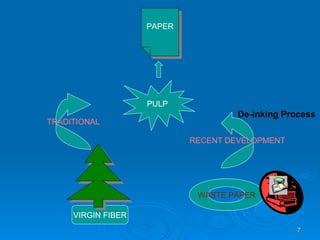

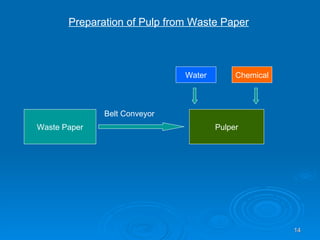

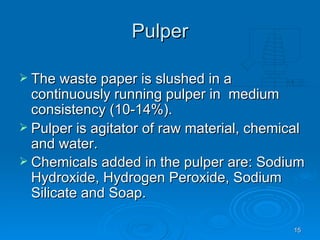

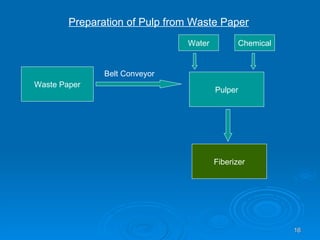

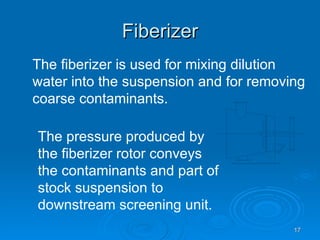

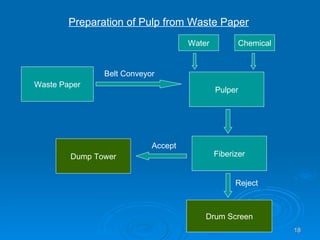

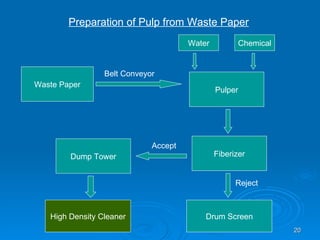

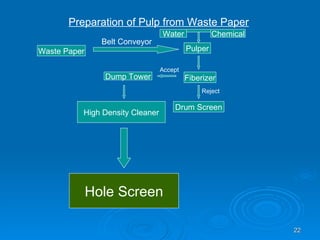

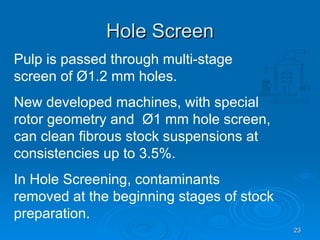

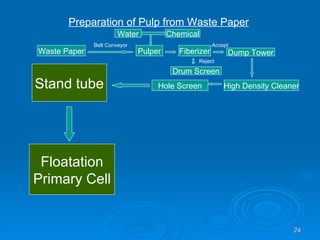

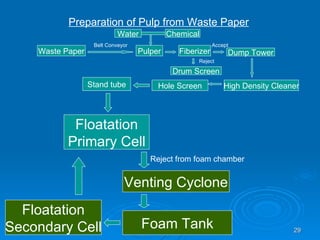

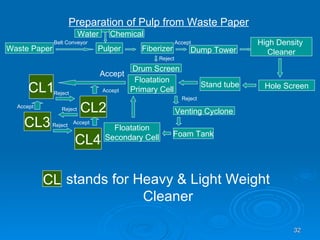

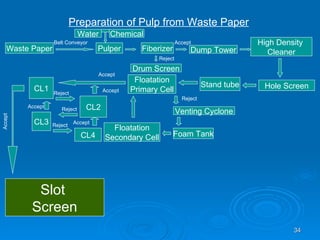

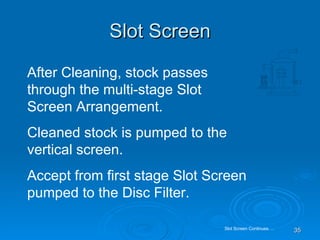

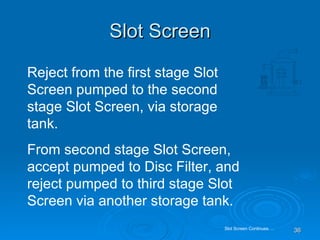

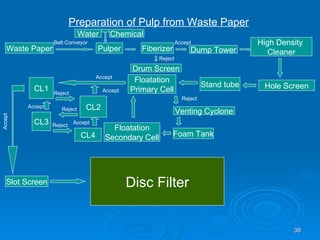

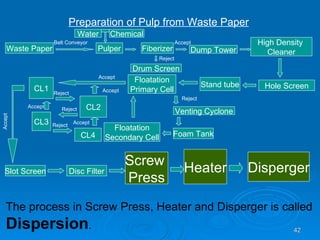

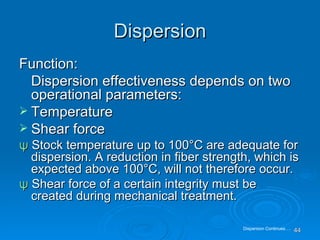

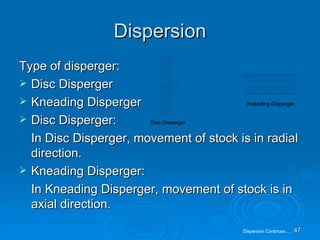

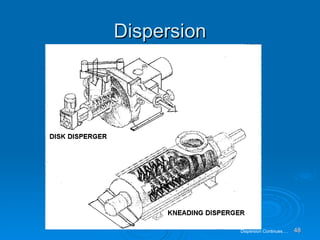

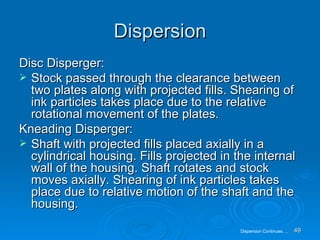

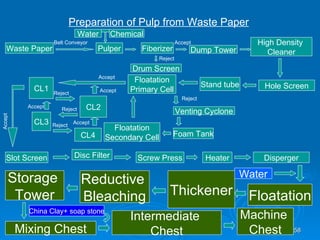

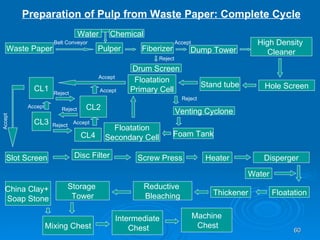

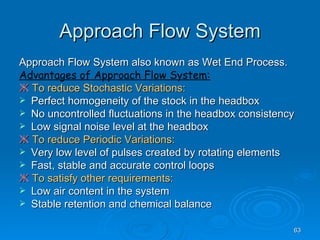

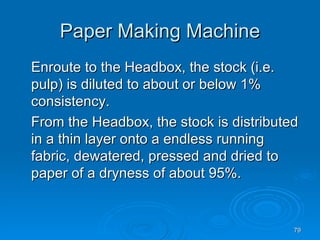

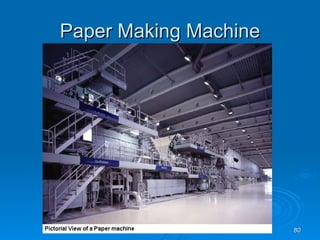

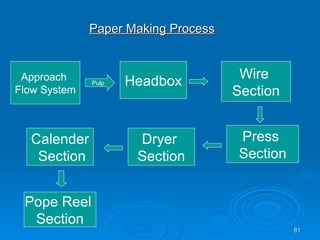

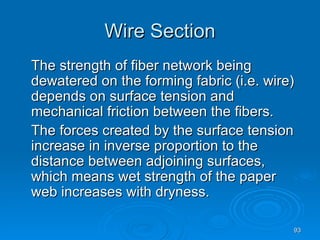

The document provides an overview of the paper-making process, detailing the stages from pulp preparation to the final paper product, facilitated by mechanical engineer Nirjhar Chakravorti. It describes the various methods used to create pulp from waste paper, including treatment processes and equipment involved in stock preparation, flotation, and dispersion. The paper industry in India is highlighted for its growth, despite low usage compared to global averages, and the process is presented as essential for understanding paper production technology.

![THANK YOU Please send your suggestion at [email_address] or [email_address]](https://image.slidesharecdn.com/papertechbasicnirjhar-090730104200-phpapp01/85/Paper-Making-Process-by-Nirjhar-122-320.jpg)