

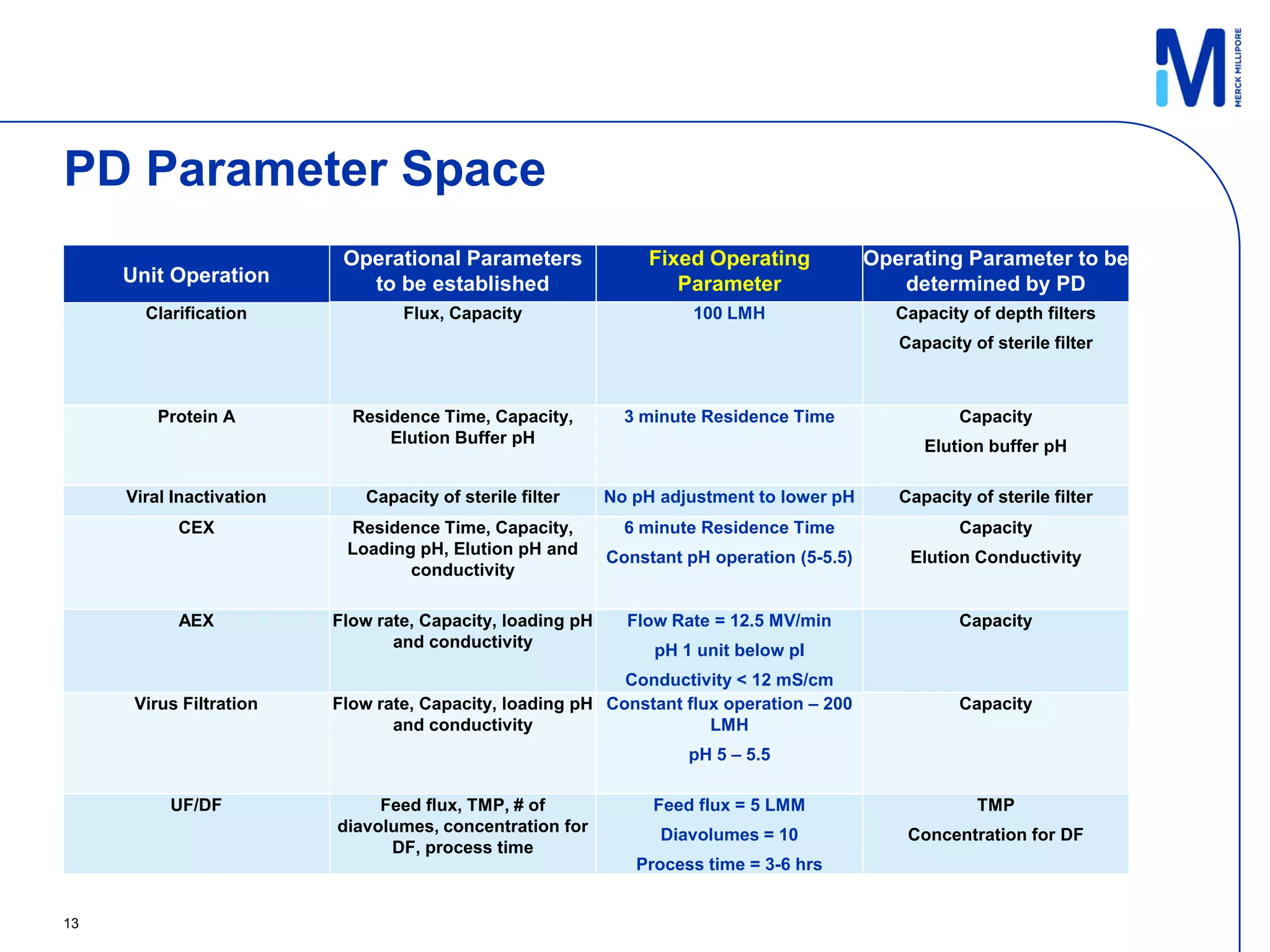

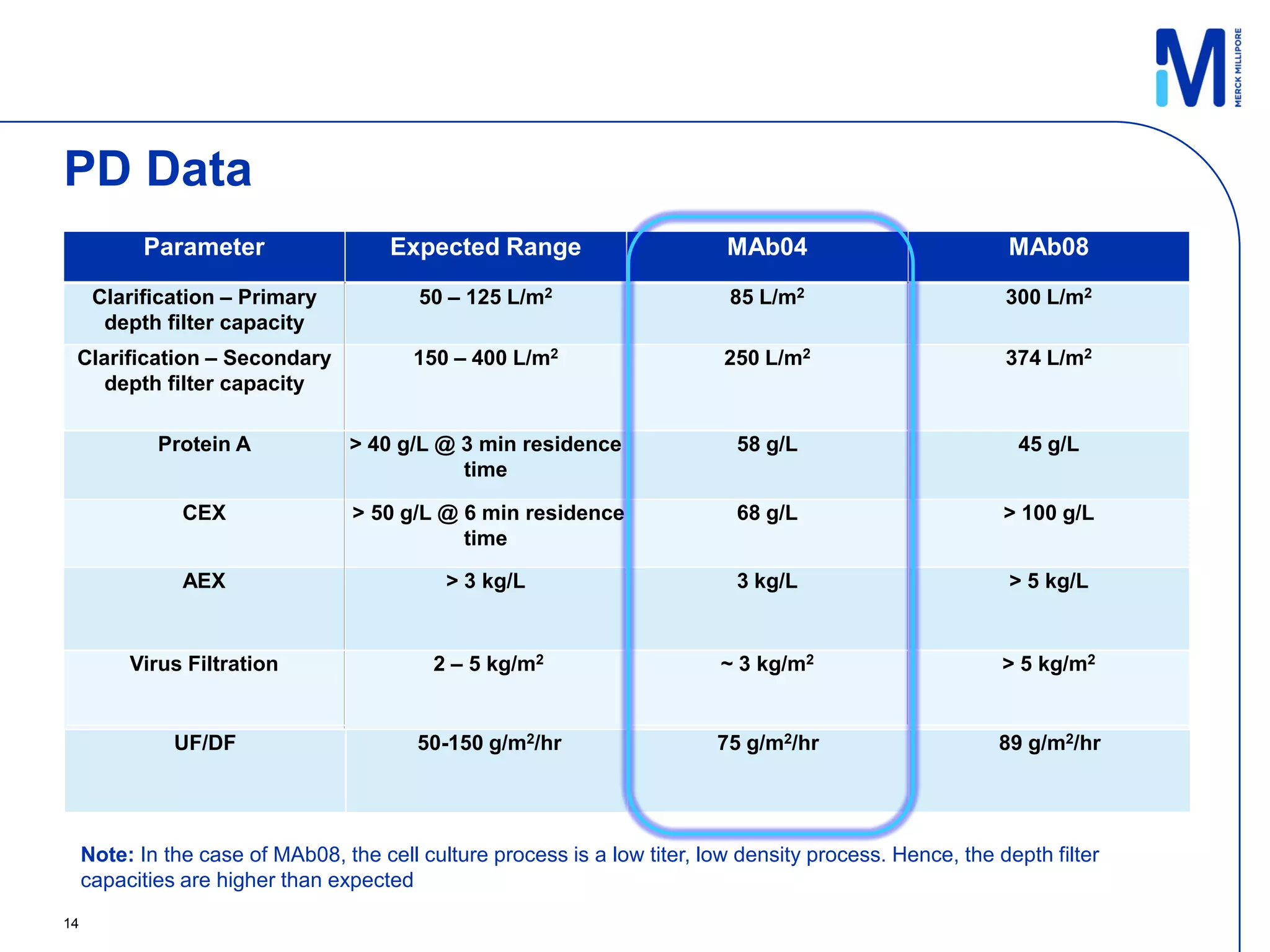

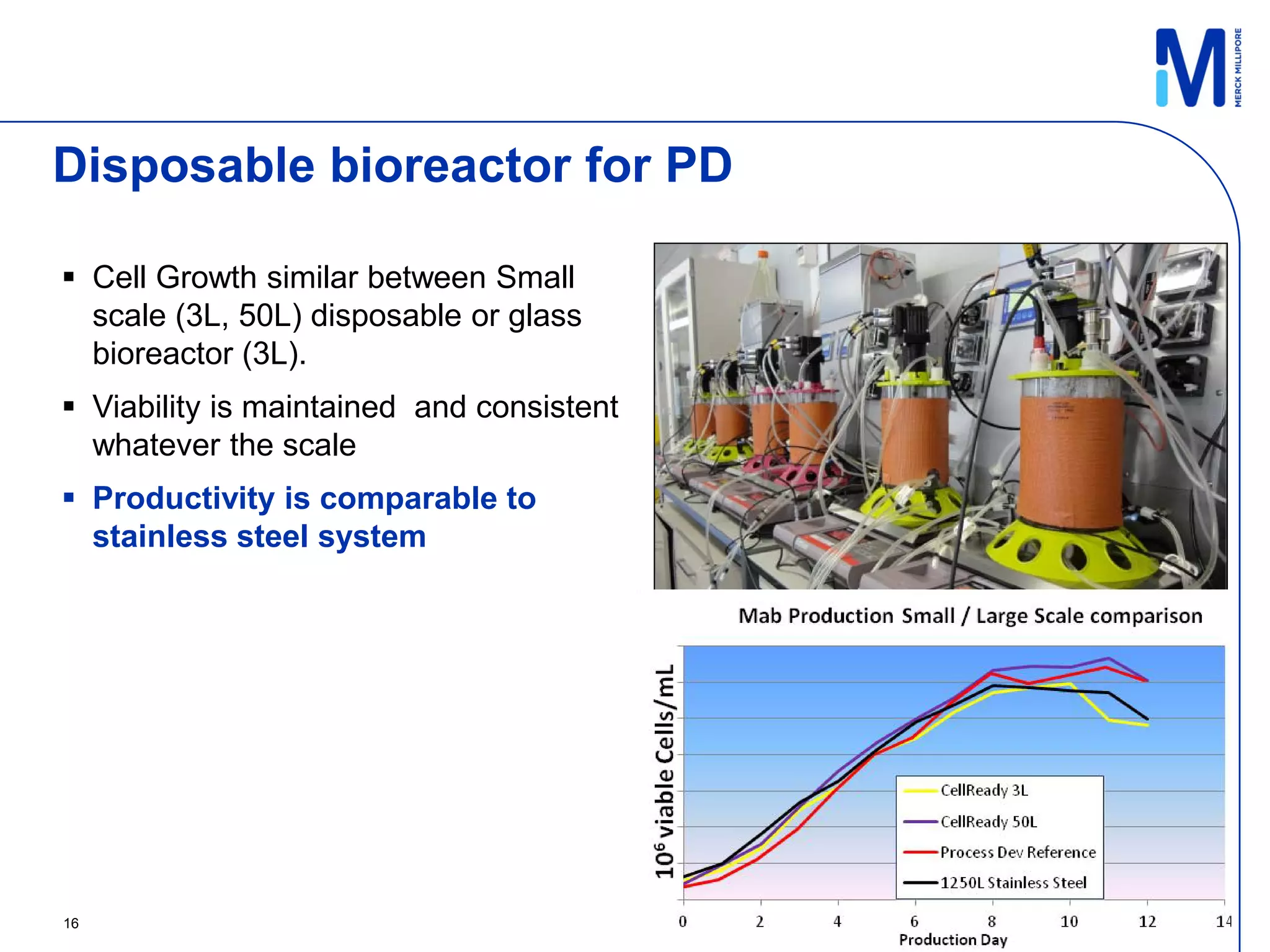

1) A template process and pre-selected operating parameters were used to minimize process development work and reduce timelines.

2) A 100L pilot scale run was conducted using commercially available single-use systems and assemblies to scale up a downstream process developed at bench scale.

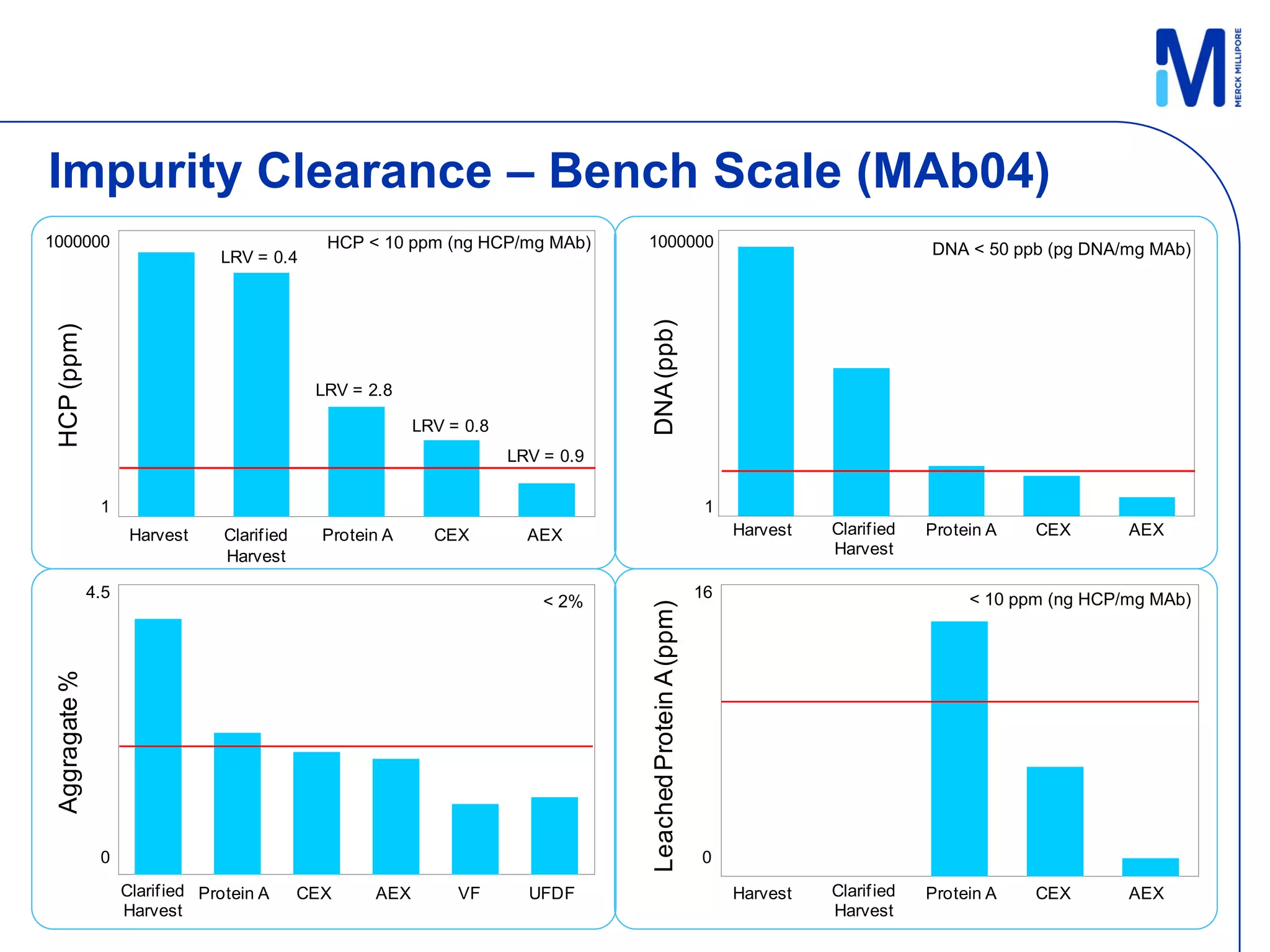

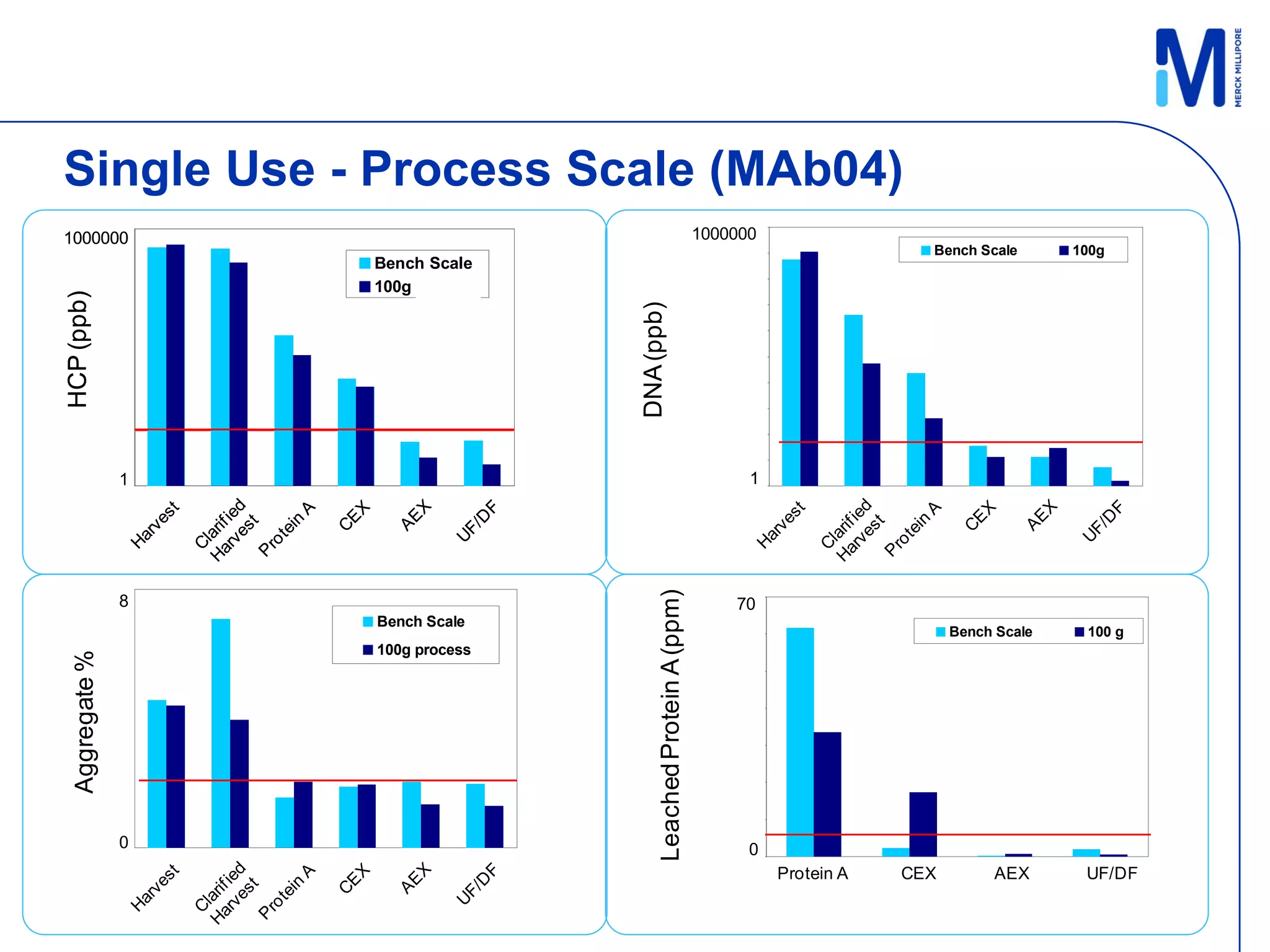

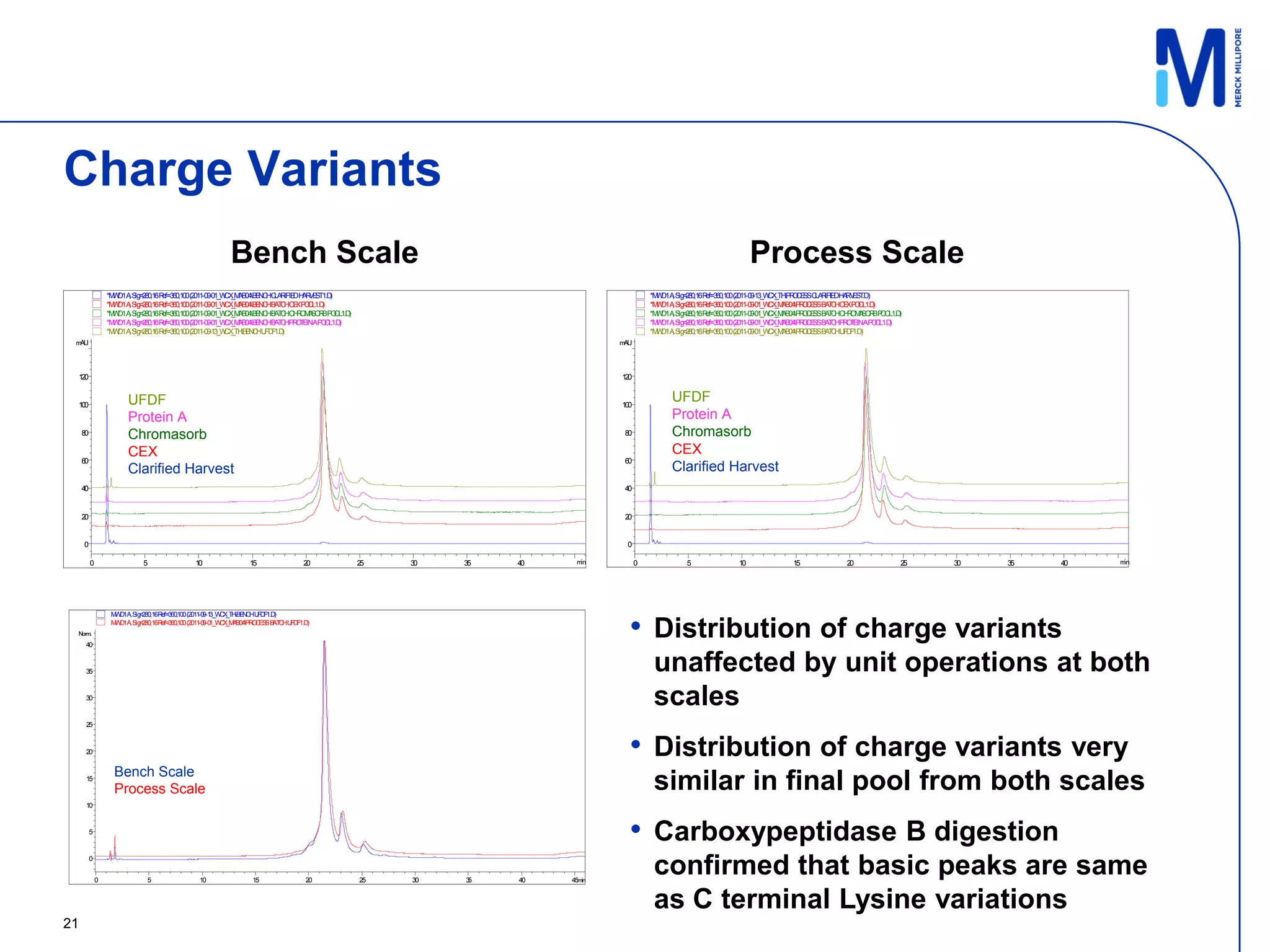

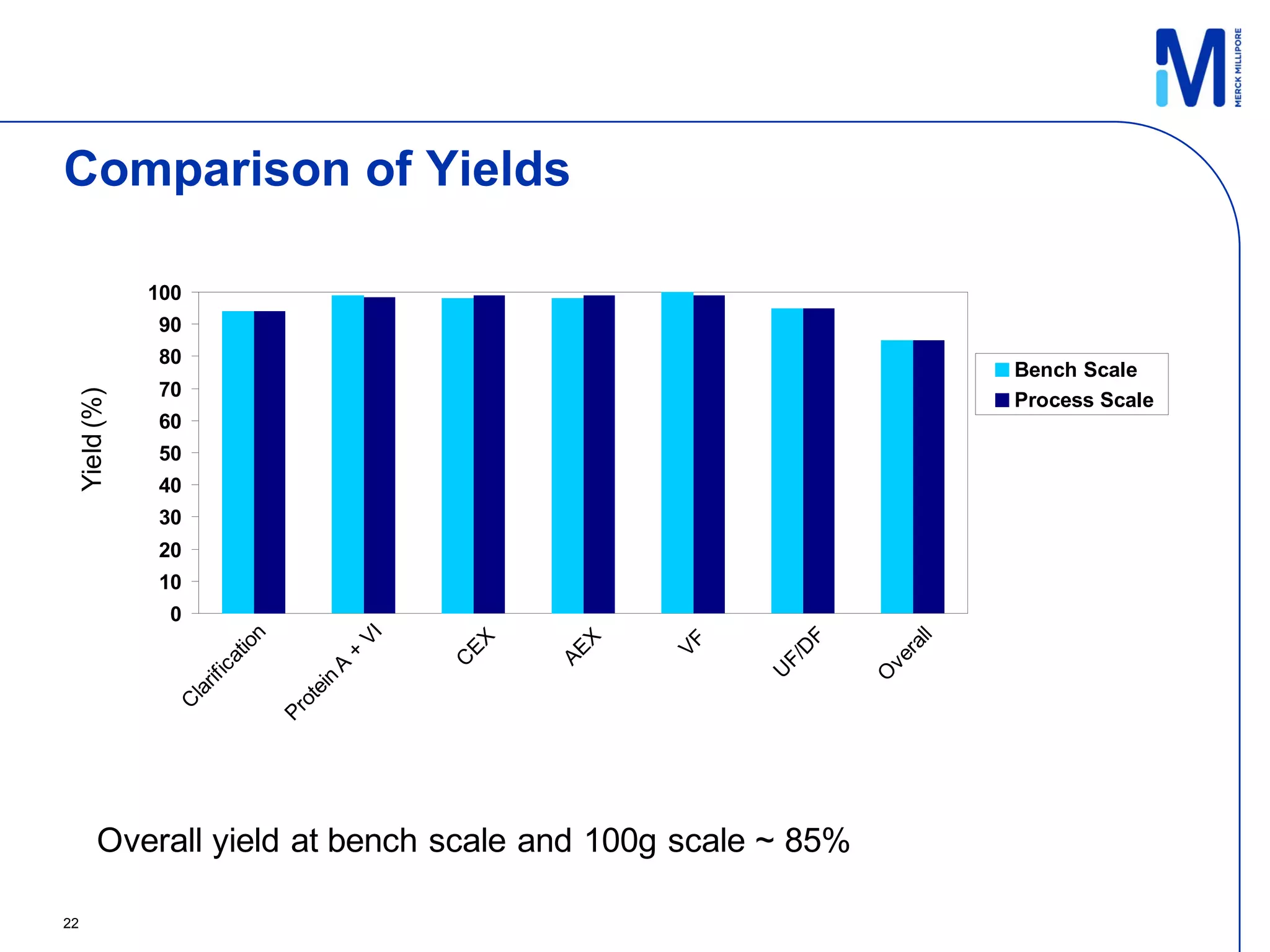

3) Comparison of bench and pilot scale runs showed similar impurity clearance, charge variant distribution, and overall yields, demonstrating successful scale up using single-use technologies.

![Proof of Principle

Pilot Scale

[100L bioreactor]

Bench Scale

Millistak

D0HC + X0HC

ProSep Ultra Plus

Selection

Millistak X0HC

Tool

e

Fractogel SO3

y

e

y

ChromaSorb

Sizing

Viresolve Pro+

Tool

P3 UltraCel

Template

10](https://image.slidesharecdn.com/pragmaticimplementationofsingle-usetechnologiestodeliverclinicalsupply-130319102625-phpapp02/75/Pragmatic-implementation-of-single-use-technologies-to-deliver-clinical-supply-10-2048.jpg)

![Cost of Pilot Scale Runs - Summary

Units Utilized

Hardware

MIX sytems 2

Drum dollies 6

200L Bioreactor 1

Buffer systems 1

Chrom systems 1

Non-chrom systems [ CLF, VF, TFF ] 3

Systems/Hardware Cost ~ $2.0M

Disposables

MIX Bags 15

2D and 3D bags 22

Sterile filters 8

Devices 11

Single use flow paths 11

Total cost of disposables* ~ $50k

23 * Excludes chrom resins and TFF membranes](https://image.slidesharecdn.com/pragmaticimplementationofsingle-usetechnologiestodeliverclinicalsupply-130319102625-phpapp02/75/Pragmatic-implementation-of-single-use-technologies-to-deliver-clinical-supply-23-2048.jpg)