India's Textile MSMEs: Driving Growth and Innovation

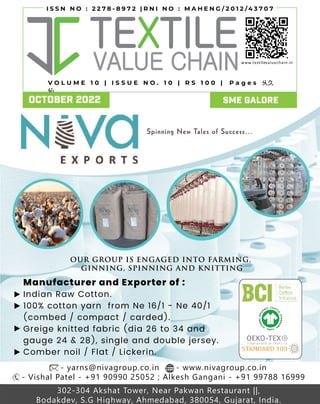

- 1. OCTOBER 2022 | TEXTILE VALUE CHAIN OUR GROUP IS ENGAGED INTO FARMING, GINNING, SPINNING AND KNITTING Manufacturer and Exporter of : Indian Raw Cotton. 100% cotton yarn from Ne 16/1 - Ne 40/1 (combed / compact / carded). Greige knitted fabric (dia 26 to 34 and gauge 24 & 28), single and double jersey. Comber noil / Flat / Lickerin. - Vishal Patel - +91 90990 25052 ; Alkesh Gangani - +91 99788 16999 302-304 Akshat Tower, Near Pakwan Restaurant ||, Bodakdev, S.G Highway, Ahmedabad, 380054, Gujarat, India. - yarns@nivagroup.co.in - www.nivagroup.co.in Spinning New Tales of Success... V O L U M E 1 0 | I S S U E N O . 1 0 | R S 1 0 0 | P a g e s וז ژ I S S N N O : 2 2 7 8 - 8 9 7 2 | R N I N O : M A H E N G / 2 0 1 2 / 4 3 7 0 7 www.textilevaluechain.in OCTOBER 2022 SME GALORE 87

- 2. TEXTILE VALUE CHAIN | OCTOBER 2022 2 F I B E R - R E I N C A R N A T E D 100 % DYEING GUARANTEE High Tenacity Near Virgin Polyester Staple Fibre For Yarns & Non Wovens Denier 1 to 25 | Cut 25 to 102 MM TM INDIA

- 3. OCTOBER 2022 | TEXTILE VALUE CHAIN 3

- 4. Cover Page: Niva Exports Back Page: RAYMOND Front Inside: JB ECOTEX Back Inside: RAYSIL 03: LE MERITE 05: Radheshyam 07: RAMESWAR 09 : S P Yarns 10 : TAI Conference 13: 11: TEXPERT 17: ZYDEX 18: Real Prince 21: Art Yarn Exports 24 : FIOTEX 12: YASH MACHINES 25: Saanika Industries 32: KEN INDIA 33: TVC Digital Media COVER STORY EVENT REPORT INTERVIEW ARTICLE INDIA, A FERTILE GROUND FOR MSME GROWTH ! ROLE OF SMES OF INDIAN TEXTILE INDUSTRY AFTER COVID SMES: THE BACKBONE OF INDUSTRY INNOVATION & INTELLIGENCE DRIVING MARKET INNOVATION & MANAGEMENT NEEDED FOR SUCCESSFUL VENTURES SPORTS TEXTILES – YOUR ROAD TO SUCCESS FUTURE CHALLENGES AHEAD IN TEXTILE EDUCATION EFFECT OF COTTON YARNS ON COMFORT CHARACTERISTICS OF WOVEN FABRICS IMPACT OF TEXTILE PRODUCTION ON CLIMATE CHANGE OUTSTANDING SUCCESS OF 2ND CMAI FAB SHOW TEXPROCIL EXPORT AWARDS PDEXCIL CELEBRATES 27 YEARS … OPPORTUNITIES WITH EGYPT COTTON FEDERATION COTTON USA CELEBRATES COTTON DAY | 13 | 19 | 22 | 27 | 30 | 37 | 43 | 57 | 60 | 64 | 66 | 72 | 74 | 70 FREECULTR PARTNER WITH FIFA 2022 | 67 ODISHA HOLDS INVESTORS’ MEET | 76 SHRI GODINHO UPCOMING | 79 INDUSTRIAL POLICY NATURAL FIBRE TRADE REPORT ADVERTISER INDEX NEWS EVENT CALENDAR | 08 | 36 CONTENTS... 26: SHAHLON SILK 29: USTER 41: DTG 2023 42: D. BADAMI 49: Alliance Fibres 50: LRT 57: ATE 58: SITEX 2023 59: Ramkrishna 62: Texfab Industries 63: Wellknown 65: OMAX 68: Astra Tech 69: Chintamani 71: Saurer 73: Meera Industries 75: Unitech 78: Cosmo 80: Vatsal Exports 81: Indian Petrochem 82: Swiss Textile Mach 83: Yarn Fair 2023 84: Staubli 85: Uniform And Sportswear Expo 34: LUWA 35: GSCS 40: SSPL

- 5. OCTOBER 2022 | TEXTILE VALUE CHAIN 5

- 6. TEXTILE VALUE CHAIN | OCTOBER 2022 6 EDITORIAL Textile Value Chain In India, the small industry, especially in the garment and textile sectors, have enjoyed favourable treatment from the Government. This is one of the major reasons for the mushrooming of MSMEs across the country. The Scheme for Integrated Textile Parks (SITP) was launched in 2005 to encourage private investments and employment generation in textile sector. The scheme targets industrial clusters/locations with high growth potential, which require strategic interventions by way of providing world-class infrastructure support. A total of 59 textile parks have been sanctioned under SITP by the Ministry of Textiles, out of which 22 textile parks have been completed. Under the Scheme for Integrated Textile Park (SITP), some 26,282 people in Gujarat got employed in textile parks followed by Maharashtra (22,910), Andhra Pradesh (19,137) and Tamil Nadu (9,995). The ITP scheme was intended to cover all segments of the textile industry from spinning, weaving to garmenting. The Ministry is implementing the Integrated Processing Development Scheme (IPDS) for enabling the textile processing sector to meet environmental standards through adoption of appropriate technology, specifically in the area of water and waste water management. The Scheme is a demand driven scheme. The Ministry has sanctioned 7 Projects under the IPDS for setting up ‘Common Effluent Treatment plants’ (CETPs) with Zero Liquid Discharge (ZLD) systems out of which 3 projects are in Rajasthan, 3 projects in Tamil Nadu and 1 project in Gujarat. Also, required CETPs may be included in SITP proposal under ‘Common Facility’ component. The cluster-based approach is increasingly being recognized as one of the strategies for cost effective, inclusive, sustainable and integrated development of Micro, Small and Medium Enterprises (MSMEs), the world over. The textile sector in India has been struggling to compete in the global market, due to loss in cost competitiveness and inability to move up the value chain. Integrated textile parks can play a major role in addressing these obstacles and enable the sector to win back lost glory in the global market. MSMEs on cusp of big growth! All rights reserved Worldwide; Reproduction of any of the content from this issue is prohibited without explicit written permission of the publisher. Every effort has been made to ensure and present factual and accurate information. The views expressed in the articles published in this magazine are that of the respective authors and not necessarily that of the publisher. Textile Value chain is not responsible for any unlikely errors that might occur or any steps taken based in the information provided herewith. REGISTERED OFFICE: TVC MEDIA AND PROMOTION PVT LTD. 504, Suchita Business Park, Patel Chowk, Pantnagar, Ghatkopar (East), Mumbai- 400075, Maharashtra, INDIA. Cell: +91-9769442239 Email: info@textilevaluechain.com Web: www.textilevaluechain.com Owner, Publisher, Printer and Editor - Ms. Jigna Shah Printed and Processed by her at, Impression Graphics, Gala no.13, Shivai Industrial Estate, Andheri Kurla Road, Sakinaka, Andheri (East), Mumbai 400072, Maharashtra, India. EDITOR AND PUBLISHER Ms. Jigna Shah ADVISOR - EDITORIAL & MARKETING Mr. Samuel Joseph EDITORIAL ASSISTANT Ms. Gargi CREATIVE DESIGNER Mr. Ganesh Shinde MARKETING AND ADVERTISING ENQUIRY Mohammad Tanweer +91-9167986305 sales@textilevaluechain.com SUBSCRIBTION - Samuel Joseph EDITORIAL TEAM Ms. Vaibhavi Kokane +91-9869634305 textilevaluechain123@gmail.com

- 7. OCTOBER 2022 | TEXTILE VALUE CHAIN 7

- 8. TEXTILE VALUE CHAIN | OCTOBER 2022 8 TEXTILE VALUE CHAIN | OCTOBER 2022 36 1 - 10 NOV 2022 BAGHDAD INTERNATIONAL FAIR Baghdad , Iraq 4 - 6 NOV 2022 UNIFORMS SPORTSWEAR EXPO Mumbai, India 8 - 9 NOV 2022 INDIAN PETROCHEM – 2022 Mumbai, India 8 - 10 NOV 2022 SOURCE TEXTILE & APPAREL EXPO Lagos, Nigeria 15 - 17 NOV 2022 ADVANCED RECYCLING CONFERENCE Cologne , Germany 24 - 26 NOV 2022 INTERDYE & TEXTILE PRINTING EURASIA Istanbul, Turkey 24 - 26 NOV 2022 INTERNATIONAL CONFERENCE STRUTEX 2022 Liberec, New Republic EVENTS - NOVember

- 10. TEXTILE VALUE CHAIN | OCTOBER 2022 10 A Step Towards Textile 4.0 Digitization and digitalization are parts of a digital transformation. In short, Digitization is concerned with events that have already occurred. Digitalization is concerned with current events. Digital transformation refers to events that will occur in the future. DIGITIZATION DIGITALIZATION DIGITAL TRANSFORMATION Digitization is about the conversion of analogue data to digital data for all assets, processes, and measurements. Digitalization involves data- driven applications, data integration, analytics, and metrics with the purpose of m a k i n g p r o c e s s e s m o r e automated using digital data. Digitalization adds value by improving the delivery of products. Digitalization is related to business processes. Digital Transformation is the process of fundamentally utilizing digital technologies, and it refers to the cultural shifts to better or replace what was previously available. Digital Transformation is defined in simple language as the novel use o f d i g i t a l t e c h n o l o g y t o accelerate business strategy. Digitization Benefits: 1. Faster access to information 2. Easier to store at much less cost 3. Improved digital preservation 4. Easy to retrieve & ability for integration 5. Sharing data easily Digitalization Benefits: 1. Efficiency & Productivity Improvements 2. Improved transparency 3. Faster & better Decision Making 4. Improved Customer satisfaction 5. Enhances & transforms an existing business process or processes. 6. Converts a process from a human-driven event to a software-driven event Digital Transformation Benefits: 1. Helps businesses grow into new areas, introduce new goods, and attract new customers. 2. Creates a comprehensive change to a company's business strategy. 3. Digital transformation is an ongoing process, not a one- time activity. 4. It introduces new business models and alters the way businesses are conducted. 5. It aims at ensuring that the end consumer is satisfied, which is the centre point of doing business. lHowDigitalizationAffectstheTextileIndustry Topics to be Covered

- 11. OCTOBER 2022 | TEXTILE VALUE CHAIN 11 ve in

- 12. www.yashtex.com sales@yashtex.com I +91 9167772065 I PRODUCTS Fabric Rewinding Machines Fabric Folding Machines Slitting Cutting Solutions Batch Preparation Machines Roll Packing Machines Roll Handling Sorting Systems Fully Automatic Packing Machine Open Width Knits Inspection Machine APPLICATION Knitted Fabrics Denim Bottom Weight Suiting Shirting Home Furnishings Terry Towel Coated Fabrics and more....... M a d e in India Rewinding, Measuring Packing Solutions

- 14. TEXTILE VALUE CHAIN | OCTOBER 2022 14 In India, small has always been not only beautiful but also strong! Especially, the textile industry, the mother of all industries catering to the apparel needs of the country, has grown well beyond all expectations. MSMEs account for almost 90% of all enterprises in the country. And contributes 35% to its annual GDP. MSME sector has been a key contributor to the India’s GDP and even during the pandemic times, it showed tremendous resilience, helping the economy recover faster from the lockdown market depression. One of the key sectors that have outshone others and registered tremendous growth is the textile and apparel MSMEs. Very recently, the Government has doubled the paid- up capital and turnover eligibility thresholds for small companies, which will help more businesses and startups get access to the lighter compliance regime for such entities under the Companies Act, 2013. According to a Ministry of Corporate Affairs (MCA) notification, any company with a paid-up capital up to ₹4 crore and turnover as much as ₹40 crore would be considered a small company. This is the second revision in about just 18 months -- the limit was raised to ₹2 crore and ₹20 crore, respectively, on April 1. Small companies are not required to include cash flow statements in their financial reports, need hold only two board meetings a year as opposed to at least four for others, and do not have to rotate auditors every five years. They can file abridged annual returns and these can be signed by the company secretary or a director of the company. Most of the statutory documents of small companies needn’t be signed by a practicing professional such as a chartered accountant. Earlier, in June 2020, the Union Cabinet approved the revision of MSME’s definition based on turnover size and investment limit. The new definitions were as follows: •Microunits–investmentuptoRs.1croreandturnover below Rs. 5 crore • Small units – investment up to Rs. 10 crore and turnover below Rs. 50 crore • Medium units – investment up to Rs. 50 crore and turnover below Rs. 250 crore The new MSME definitions allowed many medium, small, and micro units to continue their “MSME” status under the revised guidelines. And avail of the various benefits for pandemic-relief, exclusively available to the MSMEs, including the collateral-free SME loan facility introduced by the Centre, from any bank/NBFC. Rewinding to 2021, the Union Budget 2021 announced India would be setting up seven Mega-Integrated Textile Region and Apparel (MITRA) parks. This move is expected to double the industry size to US$ 300 billion by attracting large investments and boosting employment. Consequently, make the country’s textile sector, a globally competitive manufacturing and export hub. Besides MITRA development, additional perks like GST reduction will help the SME-MSMEs free up capital to invest in key growth drivers like technological upgrades, new-age marketing tools, state-of-the-art infrastructure, and more. MSMEs, which account for almost 90% of all enterprises in the country, contributes 35% to its annual GDP. The GST council has already decided that any firm with a turnover of Rs. 40 lakh less need no longer register under the GST. This has come as a boon to the small players. The small industries have got a shot-in-the- arm recently with the latest revision to facilitate Ease of Doing Business further and reduce compliance burden on “small companies.” The Ministry of Corporate Affairs (MCA) has taken several measures in the recent past towards ease of doing business and ease of living for the corporates. These included decriminalisation of various provisions of the Companies Act, 2013 India, a fertile Ground for MSME Growth ! - Samuel Joseph C O V E R S T O R Y

- 15. OCTOBER 2022 | TEXTILE VALUE CHAIN 15 the LLP Act, 2008, extending fast track mergers to start ups, incentivising incorporation of One Person Companies (OPCs) etc. Earlier, definition of “small companies” under the Companies Act, 2013 was revised by increasing their thresholds for paid up capital from “not exceeding Rs 50 lakh” to “not exceeding Rs 2 crore” and turnover from “not exceeding Rs 2 crore” to “not exceeding Rs 20 crore”. This definition has, now, been further revised by increasing such thresholds for paid up Capital from “not exceeding Rs. 2 crore” to “not exceeding Rs. 4 crore” and turnover from “not exceeding Rs. 20 crore” to “not exceeding Rs. 40 crore.” The Modi government’s post-Covid flagship credit scheme for MSMEs Emergency Credit Line Guarantee Scheme (ECLGS) has benefitted around 1.19 crore businesses as of June 30, 2022. Launched in May 2020, the scheme has sanctioned collateral-free loans amounting to Rs 3.48 lakh crore till June end. Sharing the data from the Department of Financial Services in the Lok Sabha recently, Minister of State for MSMEs Bhanu Pratap Singh Verma noted that out of the total ECLGS beneficiary count, 1.13 crore were MSMEs (95 per cent) while the amount sanctioned to MSMEs stood at Rs 2.32 lakh crore (66 per cent) out of the total sanctioned. While the data on total disbursements under the Rs 5-lakh-crore ECLGS scheme was not shared by the Government, the Reserve Bank of India (RBI) in its latest Financial Stability Report (June 2022) had noted that Rs 2.54 lakh crore loans were disbursed till April 30, 2022. “Thetextileapparelindustry’scontributiontothecountry’sGDPisaround 5% and in terms of industrial output, the TA accounts for 7% of the total value, making it one of the most promising industries in India. In fact, the TA industry in India is one of the largest industries in the world and also the second largest employer in the country. It has generated approximately 45 million jobs directly and over 60 million jobs in allied industries. There have been multiple driving forces behind the monumental growth of the industry and realizing the full potential of each of these dynamics can help the MSMEs to unlock greater employment opportunities for the Indian workforce,” says an investment expert. “Being the world’s 5th biggest TA exporter, the industry enjoys a 4% share of the $840 billion global markets. The textile exports accounted for US$ 22.89 billion between April 2021 and October 2021. IBEF also suggests that the TA exports growing at a solid CAGR of 11% are expected to cross $100 bn in the next 5 years. Increasing the exports not only creates foreign reserves but also opens doors for better employment opportunities in the country. Developing MSMEs in the sector to boost exports can create an additional 75 lakh to 1 crore jobs – which is quite a number taking into consideration that the unemployment rate in India stands at 7%,” says the investment source. Textile Ministry along with the Finance Minister in the Union Budget announced several schemes and programmes to support and strengthen the industry. One such announcement for setting up seven mega textile parks across India is a welcoming move that will increase employment opportunities as well as boost the MSME growth. Another landmark proposal of the Government has been the announcement of production- linked incentives (PLI) worth $1.4bn that will prove instrumental in realizing the capacity potential of TA manufacturing units. Anticipating the significant role of the industry to create employment, the government has undertaken multiple reforms and plans to introduce labour-friendly schemes. Forexample,undertheEPFscheme, the Govt. of India will bear 12% of the garment industry employers’ contribution to the EPF for new employees earning lesser than INR 15,000/month, for the first 3 years. This reform will ensure that the workers get more in-hand wages, thus promoting employment in the formal sector,” he further added. Small companies represent the entrepreneurial aspirations and innovation capabilities of lakhs of citizens and contribute to growth and employment in a significant manner. The Government has always been committed to taking measures wXXXXXhich create a more conducive business environment for law-abiding companies, including reduction of compliance burden on such companies. Some of the benefits of reduction in compliance burden as a result of the revised definition for small companies are as under: No need to prepare cash flow statement as part of financial statement; Advantage of preparing and filing an Abridged Annual Return; Mandatory rotation of auditor not required; An Auditor of a small company is not required to report on the adequacy of the internal financial controls and its operating effectiveness in the auditor’s

- 16. TEXTILE VALUE CHAIN | OCTOBER 2022 16 report; Holding of only two board meetings in a year; Annual Return of the company can be signed by the company secretary, or where there is no company secretary, by a director of the company; Lesser penalties for small companies. Loans amounting to Rs 3.32 lakh crore were sanctioned under the Emergency Credit Line Guarantee Scheme (ECLGS) till April 30, 2022, of which Rs 2.54 lakh crore amount was disbursed, the Reserve Bank of India (RBI) said in its latest Financial Stability Report. As informed by the National Credit Guarantee Trustee Company Limited, the agency which operates the Emergency Credit Line Guarantee Scheme (ECLGS), as on 11.3.2022, a total of 117.87 lakh businesses have been supported with 100% guaranteed collateral free loans under ECLGS of which about 95.21% were MSMEs. This was stated by Union Minister of State for Finance Dr Bhagwat Kisanrao Karad in a written reply to a question in Rajya Sabha recently. The Minister stated that the ECLGS was launched in May 2020 as part of the Aatmanirbhar Bharat Abhiyaan to support eligible Micro, Small and Medium Enterprises (MSMEs) and other eligible business enterprises in meeting their operational liabilities and restarting their businesses in the context of the disruption caused by the COVID-19 pandemic. It covered all the sectors of the economy. 100% guarantee is provided to Member Lending Institutions (MLIs) in respect of the credit facility extended by them under the scheme to eligible borrowers, the Minister added. The Minister also stated that pursuant to an announcement made bytheFinanceMinisterinherspeech on the Union Budget 2022-23 that ECLGS will be extended till March 2023, Government has extended the scheme by one year, till 31.3.2023. Giving more details, the Minister stated that the structure of scheme allows easy access to credit as the lenders offer pre- approved loans based on borrower’s existing credit outstanding and there is no fresh appraisal undertaken by lenders since additional credit is sanctioned over and above the credit facilities already assessed. Further, the interest rate is also capped with a view to lower the cost of credit and loans are sanctioned without any processing charges, pre- payment charges and guarantee fee. On a question on RBI’s views on the MSME sector, the Minister stated that RBI has observed in its Financial Stability Report, December 2021 that MSMEs are reflecting signs of stress. In this connection, RBI has informed that the MSME portfolios of Commercial banks indicate accumulation in the non-performing asset and special mention account – 2 categories in September 2021, relative to March 2021. Advancements in digital textile technologies: The investments in textile technologies have been increasing year on year and with the Government’s liberal assistance under programmes such as Technology Upgradation Fund Scheme (TUFS) providing investments as well as subsidies, the textile industry is poised for illustrious growth in the coming years. Khadi and Village Industries Commission under the Ministry of MSME is also taking active measures to boost the growth of micro and small- scale textile industries in rural areas. As per the scheme, over 10,000 people were trained in 2020-2021 through various training centres of KVIC (departmental as well as non-departmental). This will create self- employment and entrepreneurial opportunities and rural development. TA sector is one such industry where women account for approximately 60-70% of the total workforce. More than 27 million women in India are employed in the textile and apparel sector. The growing employment opportunities would mean more jobs for women, thus increasing the participation and contribution of the women’s workforce in the Indian economy. The textile and apparel industry is on a rise and even with the stiff international competition from Asian countries such as Bangladesh, Vietnam, etc., the future of the industry seems brighter owning to its endowed advantages of vast raw material supply (India is amongst the largest producer of cotton yarn and fabric), ample availability of human resources, and faster adoption of advanced textile technologies. Given the sector is able to sustain and increase the domestic as well as export growth, the industry will be able to become of the most lucrative sectors for creating employment and job opportunities for skilled, semi-skilled as well as a portion of unskilled workforce, directly or indirectly.

- 19. TEXTILE VALUE CHAIN | OCTOBER 2022 19 Covid 19 / Corona Virus made our life fearful, but there is always a spark of light in the dark environment. India being an opportunist country and Jugad based economy, Indian has flourished in the difficult situation, and we are 2nd highest supplier of PPE kits in the world during this difficult period. In a short span of time, Indian has transferred operation from conventional garment / fabric units to PPE kits units. India has always proved to be in the front when it calls for low cost innovations, whereby an appreciation needs to be recorded for those SMEs especially ITAMMA members who have developed the mask making and automatic sanitizer disposal machines and disinfection chambers during the crucial and challenging Lockdown period. Thus during COVID-19 situation it is also noticed that the demand for man-made fibre (MMF) textiles all over the world is increasing as a substitute for cotton amid changes in global fashion trends. Currently MMF dominates global textile fibre consumption with 72: 28 ratio i.e., MMF 72% and 28% is Natural fibre. The share of MMF has been steadily increasing due to the inherent limitations of growth of cotton and other natural fibres. Global end-use demand for textile fibres is forecast to expand by an average of 2.80% per annum between 2015 and 2025, from 90.10 mn tons to 119.20 mn tons and global end-use demand for man-made fibres is expected to increase by 3.7% in 2025. Also it is very important to note that in 2020, Artificial Textile Machinery were the world’s 916th most traded product, with a total trade of $887M. Whereby the top exporters of Artificial Textile Machinery were Germany ($362M), China ($239M), Japan ($91.1M), Italy ($86M), and United States ($34.4M). While top importers were China ($303M), Turkey ($123M), Japan ($72.8M), Vietnam ($43.8M), and Russia ($42.4M). A ~$2.5 bn textile machine industry which is growing at 5% currently reflects on the growing strength of this sub-segment in the textiles value chain in India. Looking at the Global scenario, Indian Govt. is also promoting man-made fibres and thus it is an alarm as well as opportunity to Textile Machinery Manufacturers for the development of machines and components especially for the processing of these fibres and also to the User Industry to decide the appropriate Machine Maintenance Management in order to have a smooth functioning of these MMF. Specifically those SME Enterprises working under Cluster activity in the decentralized sectors needs to revamp/restructure their Maintenance Management in a very systematic way in order to acquire the high performance functioning of these fibres. “3D printing technology” will be playing a very vital role in the changing trends of Man-Made Textiles, not only in the stream of Fashion designing but also in the Safety Textiles and its machineries. This Technology offers enormous opportunities in production, design and performance. The benefits of additive manufacturing on supply chains takes many forms. It reduces material waste, simplifies production processes, and the on-demand production offered by additive manufacturing improves supply chain flexibility because the finished product can be manufactured in proximity to the end-user. Customers can acquire products, spare parts, and goods as needed, and businesses can produce parts as needed or forecast. Since a single 3D printer can produce a complete part without the need for tooling, it reduces dependence on fixtures and lowers production time. The application of additive manufacturing, well known as 3D printing, in textile industry is not more totally new. It is giving significant increase of the product variety, production stages reduction, widens the application areas of textiles, customization of design and properties of products according to the type of applications requirement. The advancing technical possibilities in 3D printing and 3D scanning make developments possible that will revolutionize production and trade in the fashion Role of SMEs of Indian Textile Industry after Covid - N D Mhatre, Director General (Tech.) , ITAMMA C O V E R S T O R Y

- 20. OCTOBER 2022 | TEXTILE VALUE CHAIN 20 and textile industry. Clothing and shoes will soon be coming out of the 3D printer in an individualized way, new possibilities will open up for functional textiles, and 4D printing will take the 3D process to a new level with fascinating applications. Not only 3D printing, 3D technology itself is changing the entire value chain in the apparel industry from design and prototyping to the finished product and its delivery. Up to now, the designer has designed a product with two-dimensional materials and then created one or more cost-intensive prototypes and sample collections before the product could go into mass production. These cost drivers can now be replaced by a virtual 3D simulation. The software is now mature enough to test cuts on virtual size avatars as well as colors and patterns. The folds and movement of the avatars are also realistically simulated. The 3D simulation makes the creation of the collection faster, more accurate and more cost-effective. If the prototype production is shortened, idle times and waiting times are eliminated and variants are possible at any time. This gives the company more flexibility and enables it to react much faster to new trends. In the production of technical textiles, the main focus is on functional properties. For textile companies, 3D printing processes open up possibilities that cannot be realized with conventional processes. Elements such as plug- in connections can be applied directly to textile surfaces using 3D printing. In this way, textiles are created that integrate functionalities right from the start. However, the use of 3D printers in the production of textiles is extremely complex, as plastic filaments are not used as usual. Possible applications include tailor-made components made of narrow textilesandplasticsfortechnicalapplications,theapplicationof3Dstructural elements for textile sun and noise protection, sportswear and the application of adapted mould reinforcements for protective and functional clothing. By using 3D printing in production, the textile industry can not only functionally optimize its products right from the start, but production steps such as cutting, sewing or gluing functional components to a textile can even be saved in this way. For 4D biometric printing, the researchers use a special hydrogel that contains cellulose fibres and transforms into an appropriate form upon contact with liquid. Areas in which the hydrogel could be used range from biomedicine and robotics to textile production and electronics. The digitalization of the textile industry and further development of 3D/4D technology is leading to a strong change in the industry. In the near future, tailor-made products will become realistic for consumers, production will be replaced by flexible production facilities at the point of sale and innovative applications for functional and smart textiles will be developed. The environment also benefits from the elimination of transport routes and textile waste generated during production. Therearemorethan3,000companies involved in the manufacturing of textile machineries, accessories, and trading of equipment in India. The industry not only caters to rising domestic demand but also has the potential to establish India as an export hub for textile machinery with spinning machines representing the largest export opportunity. With the help of Make in India drive, followed by ATMA Nirbhar Bharat and well supported by Vocal for Local, India is on the path of becoming the hub for hi-tech manufacturing. Whereby global giants have either set up or are in process of setting up manufacturing plants in India, thus many textile machine companies in the country are joining hands with their western counterparts to produce technologically advanced machines. And accordingly we at ITAMMA, focused all our activities to improve the technological capability of our member companies through various Technology Development Programmes like 5S, Lean, Design Clinics, Energy Audits, Yellow belt trainings etc. under Cluster Development initiatives, in order to help them to have a sustainable growth in today’s smart manufacturing competitive global market. This hard time have made us tough, and realize the importance of safety products and measures, for survival as well as a hope of sustainable business reminding us about the importance of silver lining at horizon. ITAMMA have always stood with the members in the changing trends and shall continue thesameinthischallengingsituation also through its activities to improve the technological capability of our member companies.

- 22. TEXTILE VALUE CHAIN | OCTOBER 2022 22 SMEs: The Backbone of Industry - Gargi Dandegaonkar, TVC Team C O V E R S T O R Y The Small and Medium Size Enterprises play pivotal role in the Indian Economy. This fact was highlighted by our Union Finance Minister while giving out the Union Budget for the year 2022. These SMEs are considered as the growth drivers, not only in India, but for any economy all over the world. They are seen as source for getting rid of poverty, especially in a developing country like ours. Globalisation and free trade have helped in getting new and profitable opportunities for these SMEs. However, the true potential of these SMEs is yet to be realized, mainly due to the challenges that haunt the industry. A large part of the Indian Industry is made up by the SMEs. These SMEs have characteristics like short gestation period and low administrative costs. Moreover, they are labour intensive in nature and have a large potential for employment generation. They also help in inducing growth of the industrially backward regions, which in turn ensures a balanced regional development. The Indian Textile Industry The Indian Textile Industry is one of the oldest industries in the country. Often called a mother industry, the textile industry is the second largest employment generating industry in India, second to agriculture. It is one of the largest yarns producing industry, as a whole on the international level. India is a world leader when it comes to production of jute fibre, second when it comes to production of silk and is amongst the top producers for cellulosic and synthetic yarns as well. The textile industry is directly connected to the rural economy of our country as major part of our agricultural land is in the rural areas Furthermore, the local handicraft artisans who utilise these fibres are also a part of these rural areas and have been carrying the trade from generations together, passing on this artistic legacy to the newer generations as they come. The cotton cultivation that is done in India accounts for the home textile and apparel segment which constitute the major part of the textile industry. Most of this production is carried outinfragmentedunitsscatteredintownsandvillages across the country and account for the SMEs of India. The SMEs in Indian textile industry are a result of the numerous government-led initiatives and various incentives provided for these ‘Lahu-Udyogs’ under different schemes. One such example is the recent ‘Make in India’ campaign which is focussed on generating domestic employment for the youth and utilising the strong raw material base in our country with the help of the innumerable skilled and unskilled personnel, cheap labour and a promising export potential. The textile industry is fragmented, yet is accounts for a significant part in the Indian economy. Indian Textile SMEs: A ray of Hope The Indian textile industry constitute of numerous clustered and independent SMEs. This is one of the advantages of the industry as it makes it self-reliant and independent. It also brings in the much need flexibility in the processing of the textiles across the entire value chain. Moreover, with a handy stock of raw material and the abundance of resources these SMEs can use in their design expertise to generate high-quality products with enough variations for the customers. The SMEs generate employment which in turn has many positive social impacts as well, like an improved standard of living, low crime rates due to availability of money and awareness about social causes like education, generated by the general socio-cultural programmes held for the workers at their workplace, to name a few. All this eventually leads to regional development using technological advancements and it eventually contributes to the National Economic Growth.

- 23. TEXTILE VALUE CHAIN | OCTOBER 2022 23 The Challenges in Store for the Indian Textile SMEs and How to Overcome Them The situation of the SMEs in India may seem promising and glittery on the outer end. However, there are few challenges that these industries face, which are as follows: • High Cost to Credit • Collateral Requirements • Limited Access to Equity Capital • Timely Procurement of Raw Materials • Problems of Storage, Designing, Packaging and Product Display • Lack of or Limited Access to the Global Markets • Inadequate infrastructure facilities, including power, water, road, etc. • Lack of Access to the Latest Technological Developments • Lack of skilled manpower for process of manufacturing and marketing • Branding and Marketing These challenges have a few logical and ready to be implemented solutions available. This includes imbibing best innovation practices that are accepted globally, adopting and using the latest technologies for product development and marketing, creating reliable networks and effective management in across the supply chain. On a larger level, use of renewable energy sources to ensure cost-cutting the in the manufacturing process, establishment of Innovation Centres or Centres of Excellence for the textile industry, setting up of Special Economic Zones dedicated to textile industry, granting tax incentives, developing a partnership amongst the stakeholders, empowering women, integrating the industry, quality improvement, appropriate marketing across the globe, exhibitions and guidance centres for the local people involved, promoting lean manufacturing techniques, carving out niche schemes specifically designed for the textile SMEs are some of the measures that can be taken to improve the existing structure of the Indian textile SMEs. References: •CII (2006) State of Economy, January. • Compendium of Textile Statistics 2003 2006 Office of the Textile Commissioner,Ministry of Textiles, Govt. of India. • Confederation of Indian Textile Industry (CITI) (2007-08) Annual Report 2007-08. • CRISIL-NMCC (March 2009) Enhancing Competitiveness of Indian Manufacturing Industry: Assistance in Policy Making, Final Report submitted to National Manufacturing Competitiveness Council. • CSO Annual Survey of Industries, Summary Result for the Factory Sector, Variousissues. • CSO National Account Statistics (various years). • FICCI (2005) ‘Ending of MFA and Indian Textile Industry’ New Delhi. • DGCIS (2006) Foreign Trade Statistics of India (PCC), Kolkatta. • National Manufacturing Competitiveness Council, September (2008) Report of the Prime Minister’s Group,MeasuresforEnsuringSustained Growth of the Indian Manufacturing Sector, V.Krishnamurthy, Chairman of the Committee. • Indian Cotton Manufacturers Federation (ICMF) (2002-03) Annual Report 2002-03. • ILO (2000) Labour Practices in the Footwear,Leather,TextilesandClothing Industries Report for discussion at the Tripartite Meeting on Labour Practices in the Footwear, Leather, Textiles and Clothing Industries (ILO Sectoral Activities Programme, Geneva. • J ane Korinek (2005) Trade and Gender: Issues and Interactions (OECD Trade Policy Working Paper No. 24). • Kelegama S (2005) Ready Made Garments Industry in Srilanka: PreparingtoFacetheGlobalChallenges, Asia Pacific Trade Investment Review, Vol. 1, No1. • Maurice Landes, Stephen MacDonald, Santosh K. Singh and Thomas Vollrath(2005) Growth Prospects of India’s Cotton and Textile Industry. • Working Group for Textile and Jute industry for the Eleventh Plan (2007- 12)

- 24. OCTOBER 2022 | TEXTILE VALUE CHAIN 19

- 25. OCTOBER 2022 | TEXTILE VALUE CHAIN 21

- 26. 3rd Floor, Dawer Chambers, Ring Road, Surat- 395 002. Gujarat, India Phone: +91 261 4190200 / 2635541-42 | e-Mail : info@shahlon.com | Web. : www.shahlon.com Maintaining world-class quality standards and delivering innovative products have been the foundation of Shahlon group’s manufacturing philosophy. A system of acute quality control involving multiple tests throughout each stage of operation is adopted, ensuring quality, efficiency and dependability of every product. Our wide range of yarn offerings include Applications Textured We produce all types of NIM, SIM, HIM textured and crimp yarn, in all lustres - SD, FD as well as BRT, using interna- tional standard manufactur- ing techniques. Intermingle Our carpet yarn offerings are further expanded through intermingled yarn. Carpet We have been exporting various types of yarns such as micro and high bulk to the carpet manufacturing industry, for products ranging from rugs to wall to wall carpets. Dyed With a capacity of producing 750 tons per month, world-class infrastructure, we are well-known to meet the dyeing needs of international and local markets. Space Dyed Adding further value to dyed yarn, we also manufacture and supply polyester/ viscose space-dyed yarn. Weaving Furnishing Laces Tapes Carpets Labels Velvet Knitting Government Recognized Star Export House

- 27. TEXTILE VALUE CHAIN | OCTOBER 2022 27 The formation of Century Enka Limited in 1965, was the result of keen interest taken by Mr. B.K. Birla in collaboration with AKZO Nobel of Netherlands. Over the years, it has emerged a reputed producer of high-quality Nylon Tyre Cord Fabric (NTCF) used as reinforcement material in bias tyres and Nylon Filament Yarn (NFY) used mainly by apparel industry. Century Enka is known for high quality, product innovation, fair business practices and customer satisfaction. Mr. Sanjay Mehrotra, Senior Vice President Marketing (Textiles), Century Enka Limited, spoke exclusively to the Textile Value Chain during the recent Surat Exhibition, Yarn Expo Fourth, this category is for sportswear. Nowadays, there is a changing trend amongst the younger generation. They are going more and more towards athleisure. Globally, nylon is being used for this. But, in India, Nylon is not that prominent in circular knitting. We have brought in a new product range for this. We have brought in air-textured yarns for these microfilaments with a denier range of 140-144, 200/144. So, you will get the comfort, flexibility of fabric, breathability and other desirable qualities for sportswear in this range. You are one of the pioneers in the nylon industry? Yes, Century Enka is the largest Nylon-6 producer in India. Basically, we have two verticals, one is textiles and another is the tyre cord. We are manufacturing around 3500 tonnes of nylon per month and around 3000 tonnes of tyre cord yans monthly. Going forward, in this financial year of 2023-24, the company is on expansion mode and more than 200 crore rupees investments are coming for expansion in nylon textiles, both industrial and regular textiles. What is the percentage of industrial textiles and other textiles? In total around 55-60% is of nylon textiles and the remaining 40-45% is for industry. And the new investments that What are the new developments that you have brought into this Yarn Expo Exhibition? We are into Nylon yarns, polyamide-6,youcansay.Wehave brought in some new yarns in this expo. Our focus has been on the following categories mainly: First, ethnic wear, in which we have brought in substitutes for the silk. We have introduced a new range called ‘Sutra’, its denier range is 30, 40, 60 and 80. The fall and feel for this yarn is as good as that of silk. The other new range within ethnic wear is the ‘Katan Series’, which is an air-textured yarn. This lies between 70-80 denier. you will get the same fall and feel as that of silk. Moreover, you get a satin and velvet kind of feel, without actually using satin. Second, the other new innovation is for the dress materials. We are bringing in materials made of nylon with 110-140 denier range. But they give the same feeling as that of cotton. Third, is for industrial yarn that is usedfortechnicaltextiles.Wehave introduced some high tenacity yarns in the range of 50-70, 110- 200 denier range as a substitute for the imported yarn. This range goes up to yarns of 2000 denier. These are GPT products that no one has been manufacturing in the country. There yarns are used for making products like army uniforms, backpacks, webbings, defence products, parachutes etc. you are talking about, it is for which sector? That is more for industrial yarns and technical textiles side. Innovation Intelligence Driving market Senior Vice President Marketing, Century Enka Limited I N T E R V I E W Mr. Sanjay Mehrotra

- 28. OCTOBER 2022 | TEXTILE VALUE CHAIN 28 What is your market share in nylon? Answer: In totality, as far as textiles are concerned, we are having a market share of 25-30%. Century Enka is one of the leading players in textiles and as far as industrial tyre cords are concerned, capacity-wise we are placed at number three, in India. How are you placed globally? Answer: When we say globally, China is very dominant. Compared to Indian capacities, the Chinese capacities are about 20 times. Compared to that we are small in size and there is still a long way to go. We are competitive against Korean, Taiwanese, Indonesians and the Thai producers, size-wise. But as of now we are far behind than China. Are you planning any new innovative products? Other than this, we are working on anti-microbial yarns and recycled yarns. We have very recently received the GRS certification and we are into chemical recycling of nylon, where the pre- and post-consumer waste is converted into the caprolactam, which we then use to make the recycled yarns. In the last one year, we were exporting polymers and now we are doing yarns and working in the export markets. We are getting a very encouraging response from the European markets, especially for recycled nylon yarns. How do you see the future of these recycled yarns, as these days everyone is into recycling? Basically, there are two types of recycled yarns: One is the mechanical recycling and the other is chemical recycling. Earlier, nylon was already being recycled mechanically, it was going in to the engineering plastic applications. Now, through chemical recycling we are able to recover the polymer which is as good as virgin. So, we are very much optimistic. The chemical recycling set-up is more expensive and the products are very extensive as well. We are more inclined for environment conservation and there is an awareness about these. In developed countries, there is already a demand for these, but in developed countries like India, the market is growing and demand is still increasing. Nylon is a synthetic yarn, so you cannot call it sustainable… Nylon is a synthetic fibre. The advantage with nylon is that you can recycle it 100%. You don’t need to put it in landfill; hence we can say it is sustainable. Nylon can be recycled in any form, be it fibre or fabric. Out of the total MMF, what is the percentage of nylon? Answer: It is less than 3%. In total, MMF nylon share is 3%, in India and globally as well. Nylon is a niche product and per say it is expensive when compared to polyester. It is a superior product, of course, polyester has reached many markets as compared to nylon. You have mentioned about your special range of sports textiles, how do you see the growth of sports textiles? Indian sportswear, as per our studies, is growing more than 15% per annum. It is one of the fastest growing segments. So, nylon is the fibre for making sports wear as its abrasion resistance is high as compared to cotton or polyester. The only deterrent is the cost. Internationally, the nylon-based products are very expensive, so it finds application in the high-end market, despite being a superior product. In India there are still a few limitations in the processing when it comes to sportswear, this is one of the challenges. But we are trying to overcome this hurdle. There are many upcoming start-ups. What is your advice for those? Innovation is the key. Gone are the days of mass production. Be it nylon, polyester or any other fibre, the market demands small runs and fast changes and you have to react to customer’s need for short run, fashion trends change overnight, so, one should be flexible. Innovation and Intelligence will be the driving factors for the market.

- 29. www.uster.com/qbar2 Inspecting fabrics after weaving is old school. With USTER® Q-BAR 2, smart weavers can pinpoint defects during fabric formation. It’s the right way to reduce material losses and minimize manual checks. When it comes to fabric quality issues, prevention is better than cure. The whole fabric is automatically monitored – warp, weft, selvage and leno – and faults are identified immediately. LEDs signal defect locations to the weaver, with information shown on the control unit touchscreen. It’s automatic inspection, in-process and instant, so weavers can react to prevent long-running or repeating faults. USTER® Q-BAR 2 sets the future standard, controlling the weaving process instead of the output. USTER ® Q-BAR 2 Weave it right: spot defects on the loom

- 30. TEXTILE VALUE CHAIN | OCTOBER 2022 30 Mr. Ranjit N. Turukmane Innovation Management needed for successful ventures Prof. Ranjit N. Turukmane M. Tech (Textile technology) from VJTI Mumbai, associating Centre for Textile Functions, Shirpur, District Dhule as an Assistant Professor and has a total 12 years’ of experience in teaching from SGGSIET Nanded and VJTI Mumbai. His area of expertise includes: Spinning, weaving, Technical Textiles, Man-made Fibres and Textile composites. He has published 65 research papers in National international Journals. TEXTILE VALUE CHAIN has done exclusive interview with Prof. Ranjit Turukmane, Assistant Professor, Centre For Textile Functions, NMIMS Shirpur. Textile industries of Pune, Nashik, Nagpur, Kolhapur, Vapi, Silvassa, Daman, Bharuch, Dahej, Dholka, Surat etc. Innovation is an integral part of any field of engineering and textile is no exception. Along with my doctoral programme small research projects are also floated to explore new avenues and this gives a fresh feel about creating knowledge in lesser known areas of textile value chain. Would you like to share some interesting incidents/ instances that happened with you while working as a consultant to different industries or while teaching a batch of students. Textile field is full of enthusiasm, every day is a new beginning for us, I used to learn many things daily. As such, these incidences coupledwithexperiencesteaches a lot to become stronger in life. What are the major differences in the industries earlier and now? Tell us about the work ethics as well apart from the technological advancements. Textile world is growing and adopting rapid changes as far as the technological development is concerned. Over the last 20 to 25 years the technology has been evolved to reach a new high. Industry 4.0 to 5.0 and so on helping us to use developed concept for increasing production rate with better product quality. Tell us about your educational qualifications. What motivated you to complete your studies till masters degree? And why did you chose this stream? I completed my Education in Textiles, B.Text.E from College of Engineering Technology, Akola, M. Tech from VJTI Mumbai, DBM from Dr. BAMU Aurangabad I am currently pursuing Ph.d. In Technology from NMIMS Shirpur. My father always encouraged me about Textiles, as a farmer we had a history of cotton growing fields. Hence, association and interest in textiles was there from childhood. Once joined, I decided to acquire the highest qualification in the learning process. I also completed Management courses in parallel to my textile profession. As a part of being an academi- cian, research is an integral part. How do you develop a research temperament or what motivates you to carry out research in your labs? We have well established labs in the heart of the Textile industries and our institute is an integral part of Textile park located in Shirpur (Maharashtra). Being an academician, my 39-research papers have been published in International Journals and 26 research Papers have been published in Reputed National Journals. We send our students for 6 months in plant training with dedicated projects in various How do you teach/ inform your students about the latest developments in the industry and make them ready for working in the industry? Assistant Professor, Centre For Textile Functions, NMIMS Shirpur. I N T E R V I E W

- 31. OCTOBER 2022 | TEXTILE VALUE CHAIN 31 As explained earlier, with technological advances on the shop floor, teaching-learning process in the universities have also changed a lot. With the penetration of internet, where ready information is available handy, teachers’ role has become more challenging. We need to deliver a content which is beyond the scope of digital world. Latest developments can be understood by reading international textile research journal, seminars, webinars, conferences and MDP programs. We insist students to read a lot from print media. How do you think the pandemic has affected the education system? Tell us both the pros and cons. One good thing has happened in pandemic: most of the students have become conversant with online platforms viz. Zoom, MS-Team Google meet etc. One major drawback is that some students did not have access to internet and some had to drop out due to lack of financial support (due to loss of jobs). How are management studies important for Textile students?Howdoesithelpinincreasingproductivity? Worker handling and their management is a key of success for textile students in industries. Definitely it helps in increasing the productivity and is ultimately useful for achieving certain goals of textile industry. What is your take on the new trend of ‘Organic fibres’ especially use of Organic Cotton and Natural Dyes? Natural fibers grown according to national organic standards without the use of toxic pesticides and synthetic fertilizers are termed as organic fibres. These fibers are now find uses in many value added textiles, whereas natural dyes could be useful for sustainable product development. India has already taken a leap in this business area and in coming years it would be order of the day both in domestic and export markets. Whataresomemeasuresthatneedtobetakenasapart of the Quality Management in Fabric Production? The major measure needed is the comfort properties. It should contain the wearer and satisfy the requirement of the consumer. The manufacturers should ensure quality of high-grade fabrics targeted to RMG sector and fetch added revenue. Quality management is now the keyword of success in any business composition. Consumer is the king today. What are some of the Natural Fibres that are being used? Where do they find applications? Banana, sisal, corn and jute are the natural fibres used for decorative purposes and handicraft articles. They are used to enhance look, texture and appearance of the fabric. The readers may be aware that the north Maharashtra region is a major banana producing zone. Special projects are being proposed to popularise products based on banana fibre. What would be your suggestions for start-ups in the textile manufacturing sector? How can these ventures grow, considering the immense competition that lies in this sector? Initial amount should be funded to start with small set up and this will lead towards generating more and more awareness towards entrepreneurship program. If quality and costing are given more priority in any product, then competition will be reduced and product will be known in long run. What are the different parameters that a textile technologist must consider before launching a product? How can he/she tap the market and cater to the different variety of customers? Market survey and sales analysis of a particular product is imperative before launching any product. One can tap the market by continuously knowing the sales figure for a given sector and specific product which is increasing day by day. Logistics support is also another factor which needs to be emphasised on. What is included in the concept of sustainable textiles? What are some measures taken by leading brands towards sustainable textiles? Sustainable textiles is the concept of increasing the value and life of the product for which it is going to be used. Manufacturers are using it now a days in textile so as to increase the life of the human beings. Concentrated efforts are being taken by the industry to reduce carbon foot print and to make it as low as possible. Pest free farming, reduction and alteration of polluting chemicals in processing, low temperate operations to reduce energy consumption etc. are the few approaches where industries are investing to get rid of the threats to human life. Would you like to add/ tell us something else apart from the questions asked above? India is a country where majority people are with lower or middle income range, if they are made aware of these products and it utilisation towards the welfare of human beings, then it will be a second source of generating income to every individual, leading to generating revenue and making a profitable business in their own territory.

- 32. OCTOBER 2022 | TEXTILE VALUE CHAIN 67

- 33. TEXTILE VALUE CHAIN | OCTOBER 2022 26

- 34. OCTOBER 2022 | TEXTILE VALUE CHAIN 27 luwa.com Luwa India Pvt. Ltd. — # 3P-5P, Gangadharanapalya — Kasaba Hobli, Off Tumkur Road — Nelamangala, Bangalore North — 562 123, India Luwa System for Weaving � Laminar air flow — clean air directly into the weaving zone � Direct conditioning — high humidity only where required � Increases production efficiency � Removes dust and fly. � Energy-efficient. Precise control of humidity, temperature machine exhaust

- 35. TEXTILE VALUE CHAIN | OCTOBER 2022 68

- 36. TEXTILE VALUE CHAIN | OCTOBER 2022 28 IMPORT MARKET REPORT NATURAL FIBRE SILK WOOL, FINE OR COARSE ANIMAL HAIR COTTON. OTHER VEGETABLE TEXTILE FIBRES 6 9 . 3 3 132.56 433.96 1 8 0 . 2 7 156.9 768.49 271.59 194.94 Jan-Jul 202 1 Jan-Jul 2022 6 0 . 1 63.72 5472.48 4 4 8 . 9 8 55.17 5250.68 370.42 95.06 J an-Jul 2021 Jan-Jul 2022 EXPORT MARKET REPORT units in USD million Reference: Ministry of commerce

- 37. OCTOBER 2022 | TEXTILE VALUE CHAIN 37 SPORTS TEXTILES – your road to success 1. Introduction Technical textiles have been classified in to various categories such as industrial textiles, agro textiles, medical textiles, geo textiles and so on. Amongst the various textiles in which the individual textile occupies relative importance to the other, Sports textiles contribute 10% of the world technical textile market. Increase in demand of the sports textiles is due to the demand and also by new innovations in the fibre manufacture, process and finishing treatments. Two different raw materials like hydrophobic and hydrophilic are used to develop the functional knitted structures for leisure wear, sportswear which improves the comfort of the wearer. Sportswear textiles belong to a category called Sportech, which is one of the mainstream technical textiles. This rising interest in the Sport Tech is due to a number of social factors that include increased considerations of wellbeing and good health, growth of indoor and outdoor sports facilities and the ever-increasing pursuit of the adult population of activities outside the home or workplace. Among the fabrics, knitted, non-woven, or woven, knitwear fabrics has always beenassociatedwithrelaxedclothing and fashion. Hence, sportswear has been developing as a strong element in the present conditions finding its applications in many sports like cricket, golf, football etc. Many definitionsweregivenforsportswear and znbroadly defined as “clothing designed for comfort or informal wear.” Sports garments are now standard everyday wear, especially among younger generations. The interactions between these two areas of influence, sports and fashion, are an important source of new trends in both industries. Increasinginterestinthesportswear and casual or urban fashion could be due to the dramatic increase in participation in sports activities and interest in health and fitness in the last few years. This has been reflected in the expansion of market for sports specific apparel. The global sportswear market is expected to grow at a CAGR of 6.8% over the next five years. At the same time, the share of sports apparel in amateur sports is around 85%. 2. Problems with Conventional sportswear Anyfabriceithermadeoutofwoven or knitted materials should have adequate comfort characteristics Dr. G Nagrajan Sr. Technologist Texcoms Textile Solutions, Singapore SPORTS TECH

- 38. TEXTILE VALUE CHAIN | OCTOBER 2022 38 required for some specific applications. In the case of a formal wear where the activity of the body movement is not severe, the fabric may have sufficient air permeability, able to transmit the heat out from the body and better moisture management capability. However, for the sportswear fabrics where the activity is severe, it requires the above-mentioned properties in an improved manner so as to provide comfort to the sports personnel. Conventional sportswear lack in proper absorption of sweat from the body and hence leads to stickiness and clogging of pores. This leads to increase in body temperature and brings down the performance of the player. Activewear needs to provide a thermal balance between the heat generated by the body while engaging in a sport and the heat released into the environment. Normal activewear garments do not always fulfil this requirement which will eventually lead to thermal stress. 3.Basic requirements of a sportswear fabrics During the sports activity especially in high active sports like tennis, football heat stress will be of great concern due to generation of metabolic heat which is in the range of 800 to 1200 W depending upon the activity, physical body conditions of the wearer. Due to this, the core temperature of the body increases by 1 to 2 degree Celsius and moreover the sweat generation will be around 2.5 litres/hour. To control the core temperature of the body, heat of vaporization of water takes place to enhance the cooling effect of the body, sportswear fabrics should have the ability to absorb the sweat, dissipate to the environment and provide cooling effect to the wearer. In other words, the high active sportswear should satisfy the following requirements • High stretch and elastic recovery for sufficient freedom to the wearer • Compression athletic wear (CAW) also called as “skin suits” which provides necessary comfort and anatomic fit to the body. They conform to the natural curves of the body and acts as second skin. 4. Fibres for Sportswear Natural, synthetic, regenerated and specially developed fibres are available to manufacture sports textiles. Fibres commonly used are • Natural fibres – Cotton Generally,notpreferredasitabsorbsandretainmoisture although it possesses good softness and comfort. • Synthetic fibres – Polyester, Polyamides, Nylon • Regenerated cellulosic fibres – Lyocell, Bamboo • Speciality fibres – Hygra 20, Killat N23, Lycra 25, Dacron 5. Yarn requirements Twist in yarns and linear density play a major role in sportswear fabrics for moisture transmission. It has been reported that higher twist coefficient and linear density decrease the moisture management properties like absorption time, wetting time and maximum wet area circle radius. Increase in twist coefficient improves the air permeability, water vapour permeability and wicking height but absorption is reduced. Micro denier polyester yarn is suitable as it gives better moisture transmission, faster rate of evaporation and good cooling effect when compared to that of the spun polyester, PC and 100% cotton materials. 6. Fabric parameters ➢Single knit structures Single jersey fabrics provide higher moisture absorption and better wickability than that of the knit-tuck fabrics. Since it has only knit loops it can be oriented lengthwise in wale direction and provides better wickability than that of the knit-tuck structures. Fabric comfort is characterized by factors such as porosity, pore size, thickness, density and tightness factor. Slack fabric with lower contact angle has better water evaporation rate and higher wicking rate as compared to other different knitted structures. ➢Two layer knitted fabrics Two layer knitted fabrics has become popular in sportswear. In this construction inner and outer layers are separate and have unique functionality. The inner layer is made up of hydrophobic fibre and the outer layer is hydrophilic fibre. For example, two layer knitted fabrics made of polypropylene as inner layer facing the skin and viscose or cotton as outer layer. Such type of fabrics exhibits higher overall moisture management

- 39. OCTOBER 2022 | TEXTILE VALUE CHAIN 39 capability due to quick transfer of liquid moisture from inner to outer layer. ➢Biomimetics structure It refers to replicating or mimicking the mechanism found in nature. Biomimetic warp knitted structures developed with two guide bars using polyester and nylon with branched structures. In this structure, the inner layer has a smaller number of longer loops than the outer layer. Pumping of water upwards from inner to outer facilitates better water transport properties. In other words, the fabric has faster initial water absorption, quicker spreading and lower air resistance than the other fabrics of similar material and construction. 7. Evaluation methods for sportswear fabrics Subjective and objective evaluation methods have to be carried out for sportswear fabrics. In subjective method, wear trials have to be conducted for players by asking them to reveal the comfort after vigorous activity.Thesubjectsneedtobeevaluatedforsensation comfort of the fabrics like clingy, damp, clammy, heavy etc. Moisture comfort sensory perception is the main contributing factor for sportswear fabrics. There are many objective methods available and some of the important comfort properties required to be evaluated for an active sportswear fabric are 1. Air permeability 2. Thermal conductivity 3. Moisture management capability 4. Water vapour permeability 5. Water absorbency Air permeability determines the ability of air flow through the fabric. Air permeability is a function of fabric thickness and surface porosity. In knitted fabrics, the pore size and distribution in a fabric is a function of fabric geometry. Loop length is one of the structural parameters that determine pore size in knitted fabric. When the loop length increases, the air permeability also increases and vice versa. Thermal comfort is the state of mind that expresses satisfaction with the thermal environment, which means that a person feels neither too cold nor too hot . As an interface between the human body and the environment, textiles play an important role in the heatexchangebetweenthebodyandtheenvironment. Thermo physiological comfort determines the breathability and moisture management. It means that it determines both the heat and moisture transport through a fabric, whether the moisture is in the form of liquid or vapour form. Moisture Management Capability determined by OMMC index by the instrument determines the capability of fabrics suitable for sports wear fabrics. The instrument provides detail information like wetting time, spreading time, accumulative one-way transport and assigns OMMC index value. Higher the value better the moisture management capability and vice versa. Water vapour permeability depends on the porosity of the fabric and diffusivity. Diffusivity of water vapour depends on the fabric type, structure and its construction. Water absorbency is the ability of the fabric to absorb, penetrate and spread quickly which depends upon the type of fibre and also the material construction. Regenerated cellulosic fibres has faster absorption rate than cotton layered fabrics because of more porosity. 8. Finishing treatments for sportswear In general, sportswear gets contaminated easily due to perspiration which leads to growth of bacteria. Fragrance finished fabrics with microencapsulation and antimicrobial finishes like betacyclodextrin kills bacteria. Finishing treatments enhance the comfort level by quick wicking and evaporation. Nanodry finish LLC is also found suitable for the fabrics as it increases the absorbency of sweat. 9. Conclusion Sports textiles is vast and challenging field in which the required functionality can be developed depending upon the fibre, yarn, fabric characteristics and finishing treatments. Moisture management properties have to be carefully observed for any sportswear as it has larger influence on comfort sensation of the wearer. High performance fibres like Cool Max, Thermolite, Thermocool are offered by Advanced Fibre Technology for various sports applications. PIC : akoa

- 41. TEXTILE VALUE CHAIN | OCTOBER 2022 32

- 43. OCTOBER 2022 | TEXTILE VALUE CHAIN 43 FUTURE CHALLENGES AHEAD IN TEXTILE EDUCATION ABSTRACT Indian textile industry is one of the leading textile industries in the world.Indiantextileindustrylargely dependsupontextilemanufacturing and exports. It also plays a major role in economy of the country. The sector contributes about 14% to industrial production, 4% to the GDP and 17% to the country’s export earnings. It provides direct employment to over 35 million people. The textile industry is the second largest provider of employment after agriculture. India has the potential of increase its textile and apparel share in the world trade from current level of 4.5% to 8% and reach US$80 billion by 2020. The global technical textile industry is estimated at US$127 billion and its size in India is pegged at US$11 billion. Thus, the growth and all round development of industry has a direct bearing on the huge requirement of technocrats. To develop this industry human need to research, invent new technology which helps to develop garments and clothing industry. Now-a-days the demand of textile education is increased because there are a large textile and garments industry in many countries which produced and develop garment so that they need technical and educated person. So many countries has a large number of textile universities, colleges and institutes which provides different types textile degree including postgraduate, undergraduate, diploma degree, etc. If anyone wants to build their carrier in textile industry, he/she should take up a textile related degree which helps them more. Keyword: Technical Education, quality, authority, research work, skill gap Dr.J.ANANDHAKUMAR Lecturer, Department of Textile Processing, GRG Polytechnic College, Coimbatore, Tamil Nadu, India SKILL DEVELOPEMENT

- 44. TEXTILE VALUE CHAIN | OCTOBER 2022 44 INTRODUCTION In India Technical Education has been drastically growing from the past few decades. Previously only a hand full of students was able to access this technical education. But in today’s scenario, Technical Education is one of the most popular choices of lakh of students. The southern most states of India accounts to have more than 69 per cent from the total count of technical education. Last year around 8.19 lakh student enrolled in 2,297 engineering colleges all across the country. In the present academic year, Tamil Nadu alone has around 85 new self-financing colleges which were approved by the AICTE. The total number of engineering colleges adds up to 444. Andhra Pradesh is having the highest number of engineering colleges which add up to 523. In other states like UP, Rajasthan and Orissa jointly add up for just 14 per cent of India’s technical colleges. This regional disproportion and quality are at present the serious apprehension of the authority concerned. The production and supply chain of textiles industry is very vast and one facet of the industry is different to another in varied skill sets for manufacturing of the products. For example-The RMG industry requires specialized job roles for cutting, stitching, washing, packing etc for apparel making. Further, each skill level has been segmented into different levels depending upon the importance and assigned role in the supply chain. For ex. the cutting activities in RMG industries by job roles like cutting, cutter, cutting master etc. Similar is the case for weaving and knitting industry and other value chain activities. Hence, there is a need to have mapping of the occupations based on the activities performed and skill level required in the production process. The occupational mapping of this sector may bring about an overview in the different manpower’s required by each segment of the industry. In order to study the textiles and clothing industry requirements of skilled manpower for each job role and the present availability in the labor market, a Skill gap analysis for each job roles has to be taken up. The skill gap analysis will provide detailed information on present available workforce on each job role, industry requirements, may also project the future requirements of each job role etc. Accordingly, the demand and supply gap in the skilled workforce may be identified for bridging the gap by means of skill development. The gap analysis may also help in developing measures to make a balance between supply and demand of job roles. 1. TECHNICAL EDUCATION SCENARIO India has established vast infrastructure facilities with regard to the Technical education. This has provided the country with a niche advantage in the globalized economic environment. The technical education will aid for the growth of a countries economy and also in national growth. In the past 25 years the growth rate of technical education was phenomenal. There was a huge rate of increase in the total number of institution from 158 in the year 1980 to 1,346 in the year 2005. This has also increased the intake of students in the Engineer- ing degree level from a minuscule of 28,500 to around 4, 52,260 in the same period. At present the total in- take has grown to 8, 19,000 in the last year. The man- ifold boost in the intake and augmentation in the total number of technical institution has resulted in a major increase of pressure on the excellence of educations of engineering and technology field [1]. 1.1 All India Council for Technical Education (AICTE) This can be easily seen in the obvious increase of courses being offered in these institutions. The engineering courses have almost quadrupled recently. Previously there were just three basic branches in the engineering which were commonly known as Civil, Electrical and Mechanical. These courses were on the basis of Soil, Coil and Oil branches. At present these 3 major branches have been stretched and expanded to 41 courses in under graduation alone and more than 100 courses in Post graduation. Some of the latest and very popular areas include Biotechnology, Nanotechnology etc. Environmental Engineering, Ocean Engineering and Climate Change etc are few other courses in relation to the advancement of the branches in engineering. To perk up the technical education and arrive at global standards there are certain areas which require immediate attention.