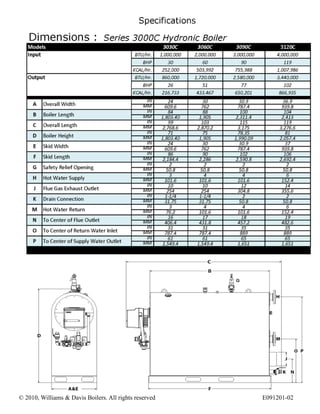

The document outlines the features and specifications of the Series 3000 hydraulic boilers by Williams & Davis, highlighting their ultra high efficiency, modular design, and compliance with ASME boiler codes. It emphasizes advanced features like fully modulating burner operation, linkageless controls for improved fuel efficiency, and a robust structural skid for stability. Additionally, it assures operational testing of each boiler and offers an industry-leading 5-year warranty with options for longer coverage.