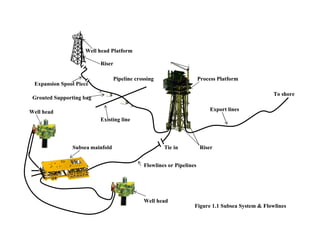

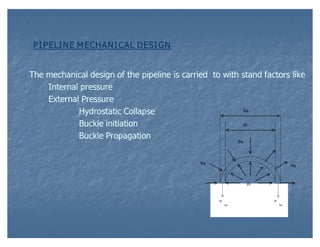

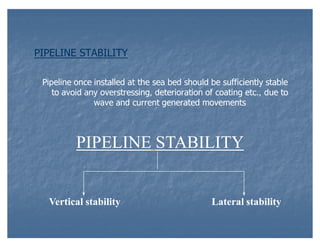

This document provides an overview of subsea pipeline systems. It discusses the key components including wellhead platforms, risers, pipelines, manifolds, and flowlines. It then describes various types of subsea pipelines and their purposes for transporting hydrocarbons from offshore production units to shore. The rest of the document outlines the major design considerations and analyses performed for subsea pipelines, such as sizing, material selection, mechanical design, stability, crossings, and cathodic protection. Standards and codes used for subsea pipeline design are also listed.

![Vertical stability

Sinking in to the sea bed during maximum fluid density

condition.

Floating of Buried Pipeline during Empty condition Soil

Liquefaction.

The Pipe sinkage is determined as the depth at which the applied

pipe pressure equals the soil bearing resistance.

Soil deformation(pipe sinkage)H,is given by:

sinkage)H

H = D/2-[(D/2)2 ± (B/2)2]1/2

D/2-

Where,

D = Overall pipe outside diameter including pipe coatings

B = Projected contact area between pipe and soil =P/qu

Where,

qu = CNC +1/2BK NK

+1/2BK

qu = Ultimate bearing capacity of soil

P = Pipe submerged weight including pipe coatings and in water

filled condition per unit length.](https://image.slidesharecdn.com/98338181-overview-to-subsea-system-131023214853-phpapp02/85/subsea-20-320.jpg)