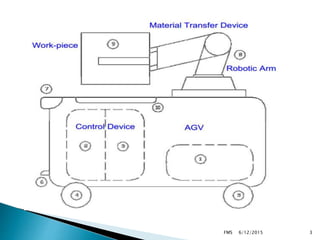

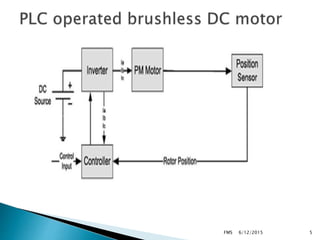

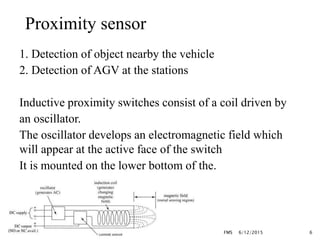

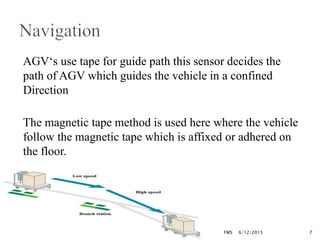

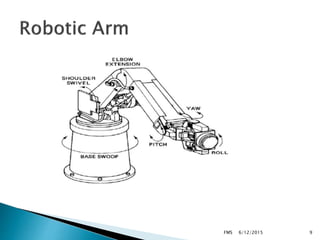

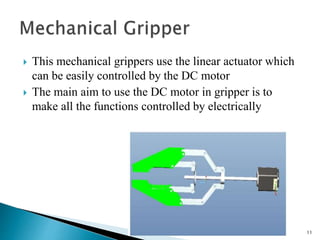

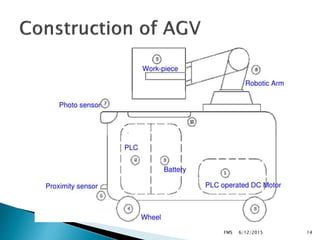

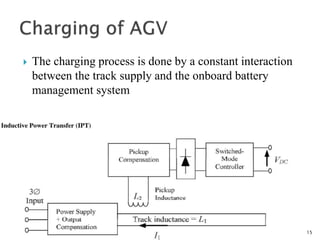

The document discusses automated guided vehicles (AGVs) designed for material transportation, highlighting the various sensors used, such as optical and magnetic sensors. It details the components of AGVs, including PLC systems for control, robotic arms for material handling, and the mechanisms for navigating paths with magnetic tape. Additionally, it emphasizes the advanced design and efficiency of these vehicles, enabled by modern technology and control systems.