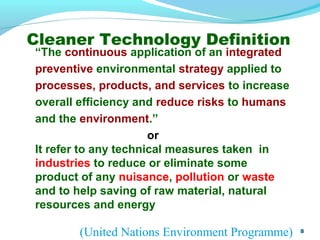

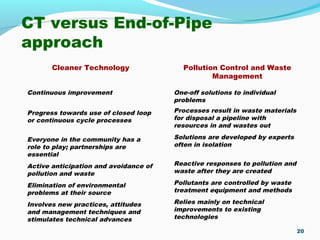

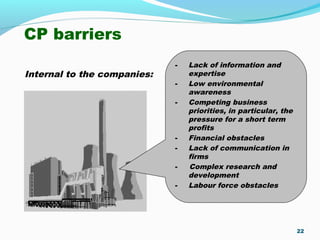

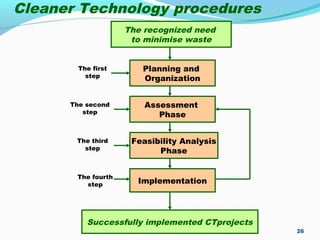

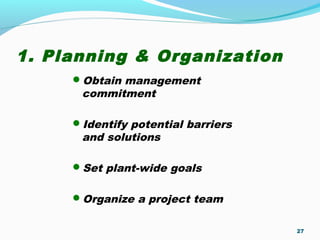

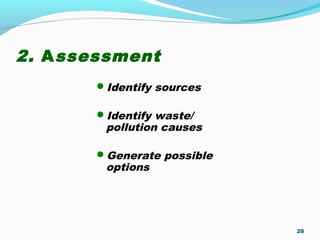

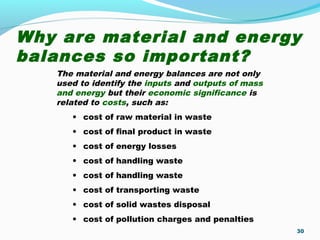

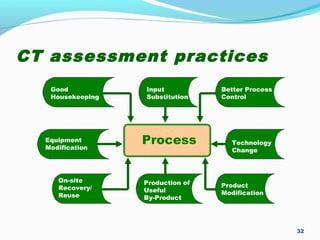

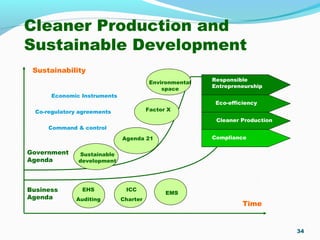

This document discusses cleaner technology and waste reduction strategies. It defines cleaner technology as the continuous application of preventative strategies to increase efficiency and reduce risks. It discusses various cleaner technology practices like good housekeeping, input substitution, and technology changes. The benefits of cleaner technology include improving the environment, increasing economic benefits and productivity, and gaining competitive advantage. Barriers include a lack of information and competing priorities, while drivers include improvements in productivity and environmental reports.