Millipak® Final Fill Filters

•

0 likes•539 views

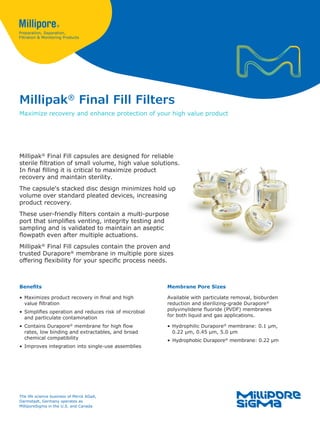

This product guide covers the basics of Millipak® Final Fill Filters. Learn how to maximize product recovery and enhance protection of your high value product.

Report

Share

Report

Share

Download to read offline

Recommended

Parvovirus Filtration Best Practices - 25 Years of Hands-On Experience

In this webinar, you will learn:

- how to measure filter performance and capacity,

- how to optimize filter virus removal capability,

- and avoid potential pit-falls

Detailed description:

This webinar will cover all aspects of parvovirus filtration best practices: process development/ optimization, pilot scale-up, and validation and explain the important connections between these activities. The rationale for the recommended best practices will be explained by discussing the underlying mechanisms that control filter performance.

Normal Flow Filtration: Design and Scale Up

This presentation explores bioprocessing filtration best practices, including design and scale up methods. You will learn:

• What is filtration?

• Filter capacity and fouling models

• Filter sizing approaches

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/remotevisit

Introduction to Tangential Flow Filtration (TFF)

This presentation provides an introduction to tangential flow filtration and reviews the following:

- TFF process basics and terminology

- TFF membrane technology

- TFF hardware, devices and systems

- Growing applications and the future

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/mlab

Find your filter. What’s best for your process?

Selecting the right aseptic filter for your process can be complicated: today’s biomanufacturer has many filter choices each offering distinct benefits. Understanding the specific needs for individual operations, in terms of flux, capacity, bioburden reduction or sterilizing performance, gamma or thermal compatibility and single or multi-use will inform decisions that have implications for the life of the process. This webinar will provide general customer guidance and explain the benefits and disadvantages of different options to help guide customers to the most appropriate filter for their operation.

In this webinar, you will learn:

- How filter design impacts performance

- Important criteria for filter selection

- New choices and options to maximize productivity for biomanufacturers

Single-Pass Tangential Flow Filtration (SPTFF) Theory and Practice

This data-driven presentation explores the theoretical and practical implications of single-pass tangential flow filtration in bioprocessing and will address the following:

• What is single-pass TFF and how does it work?

• How does SPTFF improve process economics?

• How can single-use technology be utilized for speed and safety?

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/mlab

Find your filter. What’s best for your process?

Selecting the right aseptic filter for your process can be complicated: today’s biomanufacturer has many filter choices each offering distinct benefits. Understanding the specific needs for individual operations, in terms of flux, capacity, bioburden reduction or sterilizing performance, gamma or thermal compatibility and single or multi-use will inform decisions that have implications for the life of the process. This webinar will provide general customer guidance and explain the benefits and disadvantages of different options to help guide customers to the most appropriate filter for their operation.

In this webinar, you will learn:

- How filter design impacts performance

- Important criteria for filter selection

- New choices and options to maximize productivity for biomanufacturers

QBD for Downstream Virus Filtration

Learn how Quality By Design (QBD) principles can be applied to understand the critical processing and feed parameters affecting virus retention, allowing the development of a streamlined validation approach and robust process control strategy for virus clearance via filtration.

In this webinar, you will learn:

•How to simplify validation study design

•Identify critical process and feed parameters affecting virus retention

•How to compile a robust regulatory filing package

Abstract:

ICH Q8 defines Quality by Design (QbD) as “…a systematic approach to development that begins with predefined objectives and emphasizes product and process understanding and process control, based on quality risk management.” Within the context of virus clearance for bioprocesses, QbD principles can be applied to understand the critical processing and feed parameters affecting virus retention, guiding the development of a streamlined validation approach and robust process control strategy for virus clearance unit operations. We will explore how QbD principles can be applied to downstream virus filtration of mAbs and recombinants, the application of these principles within the framework of the Viresolve® Pro Device (parvovirus retentive filter), the benefits through simplifying the validation strategy and increasing the robustness of your regulatory filing package.

Selection, sizing, and operation of bioprocess filtration trains for optimal ...

To increase filter lifetime and improve the economics of filtering bioprocess streams, a prefilter is often installed upstream of a final sterilizing-grade filter. However, determining the economic optimum prefilter and final filter configuration can be challenging. Numerous prefilter options are available, the prefilter to final filter area ratio must be determined, and operating conditions must be selected that will both satisfy the filtration requirements and provide for an economical process that minimizes the filtration system footprint.

One approach towards achieving an optimal filtration system design is to test the bioprocess fluid with several filter configuration combinations and at a range of operating conditions. However, this can be a daunting task and even impractical given the high cost and limited availability of valuable bioprocess fluids. A better approach is to run a limited filtration trial and use a mathematical model that can accurately predict the behavior of the prefilter and final filter under different conditions.

In this webinar we describe a filtration model and test methodology to rapidly and efficiently design an optimal dual-stage filtration process. The model and methodology were applied to Milligard® PES filters, a new class of autoclavable and gamma sterilizable PES membrane prefilters that are designed to protect microfiltration and nanofiltration final filters in bioprocess streams. We show how a model fit to the data from one set of filtration conditions can be used to predict filtration performance at other prefilter to final filter area ratios and operating conditions, and to determine the economic optimum filtration configuration.

In this webinar, you will learn:

- How filters for microfiltration of biological fluids work.

- The effect of operating conditions on filtration performance.

- How to design an optimal series filtration (prefilter and final filter) process.

Recommended

Parvovirus Filtration Best Practices - 25 Years of Hands-On Experience

In this webinar, you will learn:

- how to measure filter performance and capacity,

- how to optimize filter virus removal capability,

- and avoid potential pit-falls

Detailed description:

This webinar will cover all aspects of parvovirus filtration best practices: process development/ optimization, pilot scale-up, and validation and explain the important connections between these activities. The rationale for the recommended best practices will be explained by discussing the underlying mechanisms that control filter performance.

Normal Flow Filtration: Design and Scale Up

This presentation explores bioprocessing filtration best practices, including design and scale up methods. You will learn:

• What is filtration?

• Filter capacity and fouling models

• Filter sizing approaches

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/remotevisit

Introduction to Tangential Flow Filtration (TFF)

This presentation provides an introduction to tangential flow filtration and reviews the following:

- TFF process basics and terminology

- TFF membrane technology

- TFF hardware, devices and systems

- Growing applications and the future

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/mlab

Find your filter. What’s best for your process?

Selecting the right aseptic filter for your process can be complicated: today’s biomanufacturer has many filter choices each offering distinct benefits. Understanding the specific needs for individual operations, in terms of flux, capacity, bioburden reduction or sterilizing performance, gamma or thermal compatibility and single or multi-use will inform decisions that have implications for the life of the process. This webinar will provide general customer guidance and explain the benefits and disadvantages of different options to help guide customers to the most appropriate filter for their operation.

In this webinar, you will learn:

- How filter design impacts performance

- Important criteria for filter selection

- New choices and options to maximize productivity for biomanufacturers

Single-Pass Tangential Flow Filtration (SPTFF) Theory and Practice

This data-driven presentation explores the theoretical and practical implications of single-pass tangential flow filtration in bioprocessing and will address the following:

• What is single-pass TFF and how does it work?

• How does SPTFF improve process economics?

• How can single-use technology be utilized for speed and safety?

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/mlab

Find your filter. What’s best for your process?

Selecting the right aseptic filter for your process can be complicated: today’s biomanufacturer has many filter choices each offering distinct benefits. Understanding the specific needs for individual operations, in terms of flux, capacity, bioburden reduction or sterilizing performance, gamma or thermal compatibility and single or multi-use will inform decisions that have implications for the life of the process. This webinar will provide general customer guidance and explain the benefits and disadvantages of different options to help guide customers to the most appropriate filter for their operation.

In this webinar, you will learn:

- How filter design impacts performance

- Important criteria for filter selection

- New choices and options to maximize productivity for biomanufacturers

QBD for Downstream Virus Filtration

Learn how Quality By Design (QBD) principles can be applied to understand the critical processing and feed parameters affecting virus retention, allowing the development of a streamlined validation approach and robust process control strategy for virus clearance via filtration.

In this webinar, you will learn:

•How to simplify validation study design

•Identify critical process and feed parameters affecting virus retention

•How to compile a robust regulatory filing package

Abstract:

ICH Q8 defines Quality by Design (QbD) as “…a systematic approach to development that begins with predefined objectives and emphasizes product and process understanding and process control, based on quality risk management.” Within the context of virus clearance for bioprocesses, QbD principles can be applied to understand the critical processing and feed parameters affecting virus retention, guiding the development of a streamlined validation approach and robust process control strategy for virus clearance unit operations. We will explore how QbD principles can be applied to downstream virus filtration of mAbs and recombinants, the application of these principles within the framework of the Viresolve® Pro Device (parvovirus retentive filter), the benefits through simplifying the validation strategy and increasing the robustness of your regulatory filing package.

Selection, sizing, and operation of bioprocess filtration trains for optimal ...

To increase filter lifetime and improve the economics of filtering bioprocess streams, a prefilter is often installed upstream of a final sterilizing-grade filter. However, determining the economic optimum prefilter and final filter configuration can be challenging. Numerous prefilter options are available, the prefilter to final filter area ratio must be determined, and operating conditions must be selected that will both satisfy the filtration requirements and provide for an economical process that minimizes the filtration system footprint.

One approach towards achieving an optimal filtration system design is to test the bioprocess fluid with several filter configuration combinations and at a range of operating conditions. However, this can be a daunting task and even impractical given the high cost and limited availability of valuable bioprocess fluids. A better approach is to run a limited filtration trial and use a mathematical model that can accurately predict the behavior of the prefilter and final filter under different conditions.

In this webinar we describe a filtration model and test methodology to rapidly and efficiently design an optimal dual-stage filtration process. The model and methodology were applied to Milligard® PES filters, a new class of autoclavable and gamma sterilizable PES membrane prefilters that are designed to protect microfiltration and nanofiltration final filters in bioprocess streams. We show how a model fit to the data from one set of filtration conditions can be used to predict filtration performance at other prefilter to final filter area ratios and operating conditions, and to determine the economic optimum filtration configuration.

In this webinar, you will learn:

- How filters for microfiltration of biological fluids work.

- The effect of operating conditions on filtration performance.

- How to design an optimal series filtration (prefilter and final filter) process.

Single-Use Tangential Flow Filtration for Closed Processing

Watch the presentation of this webinar here: https://bit.ly/3b7vD60

Closed processing involves use of physical barriers to separate processing fluid from the external environment. This approach reduces capital expenditures and clean room classification while accelerating time to market. This webinar will present a TFF process run in a closed mode.

Closed processing with single-use technologies is a critical enabler for efficient and robust manufacturing for novel modalities as well as continuous biomanufacturing processing. It can also reduce the dependence on classified clean rooms for traditional modalities. This approach helps to mitigate the risk of contamination by adventitious agents while enhancing operator safety.

In this presentation, we discuss the implementation of closed processing for downstream applications and present the design and performance testing of a single use manufacturing-scale tangential flow filtration system to be able to operate in both functionally and fully closed mode.

In this webinar, you will learn:

• The context of closed processing

• Differences between closed and functionally closed processing

• The drivers for adoption

• Its practical implementation to a TFF step

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

This presentation provides an introduction to tangential flow filtration applications for AAV and lentivirus and will review:

• Basics of tangential flow filtration (TFF)

• TFF AAV and lentivirus process overview

• Operating parameters optimization: flux-controlled microfiltration

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/remotevisit

Cell Culture Media Filtration – Filter Selection and Sizing

The purpose of this application note is to provide estimated filtration areas for different sterilizing-grade filters with a panel of media used for Chinese Hamster Ovary (CHO) cell culture processes.

Normal Flow Filtration: Design and Scale Up

This presentation explores bioprocessing filtration best practices, including design and scale up methods. You will learn:

• What is filtration?

• Filter capacity and fouling models

• Filter sizing approaches

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/remotevisit

Validation of Tangential Flow Filtration in Biotech Processes

Watch the presentation of this webinar here: https://bit.ly/3hUKfd7

The objective of validation of a unit operation is to demonstrate with a high degree of confidence that the process performs consistently. The present seminar will focus on the validation of the unit operation of TFF and will provide an overview of the regulatory landscape, the validation master plan, approaches to membrane re-use, cleaning validation, and best practices.

In this webinar, you will learn:

• Validation of TFF

• Validation master plan

• Membrane reuse and cleaning

• TFF scale down models

Speaker: Dr. Subhasis Banerjee,

Principal Technical Application Expert, Bioprocessing APAC

Scale-up of high area filters for microfiltration of biological fluids - Poin...

Presented at INTERPHEX on March 21-23, 2017.

High area filters can present unique challenges when scaling up from discs to cartridges. A model was developed that can be used to estimate scaled-up performance. A new small scale scaling tool is also introduced that closely mimics the filtration behavior of the full scale filter and that can be used to confirm expected scaled-up performance.

Integrity Test Troubleshooting – Beyond Rewet and Retest

Integrity testing is a critical operation, especially for sterilizing grade filters used in biopharmaceutical processing. When performed correctly, an integrity test is a fast, definitive, non-destructive way to assure filter retention performance. Fortunately, there are few ways a non-integral filter will pass the integrity test, eliminating the possibility a non-retentive filter is used undetected. Unfortunately, there are a lot of ways an integral filter can fail the integrity test, resulting in retests, lost time, productivity and potentially lost product.

In this webinar you will:

- Gain confidence in your integrity testing results

- Provide justification for retests

- Understand specific challenges and eliminate them to assure the integrity test can be performed correctly the first time

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration and filter validation remain a critical segment during the development of these segments of products. Let's find the same by understanding a checklist and visualize certain case studies.

As the sterile injectable market continues to see rapid growth (~10% to 15% per annum) – outpacing the growth of oral products – it is natural to see the diversity of parenteral product formulations increasing in parallel. The definition of complexity in parenteral formulation development is broad. It varies based on the stage of development and the specific nature of the challenge. A notionally simple, stable reproducible laboratory formulation may carry a level of complexity in aseptic control if routine means of sterilization are unavailable.

Sterile filtration process intensification can bring significant benefits to manufacturers in terms of manufacturing flexibility, reduction of risks, better turn around time, thus achieving significantly higher productivity. We will identify these scenarios with case studies to reduce complications in manufacturing and process development.

EU GMP Annex 1 Draft: Implications on Sterilizing Grade Filter Validation

Watch the presentation of this webinar here: https://bit.ly/3kk0Qs1

In this webinar, you will learn:

- About the GMP Annex 1 draft regulatory overview

- How to incorporate the integrity testing & PUPSIT in the filtration systems validation

- How to design a bacterial retention test in terms of organism selection and single vs multiple use validation

Detailed description:

In this webinar we will discuss the implications of the EU GMP Annex 1 draft on the filtration of medicinal products and how this impacts the validation studies.

Bacterial Retention Testing is a critical part of the manufacturing validation process and is required by all regulatory bodies worldwide. Using case studies, our experts will explain how the Annex 1 draft is incorporated into the filtration systems validation exercise, specifically for integrity testing & PUPSIT (Pre-Use Post Sterilization Integrity Testing), the selection and justification of the appropriate test organism, and validation implications of single versus multiple use.

Validation of membrane filter

Good Manufacturing Practice

For LVP,SVP, ophthalmic, veterinary medicine, bulk chemicals & in-vitro diagnostic

Membrane Chromatography Solutions for Single-Use, Intensified mAb Purification

Participate in the interactive webinar: http://bit.ly/NatrixChromMSIG

Explore our webinar library: www.emdmillipore.com/webinars

Improve productivity, flexibility, and economics of mAb purification process with intensified, single-use membrane chromatography.

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration and filter validation remain a critical segment during the development of these segments of products. Let's find the same by understanding a checklist and visualize certain case studies.

As the sterile injectable market continues to see rapid growth (~10% to 15% per annum) – outpacing the growth of oral products – it is natural to see the diversity of parenteral product formulations increasing in parallel. The definition of complexity in parenteral formulation development is broad. It varies based on the stage of development and the specific nature of the challenge. A notionally simple, stable reproducible laboratory formulation may carry a level of complexity in aseptic control if routine means of sterilization are unavailable.

Sterile filtration process intensification can bring significant benefits to manufacturers in terms of manufacturing flexibility, reduction of risks, better turn around time, thus achieving significantly higher productivity. We will identify these scenarios with case studies to reduce complications in manufacturing and process development.

Filter validation

Good Manufacturing Practice

For LVP,SVP, ophthalmic veterinary medicine, bulk chemicals & invitro diagnostic

For Good business Practice

A control process gives reproducibility & product consistency with in known limits

Provides license to do business.

Introduction to Tangential Flow Filtration (TFF)

This presentation provides an introduction to tangential flow filtration and reviews the following:

- TFF process basics and terminology

- TFF membrane technology

- TFF hardware, devices and systems

- Growing applications and the future

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/mlab

An Efficient and cGMP-friendly Solution to Diafiltration for Intensified or C...

View the recording here: https://bit.ly/2M6cTYD

Abstract:

Diafiltration is a critical unit operation in the downstream purification train for nearly all monoclonal antibodies and other therapeutic biomolecules, with a particular application being the final formulation step. It provides a cost-effective, efficient, and robust method for achieving > 3 logs of buffer exchange. As the biomanufacturing industry strives for more efficient and cost-conscious processes and facilities by adapting templates to be more flexible, handle larger batch sizes, require lower plant footprint, and run in an integrated or continuous mode, diafiltration has been one of the last unit operations to change. Updated technologies for chromatography, clarification, and concentration have been developed in recent years, offering significant improvements over their existing batch processing equivalents. However, it has been challenging to develop a similar intensified and continuous technology for diafiltration that exceeds established expectations around unit operation productivity while maintaining a process that is easily implementable and suitable for GMP manufacturing.

Our approach to intensified, continuous diafiltration bases the process design on membrane utilization, as opposed to flux and process time typically used for batch designs. The result is a flexible solution that offers 6-8-fold decrease in membrane area, up to 3-fold reduction in pump passes and a substantial footprint reduction. Buffer usage, extent of buffer exchange, and product yield are equivalent to a traditional constant-volume diafiltration process. The process development approach, system components, and process control rely on well-established methods and technologies, reducing risk during scaleup and manufacturing implementation.

In this webinar, you will learn:

- A new process design for continuous diafiltration and its operational robustness over a 24-hour run

- Benefits of implementing this version of intensified or continuous diafiltration in your process train

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

This presentation provides an introduction to tangential flow filtration applications for AAV and lentivirus and will review:

• Basics of tangential flow filtration (TFF)

• TFF AAV and lentivirus process overview

• Operating parameters optimization: flux-controlled microfiltration

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/remotevisit

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration and filter validation remain a critical segment during the development of these segments of products. Let's find the same by understanding a checklist and visualize certain case studies.

As the sterile injectable market continues to see rapid growth (~10% to 15% per annum) – outpacing the growth of oral products – it is natural to see the diversity of parenteral product formulations increasing in parallel. The definition of complexity in parenteral formulation development is broad. It varies based on the stage of development and the specific nature of the challenge. A notionally simple, stable reproducible laboratory formulation may carry a level of complexity in aseptic control if routine means of sterilization are unavailable.

Sterile filtration process intensification can bring significant benefits to manufacturers in terms of manufacturing flexibility, reduction of risks, better turn around time, thus achieving significantly higher productivity. We will identify these scenarios with case studies to reduce complications in manufacturing and process development.

Evaluation of Established & New Viral Filters for a Monoclonal Antibody Platf...

Program overview:

•Background

•Scope of Work

•Virus Filters for Evaluation

•Model Molecules

•Experimental Plan & Results

Parvovirus Filtration Best Practices - 25 Years of Hands-On Experience

In this webinar, you will learn:

- how to measure filter performance and capacity,

- how to optimize filter virus removal capability,

- and avoid potential pit-falls

Detailed description:

This webinar will cover all aspects of parvovirus filtration best practices: process development/ optimization, pilot scale-up, and validation and explain the important connections between these activities. The rationale for the recommended best practices will be explained by discussing the underlying mechanisms that control filter performance.

More Related Content

What's hot

Single-Use Tangential Flow Filtration for Closed Processing

Watch the presentation of this webinar here: https://bit.ly/3b7vD60

Closed processing involves use of physical barriers to separate processing fluid from the external environment. This approach reduces capital expenditures and clean room classification while accelerating time to market. This webinar will present a TFF process run in a closed mode.

Closed processing with single-use technologies is a critical enabler for efficient and robust manufacturing for novel modalities as well as continuous biomanufacturing processing. It can also reduce the dependence on classified clean rooms for traditional modalities. This approach helps to mitigate the risk of contamination by adventitious agents while enhancing operator safety.

In this presentation, we discuss the implementation of closed processing for downstream applications and present the design and performance testing of a single use manufacturing-scale tangential flow filtration system to be able to operate in both functionally and fully closed mode.

In this webinar, you will learn:

• The context of closed processing

• Differences between closed and functionally closed processing

• The drivers for adoption

• Its practical implementation to a TFF step

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

This presentation provides an introduction to tangential flow filtration applications for AAV and lentivirus and will review:

• Basics of tangential flow filtration (TFF)

• TFF AAV and lentivirus process overview

• Operating parameters optimization: flux-controlled microfiltration

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/remotevisit

Cell Culture Media Filtration – Filter Selection and Sizing

The purpose of this application note is to provide estimated filtration areas for different sterilizing-grade filters with a panel of media used for Chinese Hamster Ovary (CHO) cell culture processes.

Normal Flow Filtration: Design and Scale Up

This presentation explores bioprocessing filtration best practices, including design and scale up methods. You will learn:

• What is filtration?

• Filter capacity and fouling models

• Filter sizing approaches

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/remotevisit

Validation of Tangential Flow Filtration in Biotech Processes

Watch the presentation of this webinar here: https://bit.ly/3hUKfd7

The objective of validation of a unit operation is to demonstrate with a high degree of confidence that the process performs consistently. The present seminar will focus on the validation of the unit operation of TFF and will provide an overview of the regulatory landscape, the validation master plan, approaches to membrane re-use, cleaning validation, and best practices.

In this webinar, you will learn:

• Validation of TFF

• Validation master plan

• Membrane reuse and cleaning

• TFF scale down models

Speaker: Dr. Subhasis Banerjee,

Principal Technical Application Expert, Bioprocessing APAC

Scale-up of high area filters for microfiltration of biological fluids - Poin...

Presented at INTERPHEX on March 21-23, 2017.

High area filters can present unique challenges when scaling up from discs to cartridges. A model was developed that can be used to estimate scaled-up performance. A new small scale scaling tool is also introduced that closely mimics the filtration behavior of the full scale filter and that can be used to confirm expected scaled-up performance.

Integrity Test Troubleshooting – Beyond Rewet and Retest

Integrity testing is a critical operation, especially for sterilizing grade filters used in biopharmaceutical processing. When performed correctly, an integrity test is a fast, definitive, non-destructive way to assure filter retention performance. Fortunately, there are few ways a non-integral filter will pass the integrity test, eliminating the possibility a non-retentive filter is used undetected. Unfortunately, there are a lot of ways an integral filter can fail the integrity test, resulting in retests, lost time, productivity and potentially lost product.

In this webinar you will:

- Gain confidence in your integrity testing results

- Provide justification for retests

- Understand specific challenges and eliminate them to assure the integrity test can be performed correctly the first time

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration and filter validation remain a critical segment during the development of these segments of products. Let's find the same by understanding a checklist and visualize certain case studies.

As the sterile injectable market continues to see rapid growth (~10% to 15% per annum) – outpacing the growth of oral products – it is natural to see the diversity of parenteral product formulations increasing in parallel. The definition of complexity in parenteral formulation development is broad. It varies based on the stage of development and the specific nature of the challenge. A notionally simple, stable reproducible laboratory formulation may carry a level of complexity in aseptic control if routine means of sterilization are unavailable.

Sterile filtration process intensification can bring significant benefits to manufacturers in terms of manufacturing flexibility, reduction of risks, better turn around time, thus achieving significantly higher productivity. We will identify these scenarios with case studies to reduce complications in manufacturing and process development.

EU GMP Annex 1 Draft: Implications on Sterilizing Grade Filter Validation

Watch the presentation of this webinar here: https://bit.ly/3kk0Qs1

In this webinar, you will learn:

- About the GMP Annex 1 draft regulatory overview

- How to incorporate the integrity testing & PUPSIT in the filtration systems validation

- How to design a bacterial retention test in terms of organism selection and single vs multiple use validation

Detailed description:

In this webinar we will discuss the implications of the EU GMP Annex 1 draft on the filtration of medicinal products and how this impacts the validation studies.

Bacterial Retention Testing is a critical part of the manufacturing validation process and is required by all regulatory bodies worldwide. Using case studies, our experts will explain how the Annex 1 draft is incorporated into the filtration systems validation exercise, specifically for integrity testing & PUPSIT (Pre-Use Post Sterilization Integrity Testing), the selection and justification of the appropriate test organism, and validation implications of single versus multiple use.

Validation of membrane filter

Good Manufacturing Practice

For LVP,SVP, ophthalmic, veterinary medicine, bulk chemicals & in-vitro diagnostic

Membrane Chromatography Solutions for Single-Use, Intensified mAb Purification

Participate in the interactive webinar: http://bit.ly/NatrixChromMSIG

Explore our webinar library: www.emdmillipore.com/webinars

Improve productivity, flexibility, and economics of mAb purification process with intensified, single-use membrane chromatography.

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration and filter validation remain a critical segment during the development of these segments of products. Let's find the same by understanding a checklist and visualize certain case studies.

As the sterile injectable market continues to see rapid growth (~10% to 15% per annum) – outpacing the growth of oral products – it is natural to see the diversity of parenteral product formulations increasing in parallel. The definition of complexity in parenteral formulation development is broad. It varies based on the stage of development and the specific nature of the challenge. A notionally simple, stable reproducible laboratory formulation may carry a level of complexity in aseptic control if routine means of sterilization are unavailable.

Sterile filtration process intensification can bring significant benefits to manufacturers in terms of manufacturing flexibility, reduction of risks, better turn around time, thus achieving significantly higher productivity. We will identify these scenarios with case studies to reduce complications in manufacturing and process development.

Filter validation

Good Manufacturing Practice

For LVP,SVP, ophthalmic veterinary medicine, bulk chemicals & invitro diagnostic

For Good business Practice

A control process gives reproducibility & product consistency with in known limits

Provides license to do business.

Introduction to Tangential Flow Filtration (TFF)

This presentation provides an introduction to tangential flow filtration and reviews the following:

- TFF process basics and terminology

- TFF membrane technology

- TFF hardware, devices and systems

- Growing applications and the future

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/mlab

An Efficient and cGMP-friendly Solution to Diafiltration for Intensified or C...

View the recording here: https://bit.ly/2M6cTYD

Abstract:

Diafiltration is a critical unit operation in the downstream purification train for nearly all monoclonal antibodies and other therapeutic biomolecules, with a particular application being the final formulation step. It provides a cost-effective, efficient, and robust method for achieving > 3 logs of buffer exchange. As the biomanufacturing industry strives for more efficient and cost-conscious processes and facilities by adapting templates to be more flexible, handle larger batch sizes, require lower plant footprint, and run in an integrated or continuous mode, diafiltration has been one of the last unit operations to change. Updated technologies for chromatography, clarification, and concentration have been developed in recent years, offering significant improvements over their existing batch processing equivalents. However, it has been challenging to develop a similar intensified and continuous technology for diafiltration that exceeds established expectations around unit operation productivity while maintaining a process that is easily implementable and suitable for GMP manufacturing.

Our approach to intensified, continuous diafiltration bases the process design on membrane utilization, as opposed to flux and process time typically used for batch designs. The result is a flexible solution that offers 6-8-fold decrease in membrane area, up to 3-fold reduction in pump passes and a substantial footprint reduction. Buffer usage, extent of buffer exchange, and product yield are equivalent to a traditional constant-volume diafiltration process. The process development approach, system components, and process control rely on well-established methods and technologies, reducing risk during scaleup and manufacturing implementation.

In this webinar, you will learn:

- A new process design for continuous diafiltration and its operational robustness over a 24-hour run

- Benefits of implementing this version of intensified or continuous diafiltration in your process train

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

This presentation provides an introduction to tangential flow filtration applications for AAV and lentivirus and will review:

• Basics of tangential flow filtration (TFF)

• TFF AAV and lentivirus process overview

• Operating parameters optimization: flux-controlled microfiltration

• Scale up considerations

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/remotevisit

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration and filter validation remain a critical segment during the development of these segments of products. Let's find the same by understanding a checklist and visualize certain case studies.

As the sterile injectable market continues to see rapid growth (~10% to 15% per annum) – outpacing the growth of oral products – it is natural to see the diversity of parenteral product formulations increasing in parallel. The definition of complexity in parenteral formulation development is broad. It varies based on the stage of development and the specific nature of the challenge. A notionally simple, stable reproducible laboratory formulation may carry a level of complexity in aseptic control if routine means of sterilization are unavailable.

Sterile filtration process intensification can bring significant benefits to manufacturers in terms of manufacturing flexibility, reduction of risks, better turn around time, thus achieving significantly higher productivity. We will identify these scenarios with case studies to reduce complications in manufacturing and process development.

Evaluation of Established & New Viral Filters for a Monoclonal Antibody Platf...

Program overview:

•Background

•Scope of Work

•Virus Filters for Evaluation

•Model Molecules

•Experimental Plan & Results

What's hot (20)

Single-Use Tangential Flow Filtration for Closed Processing

Single-Use Tangential Flow Filtration for Closed Processing

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

Cell Culture Media Filtration – Filter Selection and Sizing

Cell Culture Media Filtration – Filter Selection and Sizing

Validation of Tangential Flow Filtration in Biotech Processes

Validation of Tangential Flow Filtration in Biotech Processes

Scale-up of high area filters for microfiltration of biological fluids - Poin...

Scale-up of high area filters for microfiltration of biological fluids - Poin...

Integrity Test Troubleshooting – Beyond Rewet and Retest

Integrity Test Troubleshooting – Beyond Rewet and Retest

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration of complex injectables by Partha Banerjee

EU GMP Annex 1 Draft: Implications on Sterilizing Grade Filter Validation

EU GMP Annex 1 Draft: Implications on Sterilizing Grade Filter Validation

Membrane Chromatography Solutions for Single-Use, Intensified mAb Purification

Membrane Chromatography Solutions for Single-Use, Intensified mAb Purification

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration of complex injectables by Partha Banerjee

An Efficient and cGMP-friendly Solution to Diafiltration for Intensified or C...

An Efficient and cGMP-friendly Solution to Diafiltration for Intensified or C...

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

Optimization of Tangential Flow Filtration Applications and Scale Up Consider...

Sterile filtration of complex injectables by Partha Banerjee

Sterile filtration of complex injectables by Partha Banerjee

Evaluation of Established & New Viral Filters for a Monoclonal Antibody Platf...

Evaluation of Established & New Viral Filters for a Monoclonal Antibody Platf...

Similar to Millipak® Final Fill Filters

Parvovirus Filtration Best Practices - 25 Years of Hands-On Experience

In this webinar, you will learn:

- how to measure filter performance and capacity,

- how to optimize filter virus removal capability,

- and avoid potential pit-falls

Detailed description:

This webinar will cover all aspects of parvovirus filtration best practices: process development/ optimization, pilot scale-up, and validation and explain the important connections between these activities. The rationale for the recommended best practices will be explained by discussing the underlying mechanisms that control filter performance.

Improve Process Efficiency in Bioprocess Streams by Prefiltration Optimizatio...

This poster summarizes throughput and bacterial retention performance of prefilters used to reduce bioburden in intermediate downstream process steps.

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/mlab

Reducing Contamination Risk and Improving Product Recovery During Final Steri...

Final sterile filtration operations are the focus of extensive regulatory guidance to assure the safety of medicinal products for administration to patients. All sterilizing-grade filters must be tested for integrity after use, and current draft EMA EU Annex 1 requires pre-use, post-sterilization integrity tests (PUPSIT). This poster explores the use of final fill filters to achieve the following:

• Simplify PUPSIT by reducing risk of introducing microbial contaminants to the flow path

• Maximize product recovery

• Create a safer and more efficient final filtration process

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/mlab

Reducing Contamination Risk and Improving Product Recovery During Final Steri...

Final sterile filtration operations are the focus of extensive regulatory guidance to assure the safety of medicinal products for administration to patients. All sterilizing-grade filters must be tested for integrity after use, and current draft EMA EU Annex 1 requires pre-use, post-sterilization integrity tests (PUPSIT). This poster explores the use of final fill filters to achieve the following:

• Simplify PUPSIT by reducing risk of introducing microbial contaminants to the flow path

• Maximize product recovery

• Create a safer and more efficient final filtration process

To learn more about this topic or collaborate with our technical experts, schedule an in-person or remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/mlab

Improved Product Recovery Using Blow-down and Millipak® Final Fill Filters

This application note compares hold-up volume of both pleated and stacked disc filters and highlight the benefits of filter blow-down for maximizing product recovery.

Implementing and Managing Pre-use Post-sterilization Integrity Testing (PUPSIT)

This presentation explores best practices and case studies in aseptic processing, including how to implement and manage PUPSIT. You will learn:

• Integrity Testing – the background on IT itself, why it is important, and how it works

• Filtration setups and single-use technology

• The PUPSIT debate and how PUPSIT can be achieved with current technology, final filling, formulation, filtration

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.emdmillipore.com/remotevisit

Implementing and Managing Pre-use Post-sterilization Integrity Testing (PUPSIT)

This presentation explores best practices and case studies in aseptic processing, including how to implement and manage PUPSIT. You will learn:

• Integrity Testing – the background on IT itself, why it is important, and how it works

• Filtration setups and single-use technology

• The PUPSIT debate and how PUPSIT can be achieved with current technology, final filling, formulation, filtration

To learn more about this topic or collaborate with our technical experts, schedule a remote visit at our M Lab™ Collaboration Centers: www.merckmillipore.com/remotevisit

Single-Use Tangential Flow Filtration for Closed Processing

Watch the presentation of this webinar here: https://bit.ly/3b7vD60

Closed processing involves use of physical barriers to separate processing fluid from the external environment. This approach reduces capital expenditures and clean room classification while accelerating time to market. This webinar will present a TFF process run in a closed mode.

Closed processing with single-use technologies is a critical enabler for efficient and robust manufacturing for novel modalities as well as continuous biomanufacturing processing. It can also reduce the dependence on classified clean rooms for traditional modalities. This approach helps to mitigate the risk of contamination by adventitious agents while enhancing operator safety.

In this presentation, we discuss the implementation of closed processing for downstream applications and present the design and performance testing of a single use manufacturing-scale tangential flow filtration system to be able to operate in both functionally and fully closed mode.

In this webinar, you will learn:

• The context of closed processing

• Differences between closed and functionally closed processing

• The drivers for adoption

• Its practical implementation to a TFF step

Greyhound Chromatography 'Q fil' Syringe Filters Catalogue

Greyhound Chromatography 'Q fil' Syringe Filters CatalogueGreyhound Chromatography and Allied Chemicals

The main source of particle contamination in HPLC columns originate in the sample to be analysed. Using a syringe filter before the sample is injected into the analytical instrument ensures that the sample is at its purest before the analysis begins. Greyhound Chromatography offer a wide range of syringe filters, suitable for any sample analysis.Utilizing Tubular UF Membrane Filtration for Wastewater Reuse

Water is a valuable asset to any industry. Implementing an efficient wastewater reuse and treatment system will lower the dependency on fresh water sources.

Millipak® Final Fill Filters Reduce Contamination Risks and Simplify Filtrati...

This tech note summarizes the results of microbial challenge studies that confirm the aseptic multi-purpose port (AMPP) prevents microbial contamination entering the flow path. We also show how these results can be leveraged to simplify integrity testing and product recovery following sterile filtration operations.

Greyhound Chromatography Q - Fil Syringe Filters 2020

Greyhound Chromatography's Q-Fil Syringe Filters set the new Quality standard for today’s laboratory syringe filters. Manufactured from the highest quality medical grade, high density polypropylene. Q-Fil Syringe Filters provide excellent chemical compatibility with acids, alcohols, bases, ethers, glycols, ketones and oils.

Every colour-coded filter is printed with details of the membrane material and its pore size on the outside of the filter and every box is labelled with the batch number making them ideal for traceability, GLPs and validation purposes.

Residential cartridge pdf document aqua middle east fzc

Aqua is the Biggest Industrial Group swimming pool equipments in Middle East Dubai. we Deal swimming pool equipment and supplies swimming pool equipment and accessories in dubai.

Residential cartridge pdf document aqua middle east fzc

Aqua is the Biggest Industrial Group swimming pool equipments in Middle East Dubai. we Deal swimming pool equipment and supplies swimming pool equipment and accessories in dubai.

Similar to Millipak® Final Fill Filters (20)

Parvovirus Filtration Best Practices - 25 Years of Hands-On Experience

Parvovirus Filtration Best Practices - 25 Years of Hands-On Experience

Improve Process Efficiency in Bioprocess Streams by Prefiltration Optimizatio...

Improve Process Efficiency in Bioprocess Streams by Prefiltration Optimizatio...

Reducing Contamination Risk and Improving Product Recovery During Final Steri...

Reducing Contamination Risk and Improving Product Recovery During Final Steri...

Reducing Contamination Risk and Improving Product Recovery During Final Steri...

Reducing Contamination Risk and Improving Product Recovery During Final Steri...

Improved Product Recovery Using Blow-down and Millipak® Final Fill Filters

Improved Product Recovery Using Blow-down and Millipak® Final Fill Filters

Implementing and Managing Pre-use Post-sterilization Integrity Testing (PUPSIT)

Implementing and Managing Pre-use Post-sterilization Integrity Testing (PUPSIT)

Implementing and Managing Pre-use Post-sterilization Integrity Testing (PUPSIT)

Implementing and Managing Pre-use Post-sterilization Integrity Testing (PUPSIT)

Single-Use Tangential Flow Filtration for Closed Processing

Single-Use Tangential Flow Filtration for Closed Processing

Greyhound Chromatography 'Q fil' Syringe Filters Catalogue

Greyhound Chromatography 'Q fil' Syringe Filters Catalogue

Utilizing Tubular UF Membrane Filtration for Wastewater Reuse

Utilizing Tubular UF Membrane Filtration for Wastewater Reuse

Millipak® Final Fill Filters Reduce Contamination Risks and Simplify Filtrati...

Millipak® Final Fill Filters Reduce Contamination Risks and Simplify Filtrati...

Greyhound Chromatography Q - Fil Syringe Filters 2020

Greyhound Chromatography Q - Fil Syringe Filters 2020

Residential cartridge pdf document aqua middle east fzc

Residential cartridge pdf document aqua middle east fzc

Residential cartridge pdf document aqua middle east fzc

Residential cartridge pdf document aqua middle east fzc

More from MilliporeSigma

Launch of our new Titanium Dioxide Alternative

Parteck® TA (Calcium carbonate) Emprove® Essential

The ideal morphology and particle size for enhanced opacity in tablet coating.

The Viscosity Reduction Platform: Viscosity-reducing excipients for improveme...

Protein viscosity is a major challenge in preparing highly concentrated protein formulations suitable for subcutaneous injection. Recently, the Viscosity Reduction Platform (VRP) was introduced and its technical key features and benefits for formulations were discussed. However, highly viscous solutions do not only pose a challenge when administering a drug to a patient, they can also impose technical limitations in the manufacturing process.

This white paper evaluates the effect of the excipients in the Viscosity Reduction Platform on ultrafiltration processes used to produce a highly concentrated formulation of a monoclonal antibody (mAb). Two filtration methods are demonstrated in this work.

Find more information about the Viscosity Reduction Platform on our website: https://www.sigmaaldrich.com/products/pharma-and-biopharma-manufacturing/formulation/viscosity-reduction-platform

Use of Excipients in Downstream Processing to Improve Protein Purification

Excipients are used to improve the stability of protein-based therapeutics by protecting the protein against a range of stress conditions such as temperature changes, pH changes, or agitation. Similar stresses are applied to proteins during downstream purification. Shifts in pH during Protein A chromatography, subsequent incubations at low pH for virus inactivation, and changes in conductivity in ion exchange chromatography can lead to aggregation, fragmentation, or other chemical modifications of the therapeutic protein. Given the potential impact on the protein’s structural integrity, there is a need for approaches to reduce the risk presented by the conditions during downstream processing. For example, integration of a solution to prevent aggregation of proteins would be a more efficient strategy than implementing steps to remove multimeric forms.

This white paper highlights the results from a recent paper by Stange et. al., in which protein stabilizing excipients such as polyols, sugars, and polyethylene glycol (PEG4000) were used as buffer system additives. Effect of the excipients on elution patterns, stabilization of the monomer antibody, host-cell protein removal, virus inactivation rates and binding capacity of cation exchange chromatography were explored.

Exploring the protein stabilizing capability of surfactants against agitation...

Agitation of therapeutic protein solutions during manufacturing, shipping and handling is one of the major initiators for protein aggregation and particle formation during the life history of a protein drug. Adsorption of protein molecules to liquid-air interfaces leads to the formation of highly concentrated protein surface films. The rupture of these protein films due to various mechanical processes can then result in the appearance of protein aggregates and particles in the bulk solution phase.

One technique to stabilize proteins against stress induced by liquid-air interfaces is the use of non-ionic surfactants. About 91% of antibody formulations commercially available in 2021 contained a surfactant. Polysorbate 20 and 80, composed of a hydrophilic polyoxyethylene sorbitan and hydrophobic fatty acid esters, made up the largest part being employed in 87% of said formulations.

Despite their frequent use in parenteral drug products, concerns have been raised for decades about the application of polysorbates as surfactants in biopharmaceutical formulations. Autoxidation of polysorbate, caused by residual peroxides in polysorbates, can damage the proteins and can further drive the oxidative degradation of polysorbate. Chemical and enzymatic hydrolysis of polysorbate may lead to the formation of free fatty acid particles, which may become visible; and both mechanisms eventually lead to the reduction in polysorbate concentration. Therefore, the purpose of the current study was to compare various molecules for their capabilities to reduced agitation-induced protein aggregation and particle formation; and furthermore, investigate their underlying protein stabilizing mechanisms.

The Viscosity Reduction Platform: Viscosity Reducing Excipients for Protein F...

Protein viscosity is one of the major obstacles in preparing highly concentrated protein formulations suitable for subcutaneous injection.

This whitepaper examines how combining an amino acid with a second viscosity-reducing excipient circumvents adverse effects on protein stability and improves viscosity-reducing capacity.

To find more information about the Viscosity Reduction Platform, please visit our website: https://sigmaaldrich.com/products/pharma-and-biopharma-manufacturing/formulation/viscosity-reduction-platform

Characterization of monoclonal antibodies and Antibody drug conjugates by Sur...

Watch the presentation of this webinar: https://bit.ly/3Pjpjvr

Highlights of this webinar:

- Surface plasmon resonance as a powerful tool for biologic characterization including mAbs and ADCs.

- SPR allows rapid binding analysis in real time without using labels for SARS-CoV-2 receptor binding domain mutations.

- Kinetic data is indicative of possible neutralizing activity allowed assessment of neutralizing ability of therapeutic monoclonal antibodies.

- The application can provide preliminarily efficacy information and facilitated mAbs/ACDs candidate selection process

Detailed description:

Characterization of therapeutic monoclonal antibodies (mAbs) or Antibody drug conjugates (ADCs) is challenging due to their ability to bind to a variety of proteins via their Fc and Fab domains, giving rise to diverse biological functions associated with each domain. The Fc domain of mAbs interacts with Fc receptors with varying affinities, which can influence biological processes such as Complement-dependent cytotoxicity (CDC) and Antibody-dependent cellular cytotoxicity (ADCC), transcytosis, phagocytosis, and/or serum half-life.

An important characteristic of an antibody is its Fc effector function. Antibodies can be engineered to obtain desired binding of the Fc region to Fc receptors expressed on effector cells. Hence, it is crucial to evaluate the binding interaction of mAbs/ADC with Fc receptors in the early phase of drug development to understand the potential biological activity of the product in vivo.

Surface Plasmon Resonance (SPR) is a powerful technique to establish binding kinetics in real-time, label free, and high sensitivity with low sample consumption. Along with target antigen binding, it is crucial to evaluate the binding interaction of antibodies and ADCs with Fc receptors. Our SPR case studies investigated the impact on binding kinetics of ADCs with different linkers and the binding interactions of SARS-CoV-2 spike protein variants and evaluated the neutralizing ability of therapeutic mAbs. SPR characterisation can be facilitated in all stages of the product life cycle to ensure the quality and safety of mAbs and ADCs.

The Role of BioPhorum Extractables Data in the Effective Adoption of Single-U...

Regulatory expectation does require patient safety evaluations with supporting data for manufacturing components that directly come into contact with drug manufacturing process streams. Readily available extractables data can help manufacturers using singleuse technology to accelerate product qualifications, risk assessments and process optimization

This white paper guides you on how to save time and resources with supplier-provided single-use system extractables data and gives you an overview about the overall strategy for Extractables & Leachables. At the end you will find a case study.

Find more information about filters and single-use components on our website: https://www.sigmaaldrich.com/DE/en/services/product-services/emprove-program/emprove-filter-and-single-use-component-portfolio

The Future of Pharma- and Biopharmaceutical Audits

Watch the recording of this presentation here: https://bit.ly/3zTOpe4

Detailed description:

SARS-CoV-2 showed us that technology supports us during our inspection activity even if on-site visits are not possible. Travel restrictions of various kinds will remain a risk in the future. The use of new technologies has shown that inspections and audits can be carried out despite these restrictions. We will focus on what possibilities the new technologies offer and take a look at the future of inspections and audits.

In this webinar, you will learn:

• Regulatory overview of remote audits

• The technologies needed to support the audit process

• What types of inspections are possible with the use of these technologies

• How audits may look in the future

Presented by:

Daniel Buescher, Product Manager - Digital Solutions

Moving your Gene Therapy from R&D to IND: How to navigate the Regulatory Land...

Watch the recording of this presentation here: https://bit.ly/3SqOsoP

Novel therapies, including cell and gene therapies, continue to be central to innovation in healthcare and represent the fastest growing area of therapeutic medicine. As a consequence, the number of gene therapies undergoing clinical trials has increased significantly in the last five years.

Manufacturing processes for these novel therapeutics are very complex with a high risk of contamination. Regulatory agencies world-wide have responded by issuing guidance to outline their expectations for development and manufacture of cell and gene therapies. Currently, regulatory guidance is not harmonized globally and can often lead to confusion within industry and increased risk of non-compliance.

In this webinar, we'll answer:

• Which regulatory guidelines do you need to comply for your INDs?

• When do you start implementing GMPs and validated assays?

• How do you get your QC testing strategy ‘right the first time’?

• How do you ensure testing is not your rate limiting step for the IND submission?

Presented by:

Manjula Aysola, Senior Regulatory Consultant

Dr. Alison Armstrong, Sr. Director, Technical and Scientific Solutions

Identity testing by NGS as a means of risk mitigation for viral gene therapies

Watch the presentation of this webinar here: https://bit.ly/3RijkHC

Detailed description:

Imagine you’ve just completed a manufacturing run for your viral vector. Identity testing is performed to confirm the vector sequence. But when the results come back the data reveals unexpected sequence variants! With an appropriate risk mitigation testing strategy, this situation can be prevented.

The situation described above is not hypothetical, and happens more that you think, costing valuable time and resources.

Investigatory testing has shown that sequence variants present in starting materials (e.g. plasmids) are likely to make their way to the final product. Adequate identification of low-level variants with an appropriately sensitive method is critical in ensuring the quality of the final product. A risk-based testing strategy, in the context of identity, for viral vector manufacturing will be presented, focusing on key testing points. NGS assays for identity and variant detection will be highlighted due to their extremely sensitive nature compared to traditional approaches.

In this webinar, we'll explore:

• Regulatory requirements for identity testing

• NGS applications for identity testing as compared to traditional methods

• A case study on the impact of not establishing a proper risk-based testing strategy

Presented by: Bradley Hasson, Director of Lab Operations for NGS Services

Latest advancements of melt based 3D printing technologies for oral drug deli...

Watch the presentation of this webinar here: https://bit.ly/3A2WcH4

The application of polymer excipients in 3D printing manufacturing is usually limited due to the concerns of filament strength, high processing temperature and large scale manufacturing.

Latest technology developments are targeting a direct melt deposition to simplify the process and enable a constant and efficient process. Two different processing approaches will be presented:

The advanced melt drop deposition, where individual three dimensional geometries can be created by depostition of polymer droplets and the MED® 3D printing technology which allows by precise layer-by-layer deposition to produce objects with well-designed geometric structures.

In this webinar, you will learn:

• Latest advancements of melt based 3D printing approaches

• Application examples for the individual technologies

• Deep dive in the MED® 3D printing technology to design dedicated drug release profiles

Presented by:

Dr. Thomas Kipping, Head of Drug Carriers

Dr. Xianghao Zuo, Deputy Director of R&D, Triastek

CAR-T Manufacturing Innovations that Work - Automating Low Volume Processes a...

Watch the presentation of this webinar here: https://bit.ly/3NDNIKe

Automated, fit-for-purpose tools are essential in CAR-T processing to support sustainable manufacturing of clinical and market-approved cell therapy products. This webinar will discuss how the ekko™ Acoustic Cell Processing System uses acoustic technology as a touchless approach to manipulate cells, enabling a modular tool across the CAR-T manufacturing workflow. Typical performance of templated ekko™ System processes for DMSO washout of leukapheresis material, low volume and high cell concentrate for electroporation preparation, and harvest of expanded T cells will be reviewed.

This webinar will also give an early glimpse at the ekko™ Select System for unmatched T cell selection.

In this webinar, you will:

• Uncover how the ekko™ System supports the broad industrialization of cell therapy, with particular focus on how to achieve low volume, high concentrate cell product for critical transduction and transfection steps

• Discover how ekko™ System for wash and concentrate processes throughout the cell therapy workflow achieve high cell recovery, viability, and effective residual removal

• Preview to ekko™ Select, our cell therapy selection platform, to achieve unmatched ease-of-use with direct processing from leukopaks reducing the need for preparation steps

Presented by:

Benjamin Ross-Johnsrud, Acoustic Technology Expert

Robert Scott, Mechanical Engineer III

How does the ICH Q5A revision impact viral safety strategies for biologics?

Watch the presentation of this webinar here: https://bit.ly/3t7X9tg

How does the ICH Q5A revision impact viral safety strategies for biologics?

Biologics continue to grow at a fast pace. Manufactured using cell lines of human or animal origin, these are at risk of viral contamination making safety strategies critical. A comprehensive risk mitigation strategy using multiple orthogonal measures is a regulatory expectation. ICH Q5A, the globally-harmonized guideline outlines the expectations. ICH Q5A is currently being revised to address recent scientific advancements including novel therapeutic modalities, new manufacturing paradigms, updates in viral clearance applications, and alternate detection technologies. We’ll discuss the expected changes and potential impact on viral safety strategies with case studies and examples.

In this webinar, you will learn about:

• The Importance of virus testing in biologics products

• Regulatory landscape, expectations for the Q5A revision

• What's new and changing

• Examples of alternate testing schedules, impact on viral clearance

Presented by:

Manjula Aysola, Senior Regulatory Consultant

Alison Armstrong, PhD, Sr. Director, Technical and Scientific Solutions

Improve Operational Efficiency by Over 30% with Product, Process, & Systems A...

Watch the presentation of this webinar here: https://bit.ly/3adaxWh

When implementing new automation systems, organizations must consider things like deployment time, user adoption, and costs.

They must also consider the cost of doing nothing – that is, what competitive advantage is lost in standing still? What time and quality is lost in repetitive, manual tasks rather than an automated, digital workflow? What operational efficiencies are lost?

In this webinar we examine how a product, process, and system agnostic automation platform can be deployed faster than traditional system specific software while bringing greater operational efficiencies (in many cases over 30% improvement).

To remain competitive in the market, biopharma manufacturers must adopt automation and digital technologies, but most plants still have island of automation consisting of independently functioning, standalone unit operations. This results in operational inefficiency, regulatory concerns, and a poor understanding of the process and product life cycle.

Taking the first, right step must include considering risks, costs, timelines, and technology alternatives. Traditional automation approaches tied to specific systems, processes, and products are, by their nature, limited; while an agnostic platform will address current biomanufacturing business challenges and ensure future readiness. With the right platform, a phased automation implementation can yield operational efficiency gains of up to 30% and improved product quality and regulatory compliance.

In this webinar, let's explore:

• Challenges of automation and digital technology adoption

• What a product, process, and system agnostic platform entails

• Applications and benefits of a process orchestration platform

• Ensuring future readiness with process orchestration

Presented by:

Braj Nandan Thakur, Global Product Manager - Automation

Insights from a Global Collaboration Accelerating Vaccine Development with an...

Watch the presentation of this webinar here: https://bit.ly/3Nbb5ug

Get insights and best practices from a multinational team establishing a platform for vaccine production. See how a long-term collaboration on a bench-scale process used to produce a Virus Like Particle (VLP) vaccine for SARS-CoV-2 was successfully converted to a robust GMP-compatible, scalable process.

The COVID-19 pandemic further emphasized the need for collaboration in the development of urgently needed vaccines and therapeutics. In this webinar, we take you behind the scenes of our collaboration with Technovax and Innovative Biotech in which a scalable VLP vaccine platform was optimized for use in a production facility in Nigeria in response to the need for local production of SARS-CoV-2 vaccines. The flexibility and robustness of the platform will enable its rapid deployment to support the West African pandemic readiness program. Initial development of the VLP process began in late 2019 and by March 2020, was already adapted for production of a SARS-CoV-2 vaccine.

In this webinar, you will learn:

• About building a priceless collaborative network with integrated solutions

• Virus-Like Particle Vaccines

• Process Development Overview and Challenges

• Pre-clinical Results and Next Steps

Presented by:

Jose M. Galarza, PhD,

President and Founder of TechnoVax

Naomi Baer,

Business development consultant, Emerging Biotech, BioProcess division

Youssef Gaabouri, Eng. ,

Associate Director, Head of Sales Middle East & Africa, BioProcess division

Risk-Based Qualification of X-Ray Sterilization for Single-Use Systems

Watch the presentation of this webinar here: https://bit.ly/3vQf0qv

In the single-use bioprocess industry, X-ray irradiation warrants consideration as an alternate sterilization technology. Using a risk-based qualification testing strategy is important when evaluating and implementing equivalent ionizing irradiation sterilization methods.

The urgent need for life-saving therapies as a result of the global pandemic has reinforced the criticality of flexibility in pharmaceutical manufacturing, including sterilization. The single-use bioprocess industry traditionally has employed gamma irradiation sterilization. X-ray irradiation is being considered as an additional sterilization technology for business and supply continuity. We will share a risk-based qualification testing strategy including Extractables and data generated to support comparability of gamma irradiation and X-ray irradiation as equivalent ionizing irradiation sterilization methods.

In this webinar, you will learn about:

• The comparison of gamma and X-ray irradiation sterilization

• A risk-based qualification test strategy

• Data evaluation of gamma versus X-ray sterilized single-use components

Presented by:

Monica Cardona,

Global Senior Program Manager

Paul Killian, Ph.D.,

R&D Director, Analytical Technologies

Rapid Replication Competent Adenovirus (rRCA) Detection: Accelerate your Lot ...

Watch the presentation of this webinar here: https://bit.ly/3MJ4u9V

Testing for presence of replication competent adenovirus (RCA) is a key component to ensure patient safety and a requirement for all biologicals manufactured using adenoviral vectors. For many adenoviral-based products, the RCA assay is a rate-limiting assay for lot release.

Join this webinar to learn about a rapid RCA detection assay currently in development, which combines a 7-day culture assay with a highly sensitive molecular endpoint specific for RCA. The method can detect presence of as little as 1 RCA in adenoviral vector material at an approximate concentration of 5x107 - 2x108 vector particles (VP)/mL, making it a suitable method to meet regulatory requirements while accelerating your lot release timelines.

In this webinar, you will learn about:

• Regulatory framework for adenoviral vector products

• Considerations for lot release testing of adenoviral-based therapies

• Advantages of a rapid method for RCA testing on production lot material

Presented by:

Axel Fun, Ph.D.,

Principal Scientist

Alberto Santana, MBA,

Product Manager, Biologics Biosafety Testing

The High Intensity Sweeteners Neotame and Sucralose: 2 Ways to ace the Patien...

Watch the presentation of this webinar here: https://bit.ly/3vQyN7K

Bitter medicines are an important issue, especially for pediatric applications. As several APIs have bitter tasting components, high intensity sweeteners for taste optimization are of great interest. Join our webinar to discover our new sweetener toolbox enabling safe and stable formulations.

Mask bitter aftertaste for a sweeter pill to swallow! Patients’ compliance and the therapeutic benefit are supported by a pleasant taste of pharmaceutical formulations. With the high intensity sweeteners Neotame and Sucralose, you have efficient tools at hand which are superior to other sweeteners in many aspects:

• excellent sugar-like taste profile

• outstanding sweetness factors