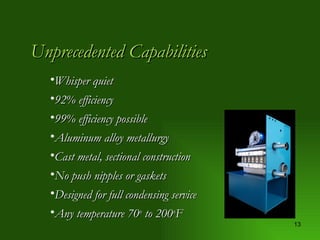

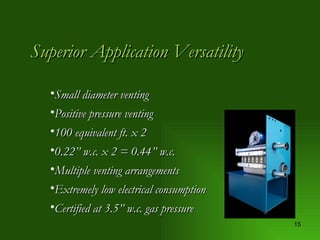

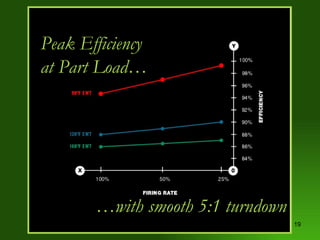

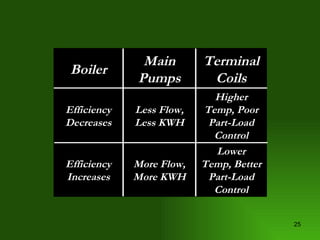

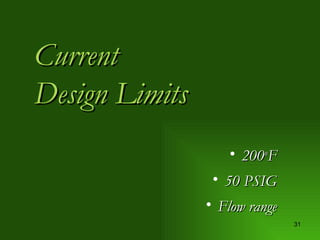

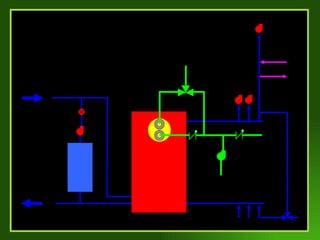

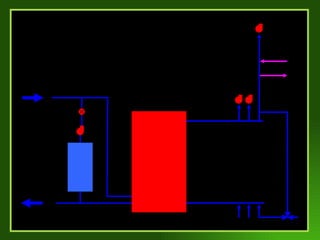

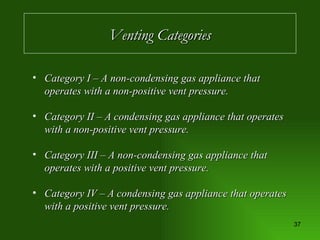

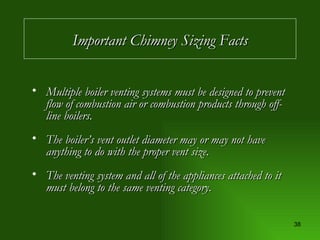

The document discusses an innovative boiler that provides significant energy savings through its capabilities and proper application. It has unprecedented capabilities like 92% efficiency, full modulation, and variable speed combustion. It also allows for superior fuel utilization, application versatility, and control capability. Integrating the boiler and understanding system design issues are essential to realizing its energy savings potential. The document emphasizes properly sizing and engineering the venting system.