1.ppt

- 1. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

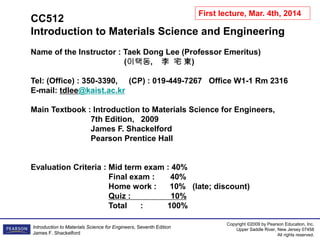

CC512

Introduction to Materials Science and Engineering

Name of the Instructor : Taek Dong Lee (Professor Emeritus)

(이택동, 李 宅 東)

Tel: (Office) : 350-3390, (CP) : 019-449-7267 Office W1-1 Rm 2316

E-mail: tdlee@kaist.ac.kr

Main Textbook : Introduction to Materials Science for Engineers,

7th Edition, 2009

James F. Shackelford

Pearson Prentice Hall

Evaluation Criteria : Mid term exam : 40%

Final exam : 40%

Home work : 10% (late; discount)

Quiz : 10%

Total : 100%

First lecture, Mar. 4th, 2014

- 2. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Lecture Time Schedule :

Every Tuesdays and Thursdays

13:00 ~ 14:30 Room : 211 (E 11)

Teaching Assistance(s) :

Mr. Eun-Shin Sohn e-mail : sohnejgood@kaist.ac.kr

Lab. T.3380 : CP : 010-9210-1349

Mr. Byungil Lee e-mail : polaris89@kaist.ac.kr

Lab. T. 3380: CP : 010-9797-4182

- 3. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Lecture Schedule for the Spring Semester, 2014

1st Week

Mar. 4, Ch. 1; Materials for Engineering

Mar. 6, Ch.2: Atomic Bonding

2nd Week

Mar. 11, Ch. 3; Crystalline Structure-Perfection

Mar. 13, Ch.3: Crystalline Structure-Perfection

3rd Week

Mar. 18, Ch 4; Crystal Defects and Noncrystalline Structure

Mar. 20, Ch 4; Crystal Defects and Noncrystalline Structure

4th Week

Mar.25, Ch.4; Crystal Defects and Noncrystalline Structure

Mar.27, Ch. 5; Diffusion

5th Week

April 1, Ch. 5; Diffusion

April 3, Ch .6; Mechanical Behavior

6th Week

April 8, Ch 6; Mechanical Behavior

April 10, Ch 6; Mechanical Behavior

- 4. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

7th Week

April 15 ,Ch 7; Thermal Behavior

April 17, Ch 8; Failure Analysis and Prevention

8th Week

April 22 or April 24 , Mid-term exam.

9th Week

April 29, Ch 9; Phase Diagrams-Equilibrium

Microstructural Development

May 1, Ch 9; Phase Diagrams-Equilibrium

Microstructural Development

10th Week

May 6, Holyday

May 8, Ch 10; Kinetics-Heat Treatment

- 5. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

11th Week

May 13, Ch 10; Kinetics-Heat Treatment

May 15, Ch 11; Structural- Metals,

Ceramics and Glasses

12th Week

May 20, Ch 12; Structural Materials - Polymers

May 22, Ch 12; Polymers, Composites

13th Week

May 27, Ch 12; Composites

May 29, Ch13; Electronic Materials

14th Week

Jun 3, Ch 13; Electronic Materials

Jun 5, Ch 13; Electronic Materials

- 6. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

15th Week

Jun 10, Ch 13; Insulators, Semiconductors

Jun 12, Ch 13; Semiconductors

?, Ch 14; Materials in Engineering Design

Environmental Degradation

16th Week ; Jun 17 or Jun 19: Final Exams

- 7. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

- 8. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

CC512

Introduction to

Materials Science and

Engineering

Lecture note is found at :

http://mse.kaist.ac.kr BBS → CC512

- 9. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Introduction to the Course of Lecture :

This lecture aims to make non-materials scientists

know “what are the materials” and “how they can be

used” for scientific research and engineering

applications, on the basis of the introduction level.

Therefore, this lecture presents the structures and

properties of materials, their origins, and the way

they enter the engineering design.

To meet the aims, the lecture deals with physical

properties, mechanical characteristics, thermal

behavior, electrical, magnetic and optical response,

durability, processing, and the way it influences

properties, and environmental issues.

- 10. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Chapter 1

Materials for Engineering

1.1 The Material World

1.2 Materials Science and Engineering

1.3 Six Materials That Changed Your World

1.4 Processing and Selecting Materials

1.5 Looking at Materials by Power of Ten

- 11. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Materials we use define our social relationship and economic quality.

The materials of the earlier human were probably for tools and weapons.

In fact, the most popular way of naming the era of human civilization is

in terms of materials from which these tools and weapons were made.

The stone age : Starts from 2.5 million years ago. (Also, wood and animal fur)

The pottery age: Before 4,000BC,domestic vessels were made and glass

artifacts have been traced back to 4,000BC

The copper age : It is estimated between roughly 4,000BC ~ 3,000BC.

The bronze age : The period from 2,000BC to 1,000BC. Better quality of

tools and weapons with the alloy of Cu-Sn.

The iron age : The period from 1,000BC to 1BC. By 500BC, iron alloys

had largely replaced bronze for tool and weapon making

in Europe.

The plastic age : Not officially referred but from second half of the 20th century,

modern culture is supported by plastic.

The silicon age : Another name of the same period of the plastic age during

which silicon technology brought big revolution of computer.

1.1 The Materials World (Or human history in terms of the materials used)

See Fig. 1.1 in next slide.

- 12. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.1 The evolution of engineering materials with time. Note the highly nonlinear scale.

(From M. F. Ashby, Materials Selection in Mechanical Design, 2nd ed., Butterworth-Heinemann, Oxford, 1999.)

WW II

Increasing demand of not only high quality

metallic alloys but non-metallic materials.

- 13. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

1.2 Materials Science and Engineering

The term of “Materials Science and Engineering” have been called in the

general branch engineering from 1960s, (in Korea from 1970s, KAIST).

Before this period, it was called Metallurgy or Metallurgical, and Ceramic

Engineering.

Because of the WW II and the space program, in addition to metals, the

MSE has grown to include contributions from many traditional fields

including metallurgy, ceramic engineering, polymer chemistry, solid

state physics and physical chemistry.

The word “science” covers the fundamentals of structure, classification,

and properties, introduced in Ch 2 ~ Ch. 10.

The word “materials” deals with five types of structural materials and

electronic materials (semiconductors), in Ch. 11 ~ Ch. 13.

The word “engineering” describes the key aspects of the selection of the

right materials for the right job, explained in Ch. 14.

- 14. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

1.3 Six Materials That Changed Our World

Six categories that encompass the materials

available to practicing engineers :

1). Metals (crystalline materials, metallic bonding)

2). Ceramics (crystalline materials, ionic bonding)

3). Glasses (mainly non-crystalline materials, ionic bond)

4). Polymers (non-crystalline materials, covalent bonding)

5). Composites (mixture of above materials)

6). Semiconductors (unique electrical conducting behavior)

- 15. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.2 The Golden Gate Bridge north of San

Francisco, California, is one of the most famous

and most beautiful examples of a steel bridge.

“Metals” give impressions

of “structural steels”.

Metallic Materials have :

1). High strength and formability

2). Ductility (plastic deformation)

Most of the bridges and

high rising buildings are

constructed with steels.

Golden Gate Bridge, connecting San Francisco and Martin County, opened

on May 27, 1937, as the longest suspension bridge of 2,737 meters.

➀. Introducing Metals

– steel bridges

Suspension bridge (현수교)

- 16. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.3 The Sundial Bridge in Redding, California is a modern masterpiece

of bridge design.

Another beautiful example of steel construction : the Redding Bride

is a 66 meter pedestrian walkway.

- 17. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

The length between towers :800m

World 5th longest cabled bridge (사장교)

Incheon Bridge (6 lanes) : Songdo – Incheon Int’l Airport

Total length : 21.38㎞, Length over the sea : 12.12㎞

주탑 높이는 63빌딩(249m)과

비슷한 230.5m

진도 7의 지진이나 초속 72m의 강풍에도 견딜 수 있고,

10만t급 배가 충돌해도 안전

- 18. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

- 19. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.4 Periodic table of the elements. Those elements that are inherently

metallic in nature are shown in color.

The shaded elements are inherently metallic and bases of the

various engineering alloys, from Fe, Al, Mg, Ti, Ni, Zn, Cu and etc.

(Si and Ge are not included in metallic group in this classification. Cf. see ceramics shown later.)

106-23=83

21/41

- 20. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.5 Some common ceramics for

traditional engineering applications. These

miscellaneous parts with characteristic

resistance to damage by high temperatures

and corrosive environments are used in a

variety of furnaces and chemical processing

systems.

➁. Introducing Ceramics :

(Lucalox lamp, See next slide, Fig 1.6)

Metal oxides, MxOy, are no longer

metals but called Ceramics.

Ceramics have the properties ;

➊. Chemically stable

➋. Very high melting point }refractory

Example : Al2O3 (alumina), Mpt. = 2020oC,

transparent, becomes translucent with impurity.

Can be used for engine in replace of metal?

Ceramics are eliminated from structural use

because of its severe brittleness.

➌. high strength but very brittle

Used in high temperature, corrosive

environments, various furnaces, chemical

processing systems.

- 21. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.6 High-temperature sodium vapor lamp made possible by use of a

translucent Al2O3 cylinder for containing the sodium vapor.

(Note that the Al2O3 cylinder is inside the exterior glass envelope.)

Lucalox lamps (GE trade name) :

High Pressure Sodium High Intensity Discharge Lamp for streetlights.

High pressure sodium lamps are quite efficient—about 100 lm/W —when

measured for photopic lighting conditions. They have been widely used for

outdoor lighting such as streetlights and security lighting. Understanding the

change in human color vision sensitivity from photopic to mesopic and scotopic

is essential for proper planning when designing lighting for roads.

(lm=lumen, for general electric lamps; 10 lm/W, for LED lamps; 100 lm/W)

Arc tube made of translucent alumina

- 22. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Theory of operation

An amalgam of metallic sodium and mercury lies at the coolest part of the lamp

and provides the sodium and mercury vapor in which the arc is drawn.

The temperature of the amalgam is determined to a great extent by lamp power.

The higher the lamp power, the higher will be the amalgam temperature.

The higher the temperature of the amalgam, the higher will be the mercury and

sodium vapor pressures in the lamp. An increase in these metal pressures will

cause a decrease in the electrical resistance of the lamp.

Because of the extremely high chemical

activity of the high pressure sodium arc,

the arc tube is typically made of

translucent aluminium oxide. This

construction led General Electric to use

the tradename "Lucalox" for their line of

high-pressure sodium lamps.

Diagram of a high pressure sodium lamp.

- 23. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Commercial ceramics are frequently made by heating (sintering)

crystalline powders to high temperatures until a relatively strong

and dense products are produced. Traditional ceramics made in this

way contains a substantial amount of residual porosity which

makes it opaque, low density and so low impact strength.

Reduction in porosity is very important to improve the quality of

ceramics and is achieved by adding a small amount of impurity (for

ex. 0.1% MgO, glass forming component) which makes high-

temperature densification process for the Al2O3 powder to make

dense product during sintering.

With this densification by impurity of MgO, the Al2O3 becomes

translucent which can be used for the high-temperature sodium

vapor lamp, shown in Figure 1.6.

Sintering of ceramics and its effects :

- 24. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.7 Periodic table with ceramic compounds indicated by a combination of one or more metallic elements (in

light color) with one or more nonmetallic elements (in dark color). Note that elements silicon (Si) and germanium

(Ge) are included with the metals in this figure but were not included in the periodic table shown in Figure 1.4. They

are included here because, in elemental form, Si and Ge behave as semiconductors (Figure 1.16). Elemental tin (Sn)

can be either a metal or a semiconductor, depending on its crystalline structure.

Ceramics are usually oxides. However, silicon nitride (Si3N4) is an important nonoxide ceramic

used in a variety of structural applications. Some ceramics are chemical compounds made up

of one of the five nonmetallic materials, C, N, O, P or S, shaded with dark blue color in figure

1.7. Very many variety of ceramic materials can be formed.

(C, N, P, S are forming none-oxide ceramics with metallic elements.)

(Now, Si and Ge are included as metallic elements in this classification, because they form ceramics.)

Nonmetallic ceramic forming elements

Metallic Elements

- 25. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.8 Schematic comparison of the

atomic-scale structure of (a) a ceramic

(crystalline) and (b) a glass (noncrystalline).

➂. Introducing Glasses – optical fibers

(Nonmetal atom : o, metal atom : ●)

Different from metals and ceramics,

glasses are noncrystalline materials.

See the figure shown below.

Crystalline ceramics Noncrystalline glass

- 26. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.9 Some common silicate

glasses for engineering applications.

(Transparent and chemically stale)

Glasses continued

The general term for noncrystalline

solids with composition comparable

to those of crystalline ceramics is

GLASS.

Most common glasses are silicates;

ordinary window glass is

approximately 72% silica (Si02) by

weight, with the balance of materials

being primarily sodium oxide (Na2O)

and calcium oxide (CaO).

Properties : transmit visible light as

well as ultraviolet and infrared

radiation, chemical inertness, and

brittleness.

- 27. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.10 The small cable on the right

contains 144 glass fibers and can carry

more than three times as many telephone

conversations as the traditional (and much

larger) copper-wire cable on the left.

Glasses continued

A major revolution in the field

of telecommunication has

occurred with the transition

from traditional metal cable to

optical glass fibers.

Alexander Graham Bell first tried to

transmit voice over a beam of light of

several hundreds meters after his

invention of the telephone.

Nearly a century later, large-scale

application could be possible by the

invention of the laser in 1960.

Nowadays, telephone conversations and any other form of digital data can be transmitted as

laser light pulses rather than as the electrical signals used in copper cables, Glass fibers are

excellent examples of PHOTONIC MATERIALS, in which signal transmission occurs by

photons rather than by the electrons of electronic materials.

- 28. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.11 Miscellaneous

internal parts of a parking meter

are made of an acetal polymer.

Engineered polymers are typically

inexpensive and are characterized

by ease of formation and

adequate structural properties.

④. Introducing Polymers

– Nylon parachutes

Polymers brought major impact of

modern engineering technology on

everyday life.

Plastics is an alternative name of polymers

because of their extensive formability during

fabrication, and they are synthetic (human-

made) materials which represent a special

branch of organic chemistry. Polymer is very

attractive with its lightweight and low-cost.

Some examples of inexpensive, functional

polymer products are shown in figure 1.11.

Polymers are long-chain molecules

composed of many (100s to 1,000s)

“mers” bonded together.

- 29. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.12 Periodic table with the elements associated with commercial

polymers in color.

Polymers continued

Small number of elements (6 elements) are involved for the formation of

commercial polymers and most of polymers are simply compounds of

hydrogen and carbon. Some other polymers contain oxygen (e.g., acrylics),

nitrogen (nylon), fluorine (fluoroplastics) and silicon (silicones).

- 30. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.13 Since its developm-

ent during W W II, nylon fabric

remains the most popular material

of choice for parachute designs.

Polymers continued

Nylon is a member of the family of synthetic

polymers known as polyamides invented in

1935 at the DuPont Co.

Nylon was the first commercially successful

polymer and was initially used as bristles in

toothbrushes (1938) followed by the highly

popular use as an alternative to silk

stockings (1940), and nylon became the

focus of an intensive effort during the early

stages of WWII to replace the diminishing

supply of Asian silk for parachutes and other

military supplies. (beginning of “INSTRON”)

Today nylon remains a popular fiber material,

but it is also widely used in solid form for

application such as gears and bearings.

- 31. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.14 Example of a

fiberglass composite

composed of microscopic-scale

reinforcing glass fibers in a

polymer matrix.

⑤. Introducing Composites - Kevlar - reinforced tires

Composites are another set of

materials made up of some

combination of individual materials

from the previous categories

materials with their own bonding

characteristics.

The excellent example is fiberglass, the

composite of glass fibers embedded in a

polymer matrix (Fig. 1.14).

Characteristic of good composites is

producing a product that is superior

to either of the components

separately that is it has both high

strength and excellent flexibility.

- 32. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.15 Kevlar reinforcement is a popular application in modern high-

performance tires. In this case, the durability of sidewall reinforcement

is tested along concrete ridges at a proving ground track.

Kevlar is a DuPont trade name for poly p-phenyleneterephthalamide (PPD-T), a

para-aramid fiber. Also, at the same time, substantial progress has been made in

developing new polymer matrices, such as PEEK and PPS which have the

advantages of increased toughness and recyclability. Therefore, Kevlar-reinforced

polymers to be composites are used in pressure vessels and tires. The strength-

to-weight ratio of Kevlar is five times higher than that of structural steels.

Kevlar fiber

reinforcements provide

significant advances

over traditional fibers

for polymer-matrix

composites.

Composites continued

- 33. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.16 Periodic table with the elemental semiconductors in dark color (Si,

Ge, Sn) and those elements that form semiconducting compounds in light color.

The semiconducting compounds are composed of pairs of elements from

columns III and V (e.g., GaAs) or from columns II and VI (e.g., CdS).

⑥. Introducing Semiconductors

– Silicon chips

A relatively small group of elements shaded in the above figure 1.16 and their compounds has an important

electrical property, semiconduction, in which they are neither good electrical conductors nor good insulators.

Instead, their ability to conduct electricity is intermediate. These materials are called semiconductors.

There are three semiconducting elements (Si, Ge, & Sn in IV A), which serve a

kind of boundary between metallic (II B, III A) and nonmetallic elements(V A, VI

A). Si and Ge are excellent examples of elemental semiconductors.

- 34. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.17 (a) Typical microcircuit containing a complex array of semiconducting regions. (Photograph courtesy of

Intel Corporation) (b) A microscopic cross section of a single circuit element in (a). The dark rectangular shape in the

middle of the micrograph is a metal component less than 50 nm wide. (Micrograph courtesy of Intel Corporation)

Fig (a) shows a combination of the

various semiconductors makes a set of

complex microcircuit and Fig (b) shows

one single circuit element in (a).

- 35. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.18 The modern integrated circuit fabrication laboratory represents the state of the art in materials processing.

(Courtesy of the College of Engineering, University of California, Davis.)

Clean room is required for elimination of any impurities.

Because semiconductors have to be high purity to perform

given characteristic properties.

- 36. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

Figure 1.19 Schematic

illustration of the integral

relationship among materials, the

processing of those materials, and

engineering design

1.4 Processing and Selecting Materials

Materials, Design and

Processing are strongly inter-

related.

For the successful selection of

materials, one has to

understand the relationships

among these three components.

- 37. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

1.5 Looking at Materials by Power of Ten

In this chapter, it is known that the principle in Materials Science and Engineering

is that “structure leads to properties”, that is, we explain the behavior of the

materials that we use in engineering design (on the human scale) by looking at

mechanisms that involve the structure of the materials on some fine scale.

Some mechanisms involve the structure of the materials at the atomic scale

(such as point defects ), the microscopic scale (such as dislocations), or the milli-

meter scale (such as structural flaws that cause catastrophic failure). In the past

decade, the significance of the nanoscale has become widely emphasized.

So, the appropriate range of “powers of ten” that will be discussed is ;

The human scale : 1 meter (structures)

The milliscale : 1 x 10-3 meter (structural flaws)

The microscale : 1 x 10-6 meter (dislocations)

The nanoscale : 1 x 10-9 meter (point defects)

The atomic scale : 1 x 10-10 meter (atoms)

- 38. Copyright ©2009 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Introduction to Materials Science for Engineers, Seventh Edition

James F. Shackelford

The end of Ch. 1