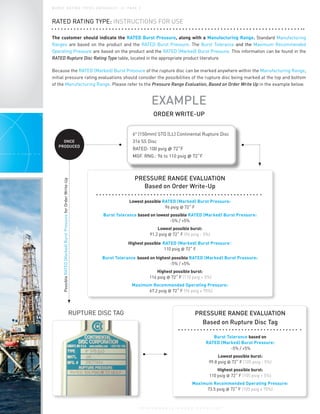

The document explains three rupture disc rating types: rated, specified, and min/max, each defining how burst pressure is indicated and ensuring compliance with relevant standards. Customers must specify the respective burst pressures and tolerances for the selected rating type, which dictates how pressures are marked on the rupture disc tag. The document also provides examples of order write-ups and details regarding maximum recommended operating pressures to ensure the optimal performance and lifespan of the rupture discs.