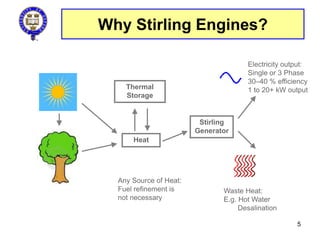

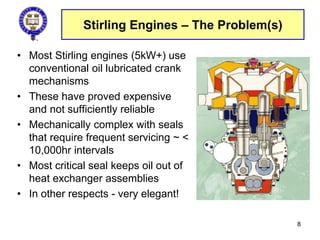

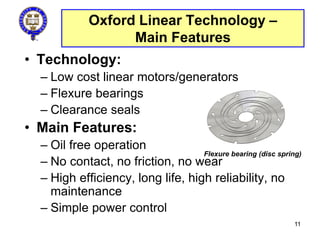

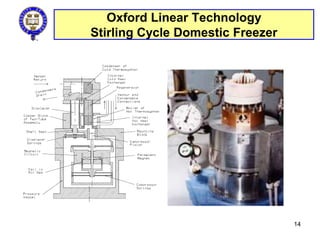

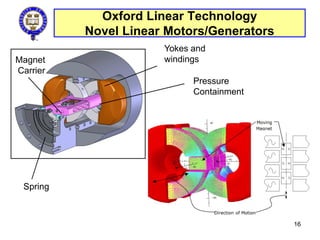

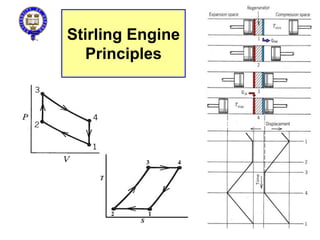

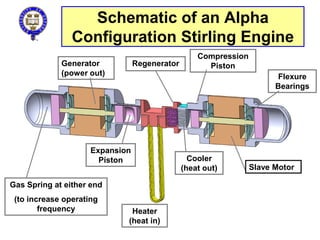

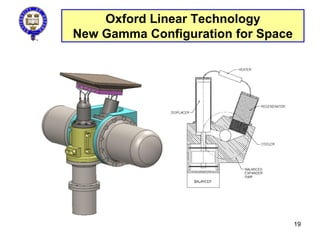

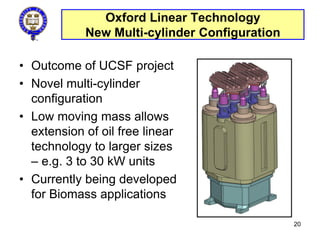

This document discusses biomass-fueled Stirling engines for off-grid applications. It outlines that biomass and Stirling engines are well-suited for power generation in remote communities due to their ability to use low-quality fuels. The document then describes Oxford University's development of linear Stirling engine technology, which uses oil-free and wear-free components like flexures and clearance seals for long life and low maintenance. This technology is well-suited for biomass applications from 5-20kW. Finally, it summarizes Oxford's work developing new Stirling engine and solar concentrator designs to further improve biomass-powered systems.