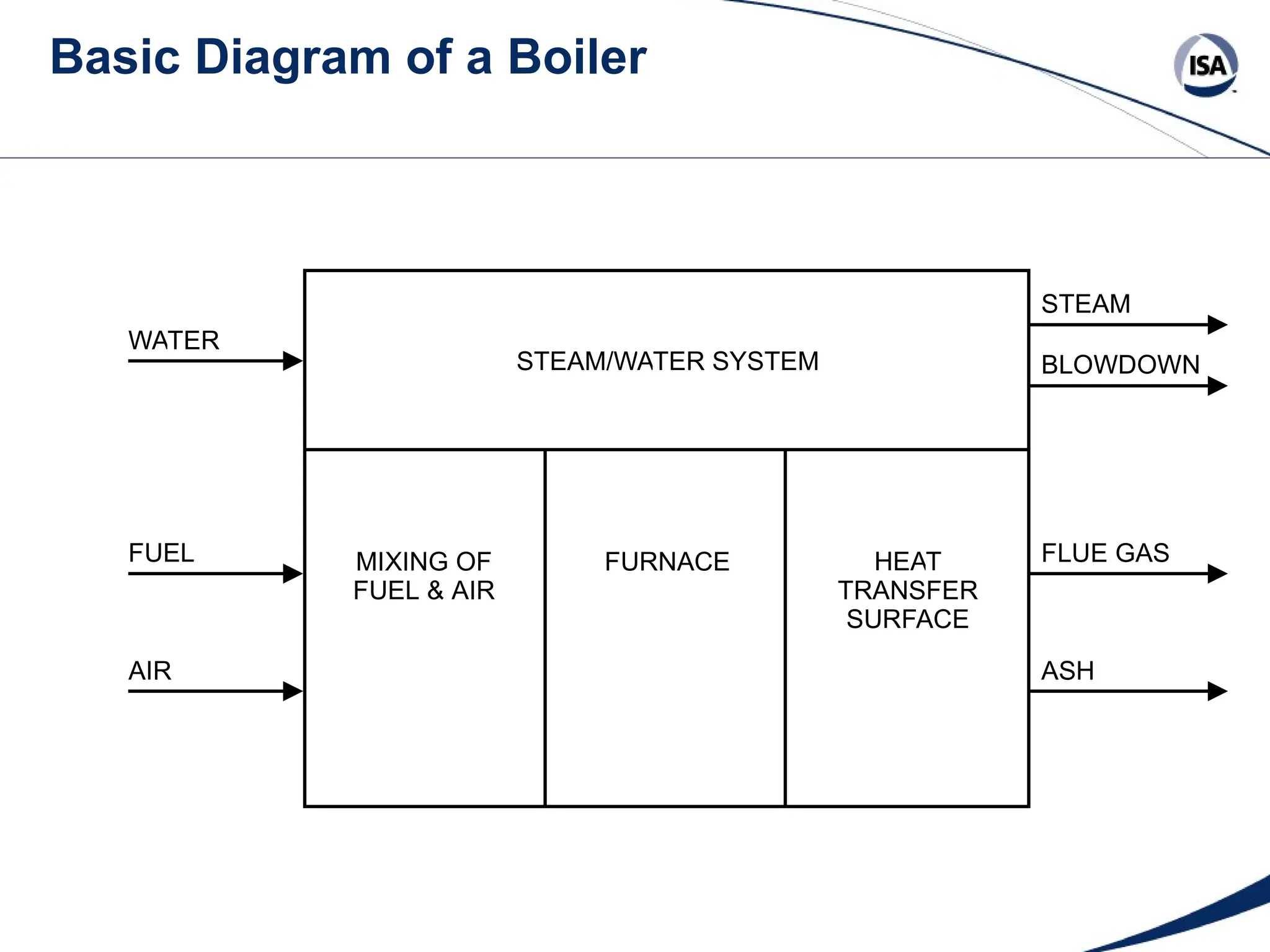

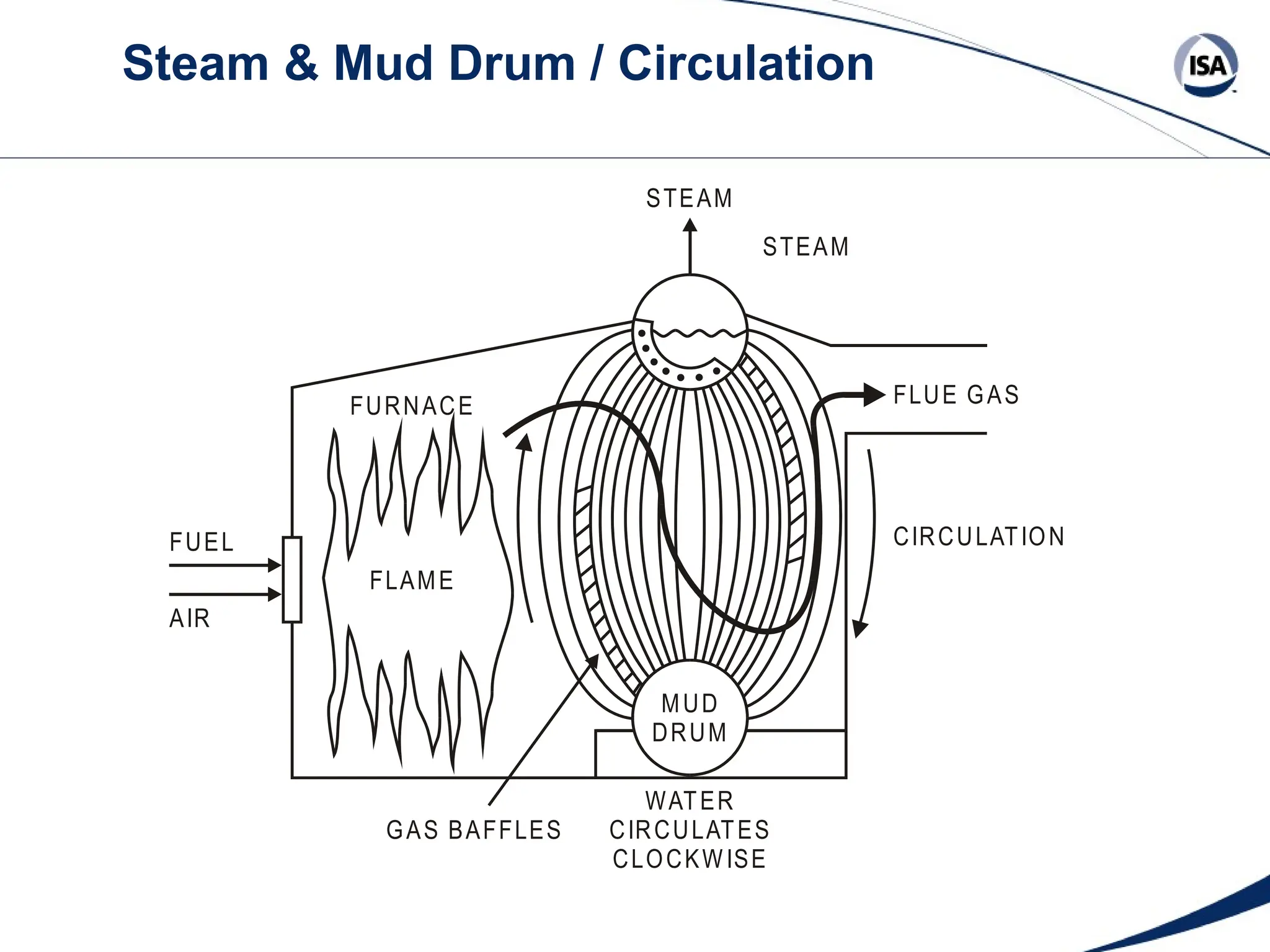

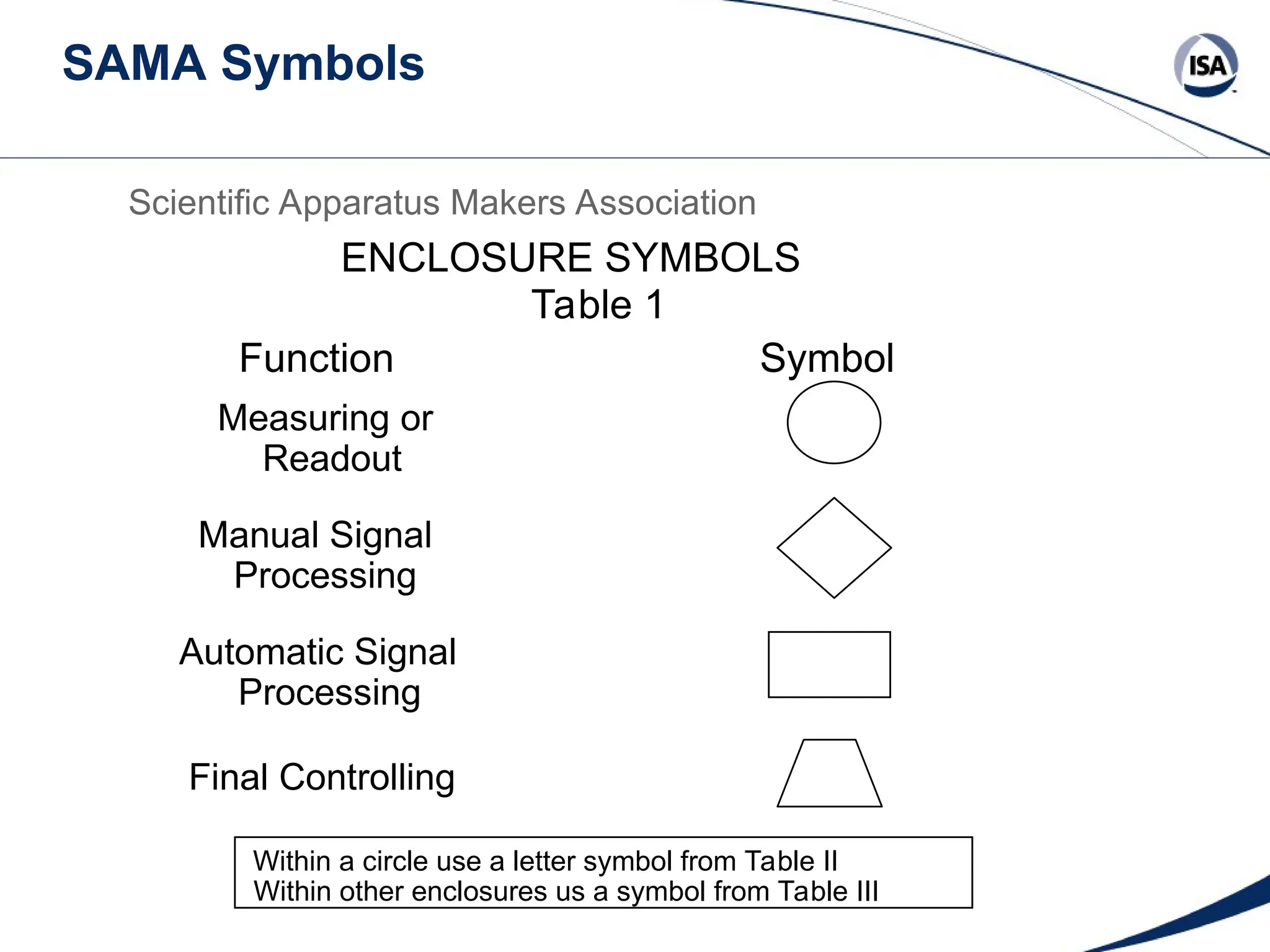

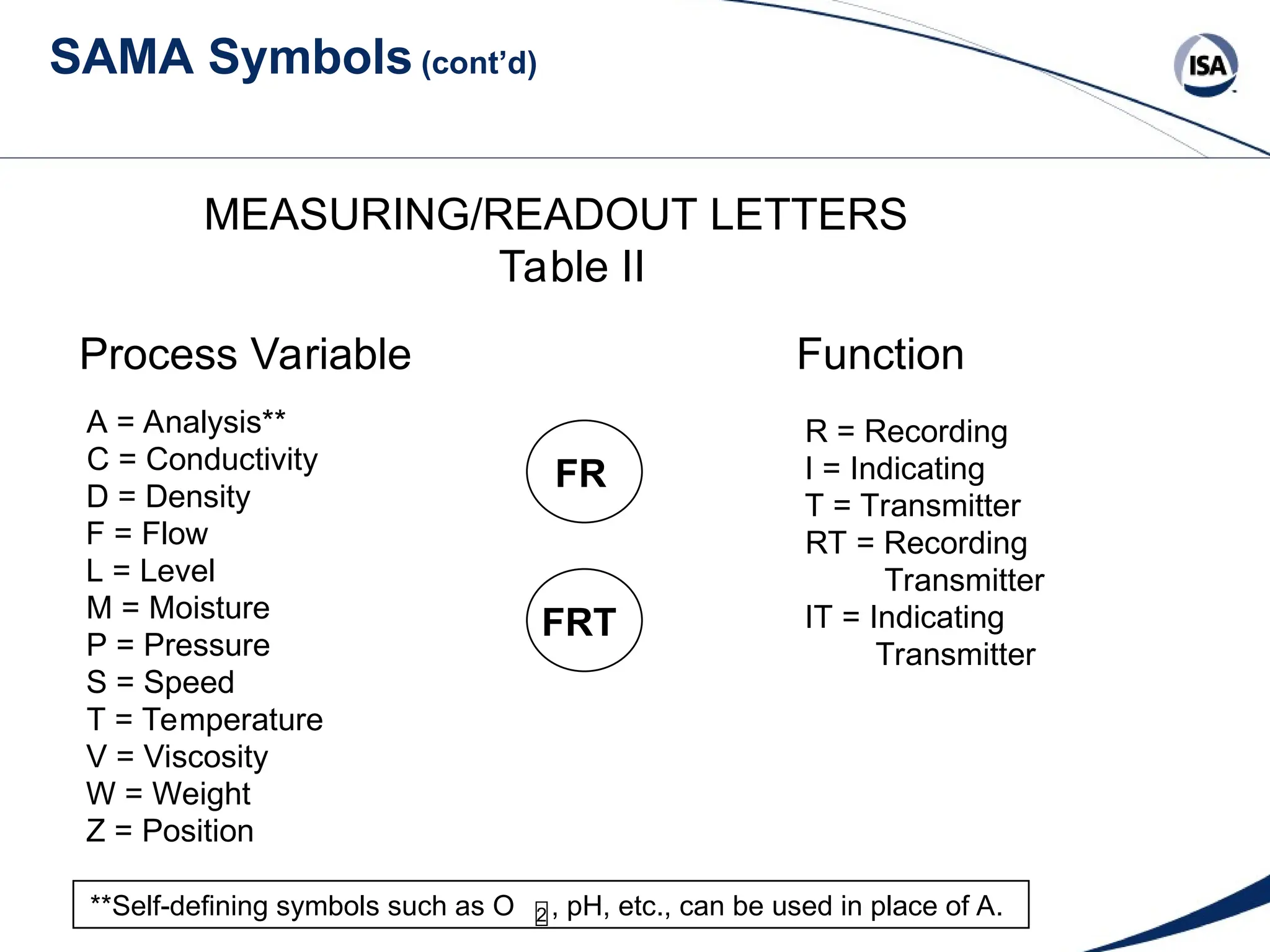

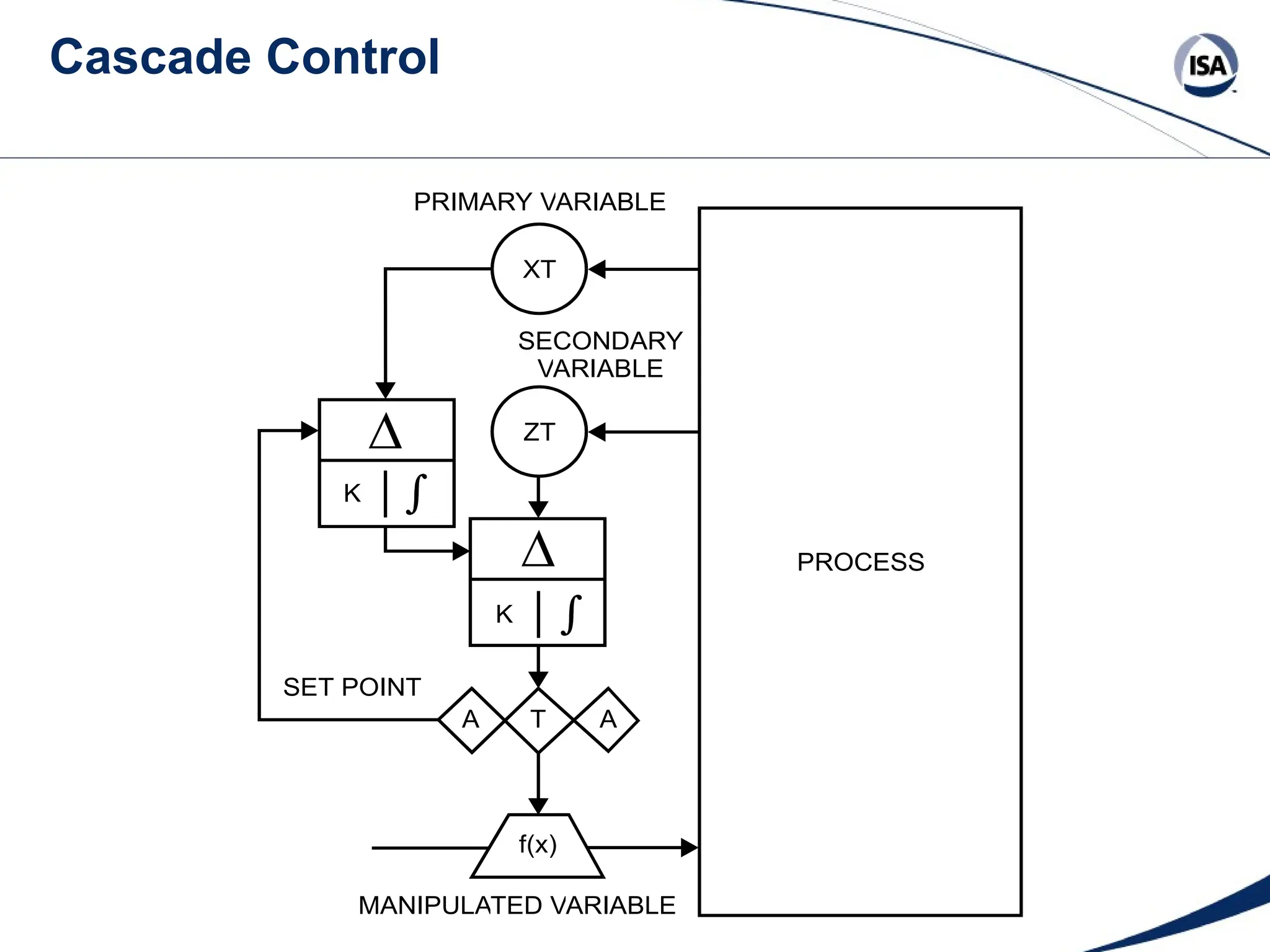

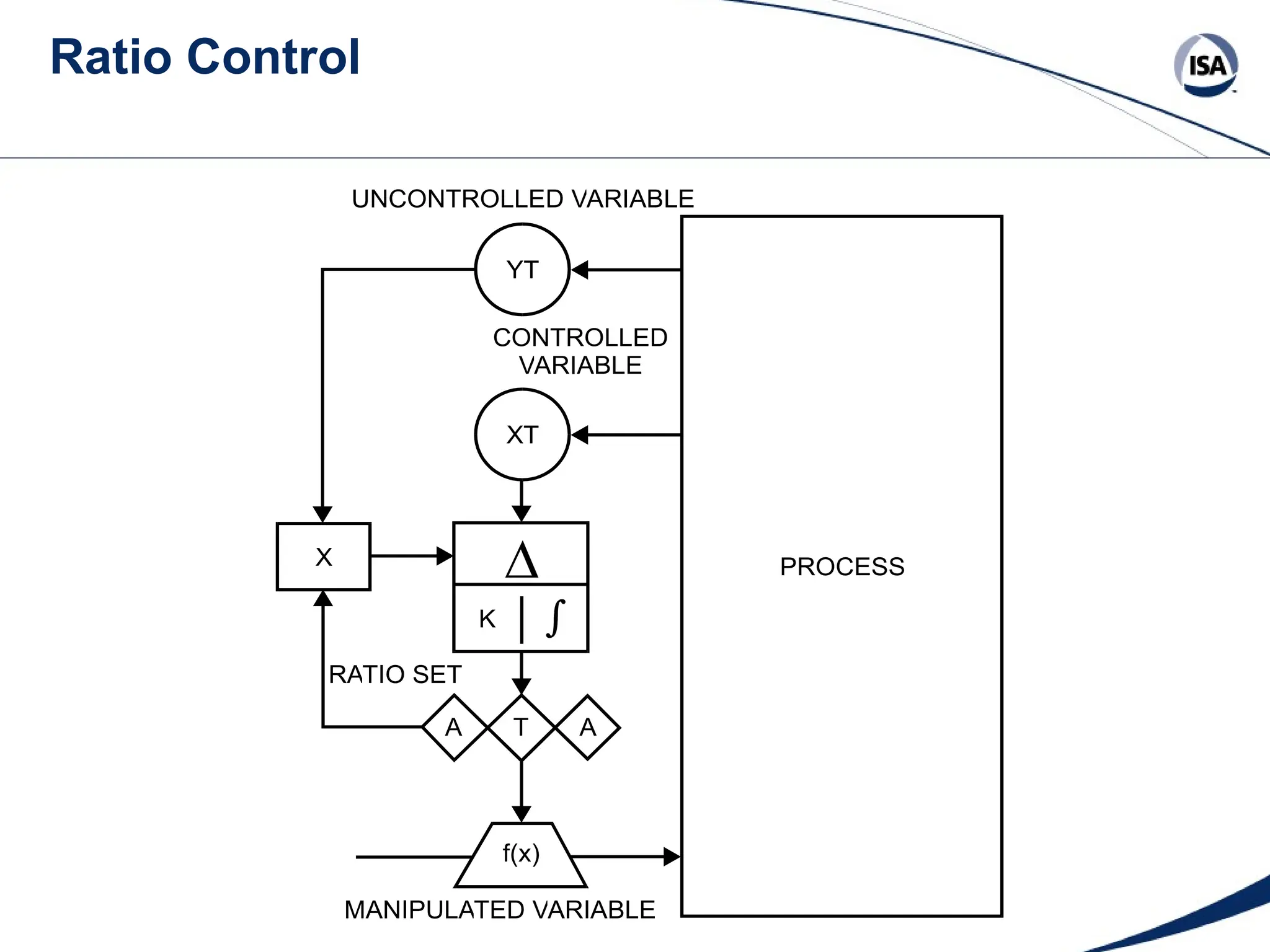

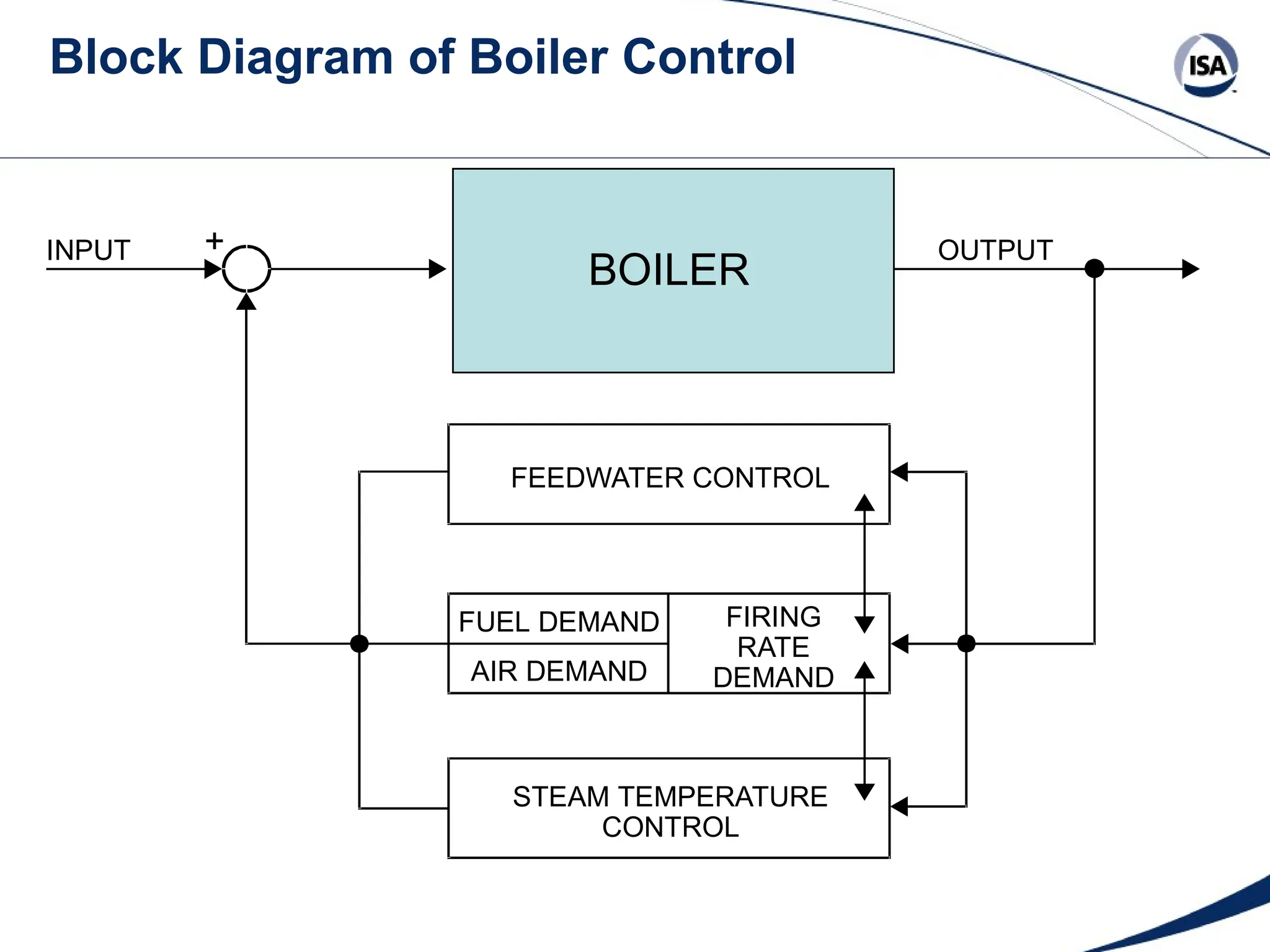

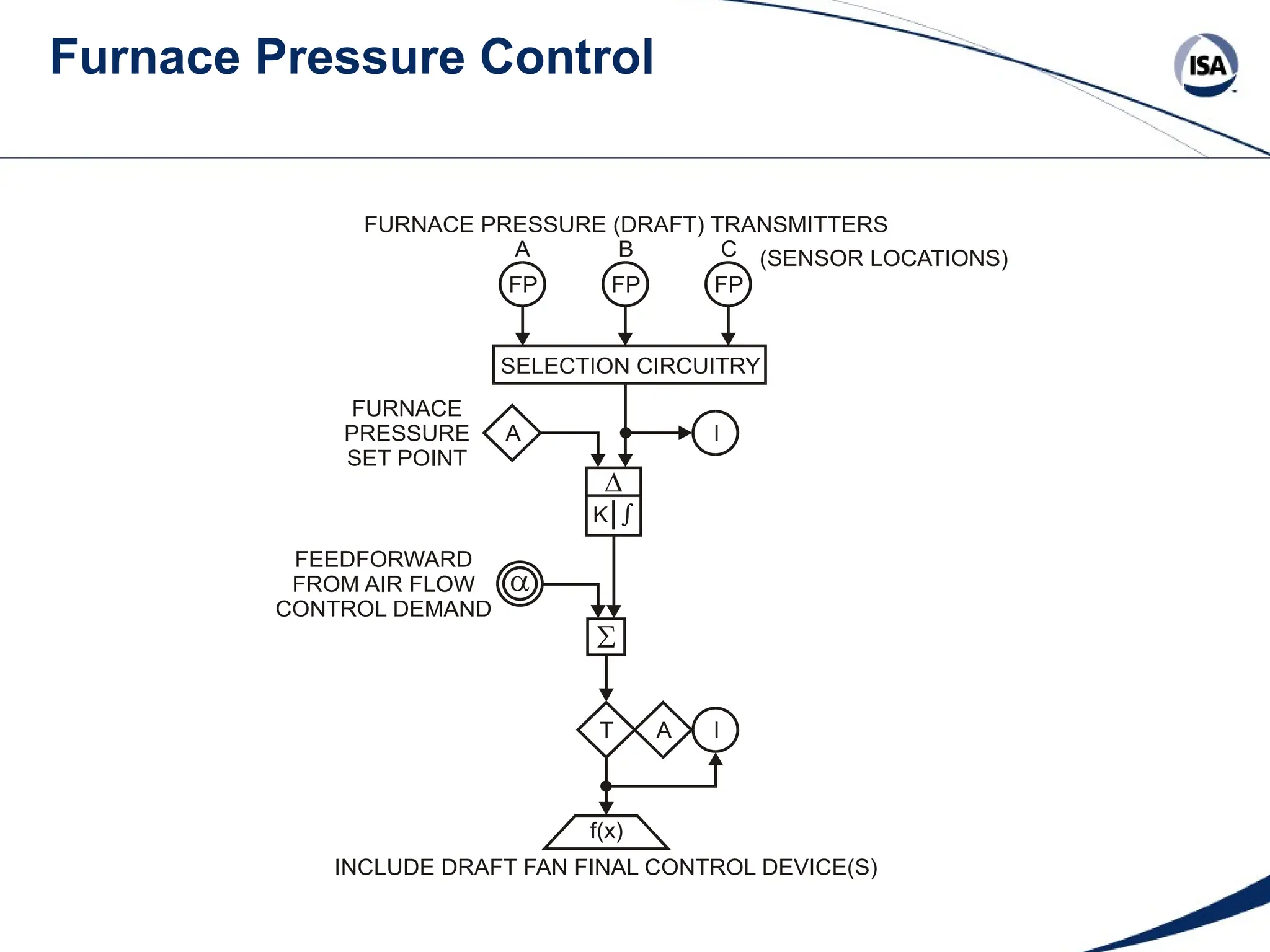

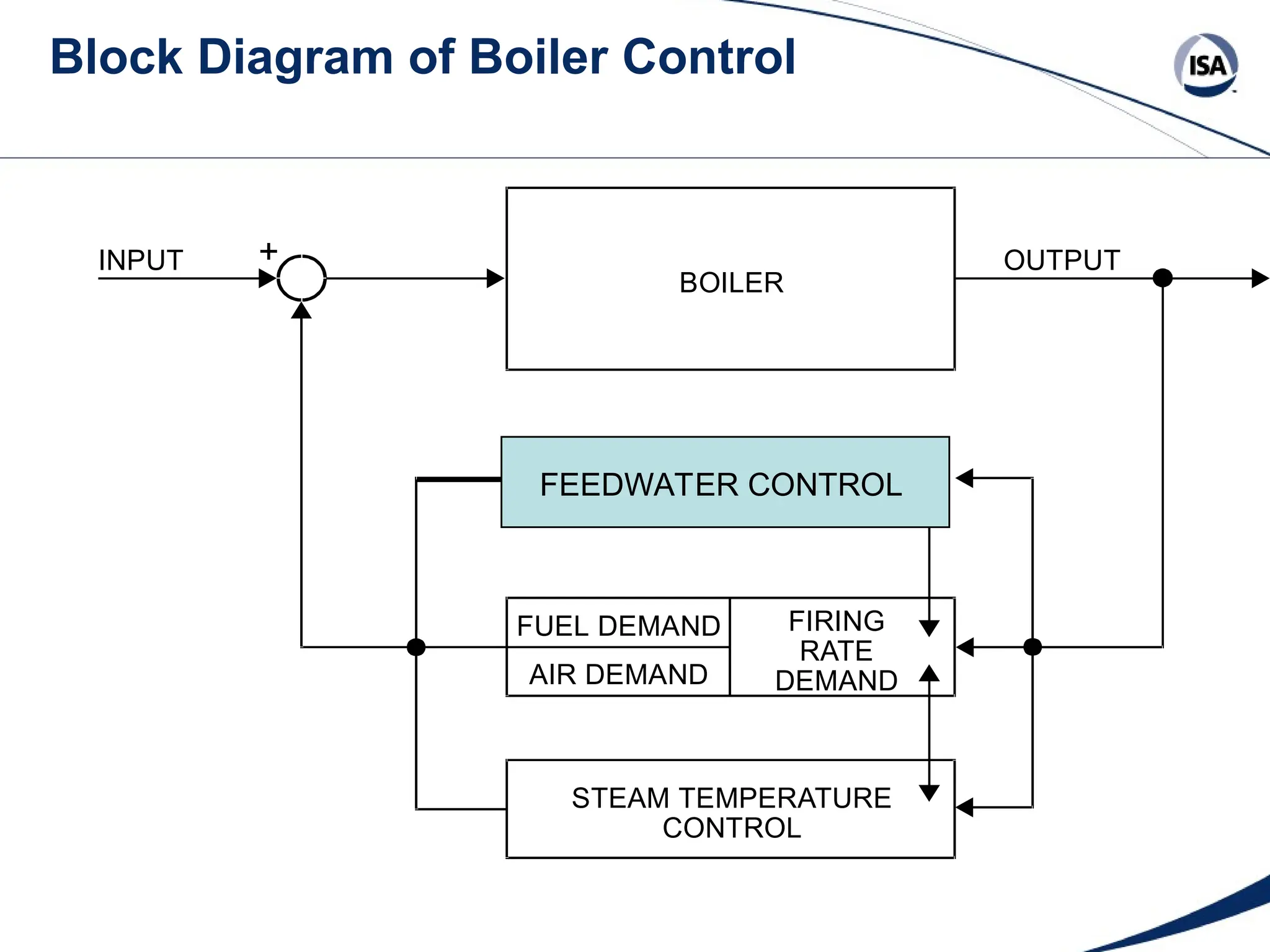

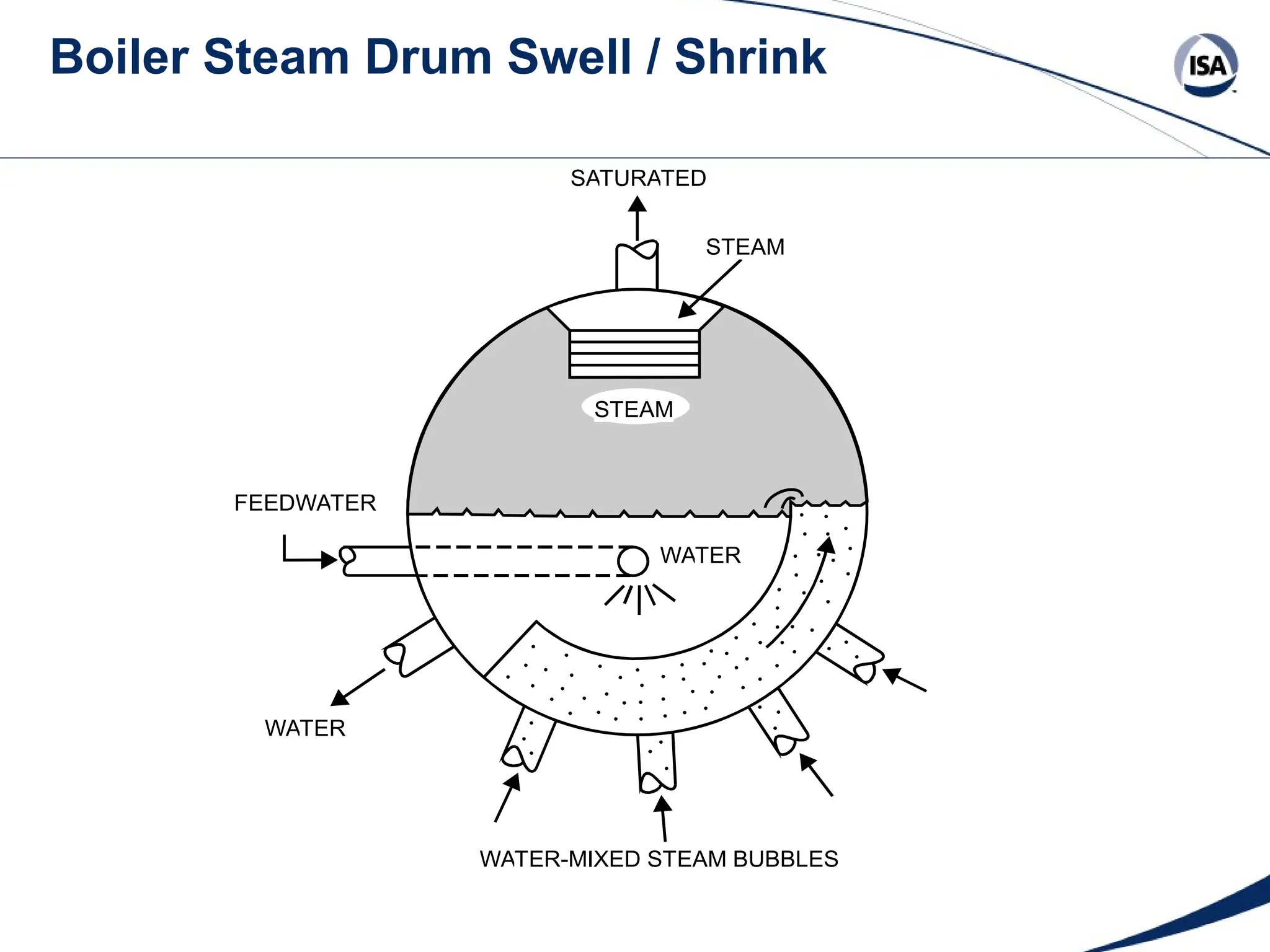

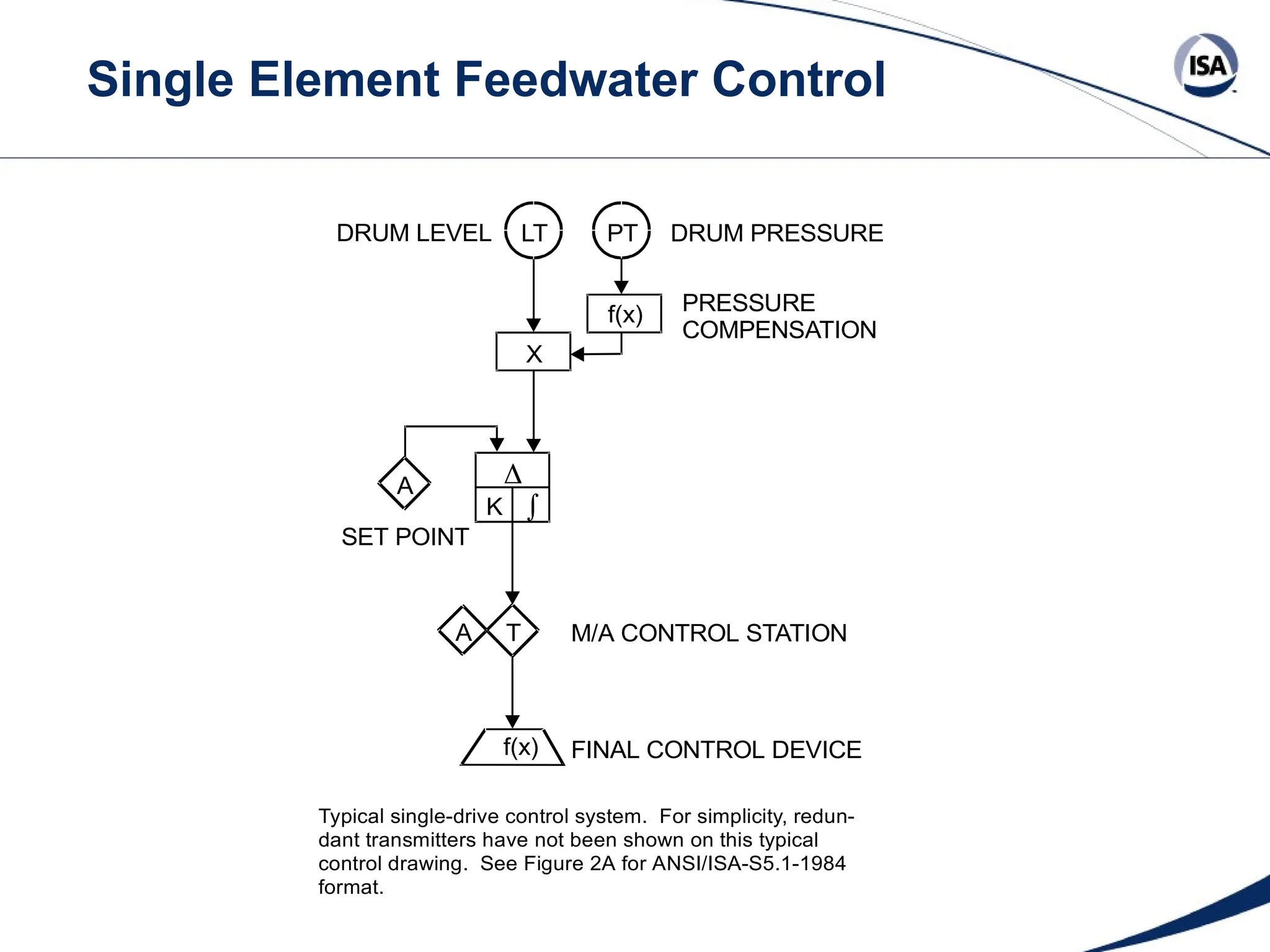

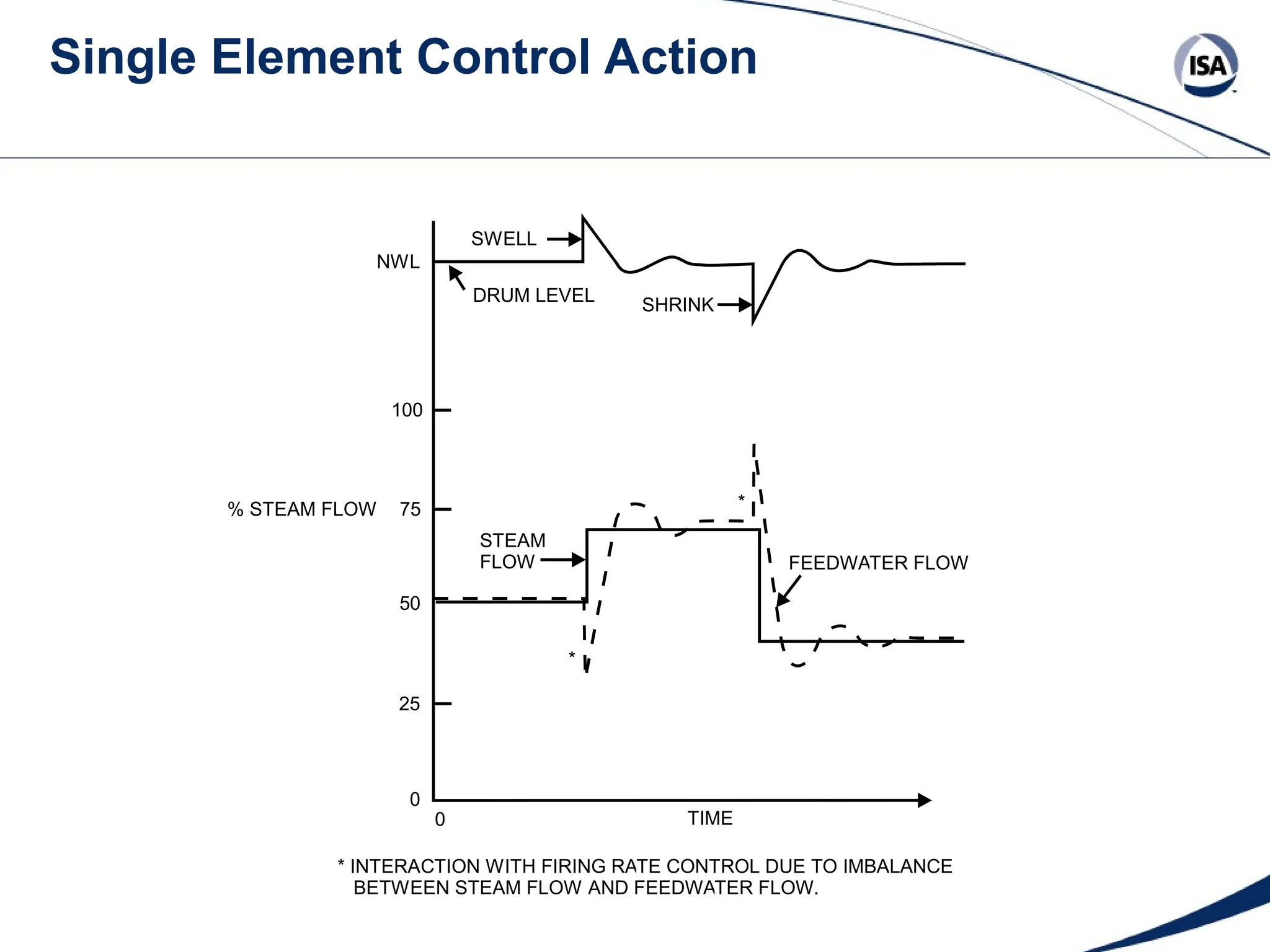

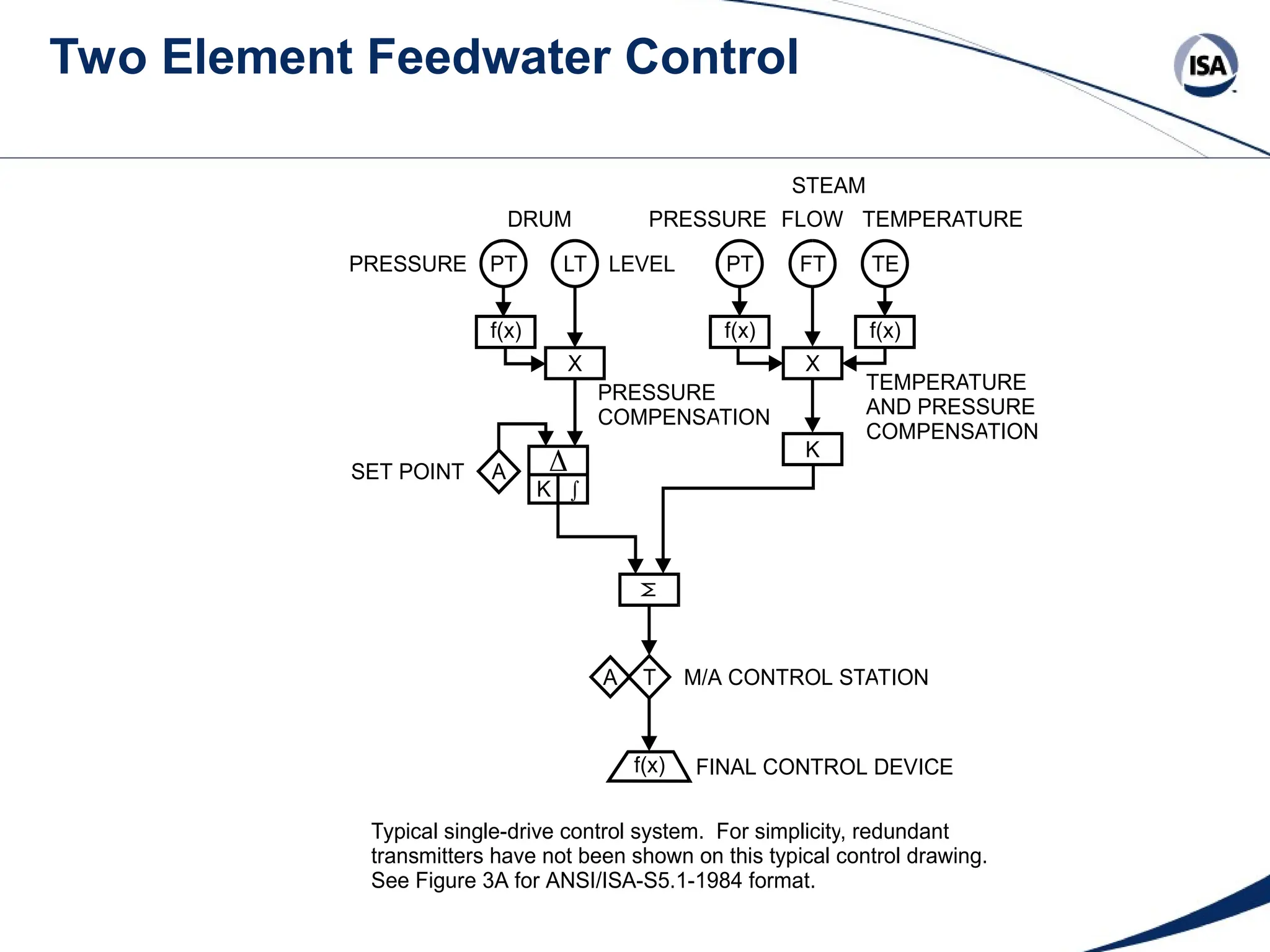

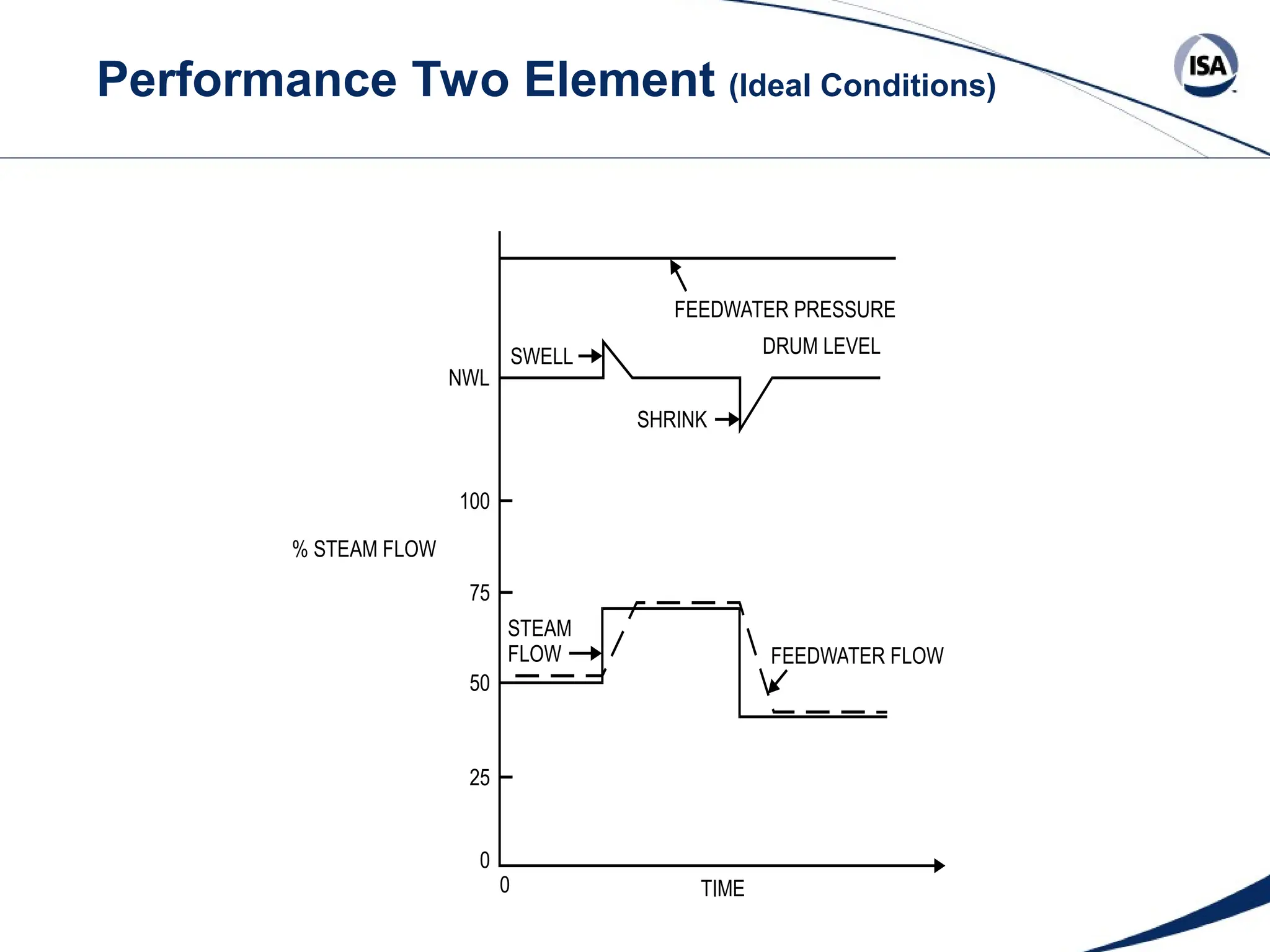

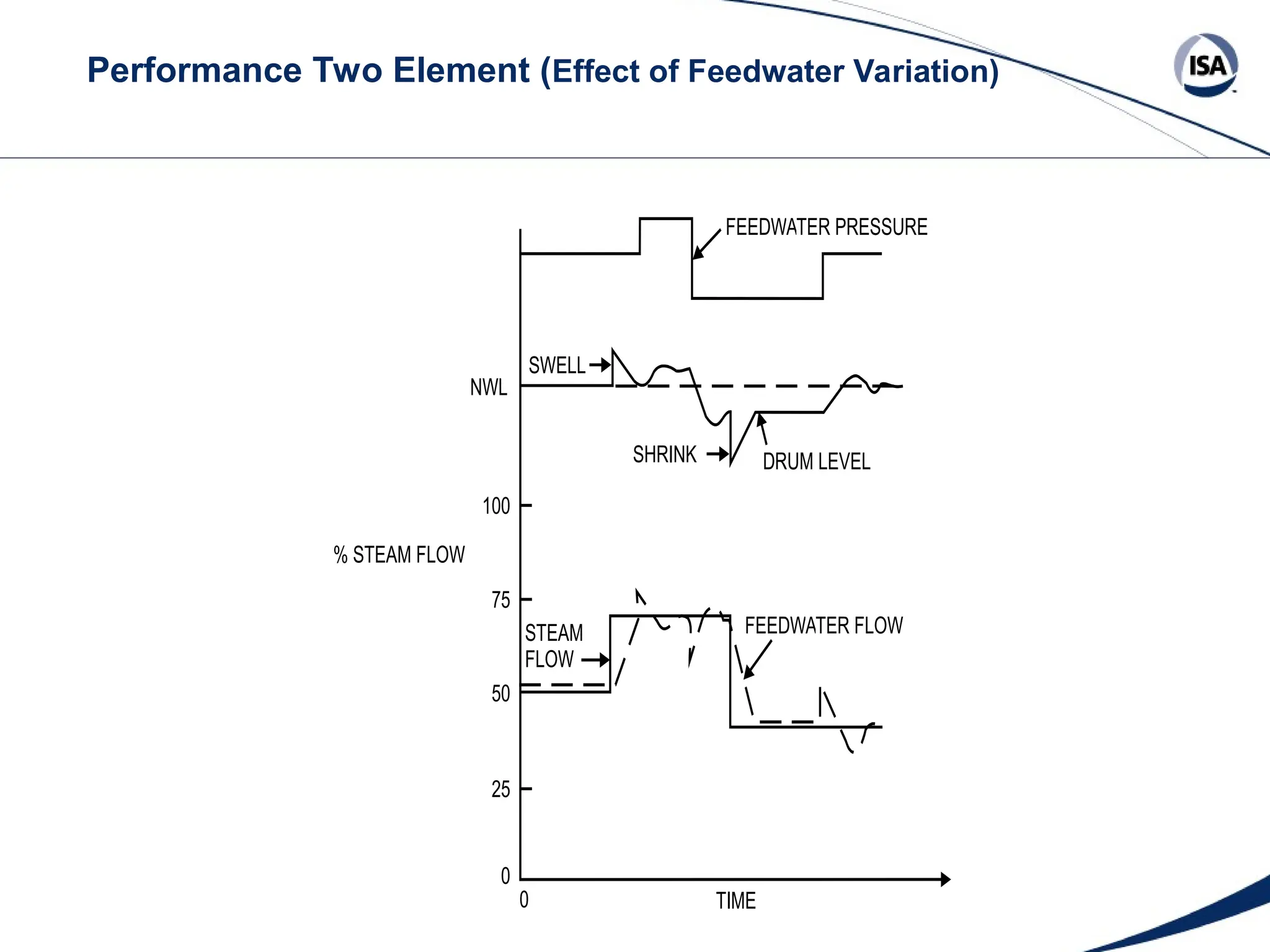

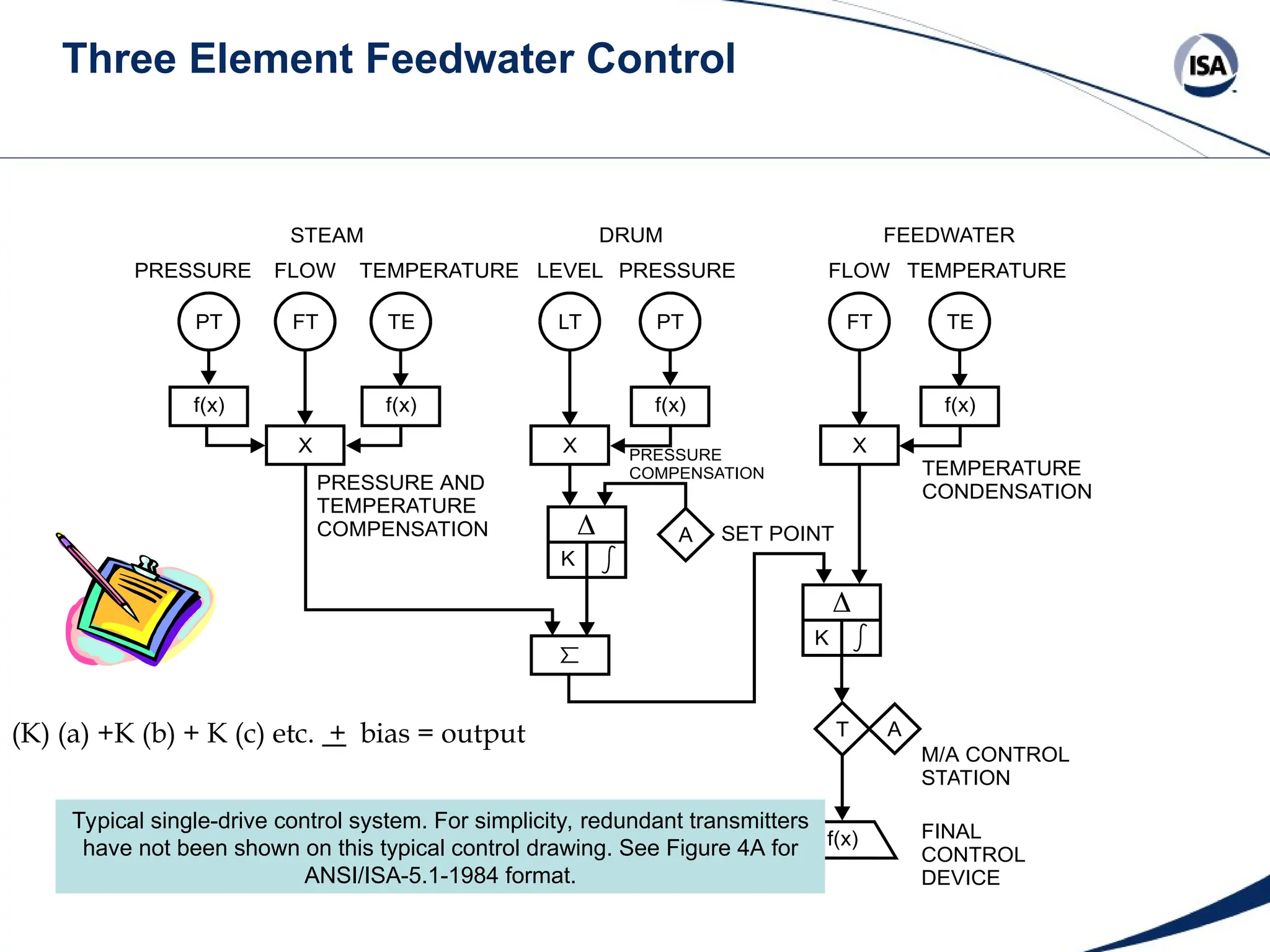

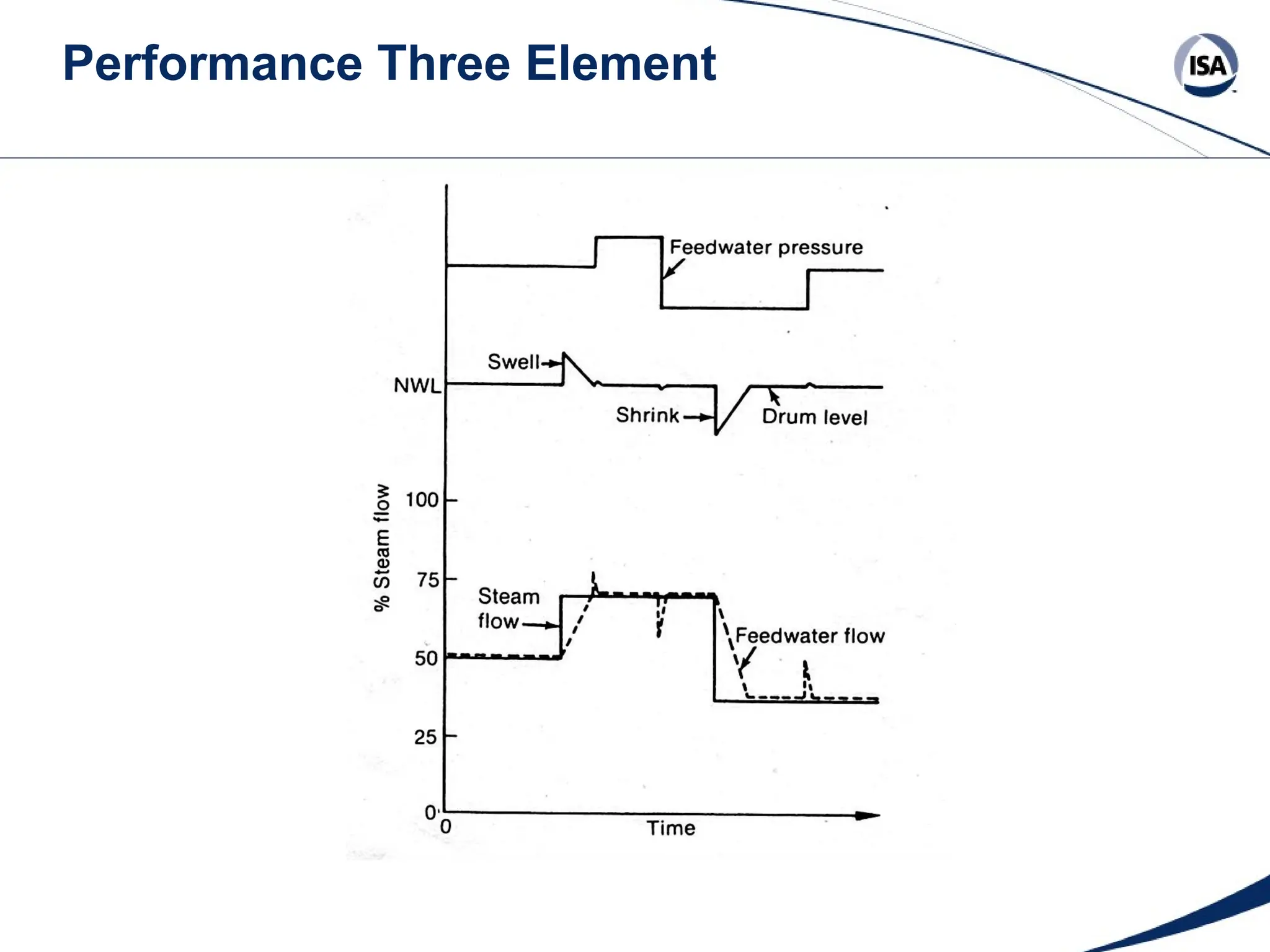

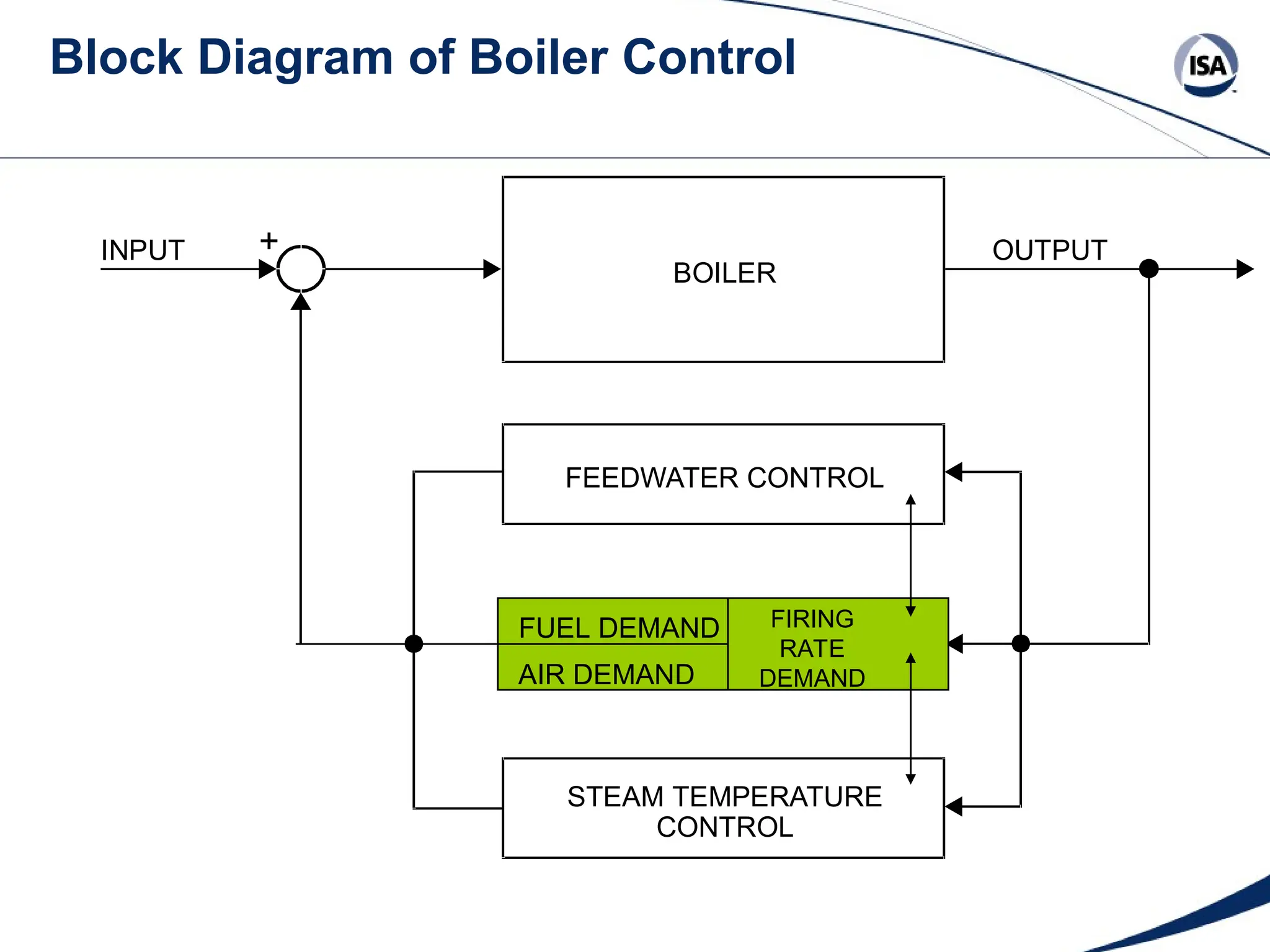

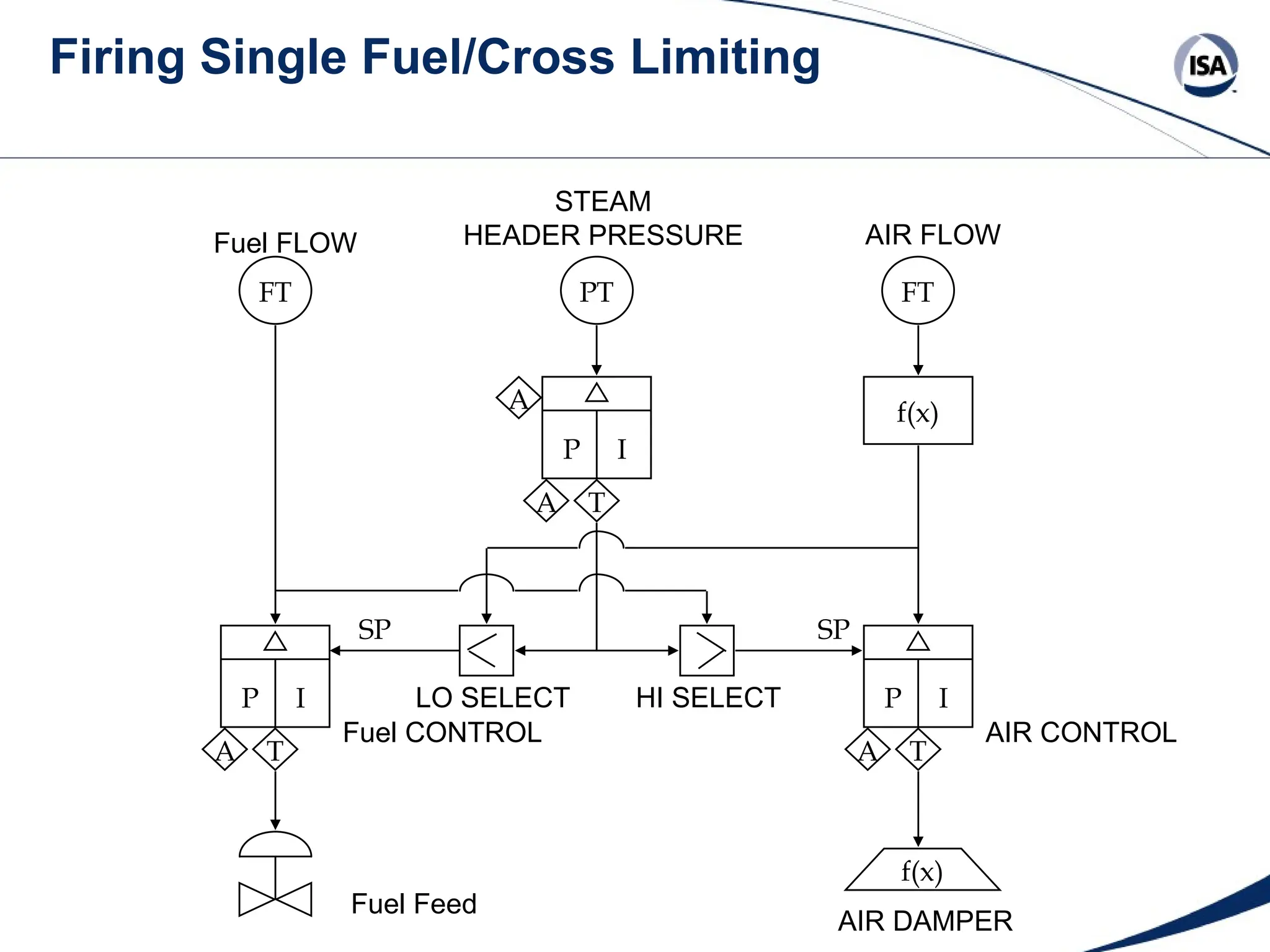

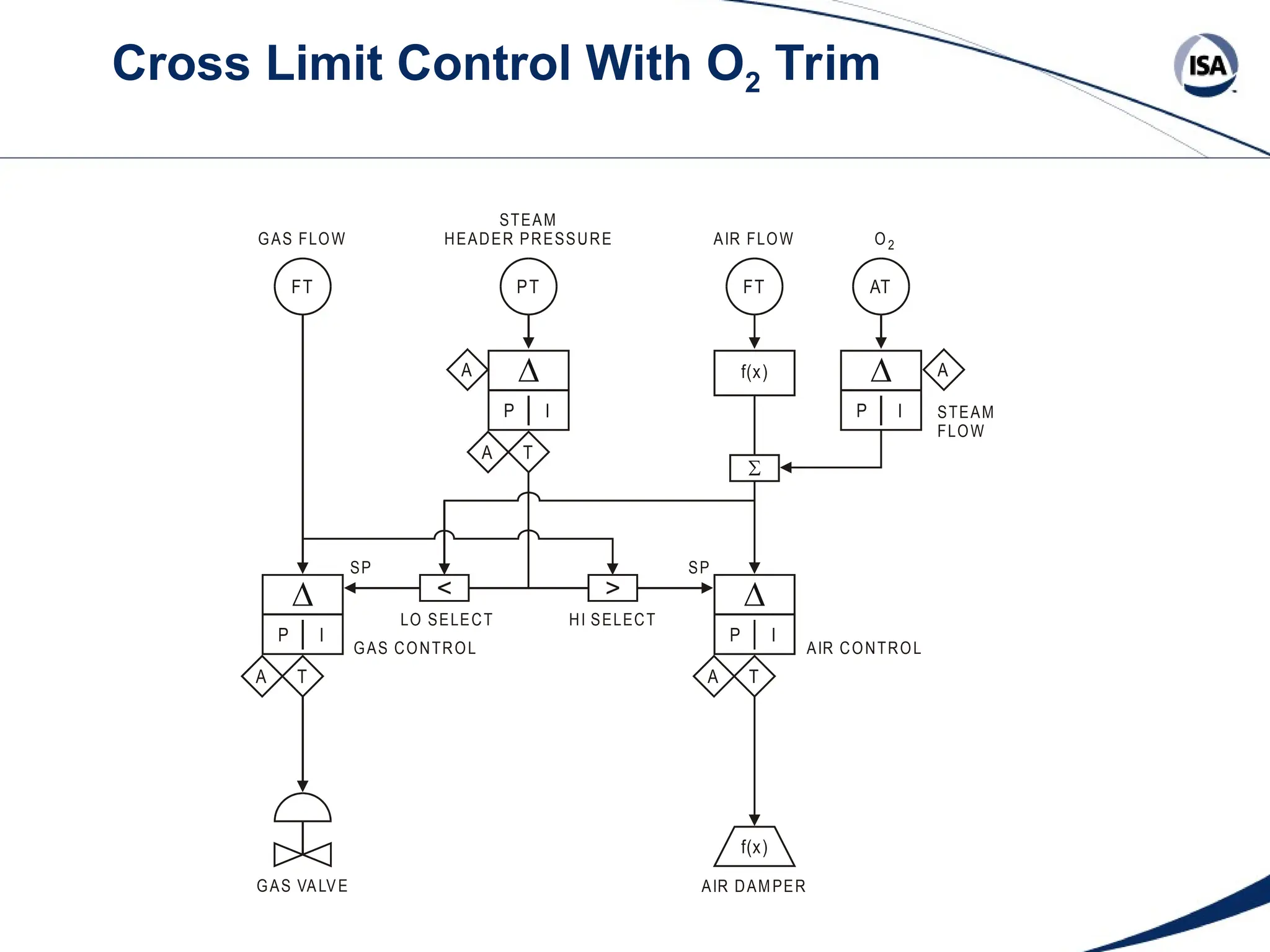

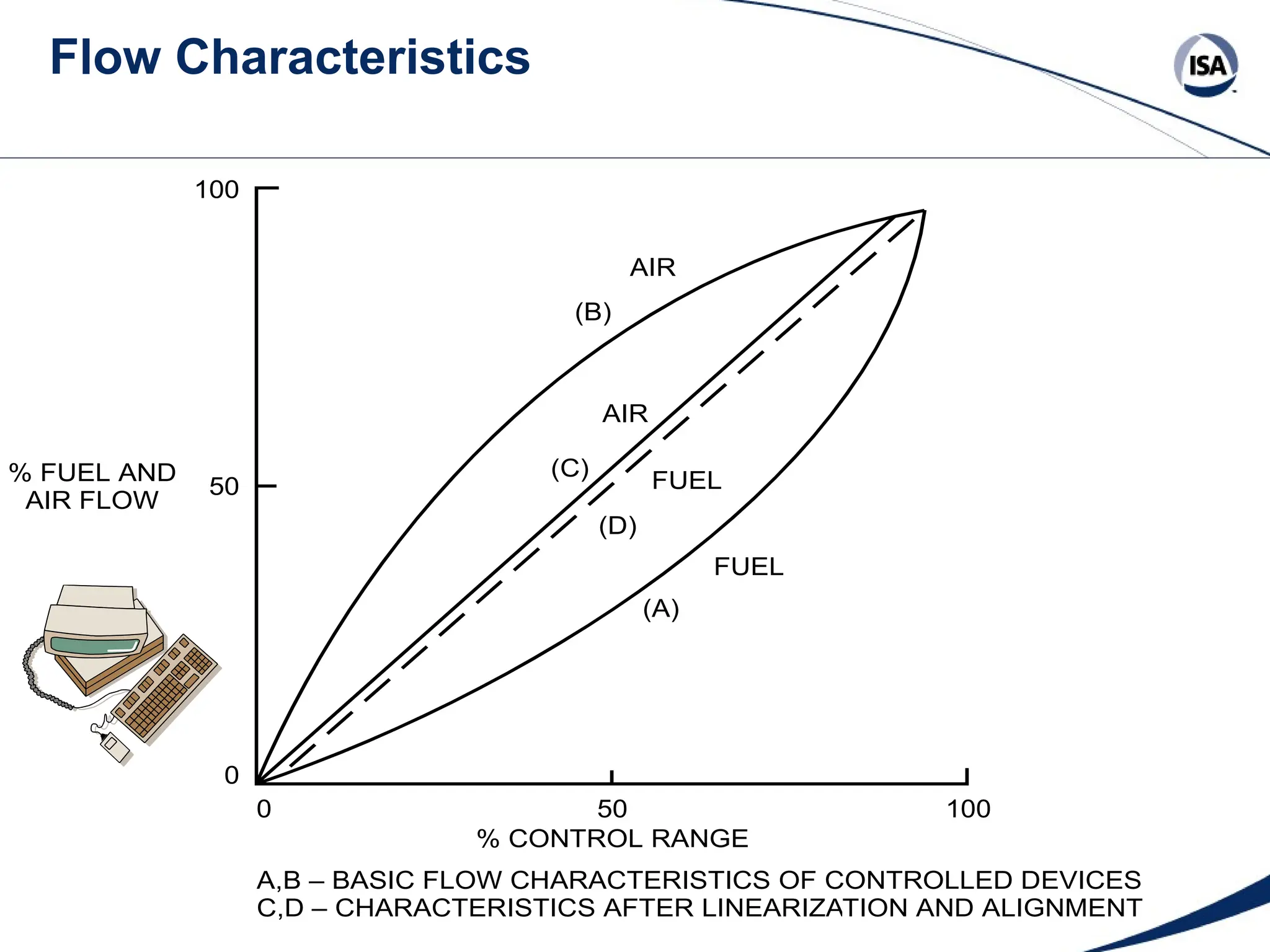

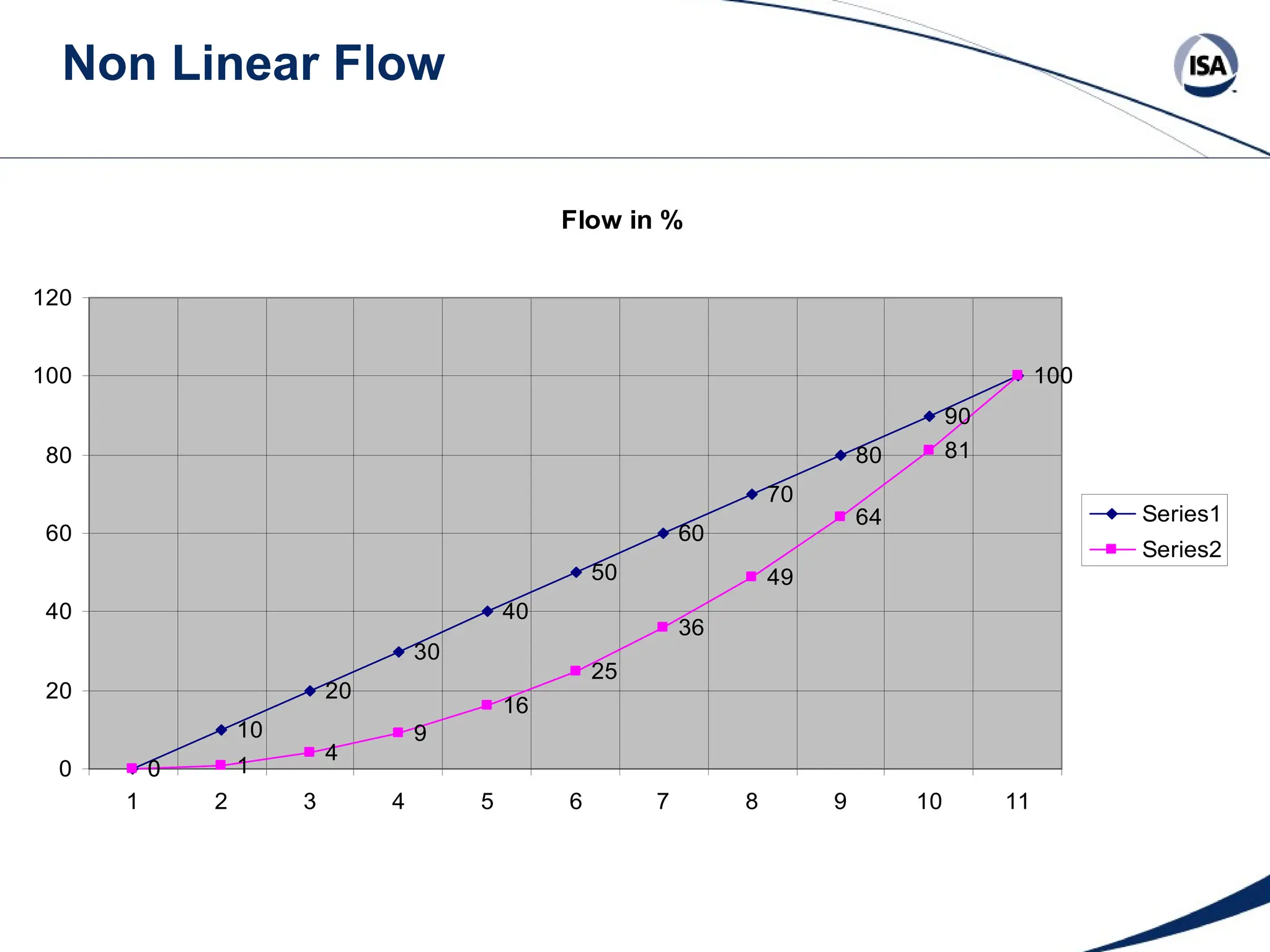

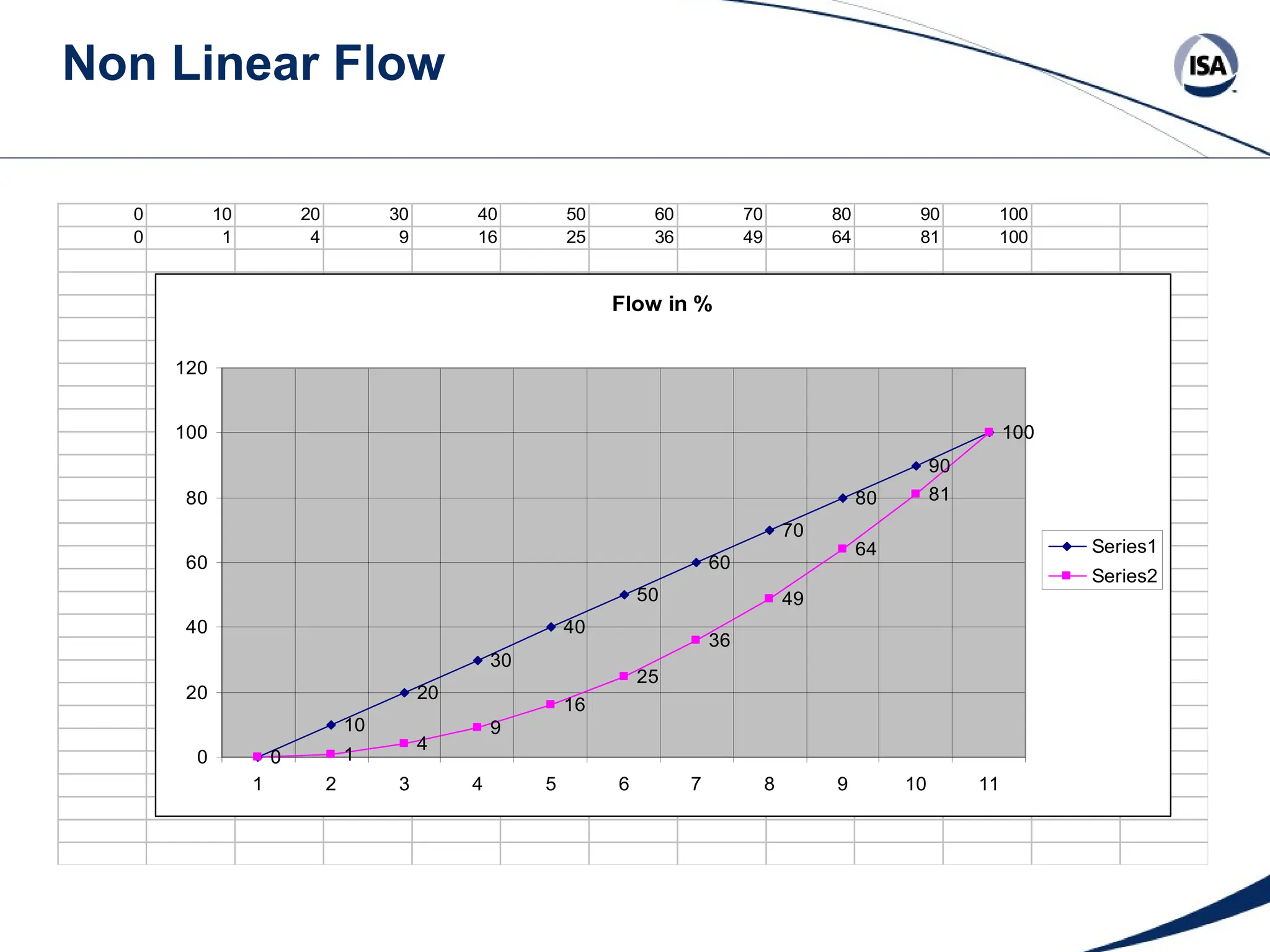

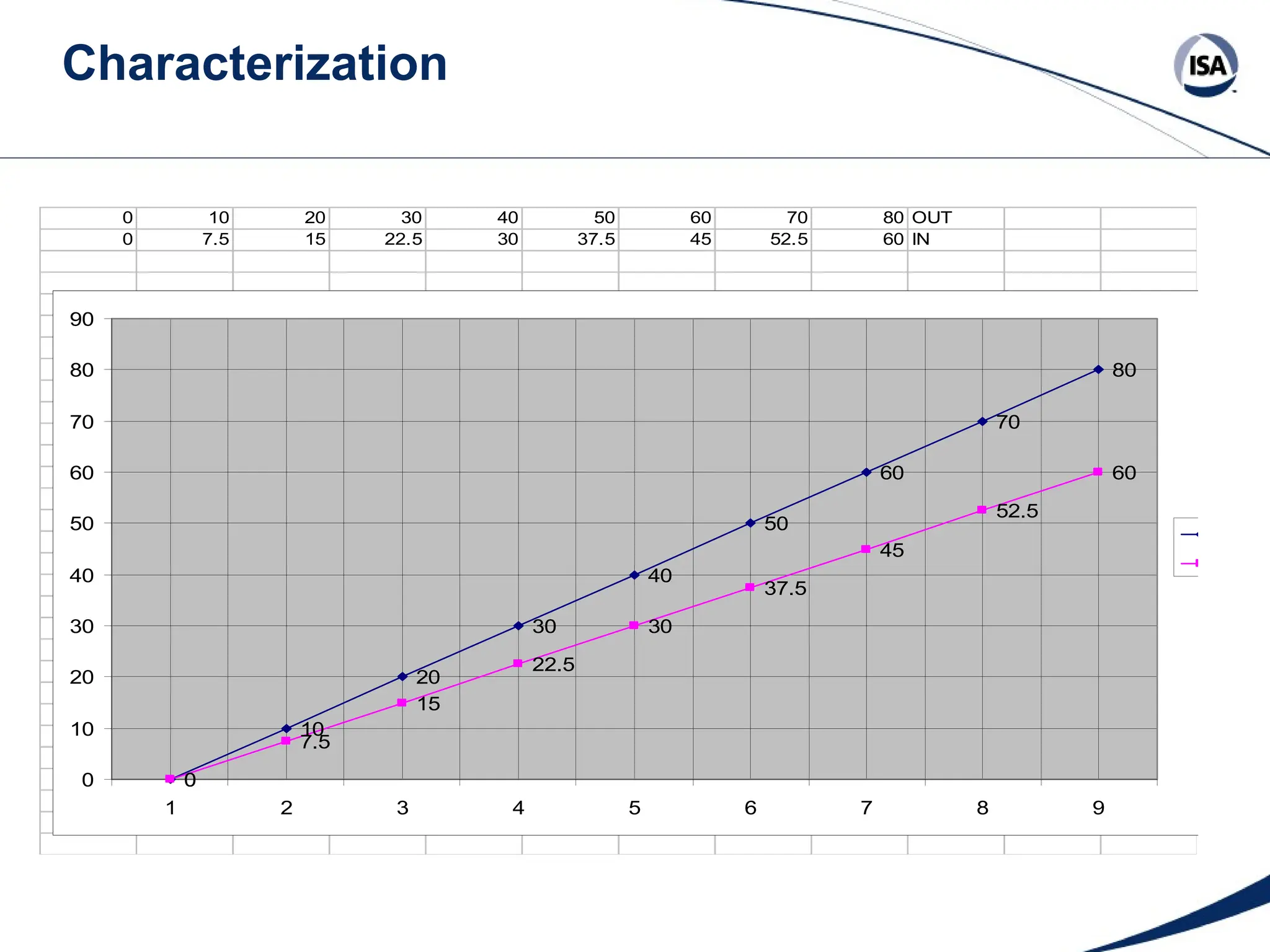

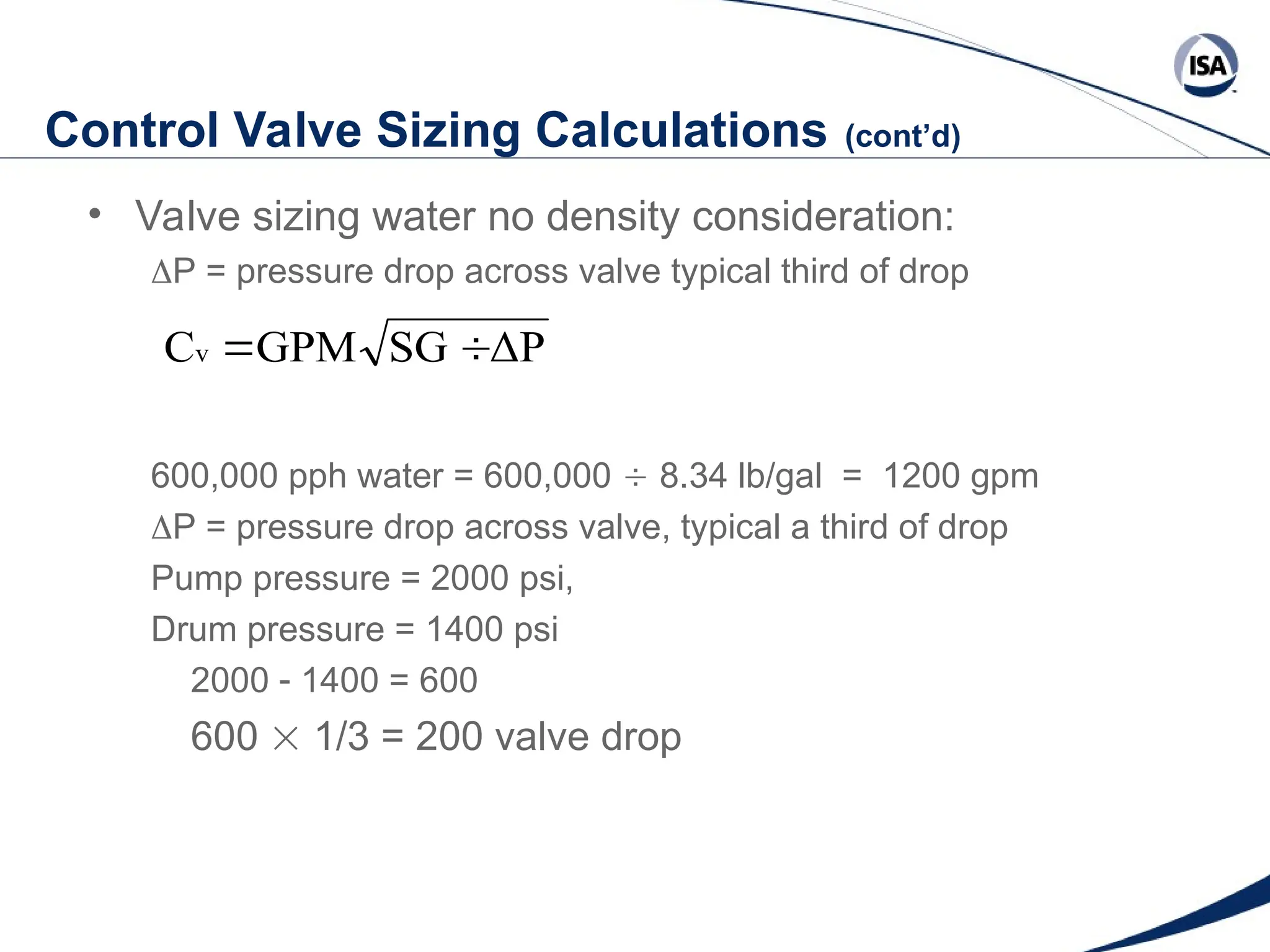

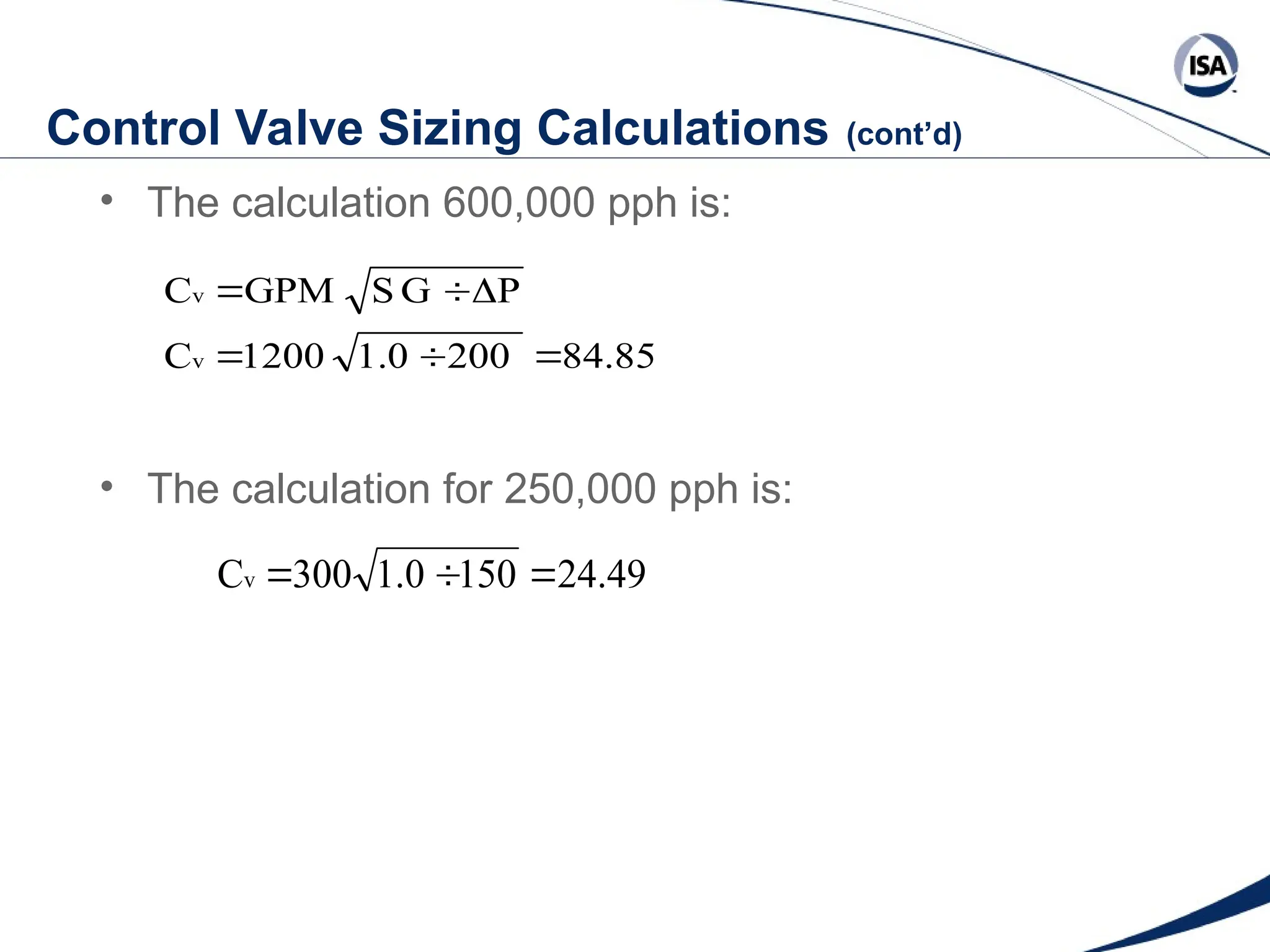

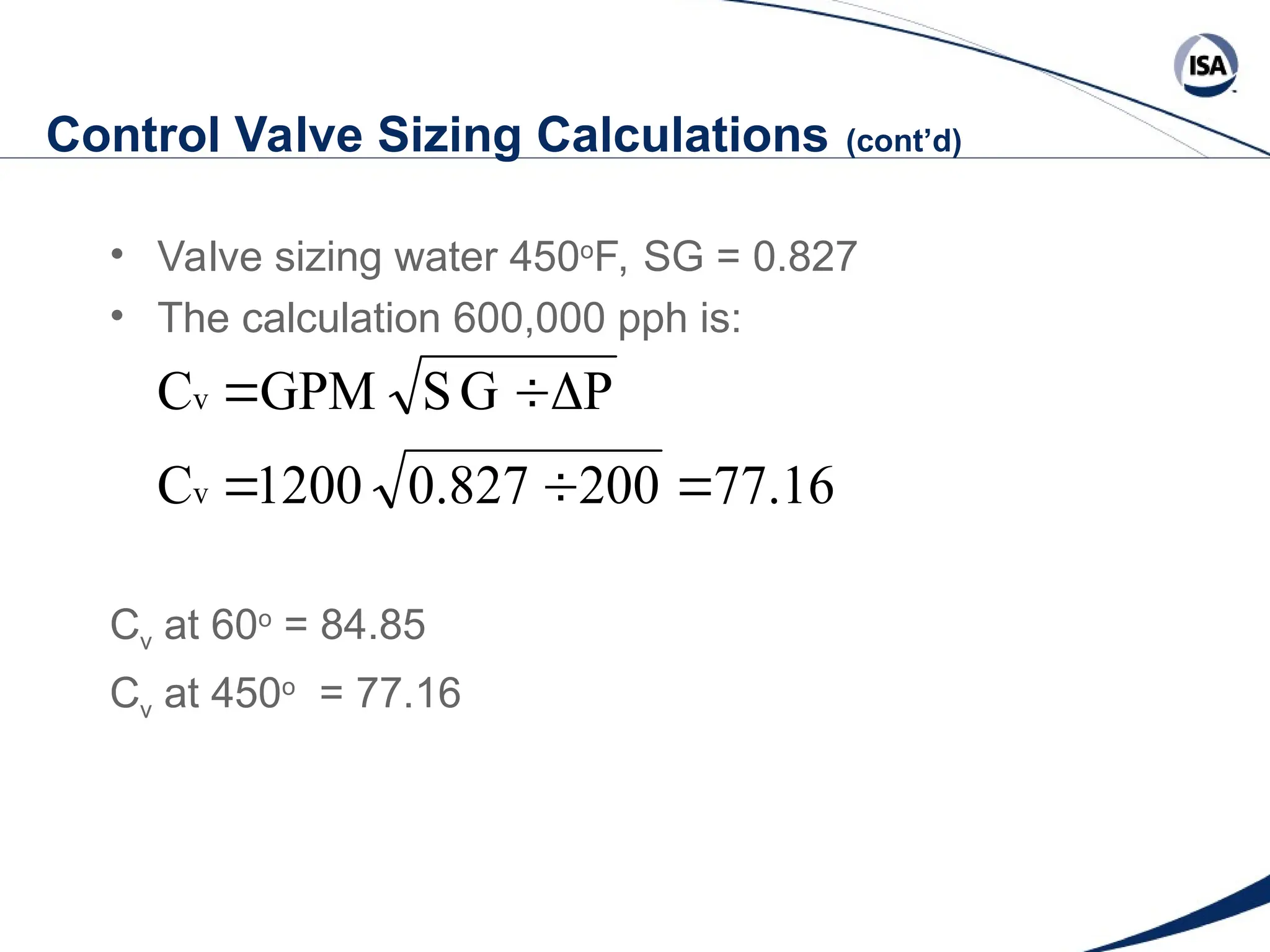

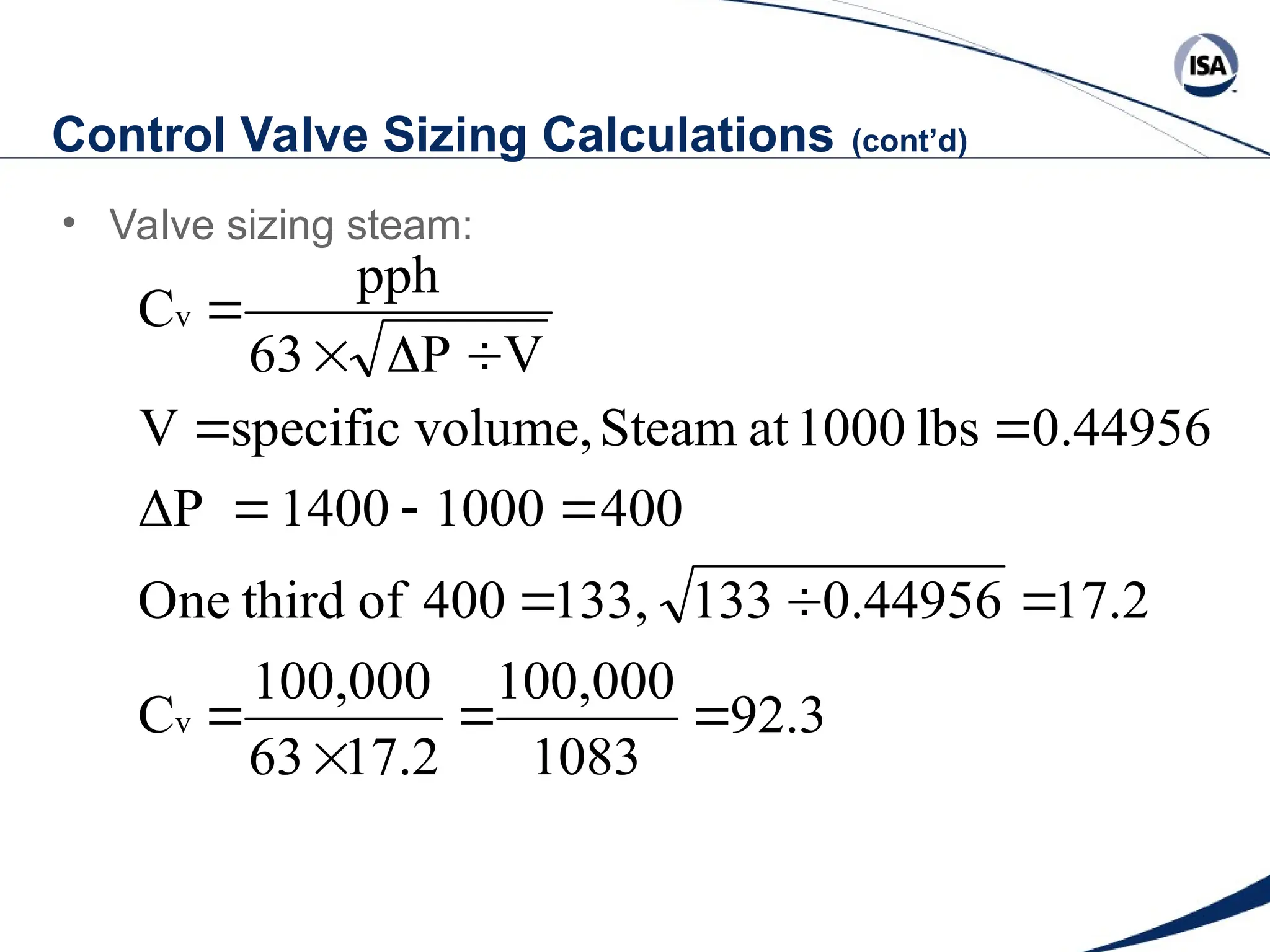

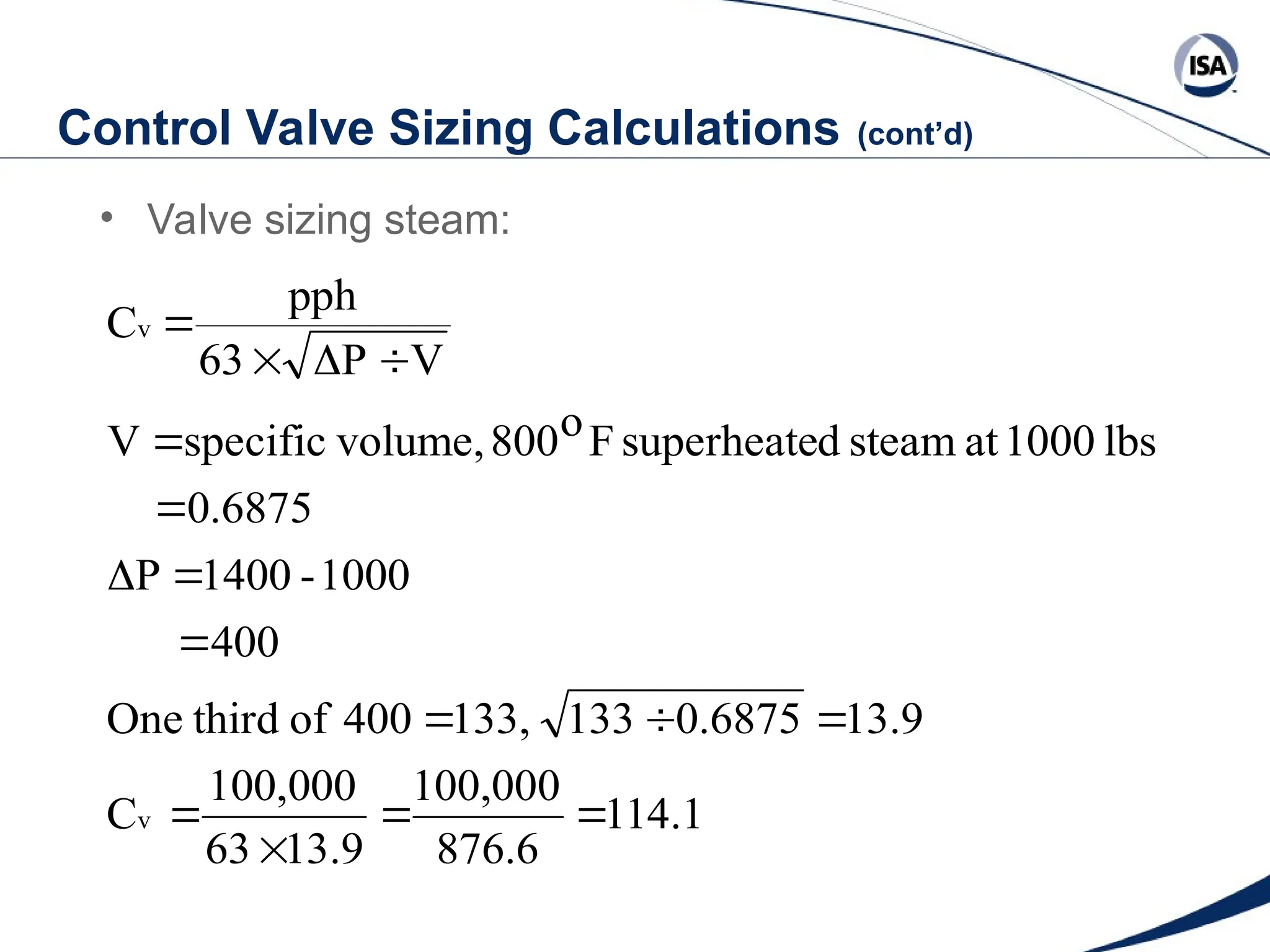

The document discusses the essential control functions required for boiler control systems, including furnace draft, drum level feedwater, fuel air ratio, and steam temperature. It outlines various control strategies, measurement specifications, and valve sizing calculations necessary for proper control of these systems. Additionally, it provides information on related educational resources and courses offered by ISA for training in boiler control engineering.