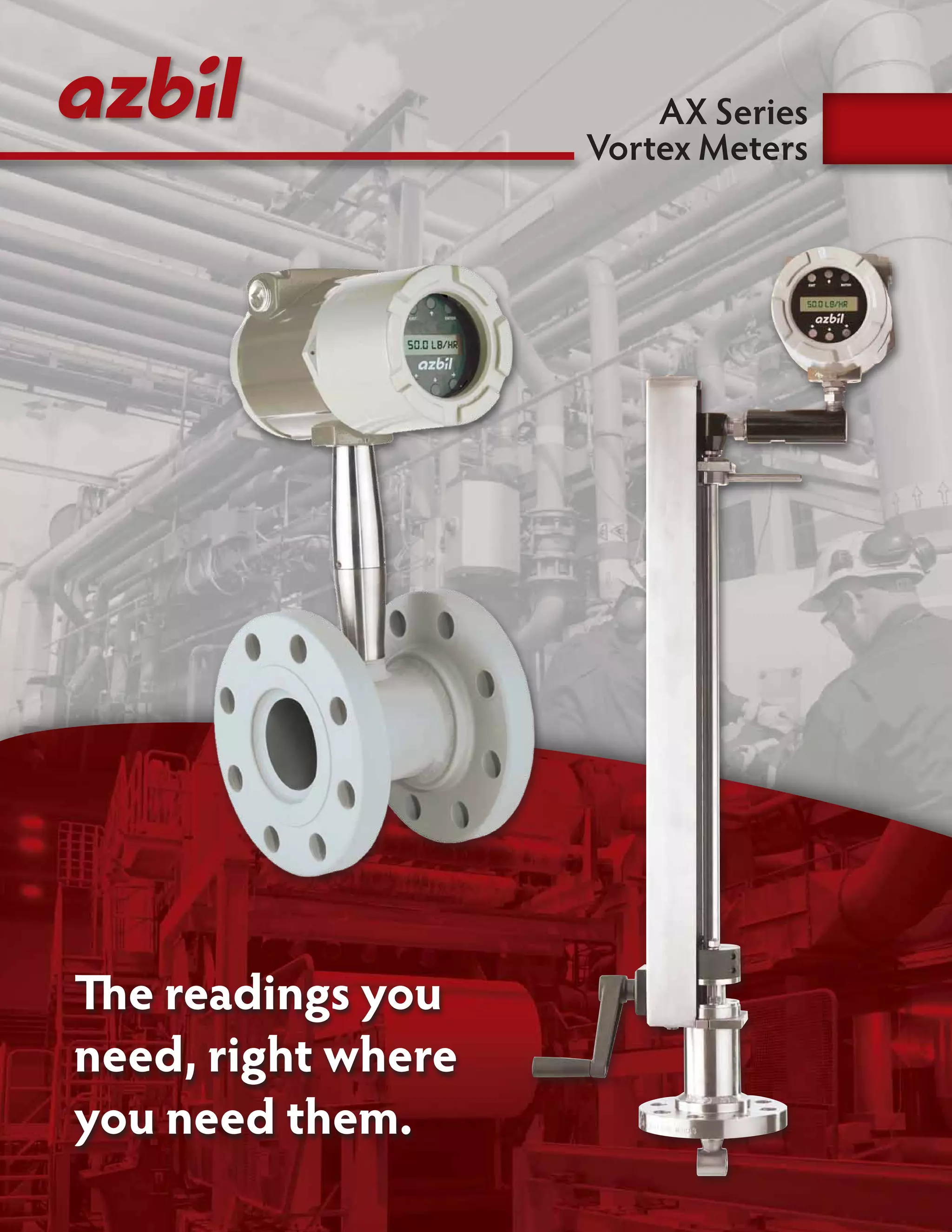

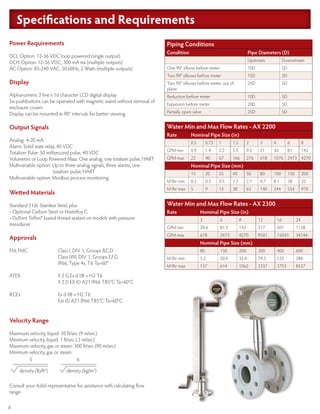

The AX series vortex meters from Azbil North America integrate multiple sensing elements to accurately measure mass flow rates of gases, liquids, and steam. They can be installed in various configurations and provide real-time energy monitoring, simplifying systems while reducing costs. With features such as hot-tap capability and remote electronics options, these meters accommodate a wide range of applications and environmental conditions.