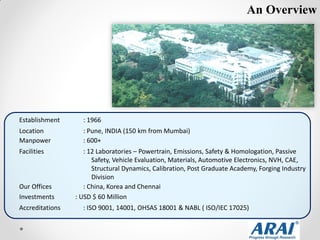

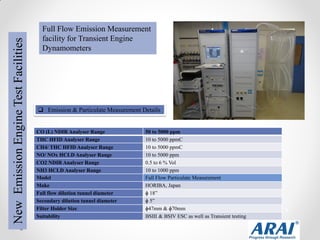

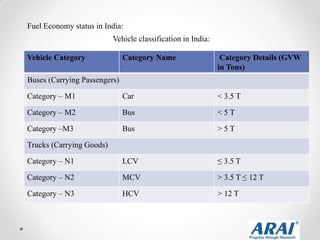

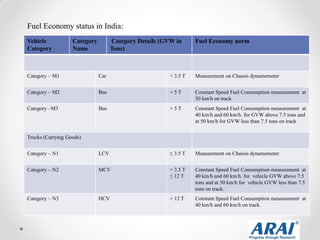

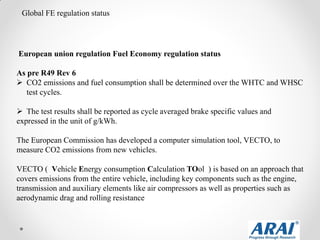

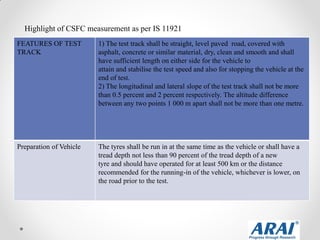

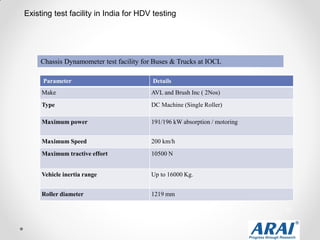

This document summarizes a workshop on heavy-duty fuel efficiency regulations held on April 29th, 2015. It provides an overview of ARAI, the Automotive Research Association of India, including their emission test facilities. It then discusses the status of fuel economy regulations in India, other countries, and at a global level. Highlights of the Indian emission standard IS 11921 are presented. Finally, it proposes a roadmap for developing heavy-duty vehicle fuel economy standards in India and lists existing heavy-duty vehicle testing facilities in the country.