Embed presentation

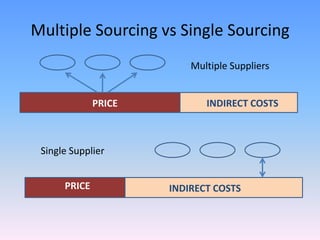

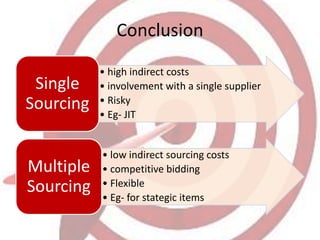

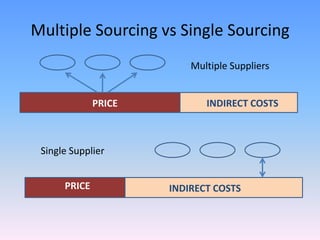

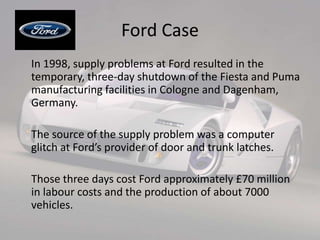

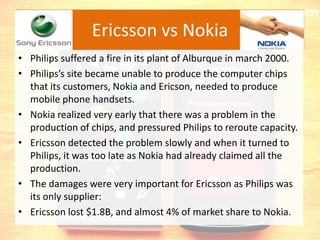

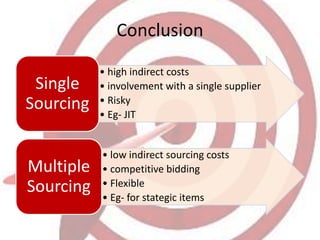

The document discusses the differences between multi-sourcing and single-sourcing in supply chains, highlighting the risks and financial implications of each approach. It cites case studies, including Ford's costly disruption due to a supplier's computer glitch and Ericsson's significant losses from relying solely on Philips for chip production following a fire. The conclusion emphasizes the importance of building a resilient supply chain to mitigate risks associated with disruptions.