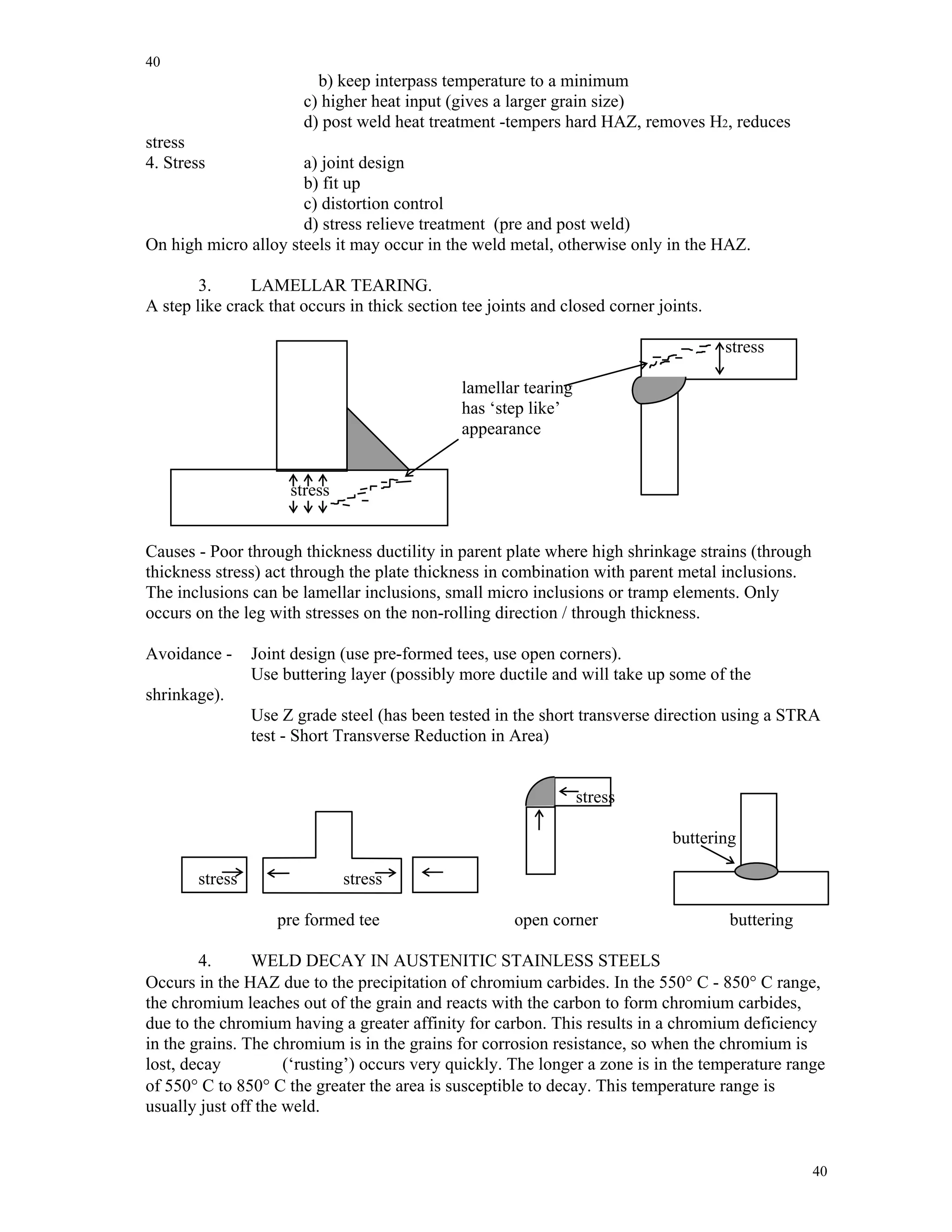

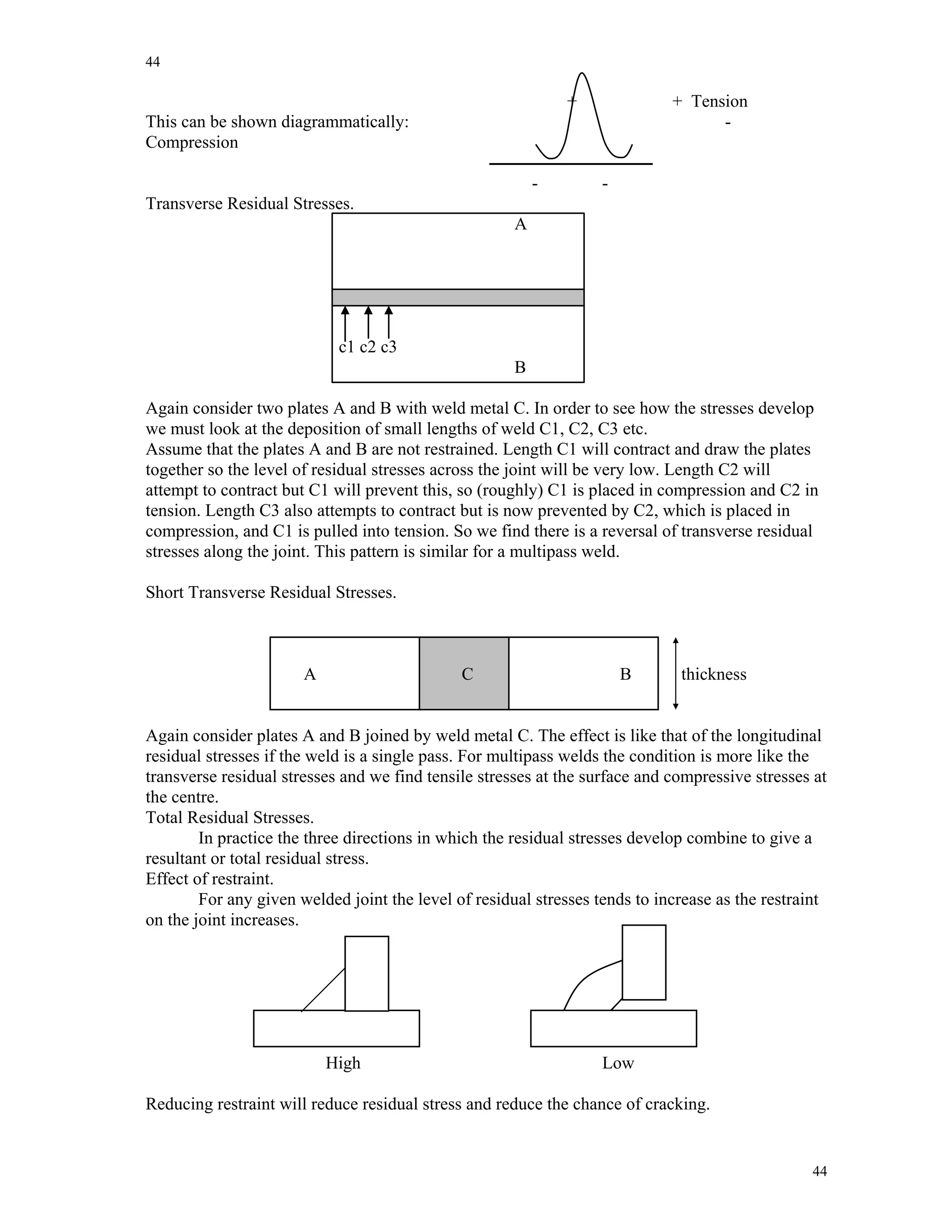

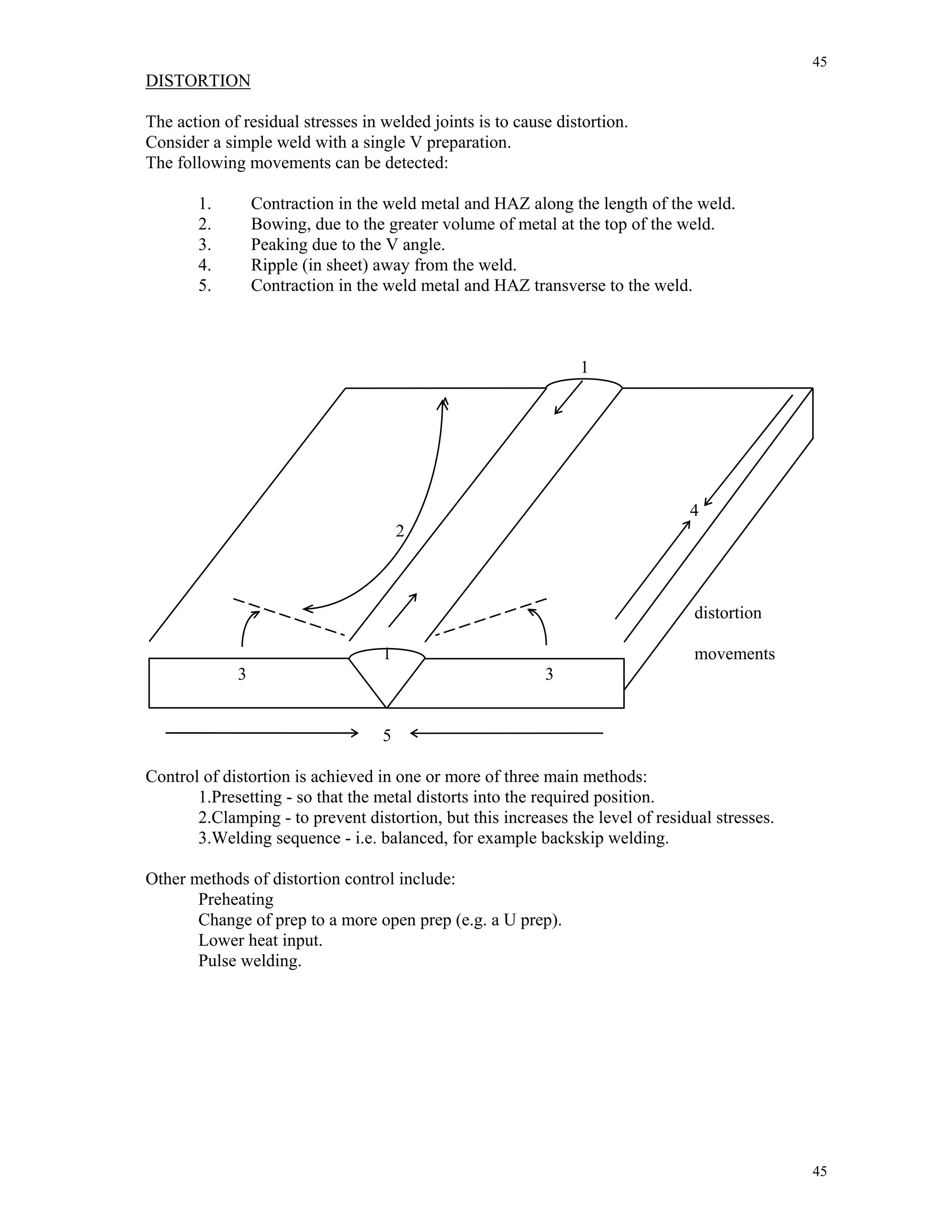

The document provides terminology and definitions related to welding inspection of steels. It discusses the duties of a welding inspector, relevant codes and standards, the welding procedure, destructive and non-destructive testing methods, defects, consumables, and welding processes. Key terms defined include types of welds (butt, fillet, edge), types of joints (butt, tee, corner, lap), features of welds (toe, face, root, throat), and sizes of different welds (full penetration butt welds, partial penetration butt welds, fillet welds).