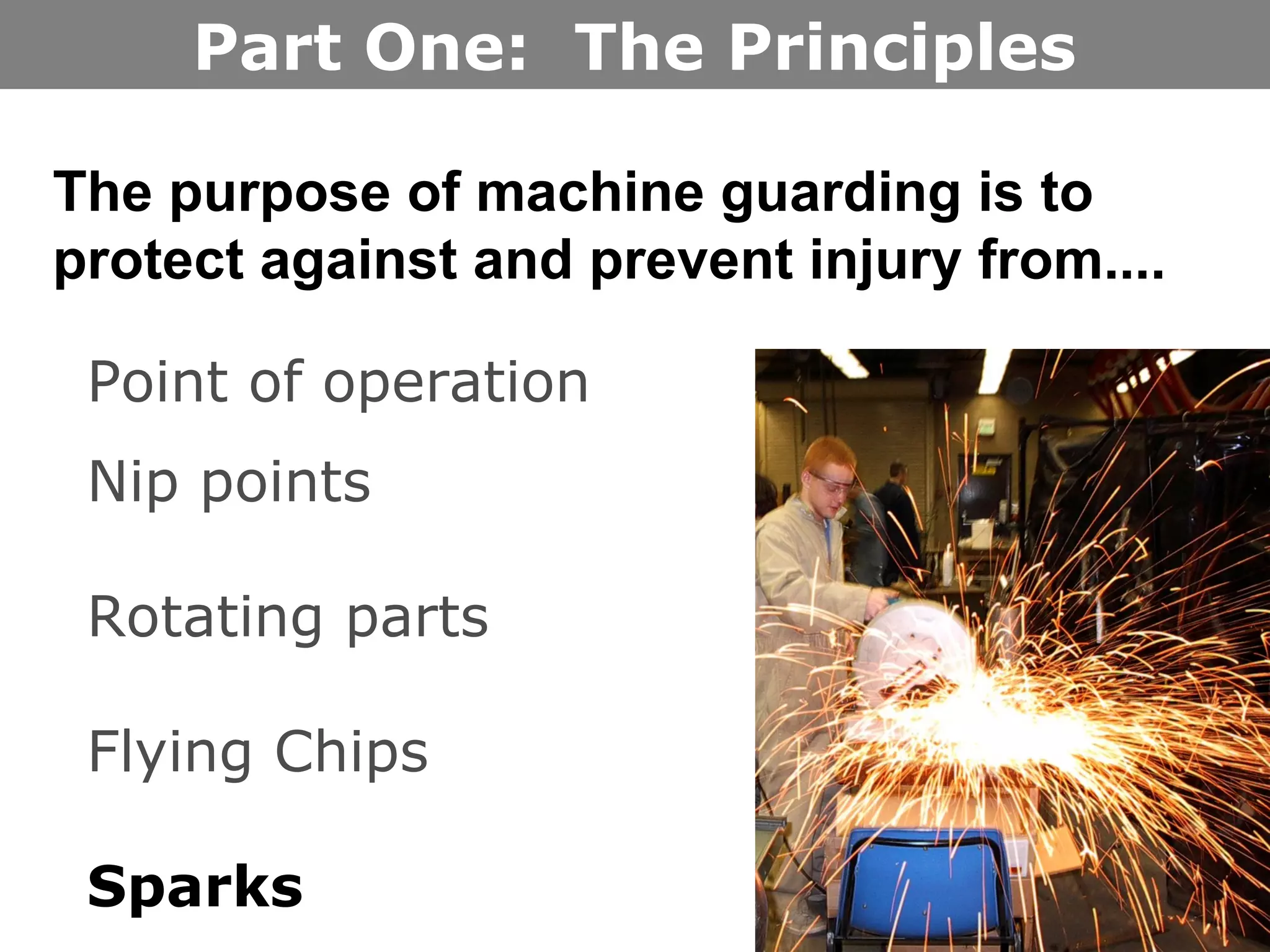

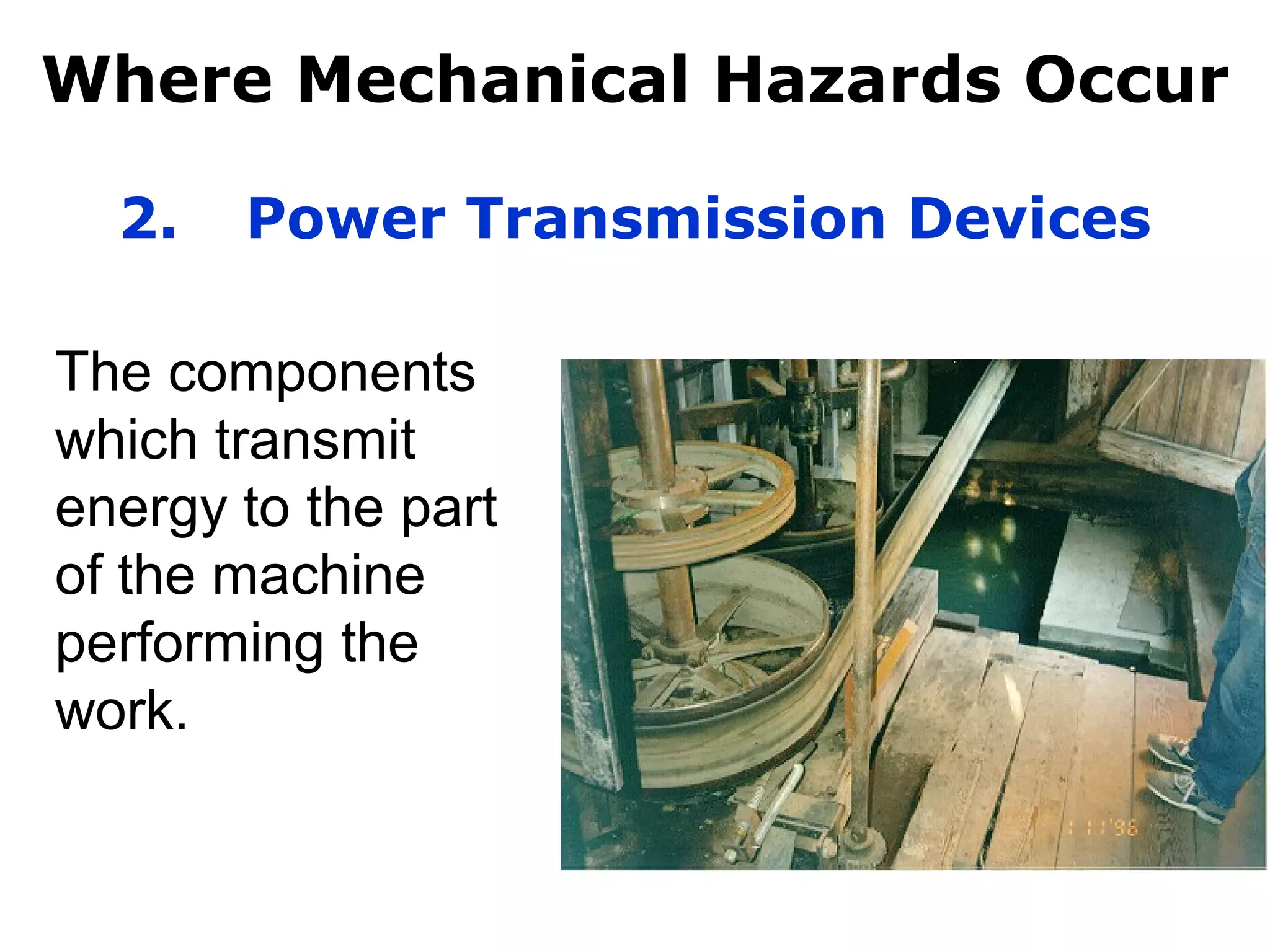

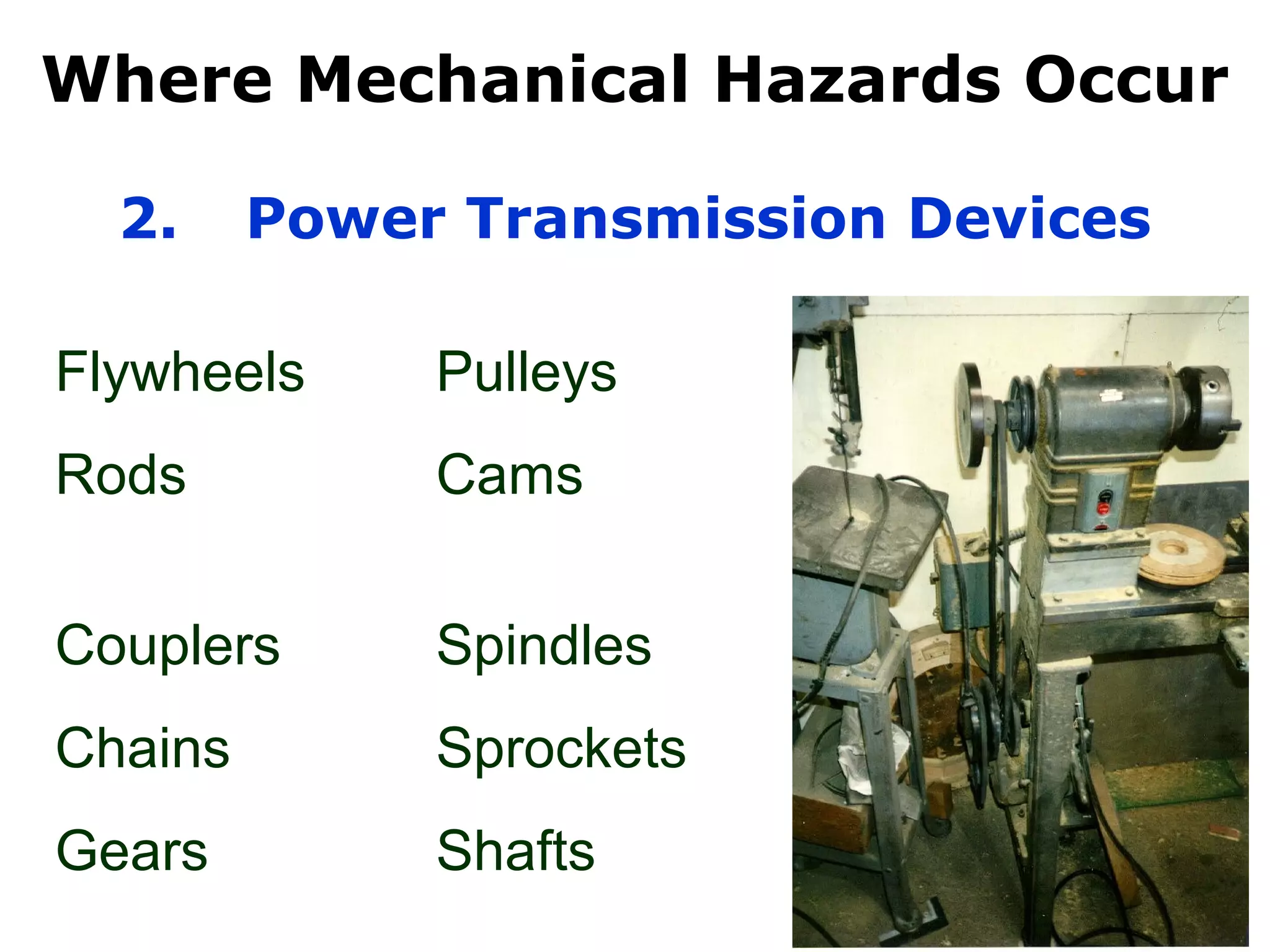

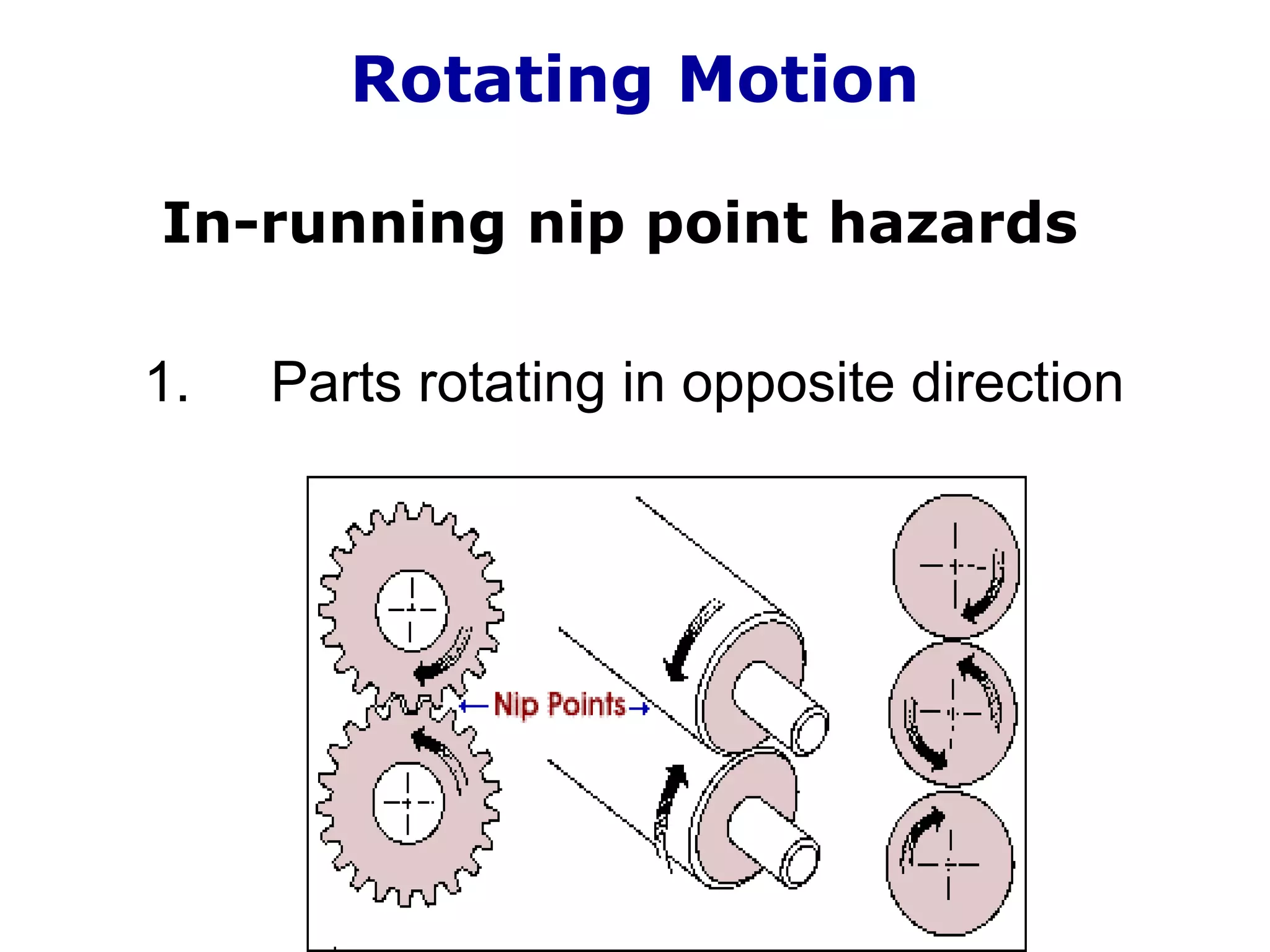

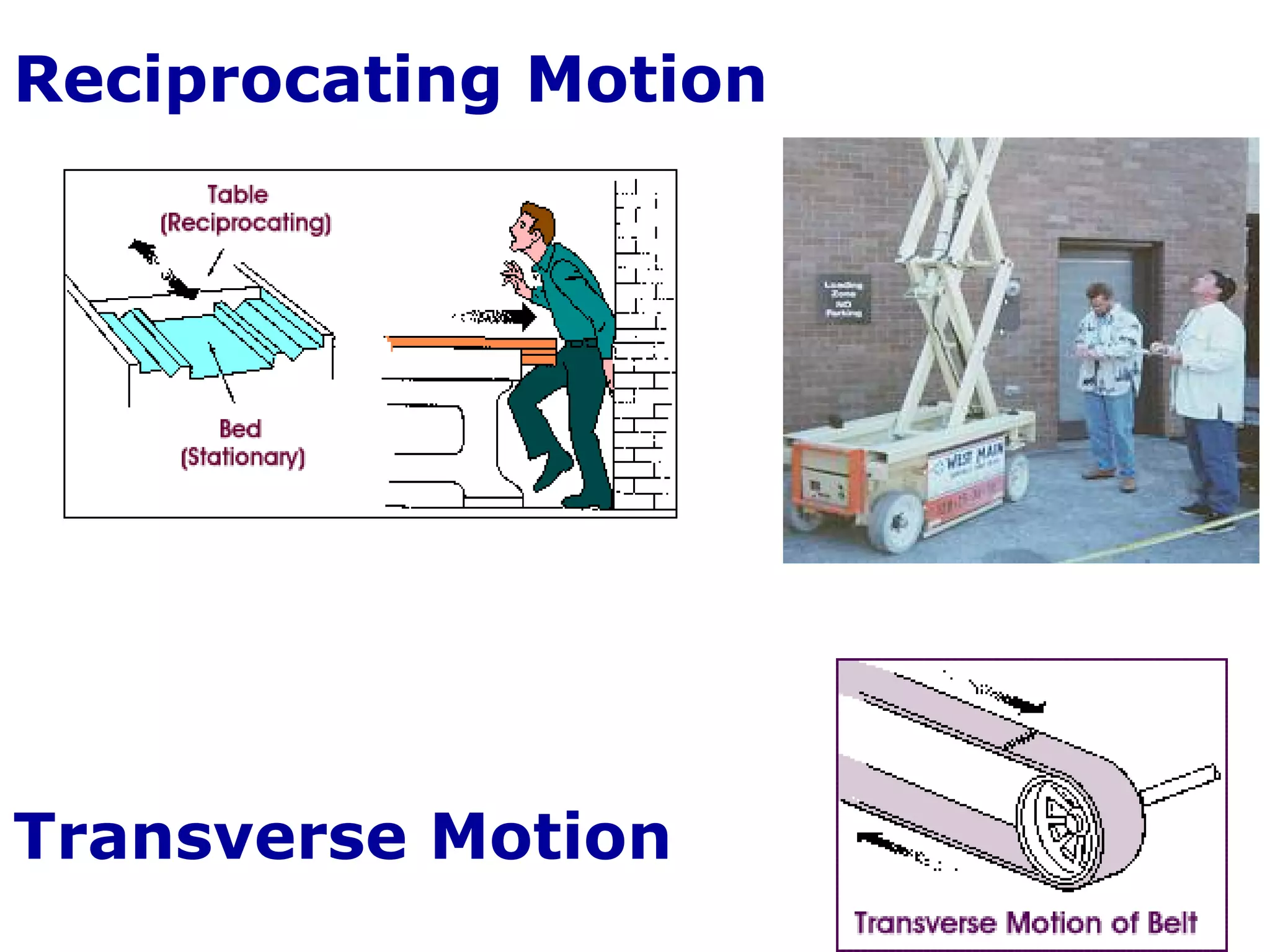

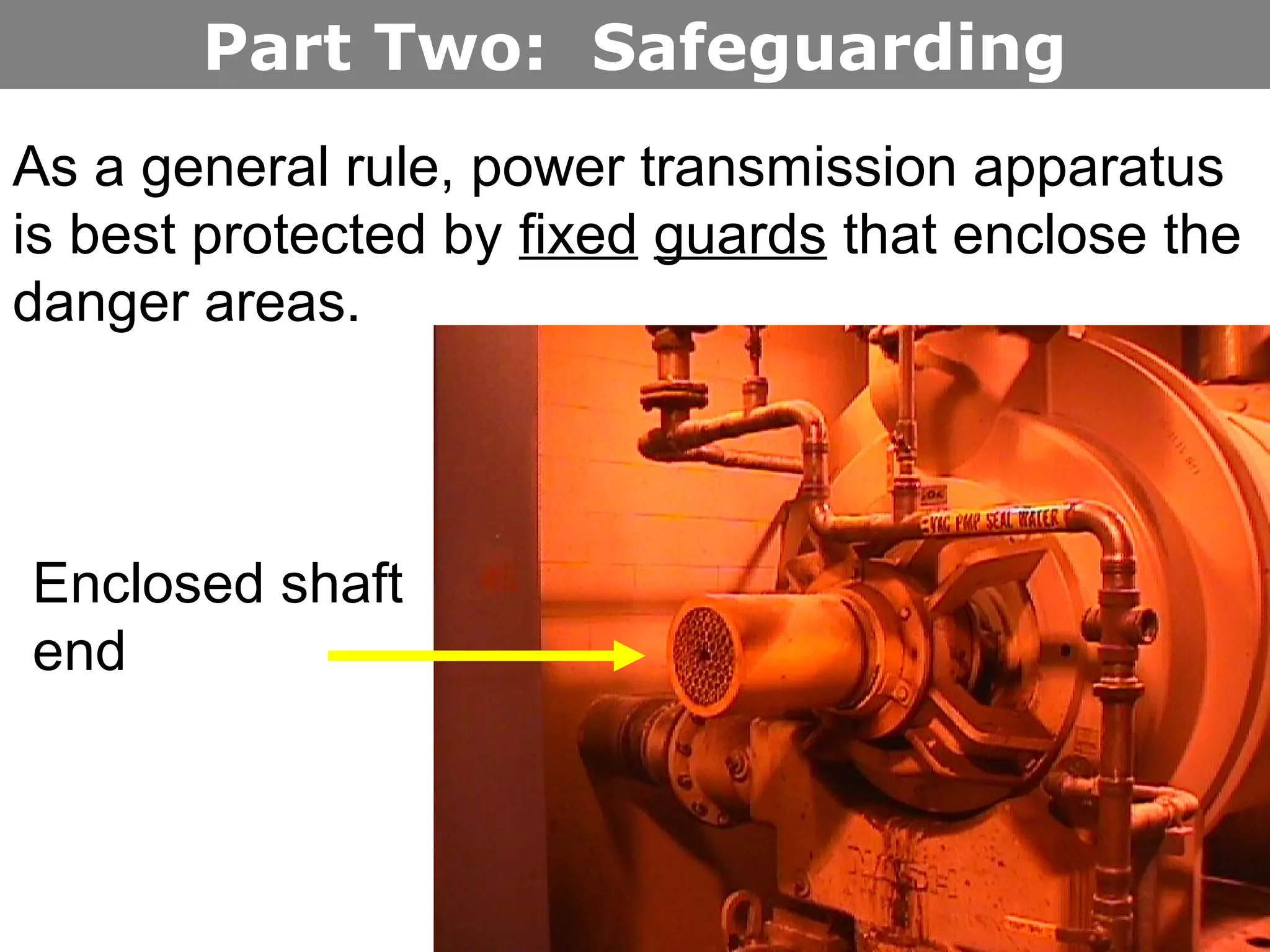

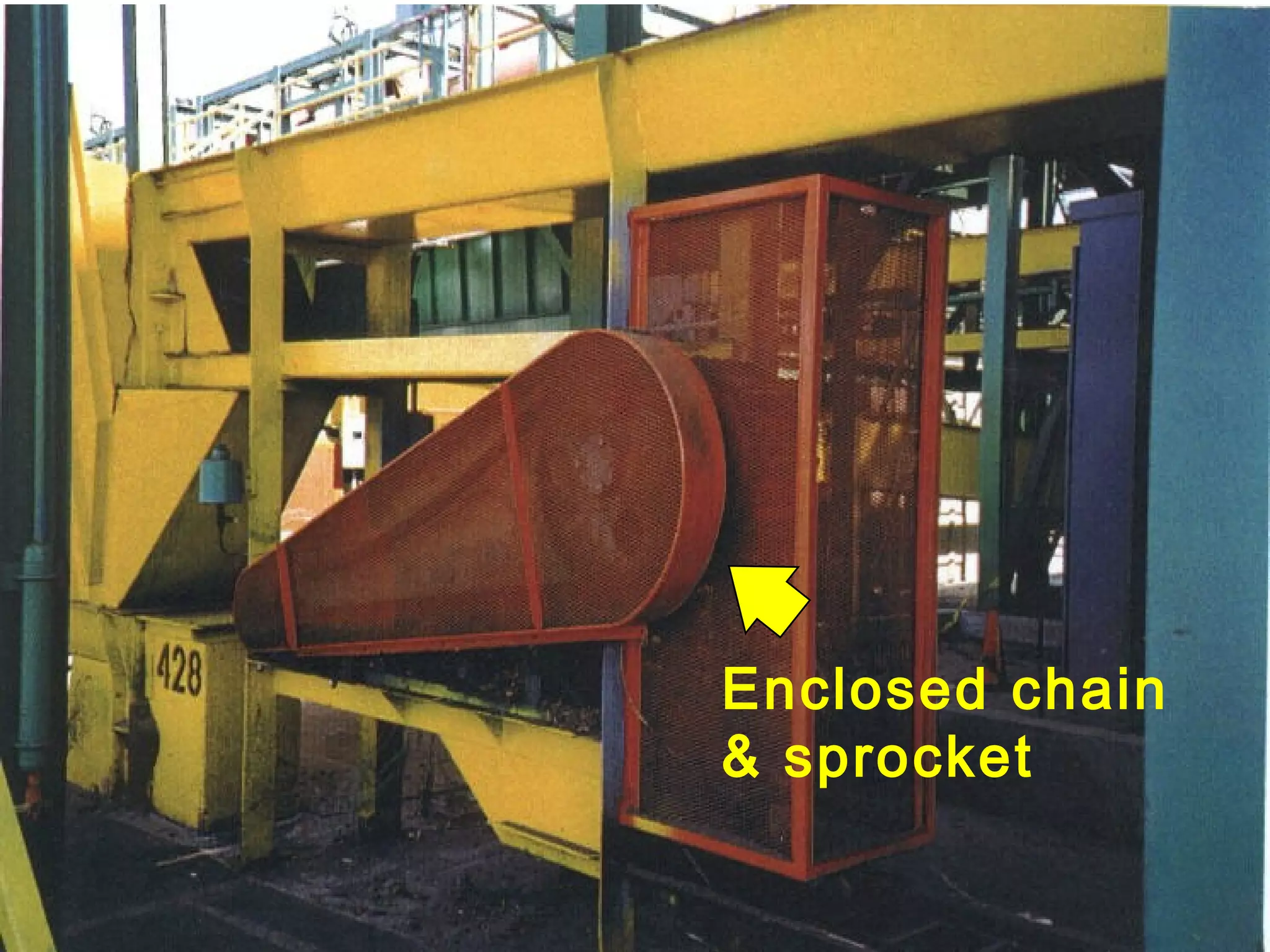

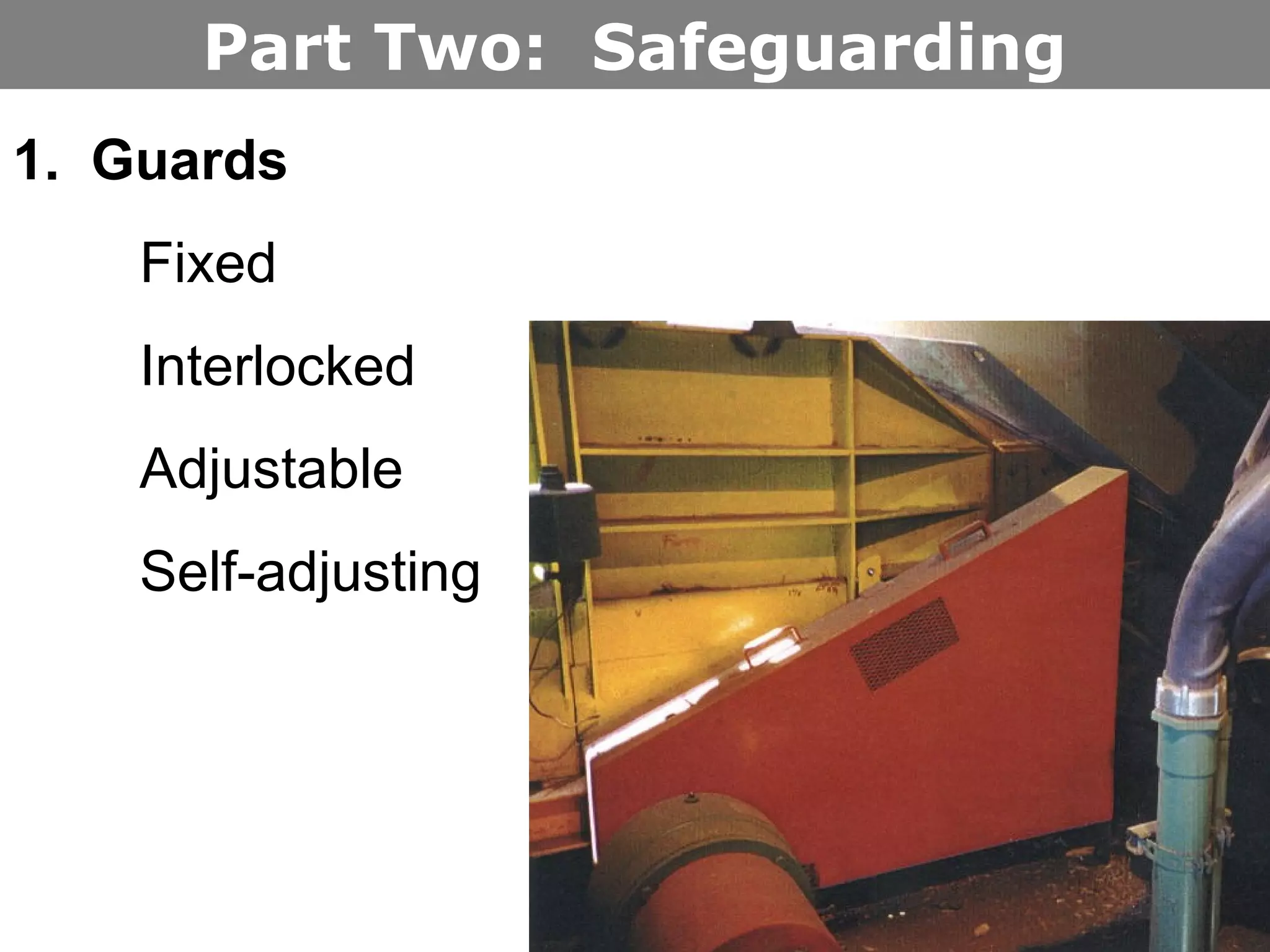

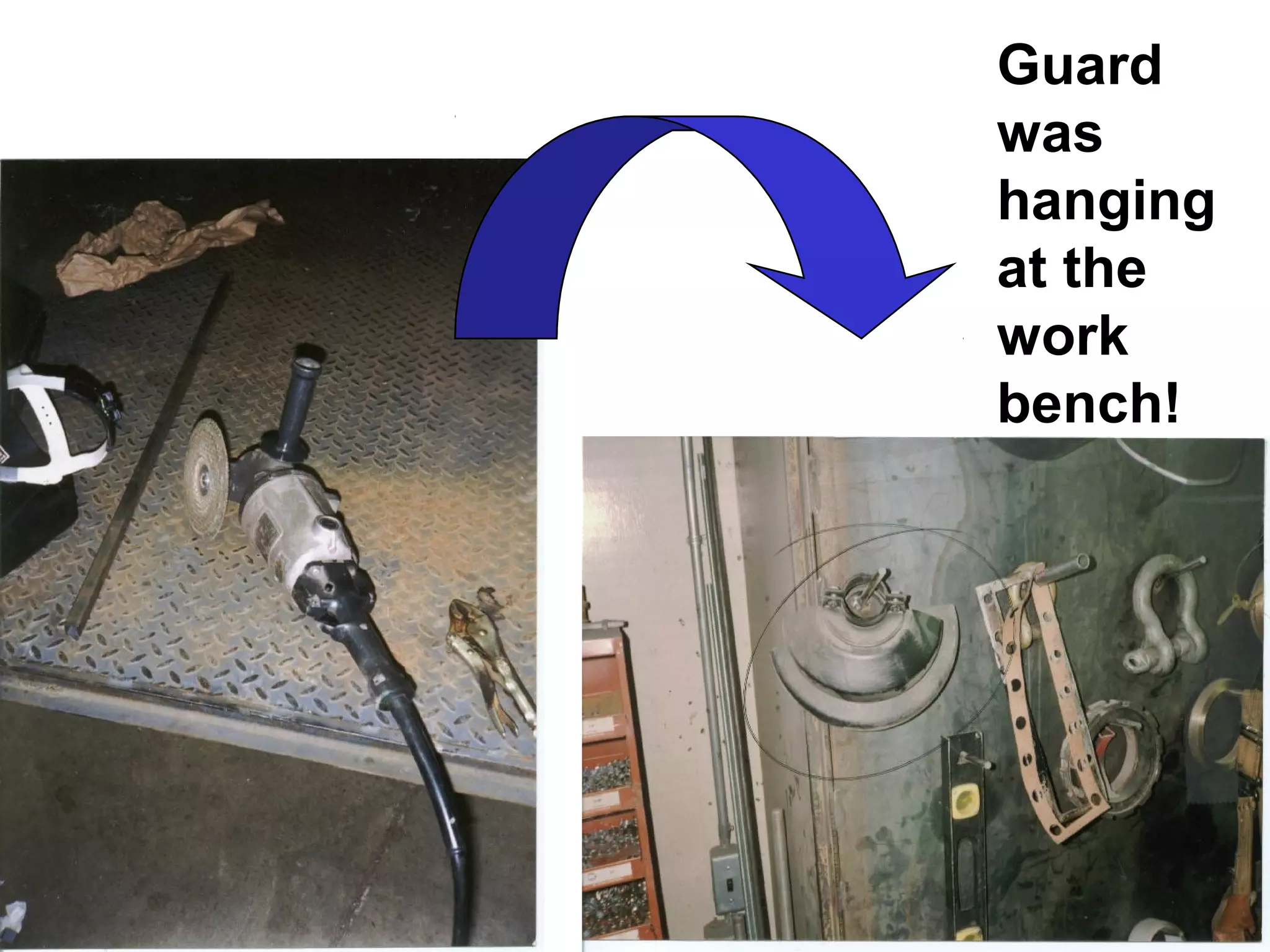

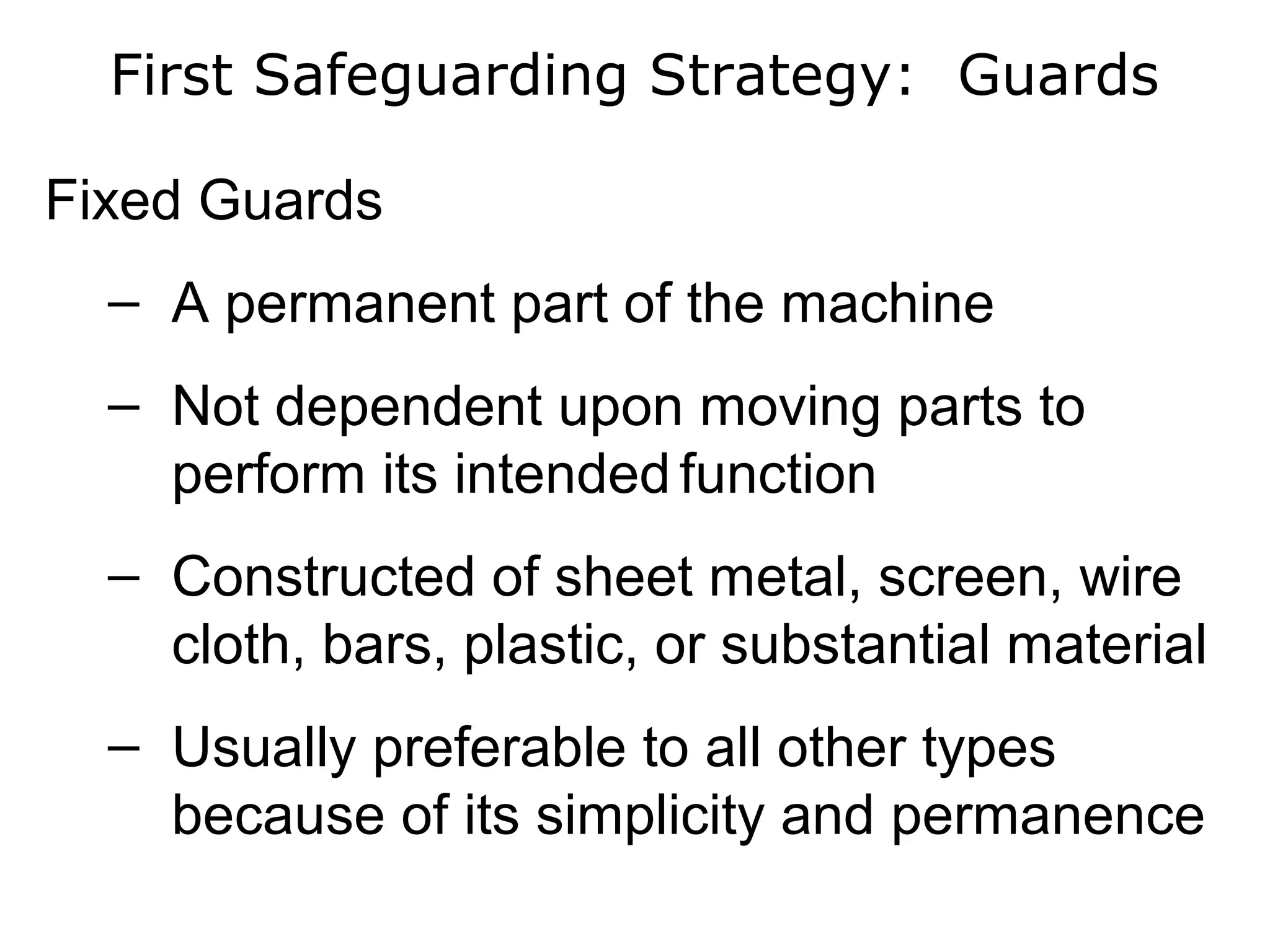

The document provides guidance on machine guarding requirements to protect workers from mechanical hazards. It discusses how hazards can occur at the point of operation, from power transmission devices, and other moving parts. It emphasizes that machine guards, presence-sensing devices, restraints, and other controls should be used to prevent worker contact with dangerous areas of machinery during operation. The overall goal is to design safeguards that prevent injury without interfering with necessary machine functions.

![Table O-10

[In inches]

___________________________________________________

|

Distance of opening from point | Maximum width of

of operation hazard | opening

____________________________ |__________________

|

1/2 to 1 1/2 ................. | 1/4

1 1/2 to 2 1/2 ............... | 3/8

2 1/2 to 3 1/2 ............... | 1/2

3 1/2 to 5 1/2 ............... | 5/8

5 1/2 to 6 1/2 ............... | 3/4

6 1/2 to 7 1/2 ............... | 7/8

7 1/2 to 12 1/2 .............. | 1 1/4

12 1/2 to 15 1/2 ............. | 1 1/2

15 1/2 to 17 1/2 ..........… | 1 7/8

17 1/2 to 31 1/2 ............. | 2 1/8

____________________________ |__________________](https://image.slidesharecdn.com/revisedosha501subpartomachineguarding-121107143657-phpapp02/75/OSHA-10-Hour-machine-guarding-presentation-4-151-2048.jpg)