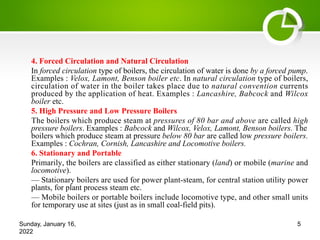

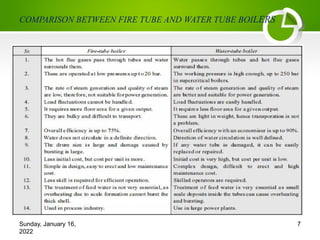

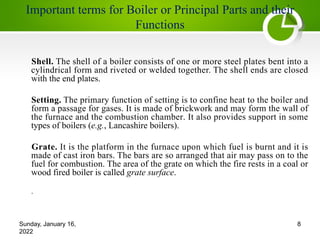

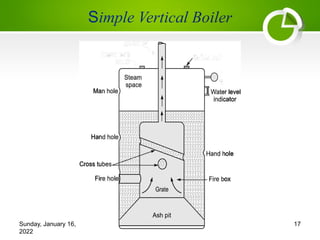

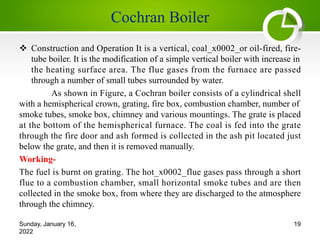

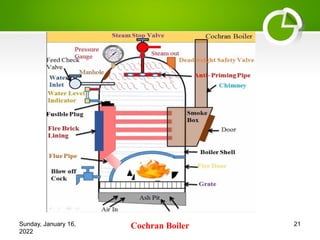

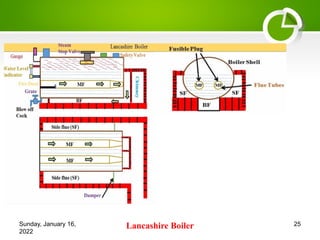

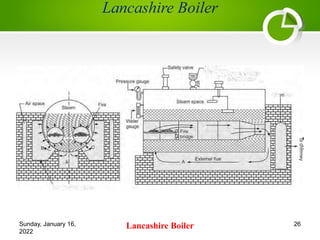

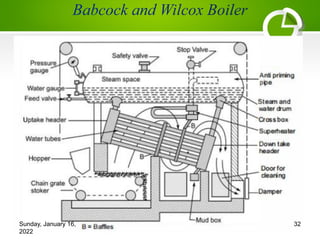

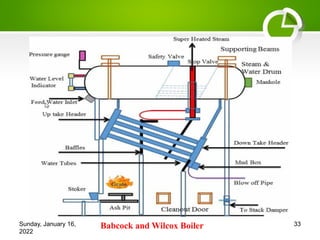

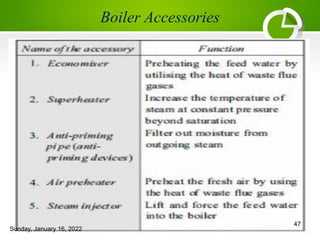

The document discusses steam generators or boilers. It defines a boiler as a closed vessel that produces steam from water through fuel combustion. Boilers are classified in several ways, including by their orientation (horizontal, vertical, inclined), whether they have fire tubes or water tubes, whether the fire is external or internal, their steam pressure level (high or low), and whether they use natural or forced circulation. Common types of firetube boilers include the Cochran boiler and Lancashire boiler, while examples of watertube boilers are the Babcock and Wilcox boiler and Stirling boiler. The document also discusses boiler parts, characteristics of good boilers, and factors to consider when selecting a boiler.