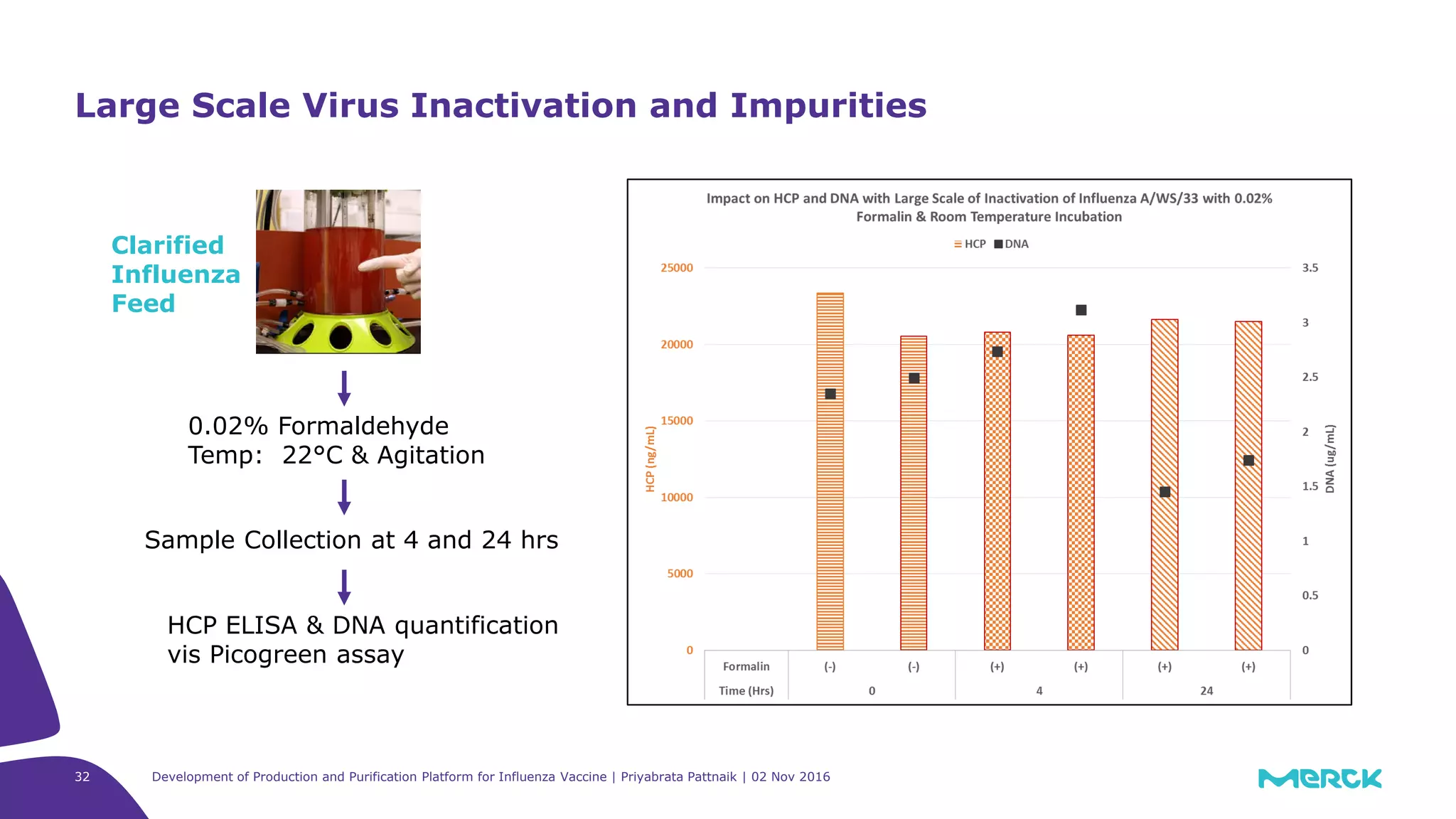

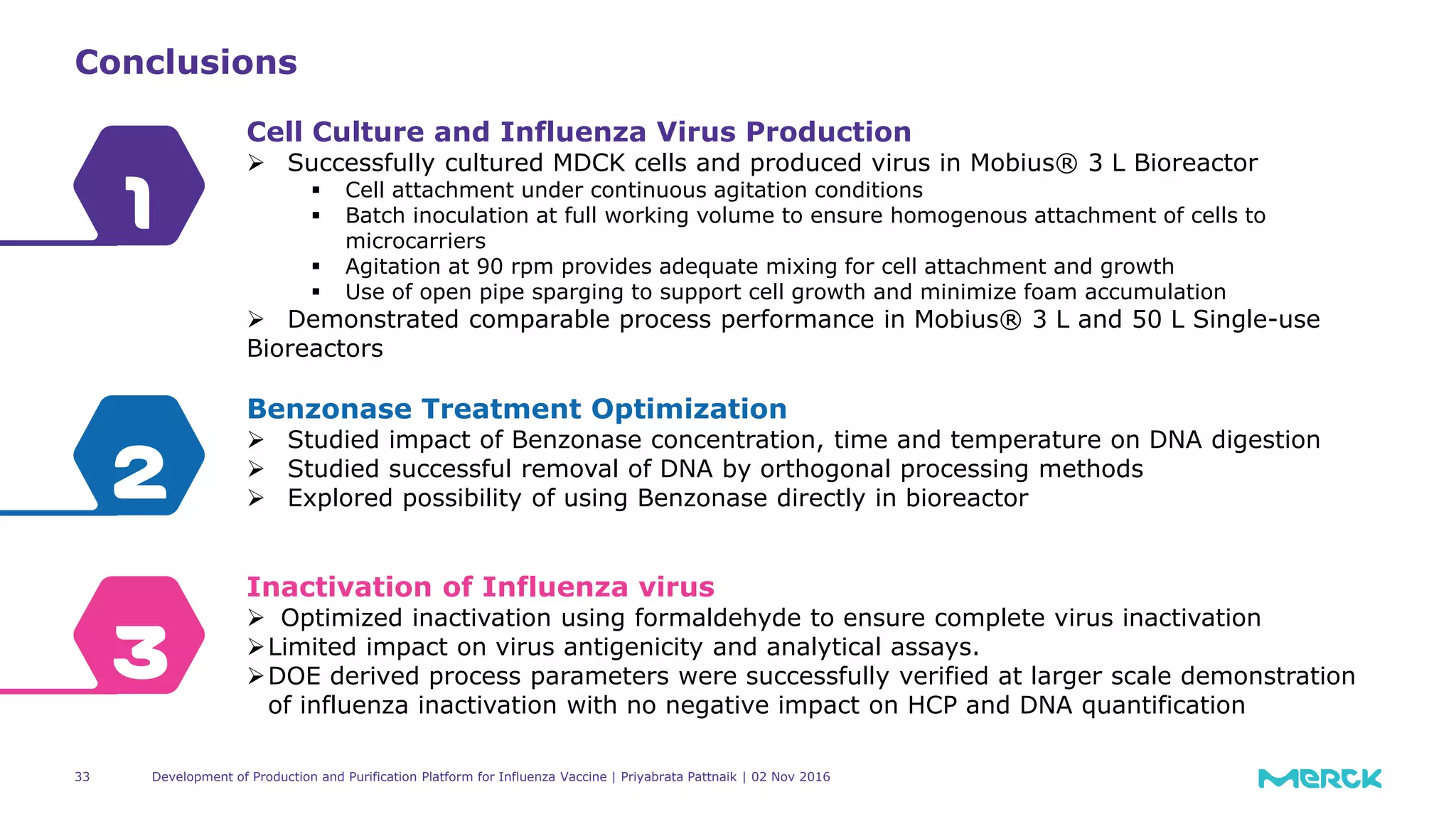

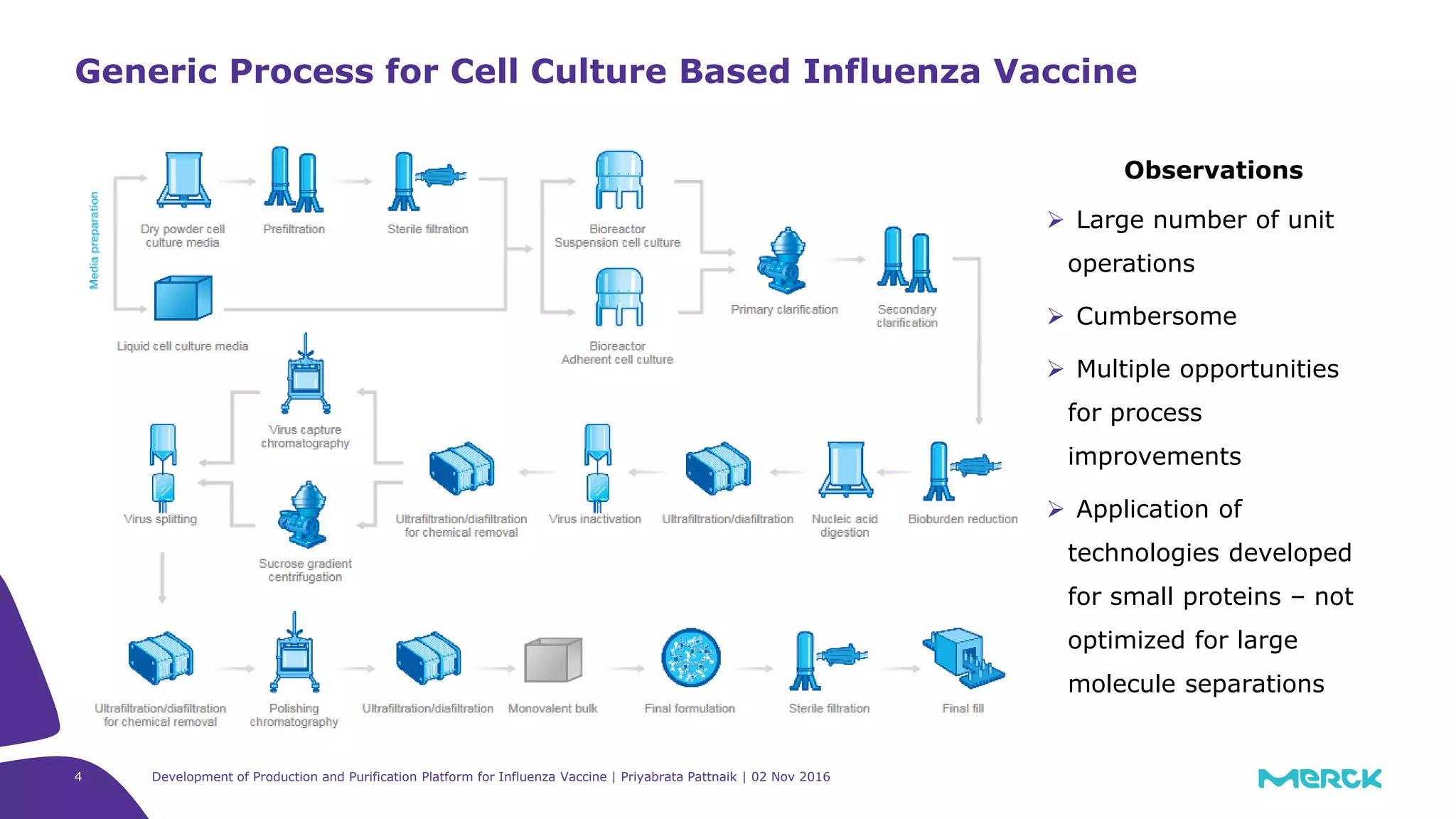

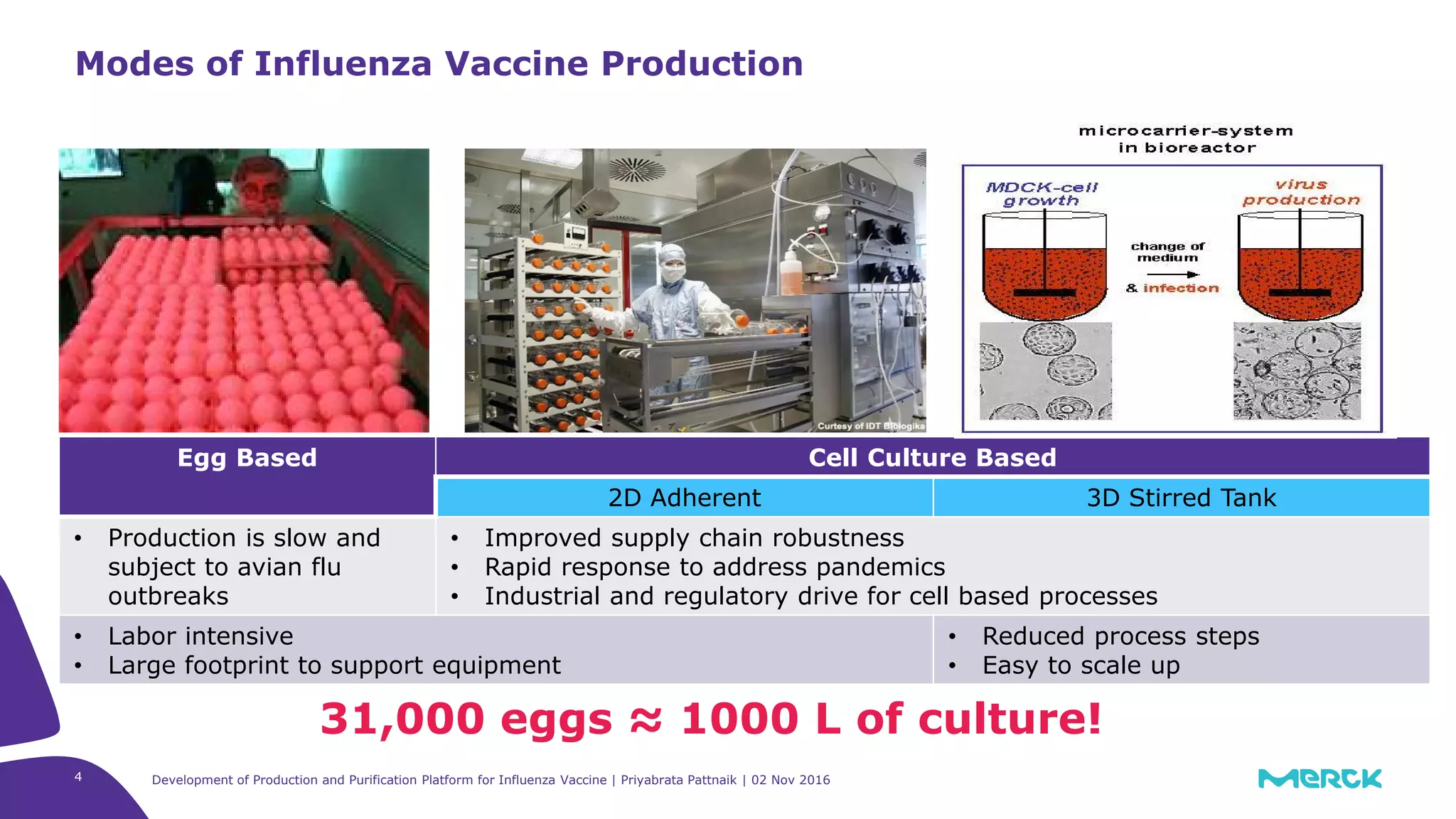

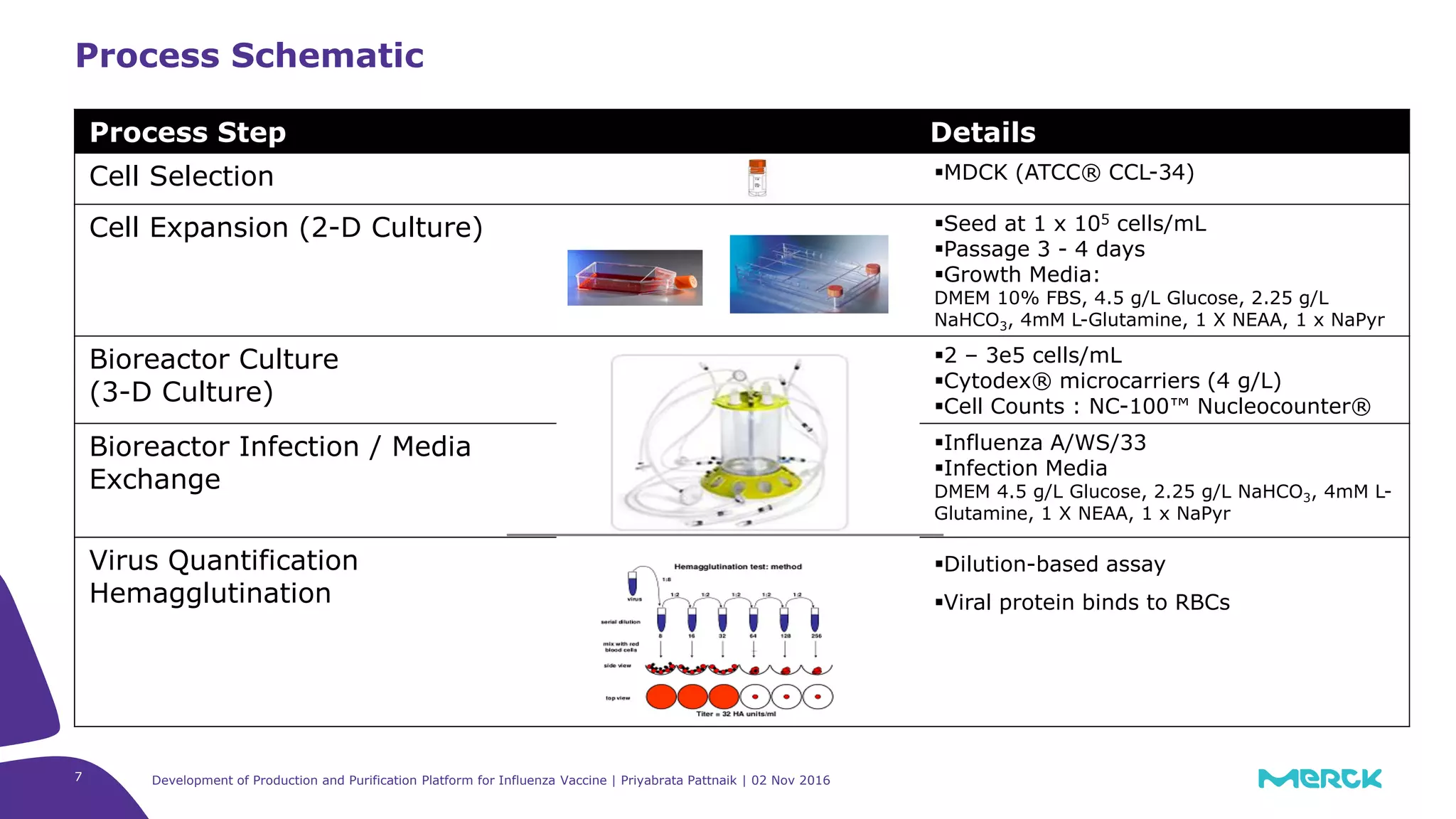

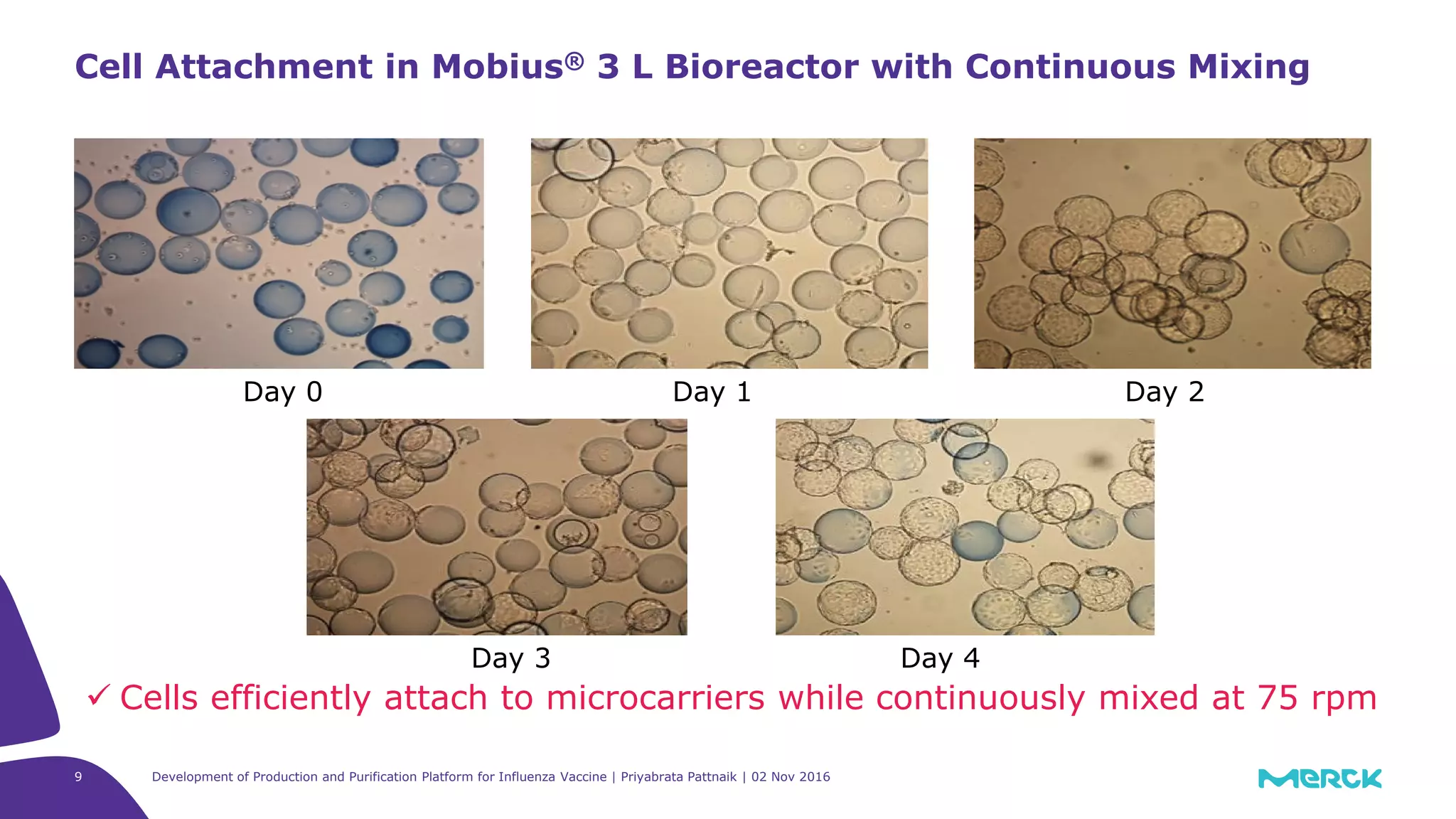

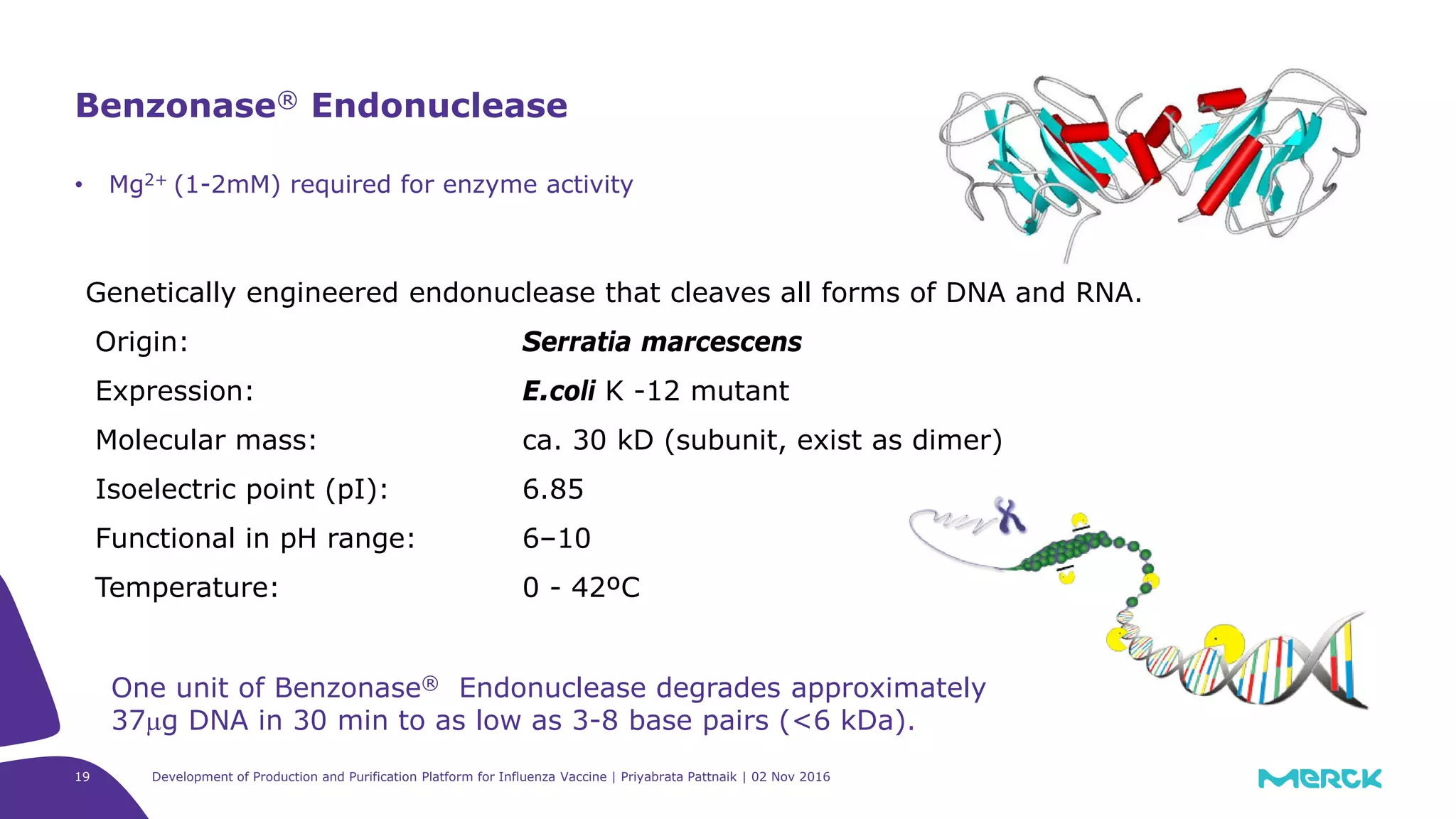

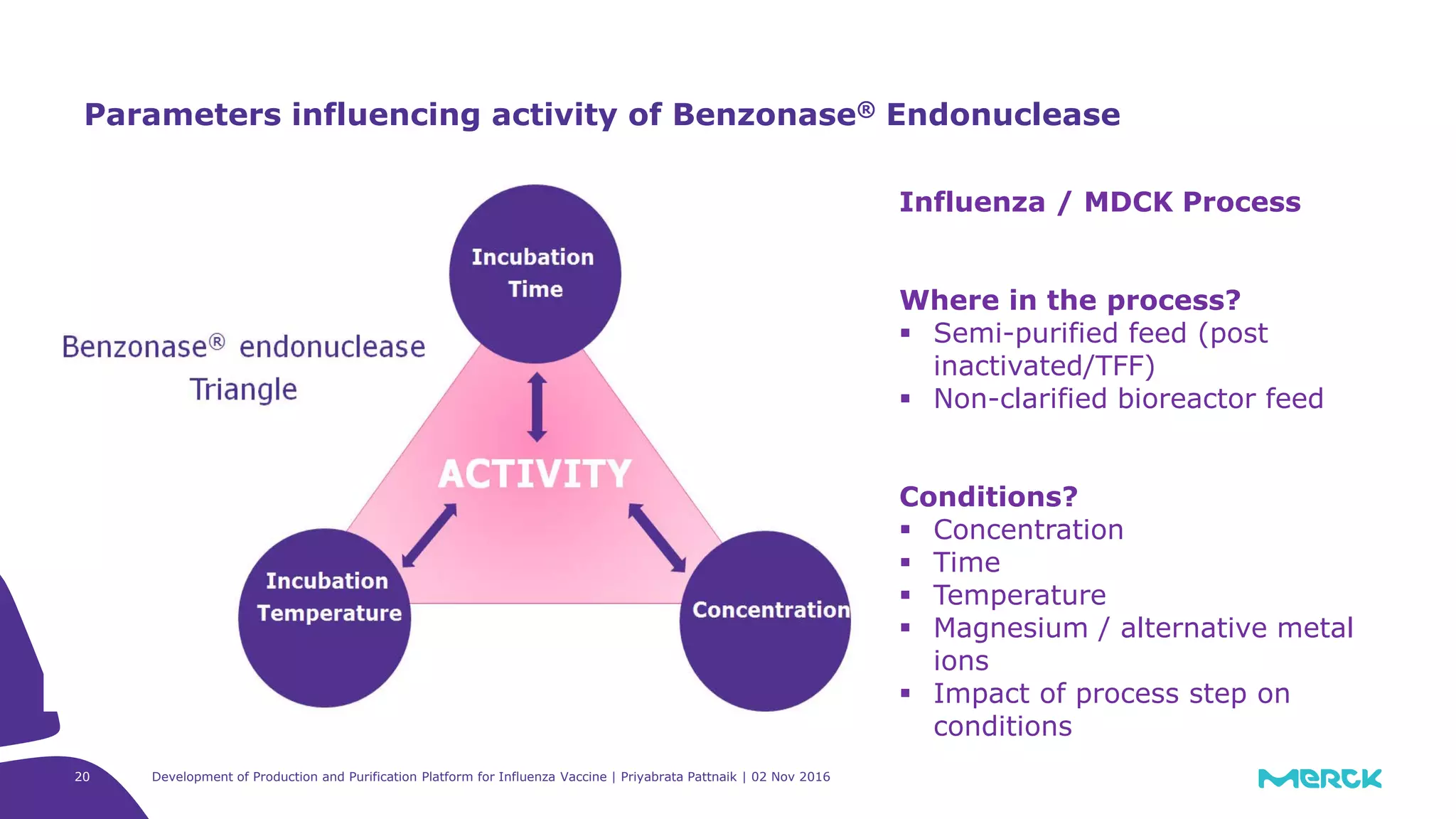

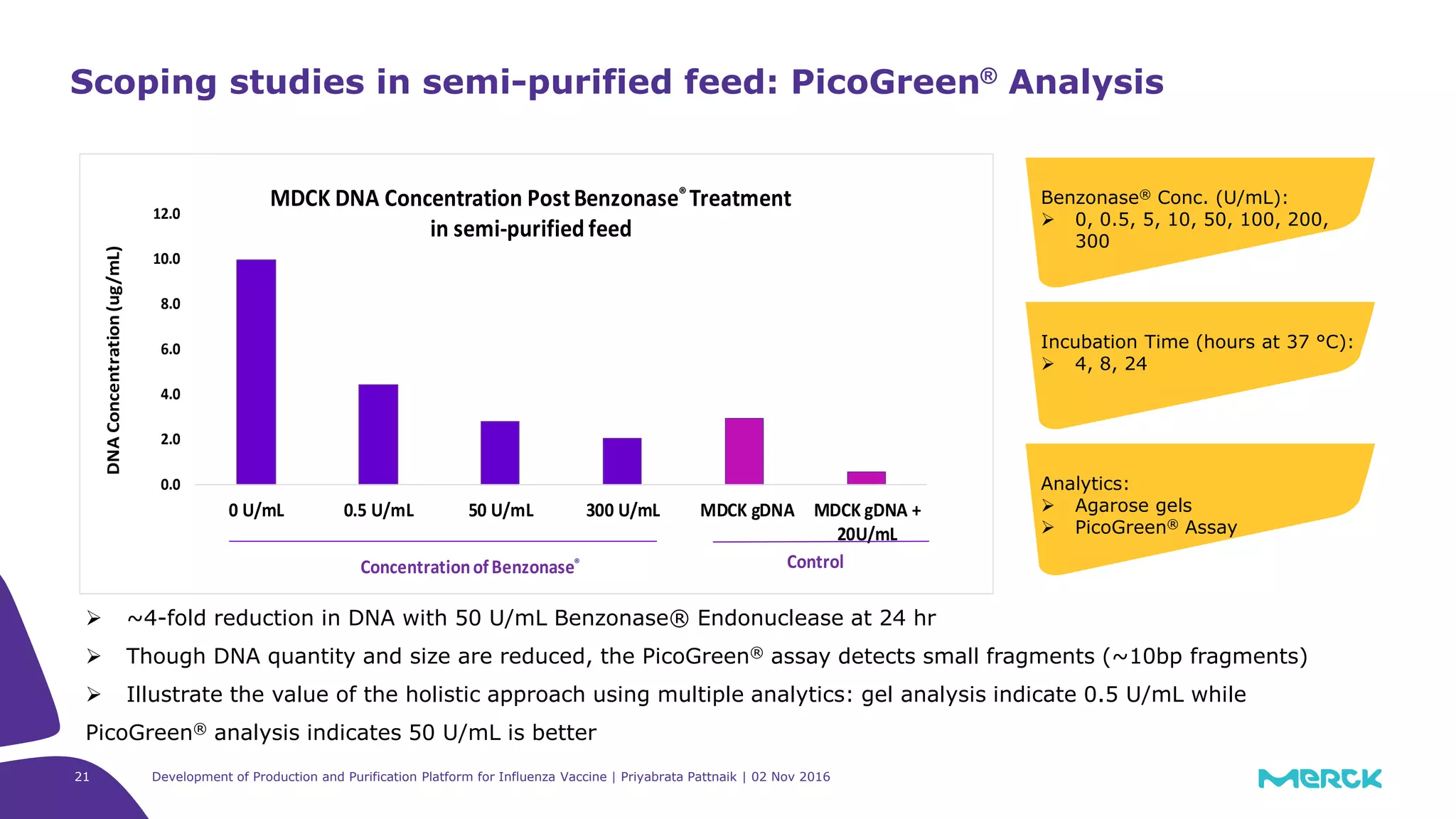

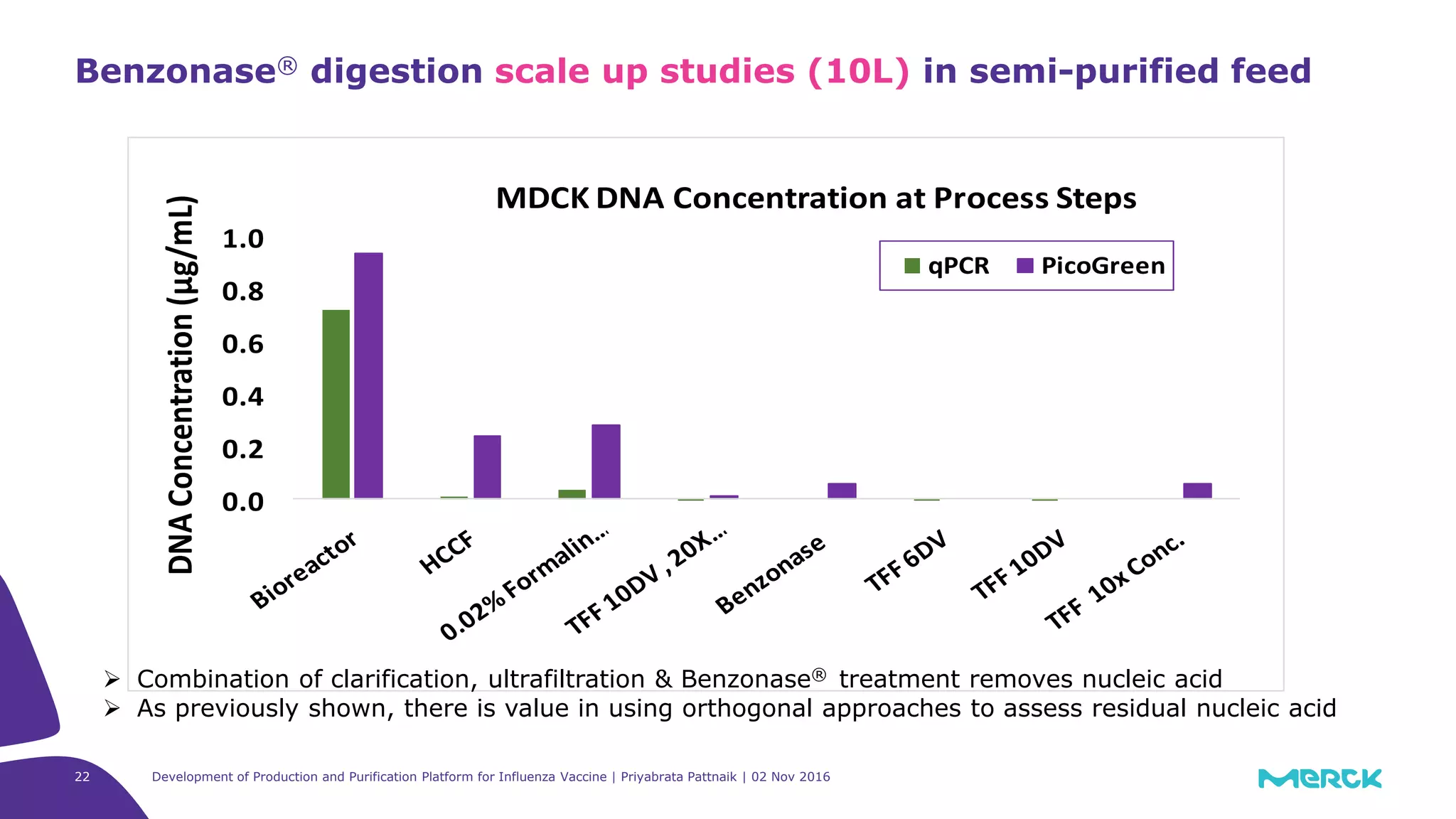

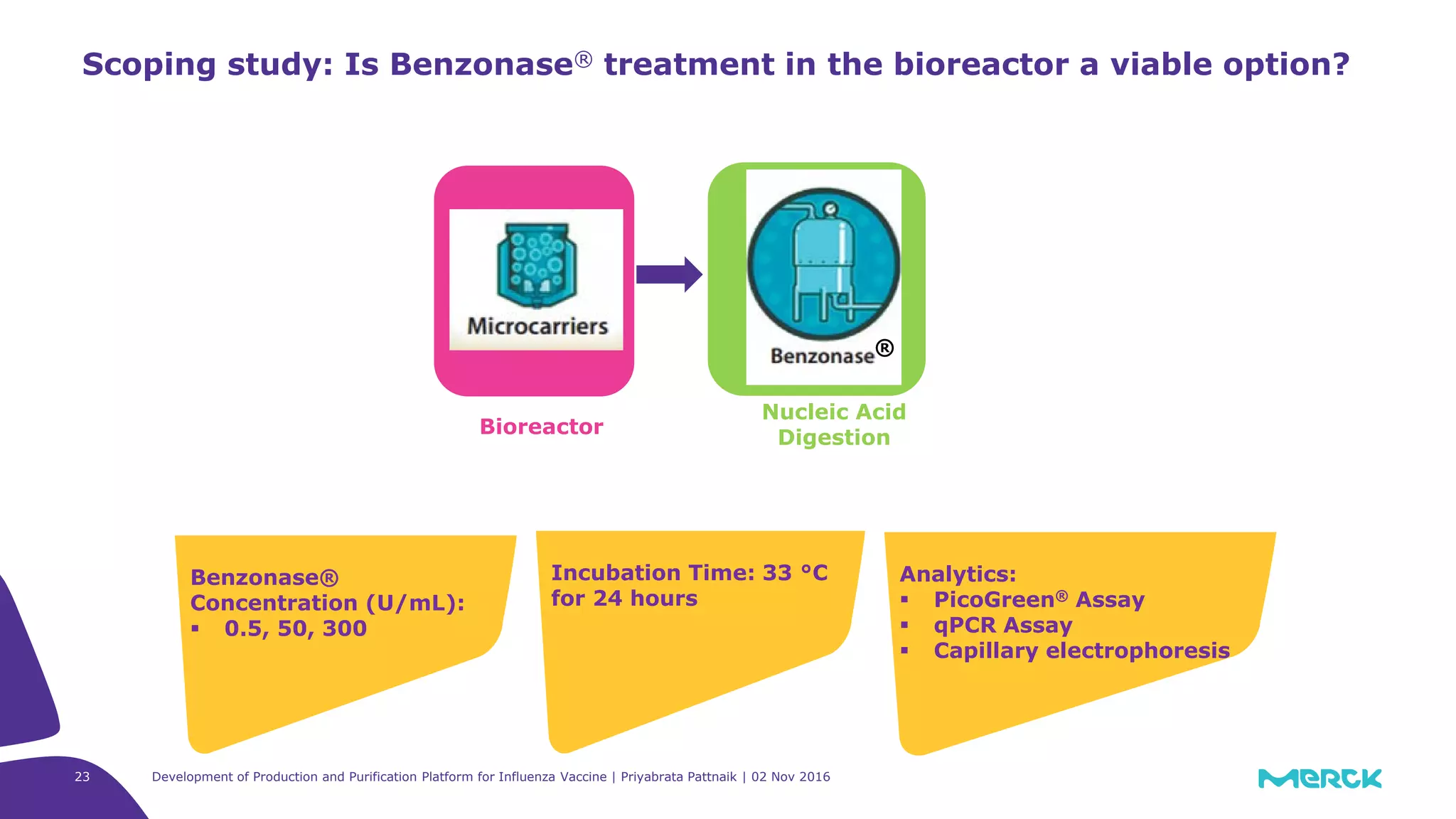

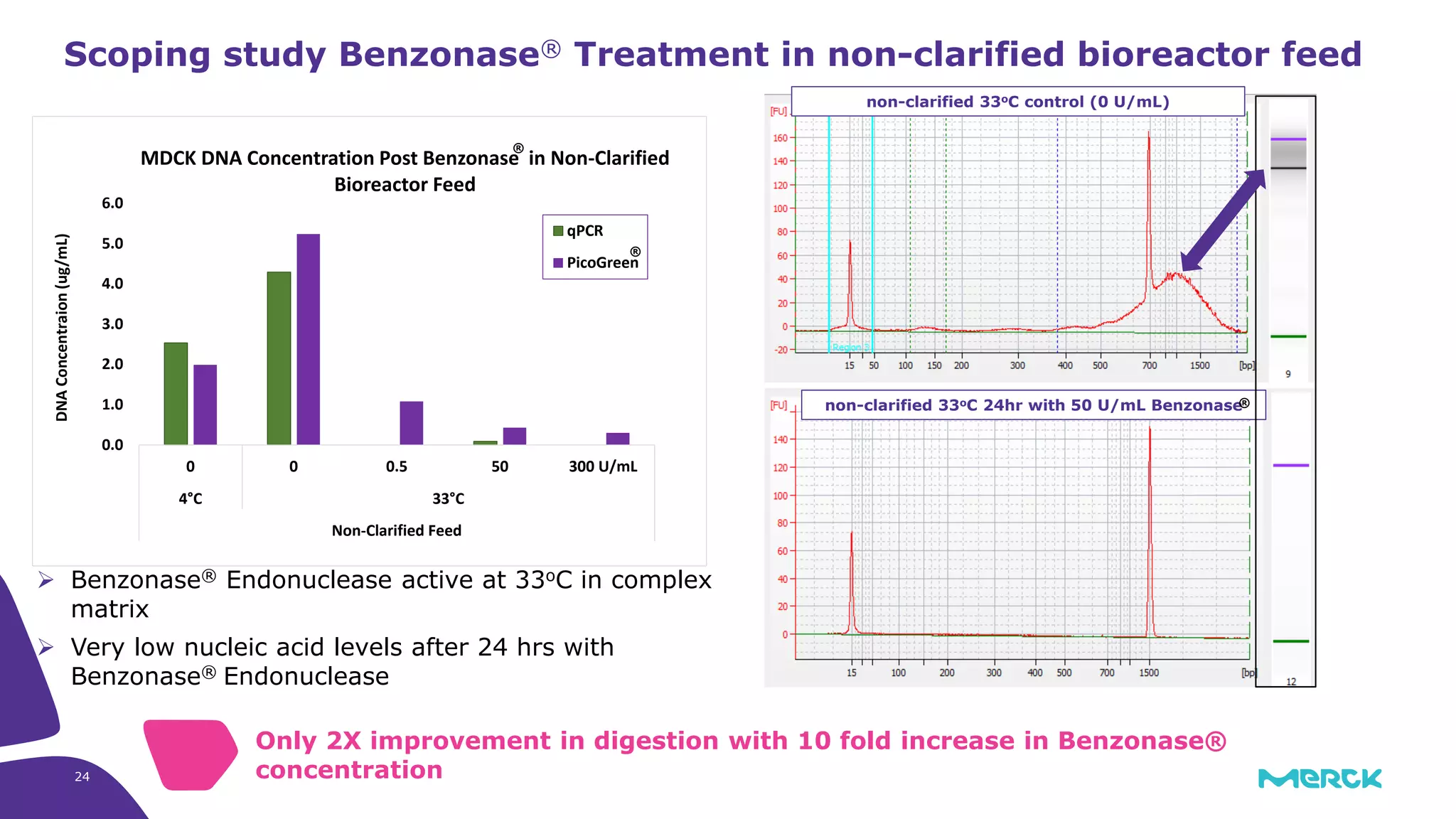

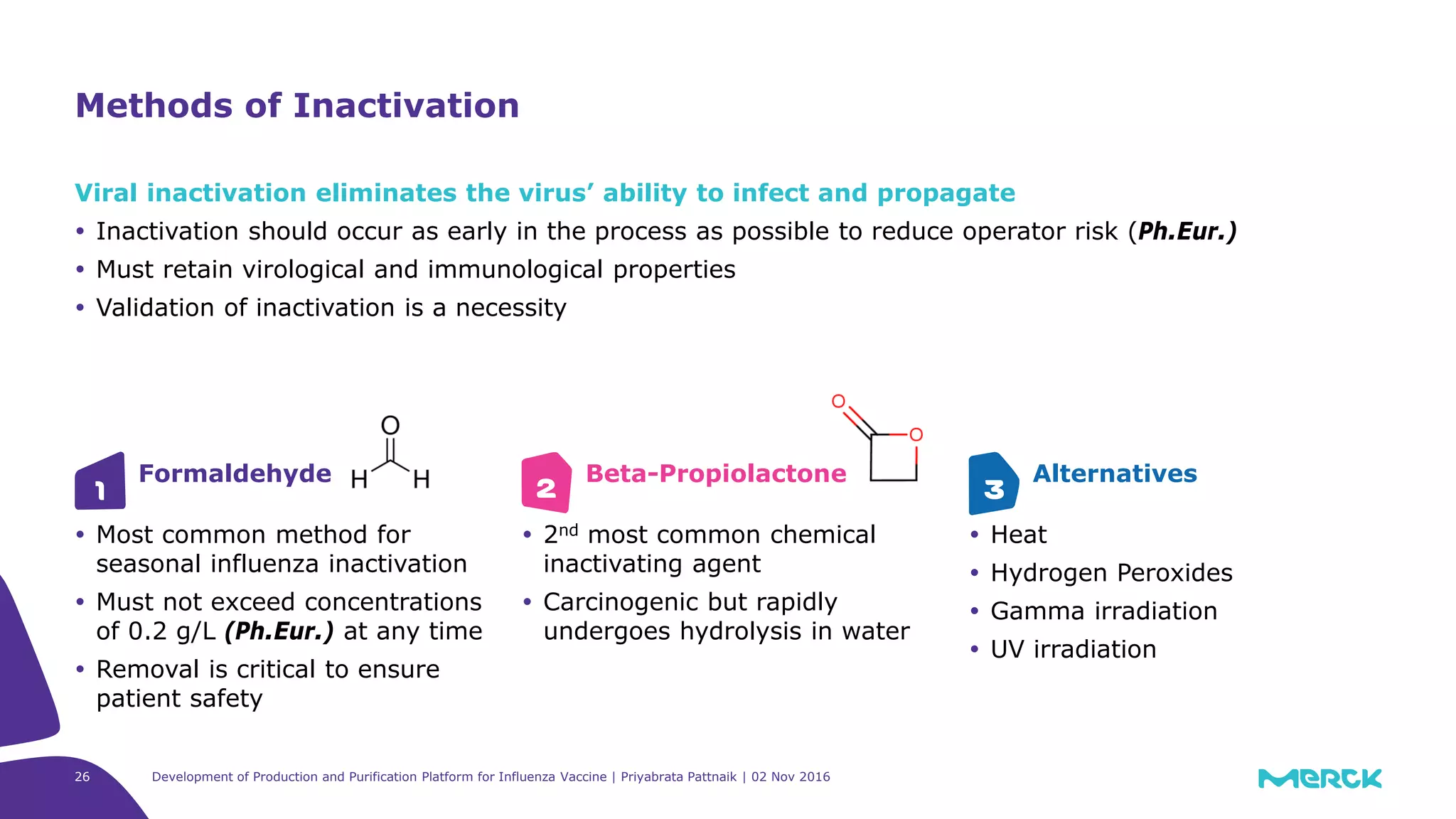

The document details the development of a production and purification platform for influenza vaccines, including upstream virus production, DNA removal using benzonase® treatment, and formaldehyde-based virus inactivation methods. It highlights improvements in cell culture techniques, bioreactor optimization, and the effects of various parameters on productivity and safety. Conclusions emphasize the effectiveness of process enhancements and the significance of monitoring viral inactivation to ensure patient safety.

![Annual Vaccine

HA protein (most common)

Typically 3-4 varieties (valences)

Dosage info (0.5mL/dose)

− HA: 15μg of each HA protein

− Formaldehyde: ≤ 200ppm

− Endotoxin: < 100 IU/dose

− Other protein: < 6 x HA content (< 300 μg/dose)

− DNA: < 10ng/dose

− Purity: 95% by gel (Coomassie blue)

Background

Influenza

3

80-120 nm enveloped virus

By National Institutes of Health; originally uploaded to en.wikipedia by TimVickers (25 October 2006),

transferred to Commons by Quadell using CommonsHelper. (California Department of Health Services) [Public

domain], via Wikimedia Commons

Development of Production and Purification Platform for Influenza Vaccine | Priyabrata Pattnaik | 02 Nov 2016](https://image.slidesharecdn.com/devofprodpurificplatformforinfluenzavaccinepattnaik-161115141406/75/Development-of-Production-and-Purification-Platformform-for-Influenza-Vaccine-3-2048.jpg)

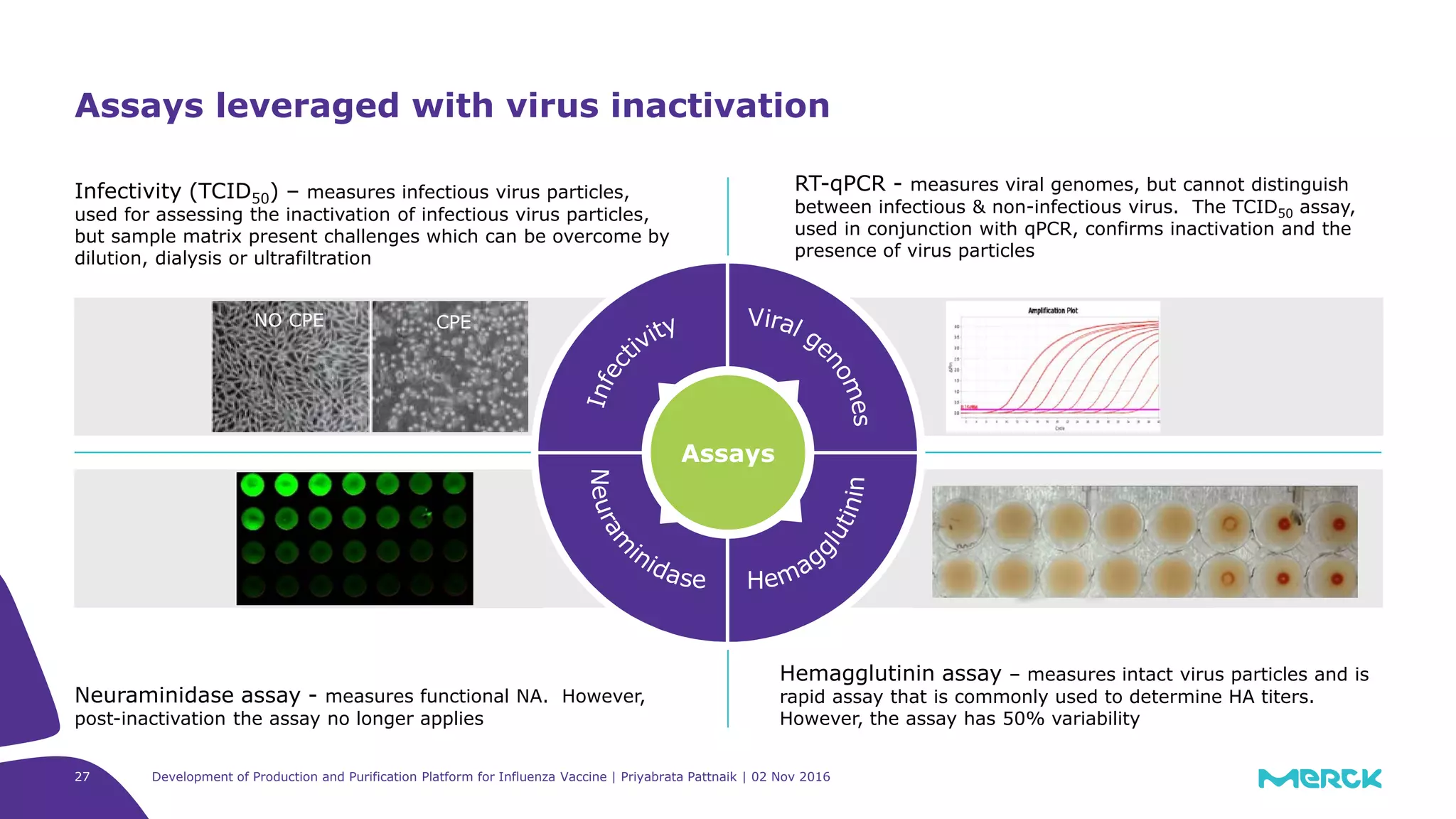

![Full factorial design

3 factors: [formaldehyde], incubation time and

temperature

Varying levels of each factor

5 x 2 x 4 factorial

Experimental setup

Clarified MDCK-based influenza feedstream

Shaker flasks with agitation

Responses

Infectivity assay (TCID50) performed for confirmation

of inactivation of Influenza

Influenza RT-qPCR analysis conducted for presence of

viral genomic RNA before and after inactivation

HA assay performed for hemagglutinin titer (Assay

variability of 50%)

Experimental Design and Responses

Development of Production and Purification Platform for Influenza Vaccine | Priyabrata Pattnaik | 02 Nov 201628

RT = 22°C-23°C](https://image.slidesharecdn.com/devofprodpurificplatformforinfluenzavaccinepattnaik-161115141406/75/Development-of-Production-and-Purification-Platformform-for-Influenza-Vaccine-28-2048.jpg)

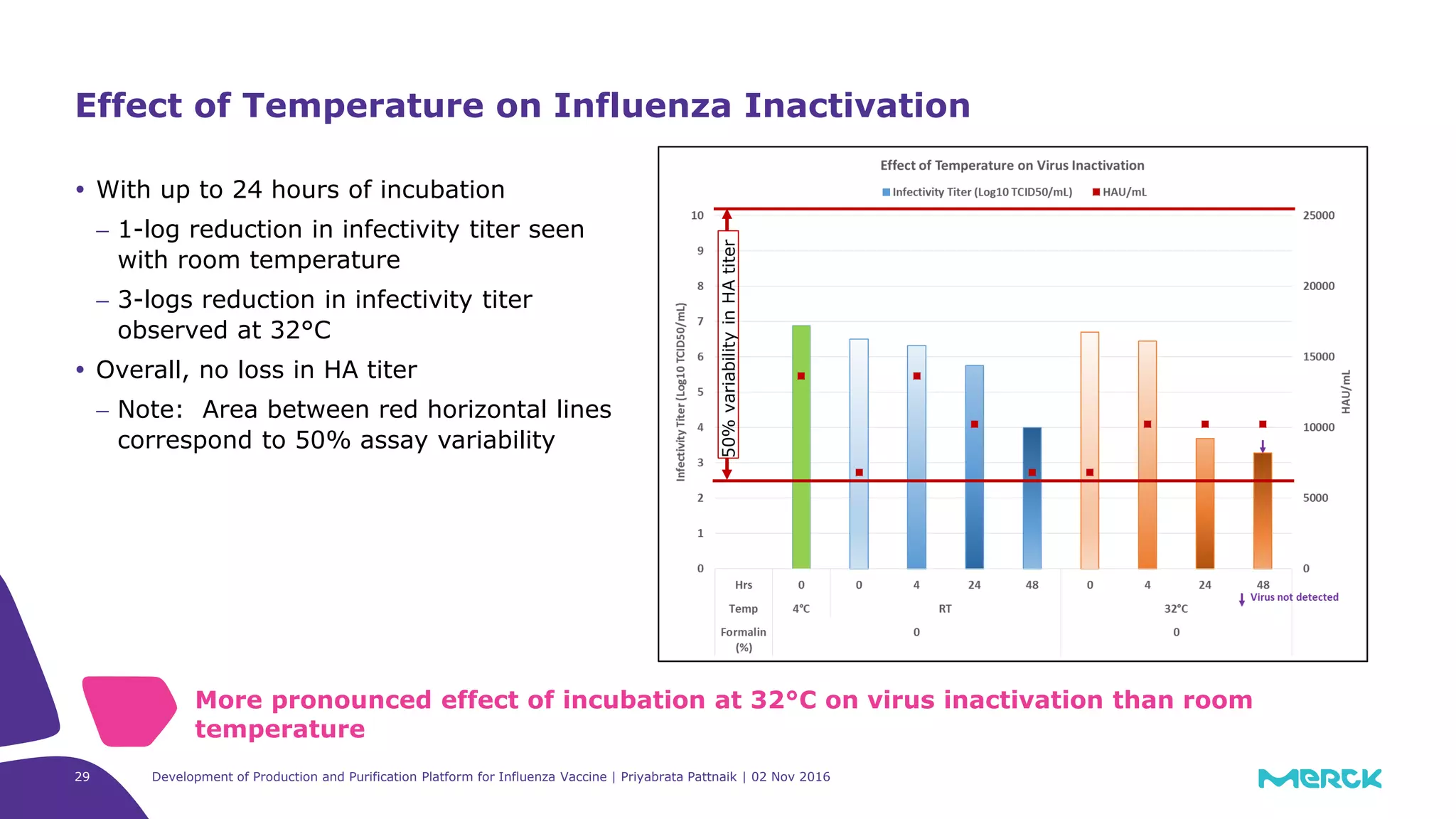

![Development of Production and Purification Platform for Influenza Vaccine | Priyabrata Pattnaik | 02 Nov 201630

5-logs reduction in infectivity titer with

0.02% formaldehyde and 4 hour incubation

at room temperature

No loss in HA titer overall

− Even with increasing [formaldehyde] and

extended incubation time

− Note: Area between red horizontal lines

correspond to 50% assay variability

Effect of Room Temperature and Formaldehyde on Influenza

Inactivation

Influenza inactivation achieved with lowest [formaldehyde] and shortest incubation

time

50%variabilityinHAtiter](https://image.slidesharecdn.com/devofprodpurificplatformforinfluenzavaccinepattnaik-161115141406/75/Development-of-Production-and-Purification-Platformform-for-Influenza-Vaccine-30-2048.jpg)

![Development of Production and Purification Platform for Influenza Vaccine | Priyabrata Pattnaik | 02 Nov 201631

6-logs reduction in infectivity titer with

0.02% formaldehyde and 4 hour incubation

at 32°C

Detrimental effect on HA titer with highest

[formaldehyde] and prolonged incubation

time

− 0.2% formaldehyde for 24 hours

− 0.2% and 0.1% formaldehyde for 48 hours

− Note: Area between red horizontal lines

correspond to 50% assay variability

Effect of 32°C Temperature and Formaldehyde on Influenza

Inactivation

Influenza inactivation achieved with lowest [formaldehyde] and shortest incubation

time

50%variabilityinHAtiter](https://image.slidesharecdn.com/devofprodpurificplatformforinfluenzavaccinepattnaik-161115141406/75/Development-of-Production-and-Purification-Platformform-for-Influenza-Vaccine-31-2048.jpg)